EVCO S.p.A. | EV3 CHIL | Instruction sheet ver. 1.0 | Code 1043CHILI104 | Page 1 of 2 | PT 21/15

EV3 CHIL Controller for single-circuit chillers

I

ENGLISH

IMPORTANT

Read this document carefully before installation and before

using the device and take all the prescribed precautions. Keep

this document with the device for future consultation.

Only use the device in the ways described in this document.

Do not use the device as safety device.

For more information see the installer manual.

The device must be disposed of according to local

regulations governing the collection of electrical and

electronic waste.

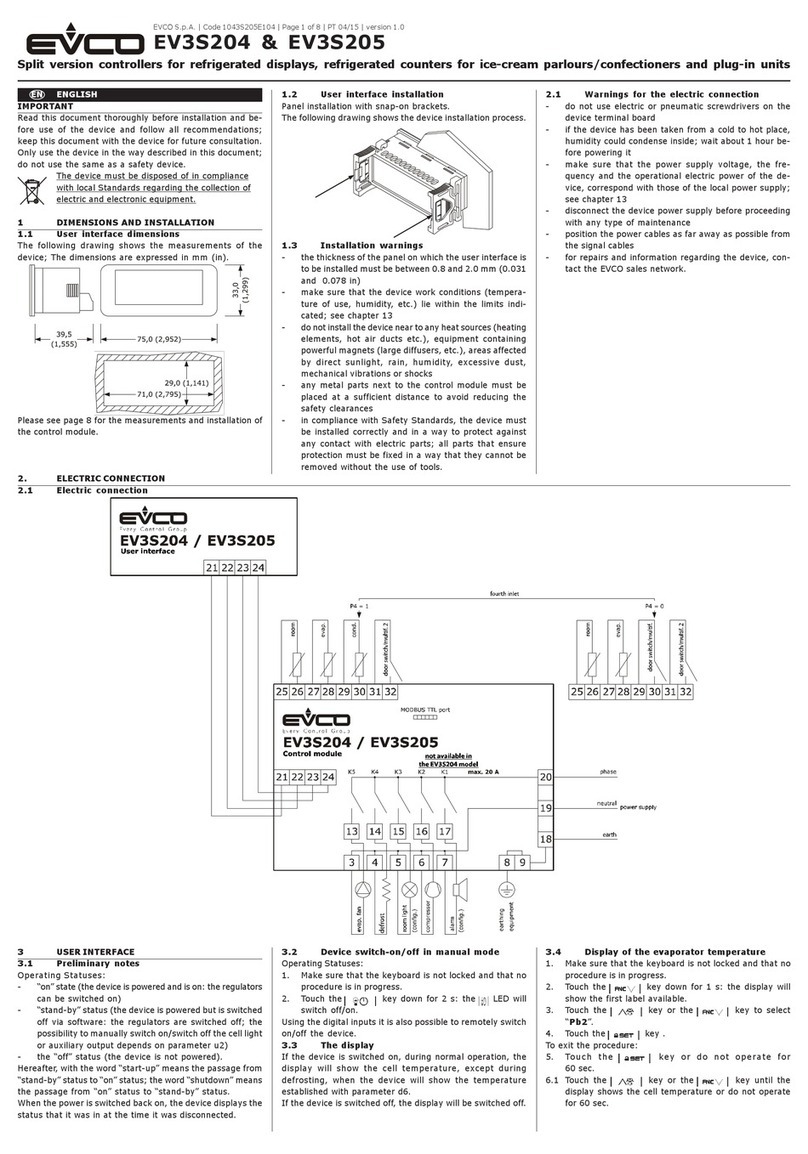

1 MEASUREMENTS AND INSTALLATION

1.1 Measurements

Measurements are expressed in mm (inches).

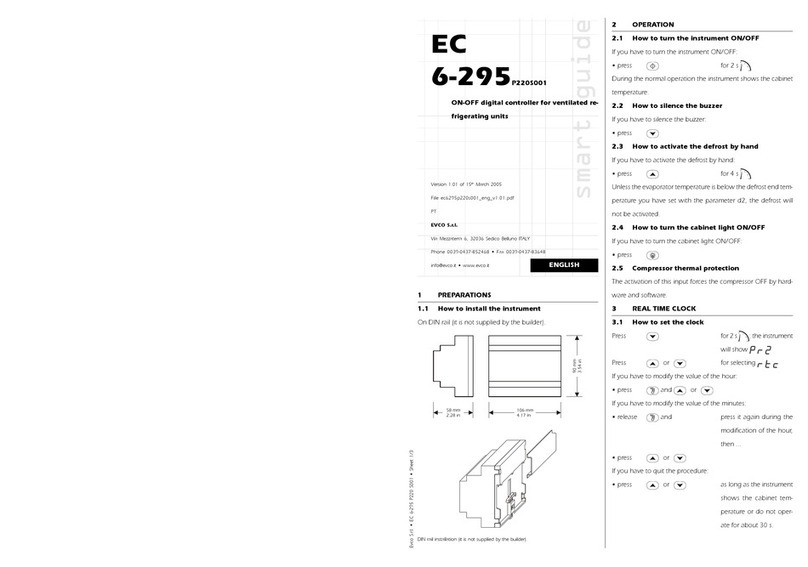

1.2 Installation

To be installed on a panel with snap-in brackets.

INSTALLATION PRECAUTIONS

- The thickness of the panel on which the device is to

be installed must be between 0.8 and 2.0mm (0.031

and 0.078 in).

- Ensure that the working conditions for the device

(operating temperatures, humidity, etc.) are within

the set limits. See the section TECHNICAL

SPECIFICATIONS.

- Do not install the device close to heat sources

(heating elements, hot air ducts, etc.), equipment

with a strong magnetic field (large diffusers, etc.), in

places subject to direct sunlight, rain, damp,

excessive dust, mechanical vibrations or shocks.

- In compliance with safety regulations, the device

must be installed properly to ensure adequate

protection from contact with electrical parts. All

protective parts must be fixed in such a way as to

need the aid of a tool to remove them.

2.1 I/O configuration

ANALOGUE INPUTS

IN1 Condensation temperature/pressure (NTC/4-20 mA)

IN2

System return temperature (NTC)

IN3

System delivery temperature (NTC)

IN4

Compressor discharge temperature (NTC)

DIGITAL INPUTS

IN5

System flow switch

IN10

On/Off

IN9

Fan thermal protection

IN8

Compressor 1 thermal protection

IN7

Maximum pressure switch

IN6

Minimum pressure switch

ANALOGUE OUTPUTS

AO1

Compressor 1 (0-10V/phase cutting/PWM)

AO2

Fan (0-10V/phase cutting/PWM)

DIGITAL OUTPUTS

DO1

Alarm

DO2

Enable fan

DO3

Circulation pump

DO4

Enable compressor 1

TK1

Compressor 2 (if installed)

TK2

Fan (if installed)

2.2 Description of connectors

Connector 1

PART

DESCRIPTION

1 Electro-mechanical relay digital outputs DO1... DO4

(max. 6A): common

2 Electro-mechanical relay digital output DO4 (2A

SPST): normally open

3 Electro-mechanical relay digital output DO3 (2A

SPST): normally open

4 Electro-mechanical relay digital output DO2 (2A

SPST): normally open

5 Electro-mechanical relay digital output DO1 (2A

SPST): normally open

Connector 2

PART

DESCRIPTION

1 Dry contact digital input IN6

2 Analogue input IN1 (NTC/4-20 mA)

3 Dry contact digital input IN7

4 Analogue input IN2 (NTC)

5 Dry contact digital input IN8

6 Analogue input IN3 (NTC)

7 Dry contact digital input IN9

8 Analogue input IN4 (NTC)

9 Dry contact digital input IN10

10 Digital input IN5

11 Analogue output AO1 (0-10V/phase cutting/PWM)

12 Analogue input GND, digital input GND, analogue

output GND and GND for powered INTRABUS port

13 Analogue output AO2 (0-10V/phase cutting/PWM)

14 INTRABUS port powered up signal

15 Power supply to transducer analogue inputs 4-20

mA (12 VDC, max. 40 mA)

16 Analogue input GND, digital input GND, analogue

output GND and GND for powered INTRABUS port

17 EV3 CHIL power supply (12VAC not insulated)

18 EV3 CHIL power supply (12VAC not insulated)

Connector 3 (if installed)

PART

DESCRIPTION

1 RS-485 MODBUS slave port: +

2 RS-485 MODBUS slave port: --

3 RS-485 MODBUS slave port: shield

Connector 4 (if installed)

PART

DESCRIPTION

1 Triac TK1 output: GND

2 Triac TK1 output (200 mA): OUT

Connector 5 (if installed)

PART

DESCRIPTION

1 Triac TK2 output: GND

2 Triac TK2 output (2 A): OUT

2.3 Example of electrical connection

See next page.

PRECAUTIONS FOR ELECTRICAL CONNECTION

- Do not use electric or pneumatic screwdrivers on the

terminal blocks of the device.

- If the device has been moved from a cold to a warm

place, the humidity may cause condensation to form

inside. Wait about an hour before switching on the

power.

- Make sure that the supply voltage, electrical

frequency and power are within the set limits. See

the section TECHNICAL SPECIFICATIONS.

- Disconnect the device from the power supply before

doing any type of maintenance.

- The devices must be fed by power of the same

phase as that feeding any module with a phase-

cutting command signal.

- If using triac digital outputs, we recommend

connecting a noise filter; do not touch the heat

dissipator because it could be very hot

- Connect the device to an RS-485 network using a

screened twisted pair. We recommend using a

BELDEN 3106A cable.

- Connect the power cables as far away as possible

from those for the signal.

- For repairs and for further information on the device,

contact the EVCO sales network.

3 SIGNALS AND ALARMS

3.1 Signals

LED

DESCRIPTION

Function mode LED

Compressor 1 LED

Compressor 2 LED

Circulation pump LED

Fan LED

Temperature LED

Pressure LED

Alarm LED

Set-up LED

On/stand-by LED

3.2 Alarms

CODE

DESCRIPTION

EA01 Condensation temperature probe alarm/

condensation pressure probe alarm

EA02

System return temperature probe alarm

EA03

System delivery temperature probe alarm

EA04 Compressor discharge temperature probe alarm

AFLo Flow switch alarm

AHtr Maximum temperature alarm

AFr1 Antifreeze alarm

AHP1 Maximum pressure switch alarm

ALP1

Minimum pressure switch alarm

AtC1 Compressor 1 thermal protection alarm

AtF1

Fan thermal protection alarm