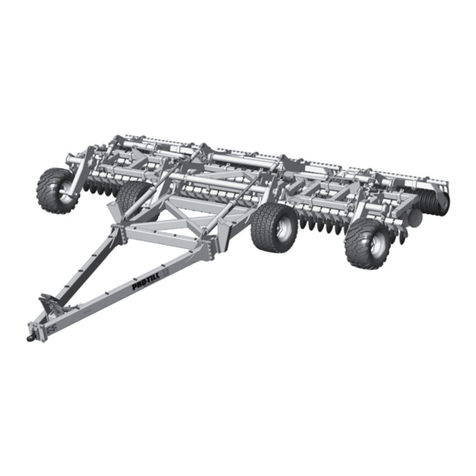

Degelman PRO-TILL 14 NT User manual

Other Degelman Farm Equipment manuals

Degelman

Degelman 7900 Series User manual

Degelman

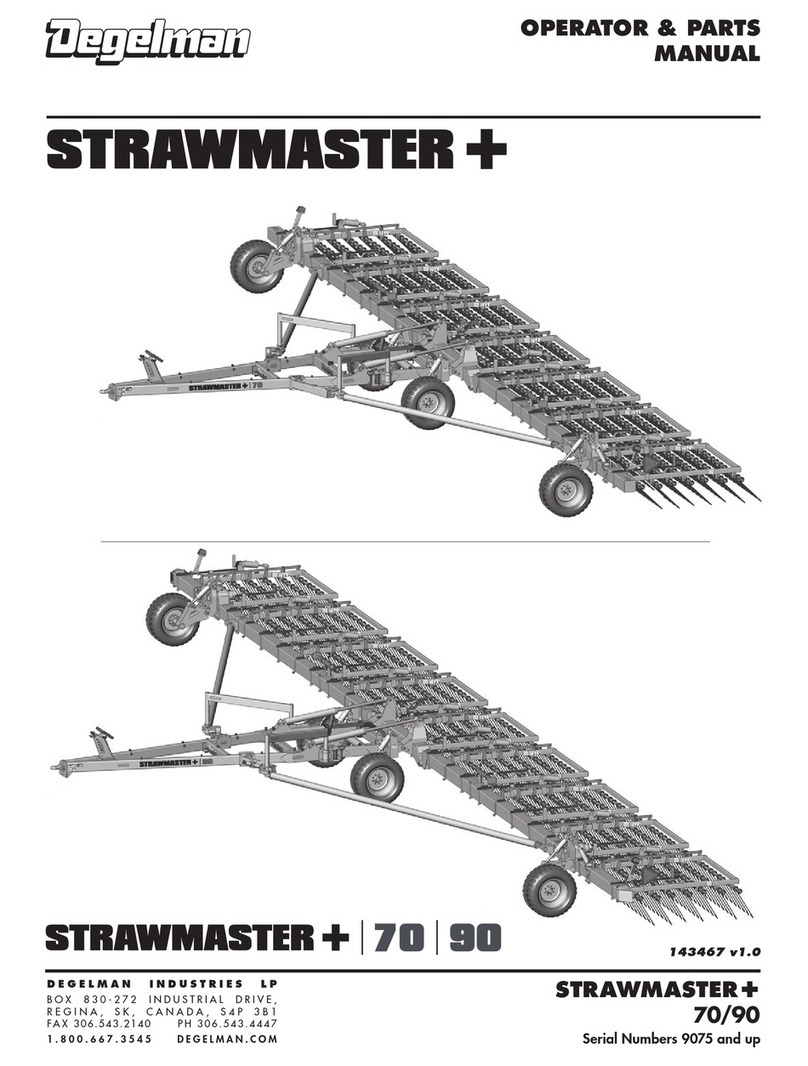

Degelman STRAWMASTER Plus User manual

Degelman

Degelman PRO-CAST 80 User manual

Degelman

Degelman Tri-Plex Landroller 7645 User manual

Degelman

Degelman PRO-TILL 33/40 User manual

Degelman

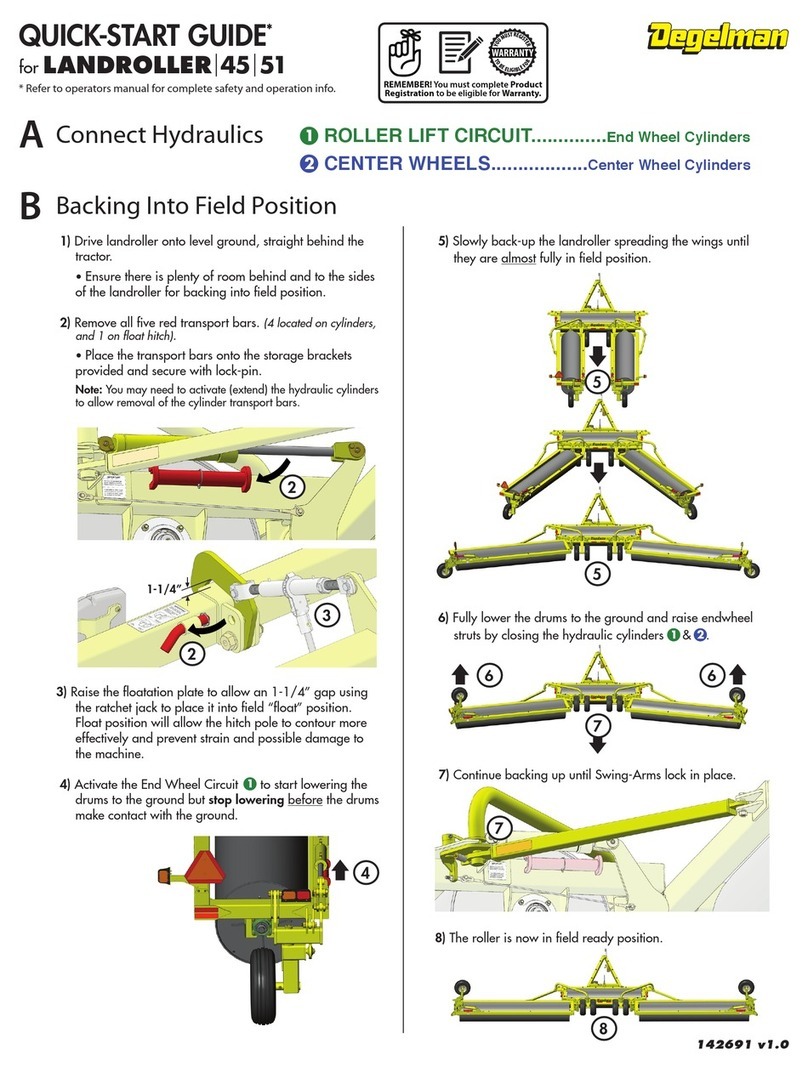

Degelman LANDROLLER 45 User manual

Degelman

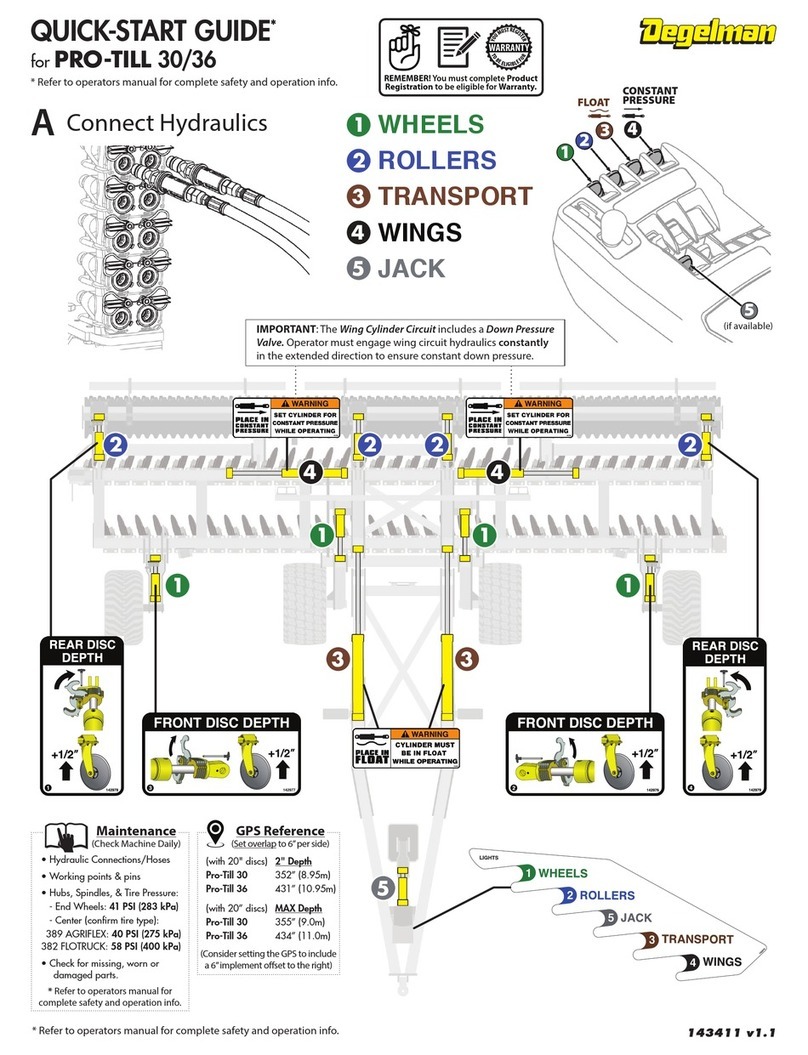

Degelman PRO-TILL 30 User manual

Degelman

Degelman PRO-TILL 41 User manual

Degelman

Degelman shuttlekart 1150 Programming manual

Degelman

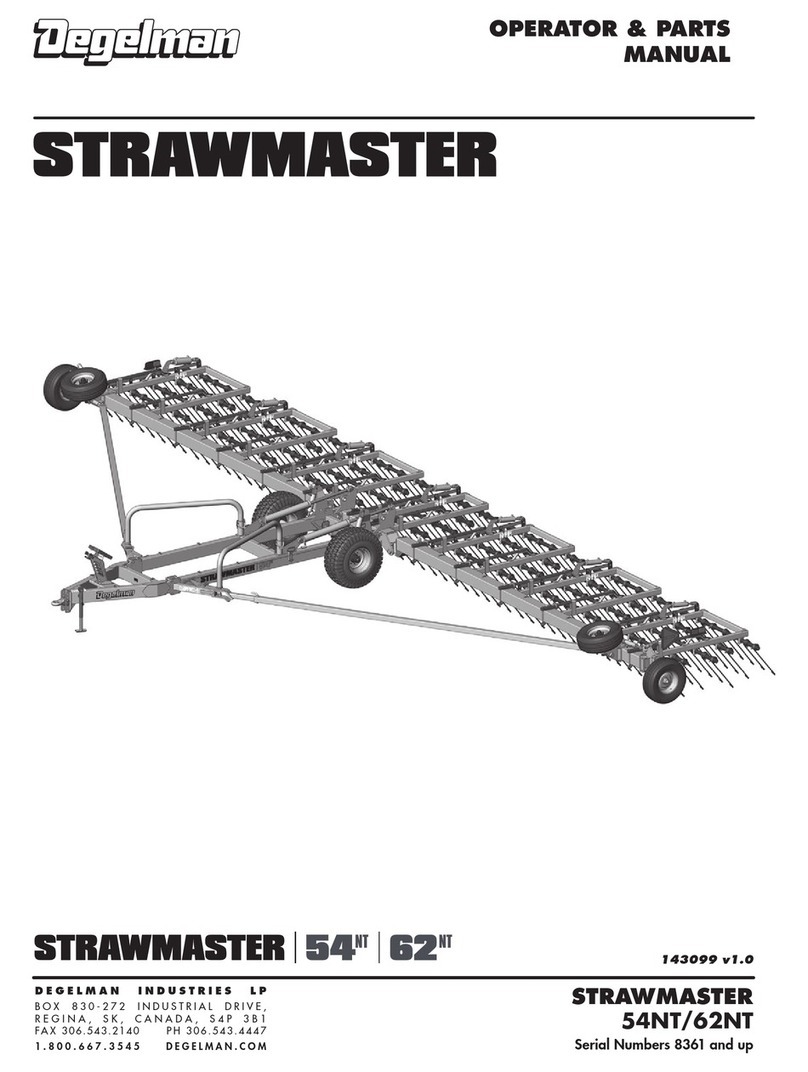

Degelman STRAWMASTER 54NT Programming manual

Degelman

Degelman Pro-Till 33 Programming manual

Degelman

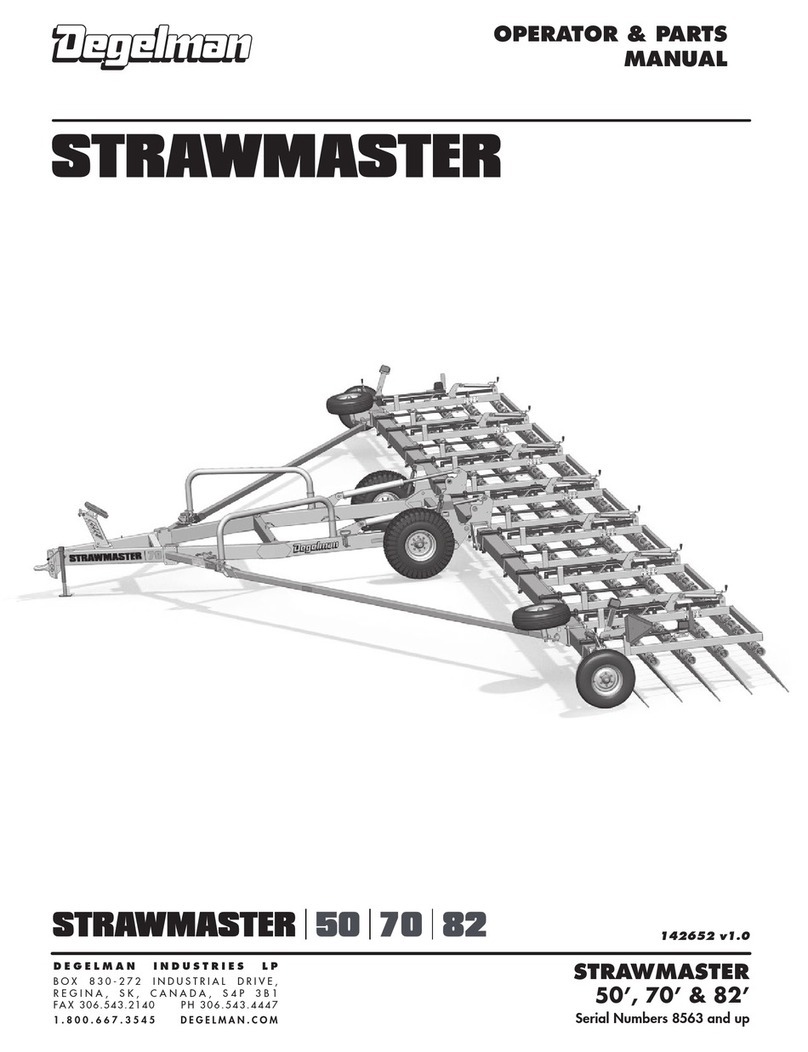

Degelman STRAWMASTER 7 Series User manual

Degelman

Degelman Tri-Plex Landroller 7634 Programming manual

Degelman

Degelman REV1500 Programming manual

Degelman

Degelman STRAWMASTER 700 Series User manual

Degelman

Degelman 9075 Programming manual

Degelman

Degelman Pro-Till 33 Programming manual

Degelman

Degelman Signature Series Programming manual

Degelman

Degelman Pro-till 26 User manual

Degelman

Degelman STRAWMASTER 50 Programming manual