De Raat Code combi B 30 User manual

Intructions Code combi B 30

• The enclosed inspecon key allows full access to the lock

and its conguraons even in case of code loss. Thus, it is at

the highest hierarchy level of the lock. Therefore, it must be

stored in a safe place, but not in the secure storage unit.

• For security reasons programming and baery replacement

should always be performed and then tested with the

secure storage unit open.

• Every correct key stroke recognized by the lock is conrmed

by an acousc signal.

• You have max. 10 sec. for each individual key stroke. If no

key is pressed during these 10 seconds, the electronics

shuts down automacally. Uncompleted operaons must

be restarted aer that. The only excepons to this are the

code status query and the programming mode with 30

seconds response me unl automac shutdown.

• Code inputs resp. all further funcons (e.g. programming

operaons) can be cancelled unl the last key stroke by

pressing the key twice.

• Do not use for your code personal or similar known data

which are easy to nd out.

• If the set code(s) is(are) not available, the lock can be

opened or reset using the enclosed inspecon key.

• The lock is designed for use in the temperature range from

+10° C to +50° C and with humidity of 30% to 80%

(noncondensing).

• The lock must never be greased with or contact other

lubricants or aggressive liquids, it must be cleaned only

with a moist cloth only (no aggressive cleaning agents).

Code combi B 30

Important notes

• Never open the lock housing. Dismount the ng only for

baery replacement and perform it strictly according to the

specicaons of these operang instrucons. Avoid touching

electronic components. Otherwise, you endanger the

funcons of the lock and loose the right for the warranty

claims.

• During start-up the serial number of the input unit is saved

in the audit memory of the lock. Replacement of the input

unit is also registered by means of an entry in the audit

memory of the lock.

• For every descripon of operaon or programming

processes hereaer it is assumed that the lock and the input

unit are in the basic state. Basic state means that the lock is

closed (the bolt lock is extended) and the lock electronics is

switched o. If you are not sure, whether the lock is closed,

check if the rotary knob can be turned counterclockwise. To

ensure that the lock is not in a running programming

process, you can press the key twice to cancel it.

• Upon delivery the lock is set by Kaba Mauer GmbH to the

assembler coder "1". For security reasons acvate the

master code with your individual code immediately in order

to deacvate the assembler code. The assembler code is

meant only for lock mounng, it is not suitable for further

permanent use.

• Furthermore, the lock has the opon for paral or full start-

up by the safe manufacturer or distributor: For a paral start

-up basic conguraons are loaded to the lock without

acvaon of the master code. So, the lock sll opens with

"1". All conguraons performed previously using soware

are immediately valid only aer acvaon of the master

code (start-up according to 8.2). For full start-up the lock has

already been provided with a master code and further

sengs if necessary. In both cases the set basic conguraon

is communicated separately by the safe manufacturer or

distributor. If a full start-up has been performed and, thus, a

master code preset as delivery code, the safe manufacturer

or distributor can save it addionally in the following

hatched text box. All pre-congured codes have to be

changed by the end user immediately aer start-up.

Glossary of abbreviations and terms

Code: Numerical sequence of 8 digits for idencaon of the operator consisng of ID and PIN. -

ID: xed 2-digit operator number. -

PIN: freely selectable 6-digit combinaon (Noce, do not use personal data such as for example date of birth). -

Operator: the master, user and courier are operators of the lock – each operator of the lock has an individual ID (00, 01..30; 95)

assigned. -

Master code: ID 00; the highest code of the code hierarchy, can open the lock, change its own code, it is required for almost all

programming funcons of the lock. Can also perform programming funcons independently in the double-code mode. -

User code: ID 01 to 30, can open the lock and change its own code. -

Courier code: ID 95, can open the lock without waing for an opening delay which might be programmed and change its own code. -

Assembler code: has no ID, can open the lock during mounng at the factory. -

OD: adjustable me which has to pass before the lock can be opened. -

OST: Opening standby me: adjustable me which starts aer the opening delay; The lock can be opened during the opening

standby me. -

Guard me: Aer entering the code 3 mes incorrectly the guard me is acvated, no inputs are possible at the lock during the guard

me. -

Double code: Two dierent valid codes are required to open the lock. -

Silent alarm: If the lock is connected to an external alarm system (intruder detecon system) and this funcon is acvated at the lock, a

silent duress alarm can be triggered (not perceivable for the intruder). -

EMA: Intruder detecon system: external alarm system for evaluaon / forwarding of the duress alarm or secured permanent

power supply (not included in the scope of delivery). -

Undervoltage indicaon: indicates that the baeries are low and must be replaced as soon as possible in order to ensure secure funcon

of the lock. -

AHK: Take-o contact: A contact in the input unit which detects whether the input unit has been opened (e.g. for baery

replacement). -

Audit: All relevant events (opening, closing, programming etc.) are saved in the audit memory (approx. 200 events) of the lock. If

the memory is full, the oldest entry is overwrien automacally. The audit can be read out using soware. -

Reset: Reset of the lock to the delivery state, only the master code and audit remain unchanged. -

Inspecon key: The inspecon key can open the lock any me mechanically independent of the electronics. Opening by means of the key

does not have any OD or guard me. The inspecon key can also be used to assign a new master code and reset the

complete lock. Reconguraon of the lock can be implemented using the inspecon key and soware without knowing or

changing the master code. Therefore, the inspecon key is posioned higher in the code structure than the master code

and must be stored in a safe place (not in a secure storage unit).

Lock system: Input unit and lock

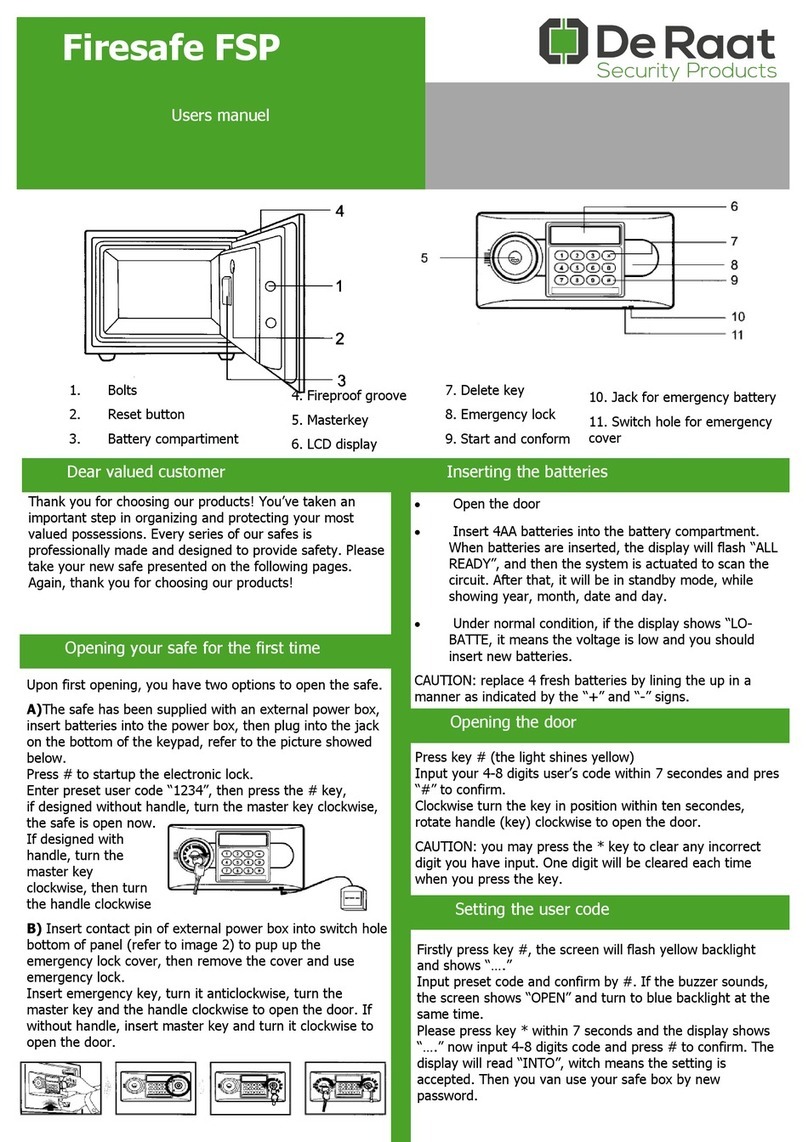

Lock housing and interfaces

The enre lock system consists of a visible input unit and the

lock installed in the secure storage unit. All programmed codes

and funcons are saved only in the lock and, thus, in the secured

area.

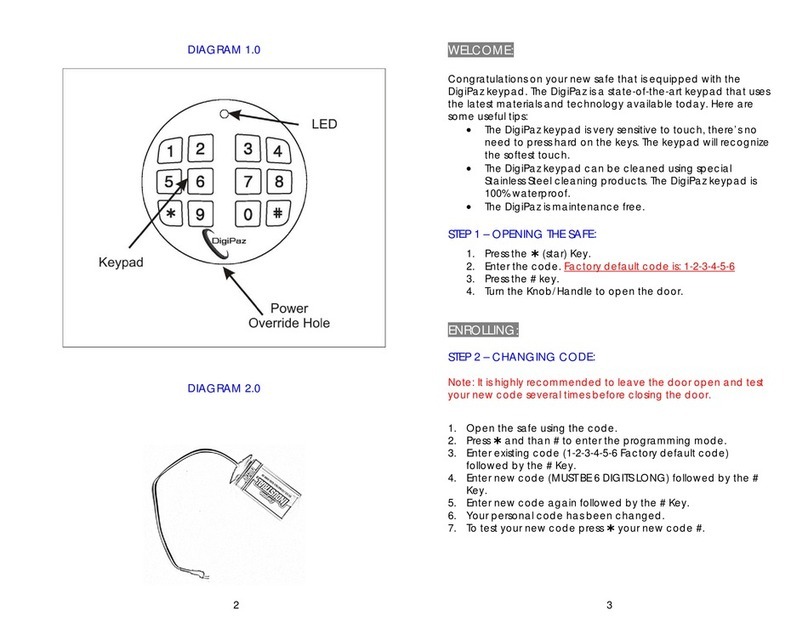

Figure 2: Mini-USB soc-

ket Special interface,

only in connecon with

original Kaba Mauer

CB30 Use PC cable!

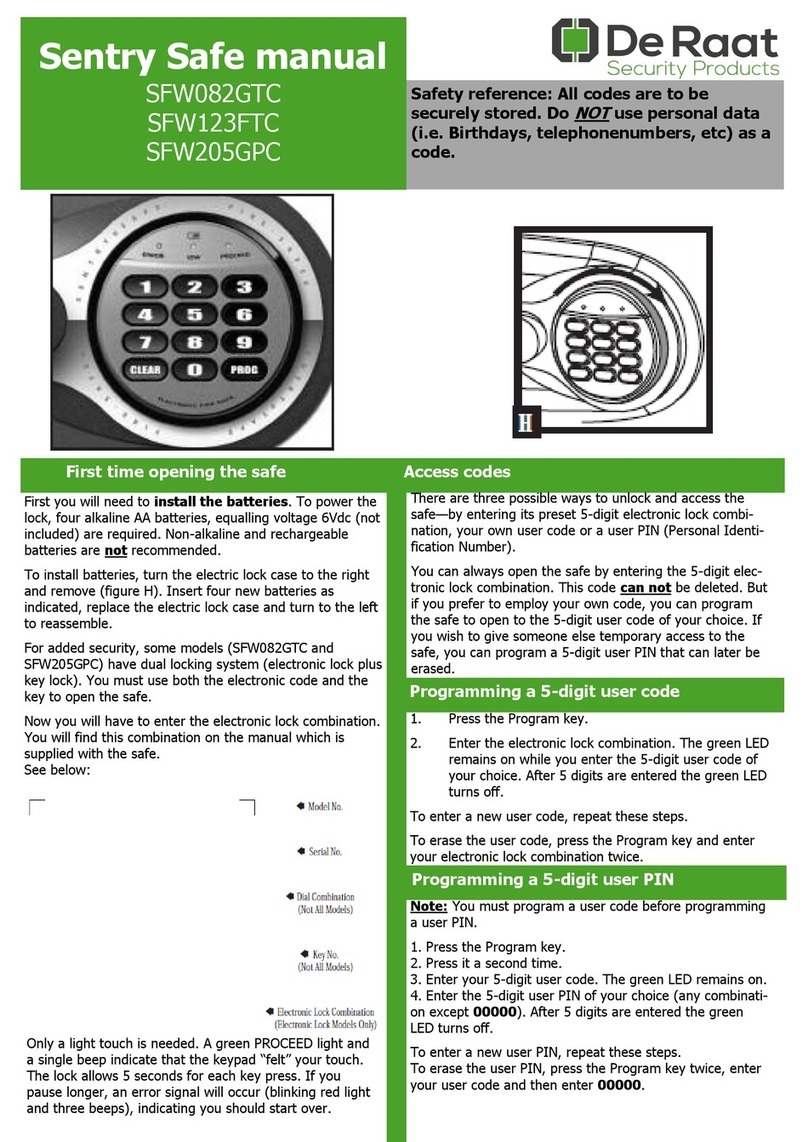

Figure 1: Input unit

Overview of authorizations

Start-up of the lock

Noodsleutel

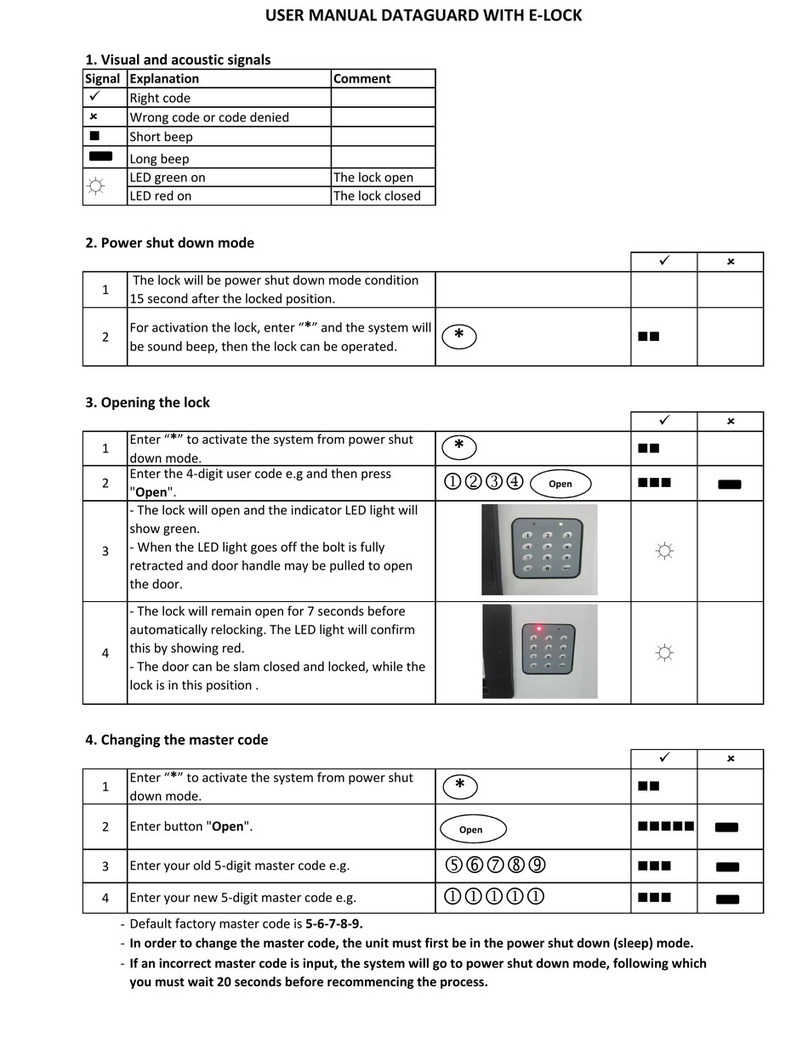

Overview of the possible signals

Activating master

Event When Signal

Pressing the key With every key stroke 1 x buzzer

Code valid 2 x Led green &

Correct input Aer pressing Enter 2 x buzzer

Error message Aer pressing Enter 3 x Led red &

Recurring input not matching 3 x buzzer

Cancelaon (manual cancelaon with or

me-controlled cancelaon if there is no input)

Take-o contact 1 x Led red and

has been acvated 3 x aer pressing Enter 1 x , buzzer then

1 x Led green

and 1 x buzzer

Guard me Permanently aer 1 x Led red

pressing Enter then 0.5 s break

Double code; Permanently aer 1 x Led green

input of the second pressing Enter then 2 s break

code is expected

OD Permanently aer 1 x Led red

pressing Enter then 5 s break

OST Permanently aer 1 x Led green

pressing Enter and buzzer then

5 s break

Undervoltage Aer pressing Enter 10 x Led red

Programming mode Permanently aer 1 x buzzer and

pressing Enter consnuous

signal LED green

Remote disable with every key stroke 1 x Led red

acvated, no

opening possible

Hardware error. Contact the Service. 3 x buzzer and

Aer pressing Enter connuous red

Code status messages

Code acve Aer pressing Enter 1 x Led green

and a buzzer

Descripon

1. Press “P” and arrow, Enter the new master code (00 xxxxxx)

and enter the arrow. (00 = ID, X = freely selected 6-digit

combinaon [0..9])

Conrm the new master code with (00 xxxxxx) and press the

arrow.

Then check the performed programming with the storage unit

sll open. To do so, proceed according to chapter 10.1.

NOTE: If the Incorrect code signal is output, the procedure must

be repeated since both codes do not match or the ID (here 00)

has been entered incorrectly. Changing of the master code can

be canceled any me by pressing twice. Alternavely, the

process can be canceled if no input is performed within 30

seconds.

Overview of the programming commands

The lock installaon as well as cabling and the rst baery instal-

laon are described in the installaon manual. As long as the lock

system has not been put into operaon, it can be opened using

the assembler code. The assembler code is intended for lock

mounng at the factory and not for further permanent use. For

correct start-up of the lock the master code must be acvated

correctly according to chapter 8.2, this makes the assembler code

invalid.

NOTE: If the start-up or paral start-up has already been perfor-

med by the safe manufacturer or distributor, the corresponding

informaon is specied in its manuals/notes. Furthermore, the

safe manufacturer or distributor can document the set master

code in this manual. For this informaon refer to the eld high-

lighted in gray in chapter 1 page 28, "Master code set by the dis-

tributor resp. safe manufacturer".

Opening with assembler code

1. Press 1 and the arrow you will see/hear 2x green led and 2x a

buzzer if it is correct. If not you will see 3x red Led and 3x a buz-

zer.

2. Turn the actuang knob within 4 seconds through 90° clock-

wise to the stop . Then open the storage unit.

Programming functions for the master

All programming funcons described here require the master

code for authorisaon.

NOTE: For security reasons, programming and tesng of

programming should always be performed with the secure

storage unit open (to have every me access to the storage unit

and the lock). Programming can be performed any me

individually and without waing mes (excepon - guard mes),

even if the double code and/or OD/OST are acvated. All

programming processes can be canceled by pressing twice.

Alternavely, the input can be canceled if no input is performed

within 30 seconds.

Programming functions for further codes

Blocking the user codes or courier codes

Aer blocking, the code cannot be used anymore unl it is

released again. In contrast to deleon, aer blocking the code

remains unchanged in the lock and can be used again aer

releasing.

Descripon

1. Press “P” and enter the valid master code and arrow.

Press “P4” and arrow.

Enter the ID to be blocked “ID” and arrow (ID = 01 to 30 for user

resp. 95 for courier)

NOTE: If the Incorrect code signal is displayed aer step 3, then

either the ID has not been acvated or it is not available. If only

the red LED is missing during the acknowledgment signal, the

code has not been blocked but released, because it had been

blocked before that. Perform the enre procedure again to block

the code again. Blocking of the master code is not possible.

Releasing the user codes or courier codes

Changing master code (P)

Aer modicaon of the master code the previous master code

is no longer valid. The funcon of the new master code must be

checked by opening the lock with the secure storage unit open

(see chapter 10.1)!

Descripon

1. Press “P” and enter the current master code and the arrow

(00 = ID, X = previously programmed 6-digit combinaon).

Enter the new master code 00 xxxxxx and the arrow

(00 = ID, Y = new 6-digit combinaon). Conrm the new master

code with 00 xxxxxx and the arrow

NOTE: The enre procedure has to be repeated in case of the

following errors: If Incorrect code signal is displayed according

to 1. aer the input of the current code, the code has been en-

tered incorrectly. If the Incorrect code signal is displayed aer

the second aempt to enter the new code as shown in 3., then

the two codes entered in 2. resp. 3 do not match.

This secon describes the basic programming procedures for

further codes (user or courier codes). This includes acvaon,

deleon, blocking and releasing of these codes. The basic code

structure is given in chapter 5 authorizaons. Furthermore, this

chapter describes the code status query used by the master co-

de to request the status of individual codes directly from the

lock.

For correct use of the lock the master code must be acvated.

Acvang user codes or courier codes (P3) Code can be used

only aer it has been acvated. When acvang a new opera-

tor, it is useful if the new code (starng from item 3 of the follo-

wing descripon) is entered directly by the respecve operator

on site. If the new code is not entered by the operator directly

but is specied by the master, it must be replaced by the real

personal code in the course of code changing as soon as possi-

ble.

Descripon

1. Press “P” and enter the valid master code, and arrow

(00 = ID, X = valid 6-digit combinaon for the master). Press “P3”

and arrow. Enter the new code ID xxxxxx and arrow (ID = 01 to

30 for user resp. 95 for courier, X = freely selectable 6-digit com-

binaon [0..9]) . Conrm the new code with IDxxxxxx and arrow

Aer the acvaon the new saved code is valid and can be used.

The new code has to be tested by opening the lock

Aer releasing of the code blocked previously, it can be used

again.

Descripon

1. Press “P” and enter the valid master code (00 = ID, X = valid 6-

digit combinaon for the master).

Press “P4” and arrow.

Enter the ID to be released ID and arrow (ID = 01 to 30 for user

resp. 95 for courier)

NOTE: If the Incorrect code signal is displayed aer step 3, then

either the ID has not been acvated or it is not available. If the

red LED is displayed addionally to the normal acknowledgment

signal, the code has not been released but blocked, because it

had been released before that. Perform the enre procedure

again to release the code again.

Deleting the user codes or courier codes

In contrast to blocking the code is irretrievably lost aer de-

leon. To use it again, it has to be acvated again . Blocked co-

des can be deleted without previous releasing.

Descripon

1. Press “P” and enter the valid master code and arrow.

Press “P5” and arrow.

Enter the ID to be deleted ID and arrow (ID = 01 to 30 for user

resp. 95 for courier)

NOTE: If the Incorrect code signal is displayed aer step 3, then

either the ID has not been acvated or it is not available. De-

leon of the master code is not possible. However, the master

code can be reassigned using the key

Code status

Programming opening delay and opening

standby time (P2)

Programming silent alarm (P8)

Activating opening delay and opening stand

by time (P2)

Opening delay (OD) is the me period which has to elapse be-

fore the lock can be opened. The opening standby me (OST)

denotes the me window during which the lock can be opened

as soon as the OD has elapsed. This program is used to set or

delete the OD (01 to 99 minutes) and the OST (01 to 19 minu-

tes). The set mes apply to all users and for the master but not

for the courier

To program opening delay (OD) and opening standby me (OST)

proceed as follows:

Descripon

1. Press “P” and enter the valid master code and arrow.

Press “P2” and arrow.

Enter the opening delay XX and the opening standby YY me

and arrow (XX = 01 to 99, YY= 01 to 19, specicaons in minutes

respecvely

NOTE: If the Incorrect code signal is displayed aer step 3, the

specied mes are outside of the maximum permied range.

The Incorrect code signal is also displayed if 00 is specied ei-

ther only for the OD or for the OST. Both inputs are not per-

mied.

Deactivating opening delay and opening

standby time

To deacvate opening delay (OD) and opening standby me

(OST), while doing so, enter "00" for the 2-digit OD as well as for

the 2-digit OST respecvely. Aer that all operators can open

the lock without delay.

Descripon

1. Press “P” and enter the valid master code and arrow (00 = ID,

X = valid 6-digit combinaon for the master)

Press “P2” and arrow .

Enter “0000” and arrow

Programming double code

The double code funcon allows to set the lock in such a way

that two oponal but dierent codes (dierent IDs) are required

to open the lock. The double code includes all operators

(master, user and courier). This programming command is used

to acvate or deacvate the double code.

Acvang the double code (P7)

In order to acvate the double code proceed as follows:

Descripon

1. Press “P” and enter the valid master code and arrow.

Press “P7” and arrow.

The double code must be deacvated in order to be able to ac-

vate it. If the red LED is displayed addionally to the normal ack-

nowledgment signal, the double code has been acvated previ-

ously and is deacvated now. To acvate it again, repeat the

enre procedure.

A silent alarm is triggered by a special code input. The message in

queson is an alarm message which iniates the lock using an

alarm output, the lock can sll be opened during this. However,

to forward the silent alarm, the alarm output must be connected

to the intruder detecon system (not included in the scope of

delivery) (for further details refer to the installaon manual or

consult an installer of intruder detecon systems). This program-

ming command is used to acvate or deacvate the silent alarm.

To open the lock using the alarm code proceed the normal pro-

cudure.

Acvang the silent alarm (P8)

To acvate the silent alarm proceed as follows: Aer that the

silent alarm is acvated and the alarm codes can be used.

Descripon

1. Press “P” and enter the valid master code and arrow.

Press “P8” and arrow

NOTE: The silent alarm must be deacvated in order to be able

to acvate it. If the red LED is displayed addionally to the normal

acknowledgment signal, the silent alarm has been acvated previ-

ously and is deacvated now. To acvate it again, repeat the en-

re procedure.

Deactivating silent alarm.

Deactivating opening delay and opening

standby time

1. Press “P” and enter the valid master code and arrow.

Press ”P8” and arrow

The silent alarm is deacvang.

Acknowledging take-off contact message (P9)

The lock is equipped with a take-o contact (AHK), which is trip-

ped when opening the input unit (e.g. to replace the baery or

aer a manipulaon); aer that it is displayed with the manipu-

laon signal for each opening/operaon unl the acknow-

ledgment (3x LED green und 3x LED red im Wechsel + 6x buz-

zer). This programming command acknowledges the take-o

contact message. This procedure is saved in the event memory/

audit of the lock like all other procedures. If the signal meno-

ned above is displayed even if no baery replacement has been

performed, the input unit might have been manipulated, for

example to spy out the code. So, before you acknowledge this

message, make sure that no manipulaon has been performed

at the input unit. If you are not sure, whether there has been a

manipulaon or not, consult an authorized service! To acknow-

ledge the take-o contact message and, thus, switch o the

manipulaon indicaon, proceed as follows:

Descripon

1. Press “P” and enter the valid master code and arrow (00 = ID,

X = valid 6-digit combinaon for the master).

Press “P9” and arrow

Lock functions for all users

Every key stroke is conrmed by a key tone ( ). The input can be canceled any me by pressing twice. Alternavely, the inp

input is performed within 10 seconds. Aer three incorrect code inputs the lock switches to guard me. For details on the g

chapter 10.5. If the undervoltage signal (10x ) is displayed aer the code entry, then the baery capacity is low and the b

as soon as possible. For further details refer to chapter 13. If the take-o contact signal (3x and 3x alternately + 6x ) is di

entry, the input unit has been opened. To nd out more read chapter 9.6. The lock has a funcon which hinders spying out of

user observaon during code input: During all opening procedures the operator can add as many further digits as necessary be

the input by pressing . All inputs starng from the 9th posion will be ignored. Noce: This funcon supports only the co

is not available for the programming procedures. Opening with acvated addional funcons: The lock oers an opon to ex

nal funcons triggered by external signals. For further details refer to chapter 10.8.

Lock functions for all users

Every key stroke is conrmed by a key tone ( ). The input can be canceled any me by pressing twice. Alternavely, the inp

input is performed within 10 seconds. Aer three incorrect code inputs the lock switches to guard me. For details on the g

chapter 10.5. If the undervoltage signal (10x ) is displayed aer the code entry, then the baery capacity is low and the b

as soon as possible. For further details refer to chapter 13. If the take-o contact signal (3x and 3x alternately + 6x ) is di

entry, the input unit has been opened. To nd out more read chapter 9.6. The lock has a funcon which hinders spying out of

user observaon during code input: During all opening procedures the operator can add as many further digits as necessary be

the input by pressing . All inputs starng from the 9th posion will be ignored. Noce: This funcon supports only the co

is not available for the programming procedures. Opening with acvated addional funcons: The lock oers an opon to ex

nal funcons triggered by external signals. For further details refer to chapter 10.8.

Opening the lock without programmed OD/OST

Opening with double code

Lock functions for all users

Every key stroke is conrmed by a key tone ( ). The input can be

canceled any me by pressing “P” twice. Alternavely, the input

can be canceled if no input is performed within 10 seconds.

Aer three incorrect code inputs the lock switches to guard -

me. For details on the guard me refer to chapter 10.5. If the

undervoltage signal (10x LED green ) is displayed aer the code

entry, then the baery capacity is low and the baeries must be

replaced as soon as possible. If the take-o contact signal (3x

LED green and 3x LED red alternately + 6x buzzer) is displayed

aer the code entry, the input unit has been opened. The lock

has a funcon which hinders spying out of codes by means of

user observaon during code input: During all opening procedu-

res the operator can add as many further digits as necessary

before compleng the input by pressing . All inputs starng from

the 9th posion will be ignored. Noce: This funcon supports

only the code input for opening and is not available for the pro-

gramming procedures. Opening with acvated addional func-

ons: The lock oers an opon to execute further addional

funcons triggered by external signals.

Descripon

1. Enter a valid opening code and arrow (ID = 00 to 30 resp. 95,

X = programmed 6-digit combinaon for the corresp. ID num-

ber).

Turn the actuang knob within 4 seconds through 90° clockwise

to the stop

Opening the lock with programmed OD/OST

Descripon

1. Enter a valid opening code and arrow (ID = 00 to 30 or 95, X =

programmed 6-digit combinaon for the corresp. ID number) If

you have entered a courier code here, proceed directly with

step .

2. If you have not entered any courier code (ID 95), the signal for

the running opening delay is displayed now (1x LED red ; 5 s

break). Wait unl it is completely over.

3. The opening standby me starts aer the opening delay (1x

LED green, Now enter a valid opening code and arrow again (ID

= 00 to 30, X = programmed 6-digit combinaon for the corresp.

ID number).

4. Turn the actuang knob within 4 seconds through 90° clockwi-

se to the stop

The running opening delay can be canceled any me by pressing

“P” twice. If the Incorrect code signal is output aer the code

input, the entry must be repeated completely. Aer 3 incorrect

inputs the lock switches to the guard me. Courier code: Aer

entering the courier code (ID 95) the lock can be opened imme-

diately if the programmed OD (opening delay) is avoided in a

certain manner (steps 2 and 3 are omied). Double code mode:

In the double code mode the enre double code must be ente-

red. The OD is, thus, started only by the input of an individual

code. Avoiding the OD/OST with the courier code in the double

code mode: To enable this, the courier code must be the rst

entered code in the double code mode. Then the second code

(not the courier code) can be entered and aer that the lock can

be opened. Inspecon key: The OD can be avoided if the inspec-

on key is used, but it cannot be deleted

Opening with silent alarm

Descripon

1. Enter the rst valid opening code and arrow (ID = 00 to 30 or

95, X = programmed 6-digit combinaon for the corresp. ID num-

ber)

2. Now the signal for the input of the second is displayed (1x Led

green ; 2 s break)

3. Enter another valid opening code and arrow (ID = 00 to 30 or

95, however, other than in step 1, Y = programmed 6-digit com-

binaon for the corr. ID number)

4. Turn the actuang knob within 4 seconds through 90° clockwi-

se to the stop

NOTE: The operator IDs of both codes must not match. The or-

der of the code input is irrelevant, unless it is necessary to open

the lock while avoiding the OD/OST, then refer to 10.2. If the

Incorrect code signal is output aer the rst code input, the en-

try must be repeated completely. If the Incorrect code signal is

displayed aer the second code input, the second entered code

is incorrect or idencal to the rst input (idencal IDs). In both

cases the input must be repeated completely. Aer a total of 3

incorrect inputs the lock switches to the guard me (see chapter

10.5). It is irrelevant here, whether the faulty input was in the

rst or the second code. Even if the faulty inputs occur in the

rst or second code alternately, aer 3 incorrect inputs the lock

switches to the guard me.

If there is a threatening situaon, the lock can be opened with

simultaneous generaon of a silent alarm, provided the silent

alarm has been acvated and the lock is connected to an intruder

detecon system (not included in the scope of delivery). A special

alarm code derived from a valid code must be entered for this

purpose (if the double code is acvated, one of the codes is su-

cient). If an alarm code is entered, the lock opens externally as

usual but a silent alarm is iniated addionally without further

visible/audible feedback. The alarm code consists of a valid code,

the last posion/digit of this code is increased or decreased by

one digit (+1 or -1). If the last code digit is 0 or 9, then the digit

next to the last in the alarm code is not changed. If an opening

delay has been programmed, this me has to elapse sll in spite

of the alarm code input. If the silent alarm is deacvated, the

alarm codes are acknowledged as incorrect codes and the lock

cannot be opened resp. the OD is not acvated.

Descripon

1. Enter a modied valid opening code as an alarm code and ar-

row (ID = 00 to 30 or 95, X = the rst 5 posions of the program-

med 6-digit combinaon for the corr. ID number, Y = increased by

1 or decreased at the 6th posion of the combinaon menoned

above)

2. Turn the actuang knob within 4 seconds through 90° clockwi-

se to the stop .

If the Incorrect code signal is output aer the code input, the

entry must be repeated completely. Aer 3 incorrect inputs the

lock switches to guard me in this case as well (see chapter 10.5)

Double code: With the acvated double code it is sucient to

enter both codes as alarm codes in order to acvate the silent

alarm. However, the alarm is acvated only if both codes requi-

red for opening have been entered completely.

Key functions

Guard time (3 or more incorrect code inputs)

Aer 3 incorrect inputs the lock switches to a 1-minute guard

me. For each further incorrect code input the guard me is

extended to 2, 4, 8 and nally to 16 minutes. During the enre

guard me no code input is possible. The guard me can only be

omied by means of the inspecon key, however, it cannot be

deleted. Only aer the guard me has elapsed, the lock can be

opened

Closing the lock

Turn the actuang knob counterclockwise through 90° to the

stop . Code input is not required.

NOTE: If there is a boltwork available (usually recognized due to

an addional rotary handle on the secure storage unit), it has to

be locked, rst, aer the door has been closed. Only aer that

the lock can be closed. Secure closing of the lock has to be

tested by trying to rotate the knob at the input unit. The knob

must not be turned through more than approx. 45°.

Changing codes (P)

Everyone is authorised to change his/her own code any me.

The master is not authorised to change the user or courier code.

But he/she can acvate, block, release and delete codes. Aer

changing the previous code is no longer valid and the new code

must be used. The funcon of the new code must be tested by

opening the lock with the secure storage unit open!

Descripon

1. Press “P” and enter the code to be changed and arrow (ID [00

to 30 or 95], X = programmed 6-digit combinaon for the corr. ID

number).

2. Enter the new code and arrow (ID the same as in 2, Y = new 6-

digit combinaon for this ID number)

3. Conrm the new code and arrow

NOTE: The enre procedure has to be repeated in case of the

following errors: If the Incorrect code signal is displayed accor-

ding to 1. aer the entry of the code to be changed, the code

has been entered incorrectly or not assigned and, thus, cannot

be changed. If the Incorrect code signal is displayed aer the

rst new code input as described in 2., the ID does not match

the ID in step 1. The ID must always be kept, even in case of co-

de modicaon. If the Incorrect code signal is displayed aer the

second aempt to enter the new code as shown in 3., then the

two codes entered in 2. resp. 3 do not match.

Opening with activated additional functions

The lock has special addional funcons (only one of them res-

pecvely) which can be set only using the oponal PC soware. If

one of these funcons is acvated, the lock reacts dierently

than described above:

a) Remote disable: If the "Remote disable" funcon is acvated

and there is an acve corresponding input signal, each key is

acknowledged with 1x LED red Thus, no input is possible.

b) OD/OST override: If any opening delay mes and the associa-

ted opening standby mes have been programmed, they can be

overridden here.

c) Double code override: This funcon turns the programmed

double code into a simple code. The second code which is requi-

red usually is omied here.

d) Omission alarm: If this funcon is acvated at the lock, an se-

parate input signal must be iniated max. 60 seconds before the

code input (e.g. by means of a hidden buon); otherwise, the

lock generates the silent alarm, in spite of correct code input.

Opening of the lock using the inspecon key is intended only for

the emergency situaon and not for permanent use. Do not ap-

ply force when opening the lock using the key! You could destroy

the lock.

For opening by means of the key the rotary handle must be dis-

mounted. Since the rotary handle can be inserted in steps of 90

° , rst, always note the posion of the rotary handle for the as-

sembly later (e.g. using an adhesive tape on the input unit to

mark the posion of the mark on the rotary handle). Insert the

enclosed Allen wrench up to the stop into the small hole on the

lateral wall of the input unit (see g. 5.1) Pull out the rotary

handle to the front from the input unit (see g. 5.2) and remove

the Allen wrench. Then pull out the square sha out of the lock

(see g. 5.3). Now the key can be inserted into the lock as shown

in g. 5.4 (lock housing horizontally with the bolt on the le). If

the installaon posion of the lock is not known, determine the

correct direcon of the key by tesng in 90° steps. Alternavely,

you can ask the service technician or the cabinet manufacturer.

Aer correct inseron for lock opening turn the key through ap-

prox. 150° to the right to the stop (see g. 5.5). The lock is open

now. Aer opening by means of the key mount the input unit

again in the reverse order as described above and place the key

to a safe place, however, do not keep it in the secure storage

Resetting the lock (P0)

This programming command is used to reset the lock. This

means that this procedure deletes all sengs of the lock (user

code, courier code, double code, silent alarm, opening delay and

opening standby me), only the master code and the audit

remain unchanged.

Descripon

1. Open the lock using the key (above)

2. Press “P” and arrow

3. Press “P0” and arrow

4. Close the lock again by means of the key and mount the rotary

handle.

This procedure can be canceled any me by pressing twice. Al-

ternavely, the modicaon is canceled if there is no input for

30 seconds or if the lock is locked using the key before step 3.

Reconguraon of the lock aer opening by means of the key

using soware For further details on the procedure refer to the

operang instrucons for the PC soware. Aer opening the

lock using the key and connecng it to the PC soware a com-

plete reconguraon of the lock is possible, namely without kno-

wing or changing the master code. Only an audit entry is perfor-

med.

Power supply

Further special functions

Connecon to the PC soware

The lock has an addional mini-USB interface on the input unit.

The lock can be programmed via this interface using the PC so-

ware available as an accessory. The following funcons are avai-

lable when using the addional PC soware: a) Reading out au-

dit b) Programming the lock sengs using soware For further

details on this refer to the operang instrucons of the PC so-

ware.

Addional funcons via the signal input

The lock has an opon which allows implemenng one of the

addional funcons via the signal input according to 10.8. The

assignment of the signal inputs is described in the installaon

manual of the lock. The funcons can only be acvated with the

oponal PC soware. The operang behaviour of the lock with

dierent input signals acve is.

Addional funcons via the signal outputs

The lock has 2 signal outputs: Details on assignment of the out-

puts are given in the installaon manual. The following outputs

are available:

a) Silent alarm.

b) Microswitch for bolt monitoring, no addional programming

possible.

Power supply

Baery replacement Do not apply force and avoid touching

electronic components! You could destroy the lock. For baery

replacement the rotary handle of the lock must be dismounted.

Since the rotary handle can be inserted in steps of 90 ° , rst,

always note the posion of the rotary handle for the assembly

later (e.g. using an adhesive tape on the input unit to mark the

posion of the mark on the rotary handle). Insert the enclosed

Allen wrench up to the stop into the hole on the lateral wall of

the input unit as shown in Fig. 6.1. Pull out the rotary handle to

the front from the input unit (see g. 6.2) and remove the Allen

wrench. Then unscrew the screw in the handle recess (see g.

6.3). Aer that the top part of the input unit can be moved as

shown in g. 6.4 and then it can be removed to the front (see

g. 6.5). The 2 baeries are located on the base part of the in-

put unit and can be replaced now as shown in g. 6.6. Only

baeries of type AAA can be used. It is highly recommended to

use high-quality brand baeries and replace them as a precau-

on every 24 months at the latest. Aer the baery replacement

mount the input unit on the base part from the front in the or-

der reverse to the one described above and move it laterally

unl it engages and the red LED turns o. Then aach the screw

to secure the top part. Now aach the rotary handle in the posi-

on in which it has been mounted before dismounng (to do so,

use the marking menoned above). If the mounng is correct,

the rotary handle can no longer be removed. Remove the mar-

king (in this way). Finally, the take-o contact message must be

neutralised (see chapter 9.6). It can be performed only by the

master. Baery replacement (example above: the input unit

keyboard is located to the right of the rotary handle. For other

mounng posions proceed correspondingly):

Undervoltage indicaon w and the baery must be replaced

promptly. As soon as the undervoltage indicaon is displayed,

the lock can sll be opened, but no reprogramming is possible

unl aer the baery replacement. Furthermore, an audit entry

is performed. As soon as the baery is almost completely ex-

hausted, no opening can be performed and every key stroke is

acknowledged with an undervoltage signal.

Permanent power supply If necessary, along with the baery power supply the lock can also be supplied with voltage permanently. The

following opons are available for this purpose: a) Power supply via the intruder detecon system and the alarm box (art. no.

3001001550) b) Power supply via the alarm box (see above) for connecon to the signalling equipment without power supply opon via

the addional 12V power supply unit at the alarm box (see above) art. no. 3002501230 c) If the lock is used without any signalling

equipment: 9V power supply unit can be connected directly at the lock, art. no. 3002501220 Even with the permanent power supply the

baeries must sll be inserted into the input unit because otherwise the lock cannot be opened by means of the code entry in case of

power failure or a fault of the permanent power supply. The undervoltage indicaon is displayed in case of the permanent power sup-

ply failure and exhausted baery. The baeries and the permanent power supply should be checked as soon as possible in this case.

Other De Raat Safe manuals

De Raat

De Raat EM 2020 User manual

De Raat

De Raat Leisure plus User manual

De Raat

De Raat Technomax Trony GTR/4P User manual

De Raat

De Raat PROTECTOR 40E User manual

De Raat

De Raat EM 015 User manual

De Raat

De Raat Firesafe FSP User manual

De Raat

De Raat Protector depo cash plus 1 E User manual

De Raat

De Raat Sun Safe ES 045 User manual

De Raat

De Raat Sentry User manual

De Raat

De Raat VP Safe User manual