2.1 Connection for standard use

■To use the TUNS1200 series, external components should be connected as shown in Fig.2.1.

■The TUNS1200 series should be conduction-cooled. Use a heatsink or fan to dissipate heat.

Connection for

standard use

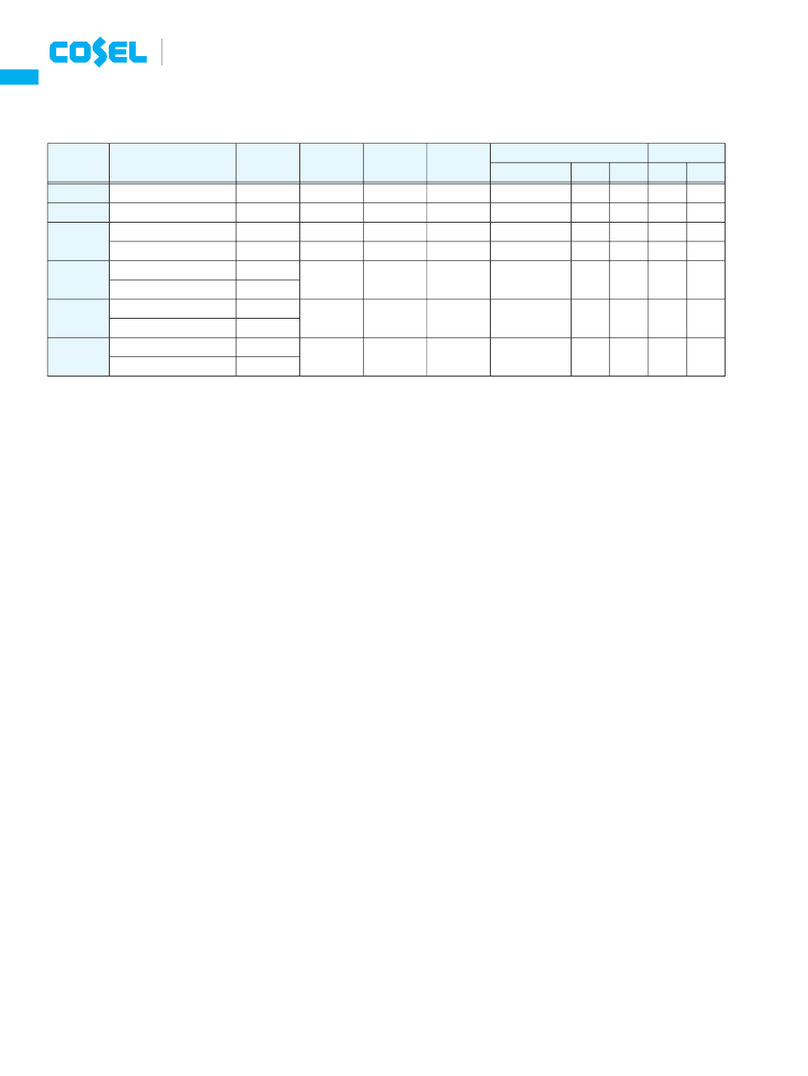

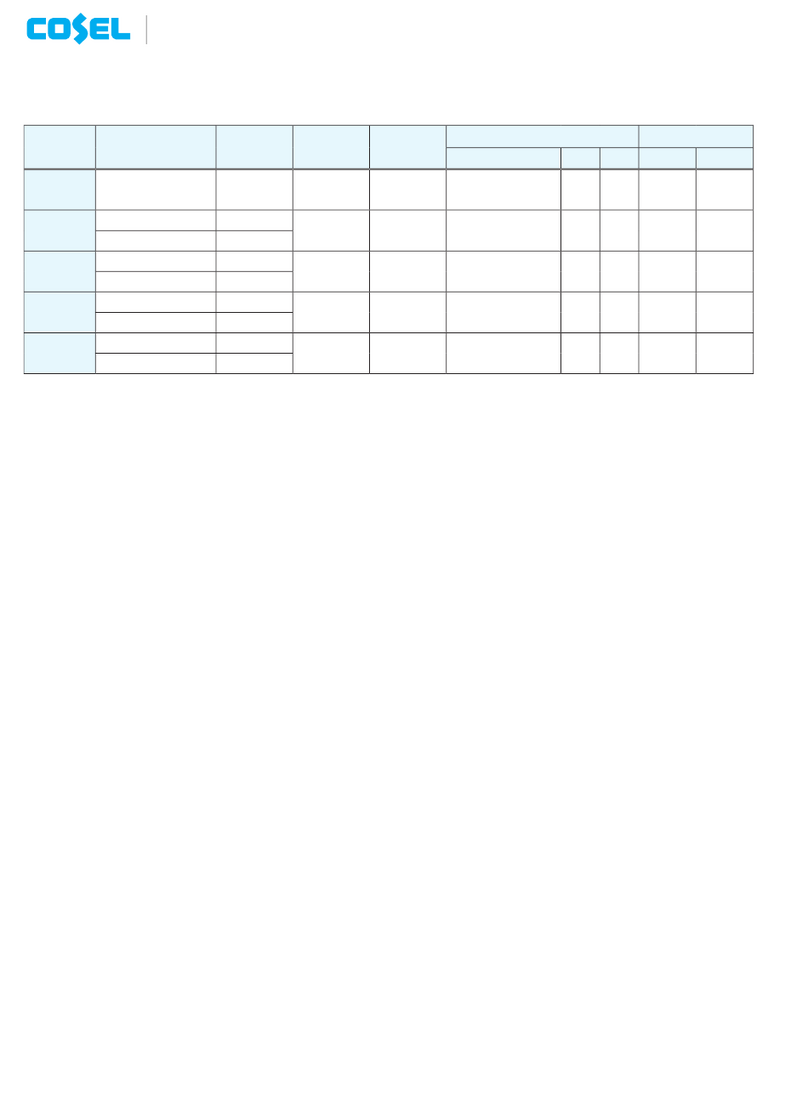

Table 2.1

Components list

・External parts should be changed according to the ambient temperature, and input and

For details, refer to the selection method of individual parts.

Applications Manual

TUNS1200

2. Connection for Standard Use

Heatsink

Rating Part name Rating Part name

1F11 AC250V/25A

0325025

(Littelfuse) AC500V/25A 0505025

(Littelfuse)

0325025

(Littelfuse) AC500V/25A 0505025

(Littelfuse)

For medical standard

application

LE155-MX × 2parallel

(OKAYA ELECTRIC INDUSTRIES)

LE155-MX × 2parallel

(OKAYA ELECTRIC INDUSTRIES)

AC400V

/2200pF

CD45-E2GA222M

(TDK)

AC400V

/2200pF

CD45-E2GA222M

(TDK)

SCR25-200-1R7A008JH

(TOKIN) 2.4mH/15A SCR25B-150-1R4A024J

(TOKIN)

SC15-E350H

(TOKIN) 2.4mH/15A SCR25B-150-1R4A024J

(TOKIN)

LE155-MX

(OKAYA ELECTRIC INDUSTRIES)

LE155-MX

(OKAYA ELECTRIC INDUSTRIES)

LE155-MX

(OKAYA ELECTRIC INDUSTRIES)

LE155-MX

(OKAYA ELECTRIC INDUSTRIES)

CD45-E2GA152M

(TDK) AC400V/1500pF CD45-E2GA152M

(TDK)

CD45-E2GA152M

(TDK) AC400V/1500pF CD45-E2GA152M

(TDK)

ELXZ250ELL222

(Nippon Chemi-Con) DC25V/2200uF ELXZ250ELL222

(Nippon Chemi-Con)

ELXZ500ELL102

(Nippon Chemi-Con) DC50V/1000uF ELXZ500ELL102

(Nippon Chemi-Con)

ELXZ630ELL471

(Nippon Chemi-Con) DC63V/470uF ELXZ630ELL471

(Nippon Chemi-Con)

C3216X7R1H105

(TDK) DC50V/1uF C3216X7R1H105

(TDK)

C3216X7R1H105

(TDK) DC50V/1uF C3216X7R1H105

(TDK)

C3216X7R2A105

(TDK) DC100V/1uF C3216X7R2A105

(TDK)

ELXS451VSN471 × 3parallel

(Nippon Chemi-Con)

ELXS501VSN471 × 3parallel

(Nippon Chemi-Con)

ECWFE2W105JA × 2parallel

(Panasonic Electronic Components)

ECWFE2J105JA × 2parallel

(Panasonic Electronic Components)

ECWFE2W105JA × 2parallel

(Panasonic Electronic Components)

ECWFE2J105JA × 2parallel

(Panasonic Electronic Components)

A5MC-5R1JK ×2series

(UCHIBASHI ESTEC)

A5MC-5R1JK ×2series

(UCHIBASHI ESTEC)

CRS32 683

(HOKURIKU ELECTRIC INDUSTRY)

CRS32 683

(HOKURIKU ELECTRIC INDUSTRY)

TND14V-621K

(Nippon Chemi-Con) 620V TND14V-621K

(Nippon Chemi-Con)

DSA-402MA

(Mitsubishi Materials) 4kV DSA-402MA

(Mitsubishi Materials)

Capacitor

for boost voltage

Capacitor

for boost voltage

Inrush current

protection resistor