Cleveland

™

Project ________________________________

Item __________________________________

Quantity _______________________________

FCSI Section ____________________________

Approval _______________________________

Date __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

STEAMCRA T®GENERATOR STYLE

HIGH SPEED CONVECTION STEAMERS

MODEL: 24-CEA-10

Cleveland Standard Features

I

ICooking Capacity for up to ten 12˝ x 20˝ x 21⁄2˝ deep

Cafeteria Pans, five each compartment.

IIInnovative PowerPak Electric Steam Generator: Twin

Vertical Atmospheric Electric Steam Generators operate

independently. Two 8 KW ire Bar Heating Elements per

generator. Strong 14 Gauge Stainless Steel Construction.

Large 5 gallon generator reservoir for each compartment for

high speed steam cooking production. Two fully insulated

rear mounted independent steam generators.

IIEach steam-cooking compartment is independently

operated and controlled by a separate stainless steel

steam generator.

IIEasy Access Generator Cleaning Port: Two Generator

Cleaning Ports located on the outside, top of the unit.

IIGenerator Cleaning ight: Indicator Light located on the

front of the unit warns operator it is time to delime genera-

tor.

IIInstant Steam Stand By Mode: Hold generator at a

steaming temperature. Allows unit to start cooking instantly.

IIDurable 14 Gauge, Stainless Steel Construction:

or compartment door, cavity and steam generator.

IITwo 60 Minute Electro-Mechanical Timers and Switches

for manual operation: Audible signal for cooking time

completion. (MCS)

IIMain Power On/Off Switch: Automatically fills generator

with water, and then starts heating elements in generator.

IIExclusive Steam Cooking Distribution System:

Exclusive Brass Steam Jets produce a high velocity

convection steam without fans. Coved Corner design in

cooking compartment distributes heat evenly, and is easy to

clean. Creased top & bottom enhance drainage. Cold Water

Condenser for each compartment maintains a dry steam.

ully Insulated cooking compartment for thermal efficiency.

Removable Stainless Steel Slide Racks.

IIAutomatic Generator Drain: Contains a “Water Jet” Spray

Rinse Drain Cleaning Cycle to keep drain clear.

IIExclusive Automatic Probe for Water evel Control:

Separate from the generator for easy access, contains a

high velocity rinse cycle to eliminate mineral build up.

IIExclusive “Cool to the Touch” Two-Piece Compartment

Door Design: ree floating inner door with reversible gas-

ket provides an air tight seal. Stainless Steel Slam/Latch

Door Latch mechanism for reliability.

IICondensate Drip Trough: Provide under lower

compartment door to collect condensate.

IIeft Hand Door Hinging: Compartment Doors hinged on

the left, controls on the right.

INSF Certified 6˝ Stainless Steel egs with adjustable

flanged feet for a one inch level adjustment.

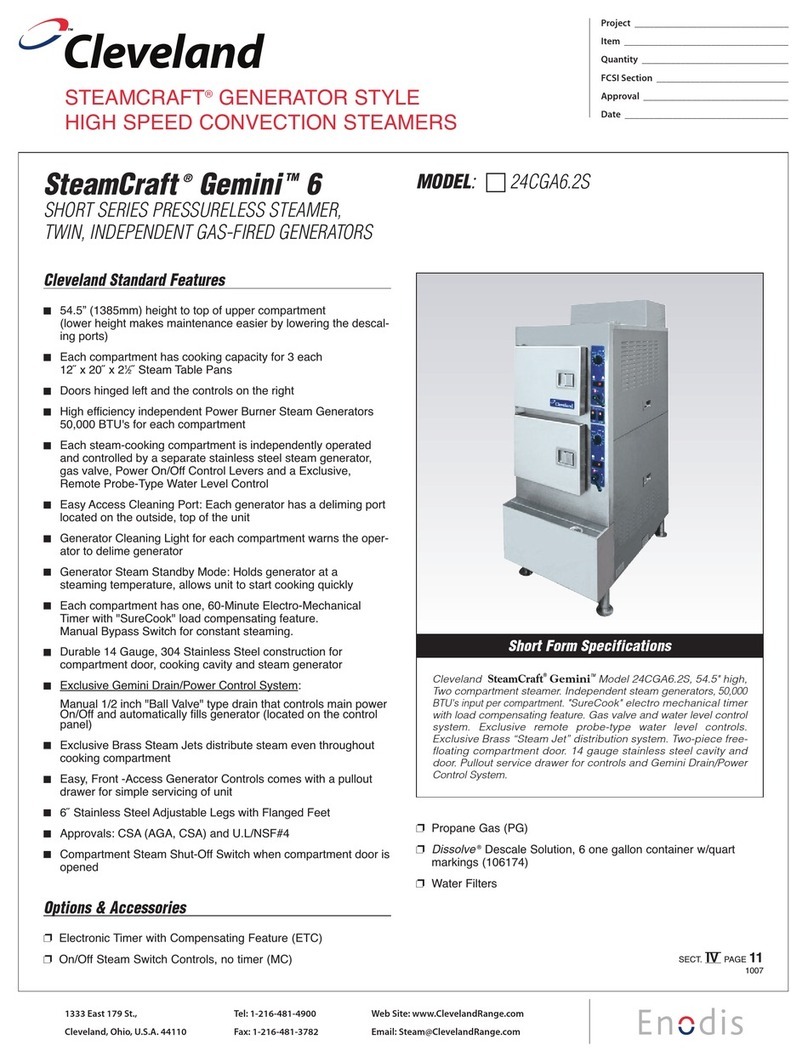

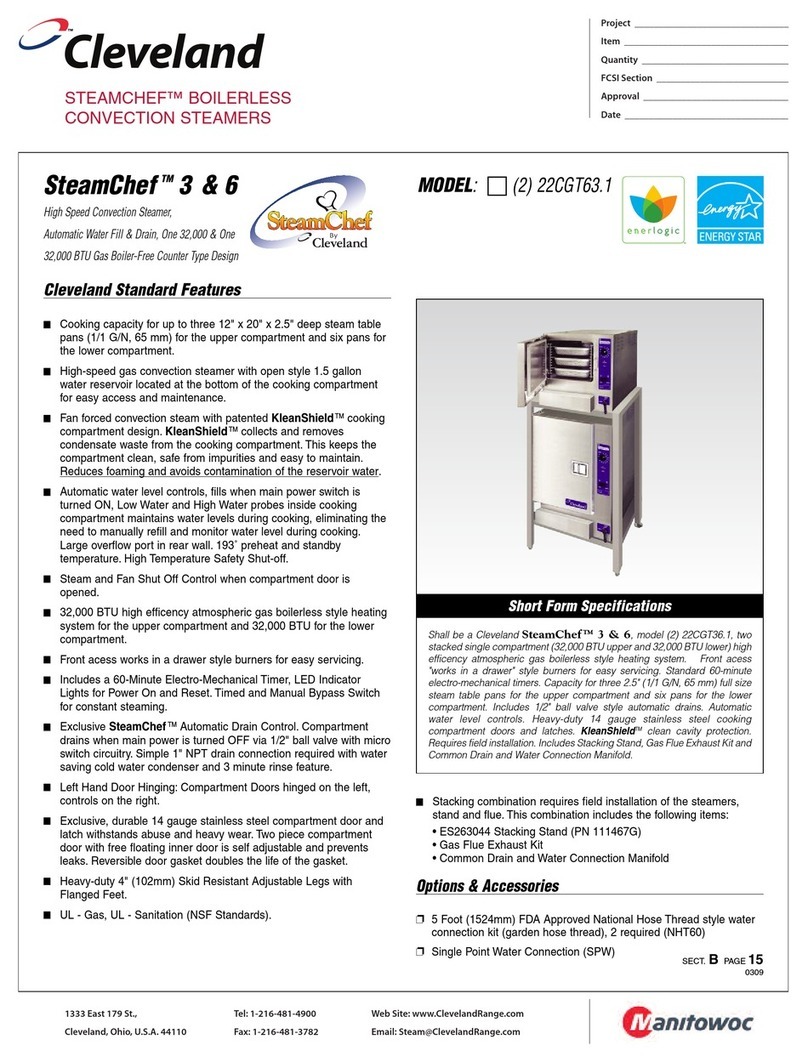

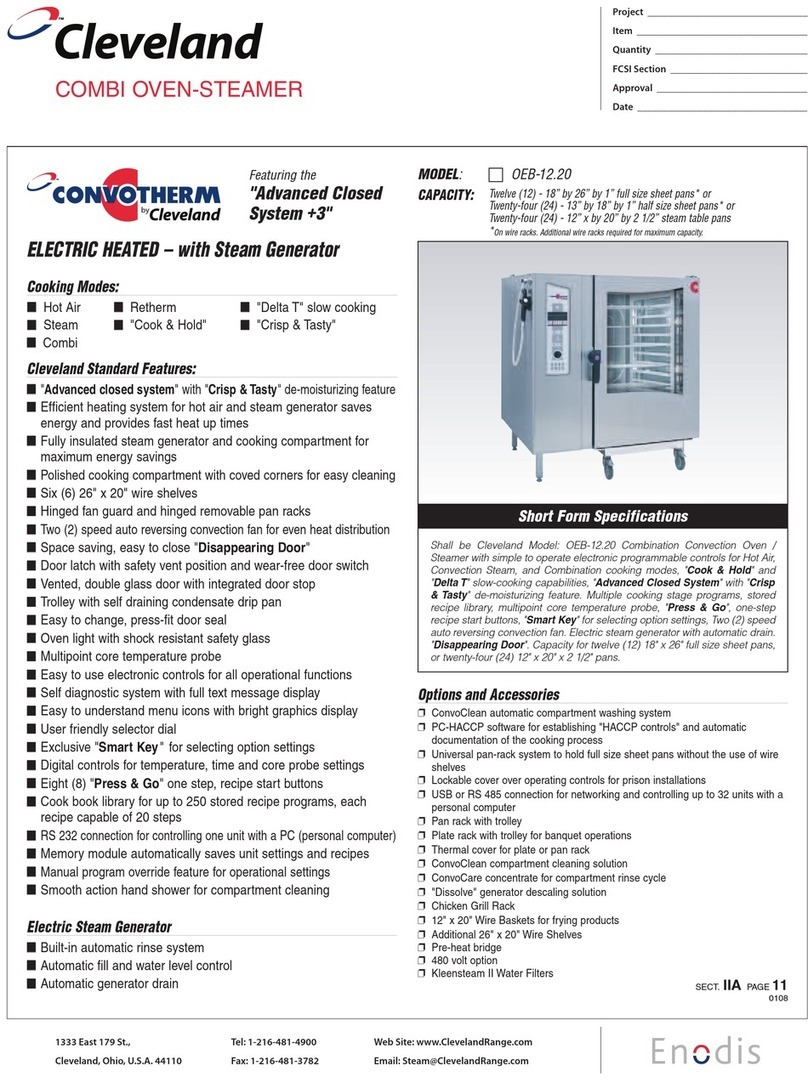

Shall be Two Compartments, Cleveland Convection Steamer series

SteamCraft

Gemini

TM

10

, Model 24-CEA-10, Twin Electric Atmospheric

Steam Generator, 32 KW input.

Remote Probe Type Water Level

Controls

. Steam Generator with Automatic Water Fill on start up. Automatic

Generator Blowdown, Two each 16.5 KW Fire Bar Heatin Elements. Choice

of Compartment Controls, Manual By Pass Operation Mode, Exclusive Cold

Water Condenser desi n, Type 430 Stainless Steel exterior and cookin

compartments.

Options & Accessories

ËRight hand Door Hinging, Controls on the Right (DHR)

ËElectronic Timer with Compensating Load eature (ETC)

ËON/O Steam Switch only for compartment controls (MC)

Ë10˝ Stainless Steel Legs (L 10)

ËDissolve ®Descale Solution, 6 one gallon container w/quart

markings (106174)

ËCompartment Door Steam Shut Off Switch (SCS)

ËCafeteria Pans in depths of 1˝, 21⁄2˝ and 4˝

ËLow Wattage Option, 8 KW each compartment (LWO)

ËWater ilters

Short For Specifications

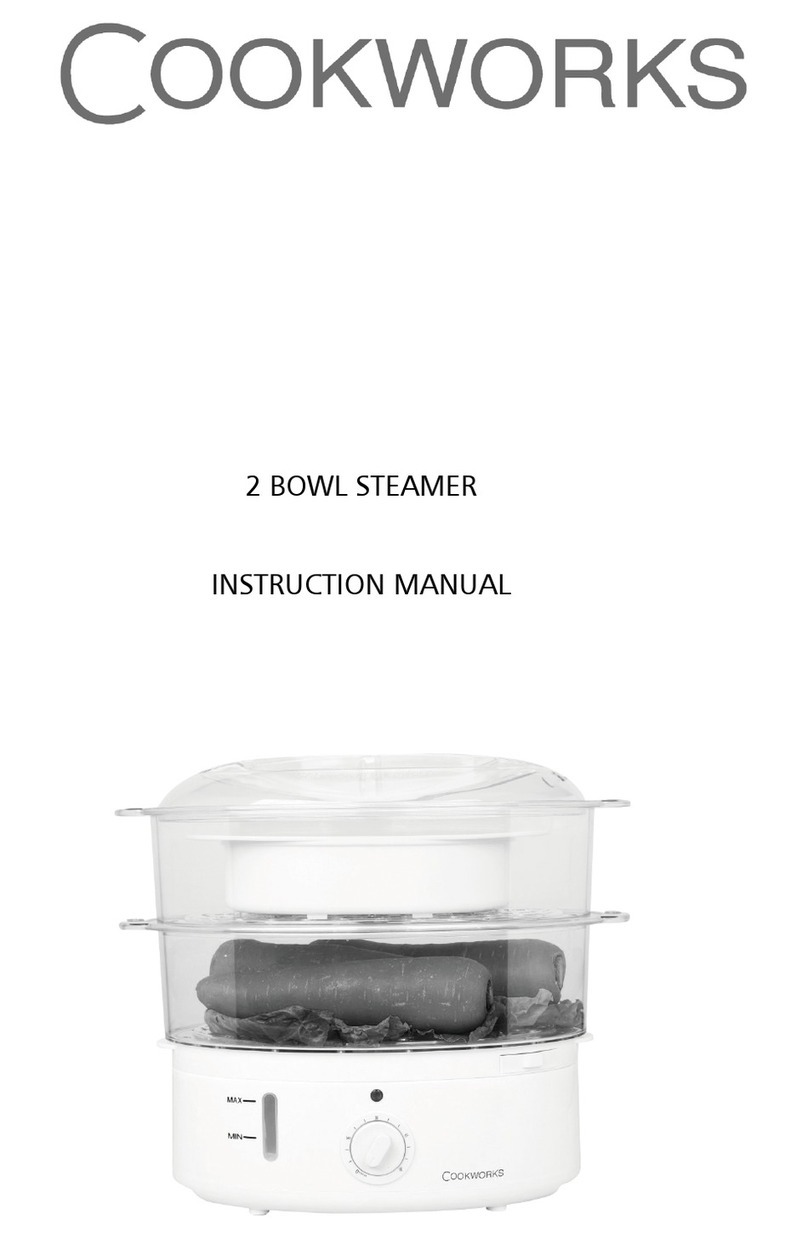

Shown with optional

Electronic Timer

Stea Craft ®Ge ini TM 10

TWO COMPARTMENT FLOOR MODEL DESIGN

PRESSURELESS CONVECTION STEAMER

TWIN ELECTRIC STEAM GENERATORS, 16 KW EACH

Shown with optional

Electronic Timer

SECT. IV PAGE 15

0707