-6-

142636 - Prong Picker (02-October-2019)

Preparation

The Rock Picker should always be parked on a level,

dry area that is free of debris and foreign objects.

Follow this procedure when attaching:

1. Clear the area of bystanders. Remove foreign

objects from machine and working area.

2. Start tractor and slowly back up to the hitch point.

3. Stop the tractor engine, place all controls in neutral,

set park brake and remove ignition key before

dismounting.

4. Use the hitch pole jack to raise or lower the pole to

align with the drawbar. Ensure that the rock picker

hitch pole is parallel to the ground. Refer to the

“Hitch Clevis Adjustments” section if needed.

5. Install the drawbar pin (with a mechanical retainer,

such as a Klik pin) and safety chain (between the

tractor drawbar and the hitch pole). Raise the hitch

jack and rotate it to its stowed position.

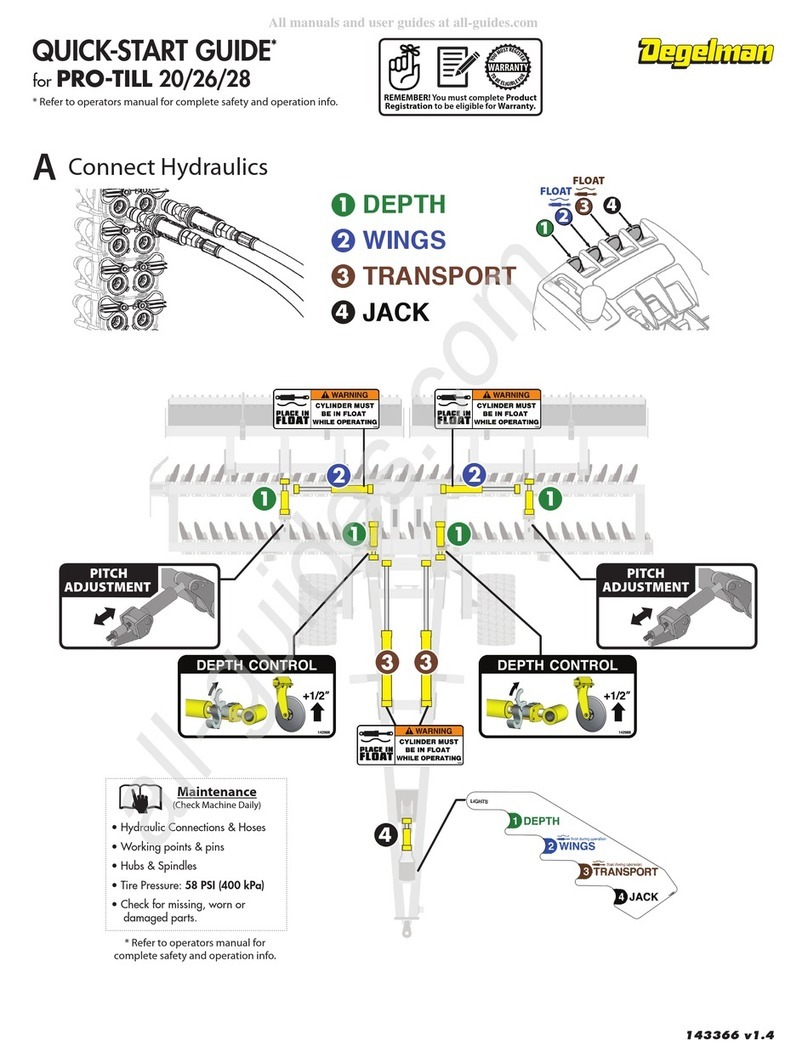

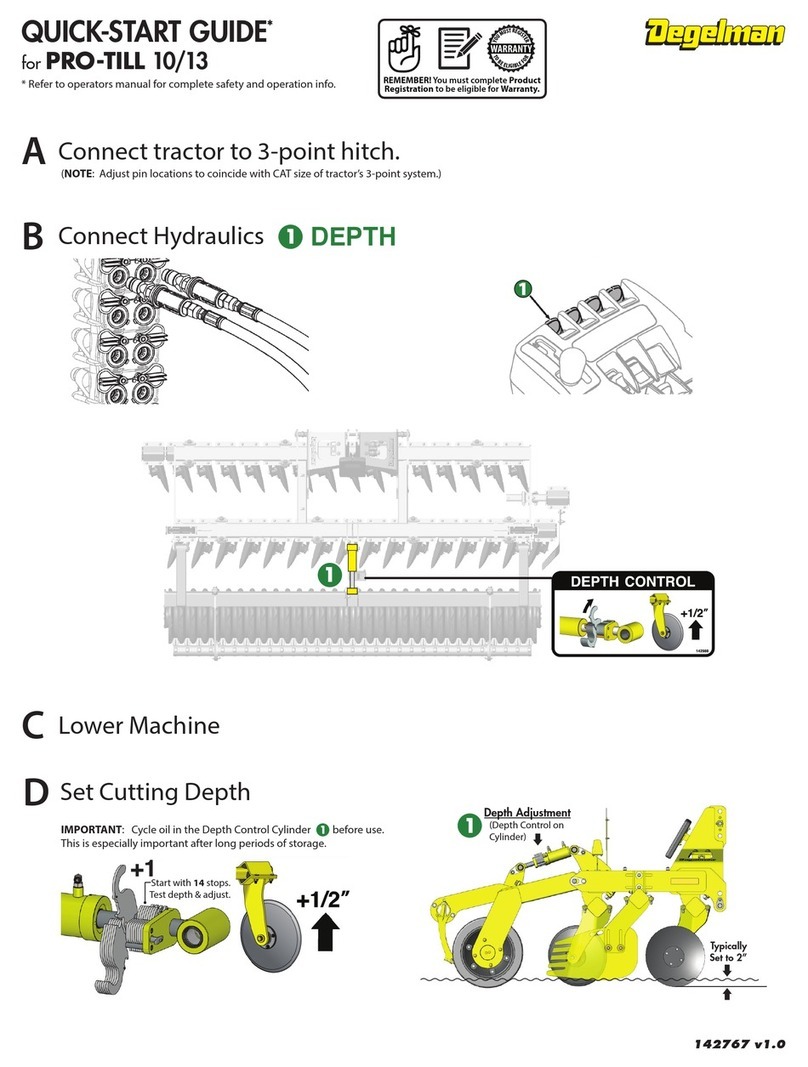

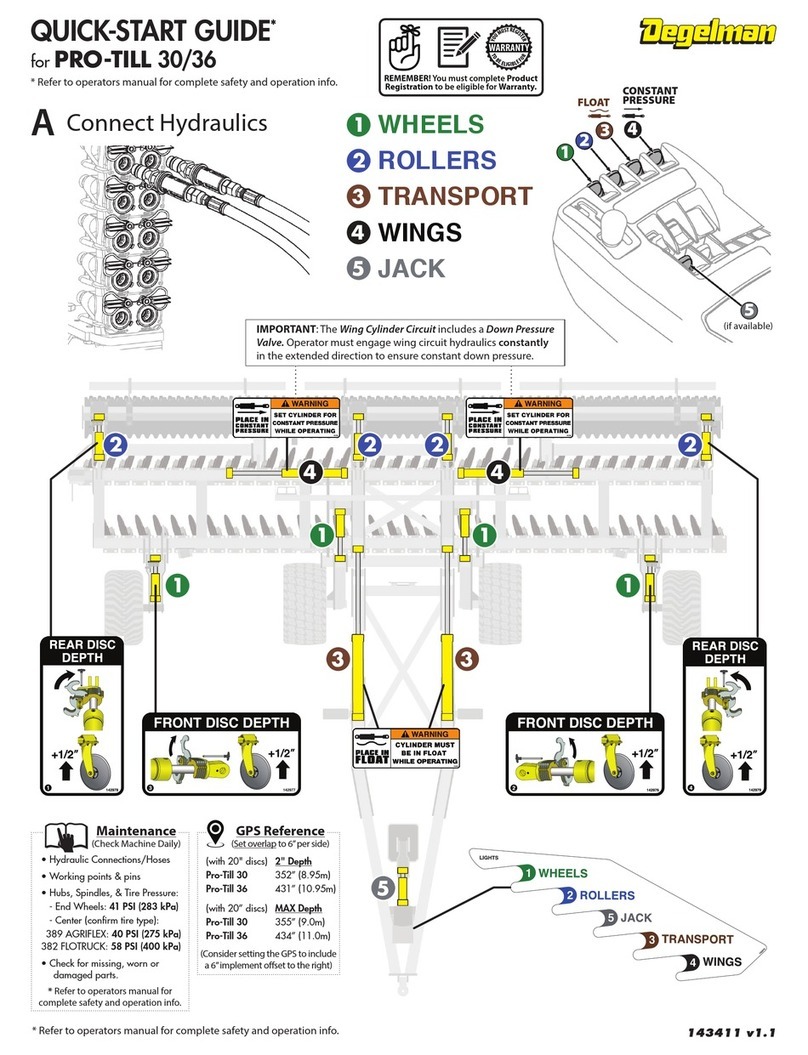

6. Connect the hydraulics.

NOTE: Connect the hoses that operate the grill lifting

cylinders to the hydraulic control operated nearest

to the operator’s seat, such that when the lever is

moved forward, the grill will lower.

7. Check that the transport pins are removed before

operation. If they are still installed, proceed to

remove them. Refer to the “Removing Transport Pins”

section if needed.

8. When unhooking from the tractor, reverse the above

procedure.

HOOK-UP / UNHOOKING

WHEN CONNECTING HYDRAULICS:

- Use a clean cloth or paper towel to clean the hose

couplers ends and also the area around the couplers

on the tractor.

- Remove the plastic plugs from the couplers (if

applicable) and insert the male ends.

- If the direction of motion is wrong after testing the

controls, reverse the couplers.

Bleeding Hydraulics: Occasionally air may become

trapped in the hydraulic circuit, making it necessary

to “bleed” the circuit. To perform this operation cycle

the hydraulics several times or, especially on older

tractors, temporarily loosen an easily accessible hose

fitting enough to allow any trapped air to escape while

cycling the hydraulics. Retighten fitting.

Follow this procedure when selecting and preparing

a tractor for use with the machine:

1. Use only a tractor of sufficient power and weight to

adequately handle the machine.

2. It is not recommended to use a tractor that is

equipped with duals. The right outer tire will drive

over the rocks, push them into the ground and make

them difficult to pick up with the grill.

3. It is recommended to pin the tractor draw bar totally

offset to the right hand side, to allow the picking grill

to clear the tractor wheels.

4. Use only a drawbar pin with provisions for a

mechanical retainer such as a Klik pin. Always

install the retainer.

5. Always attach a safety chain between the tractor

and the machine to prevent unexpected separation.

TRACTOR PREPARATION

WARNING:Use extreme care

when working around a high

pressure hydraulic system. Make

sure all connections are tight

and all components are in good

repair. Wear hand and eye

protection when searching for suspected leaks.