SSRLS-3 / SSRLU-3

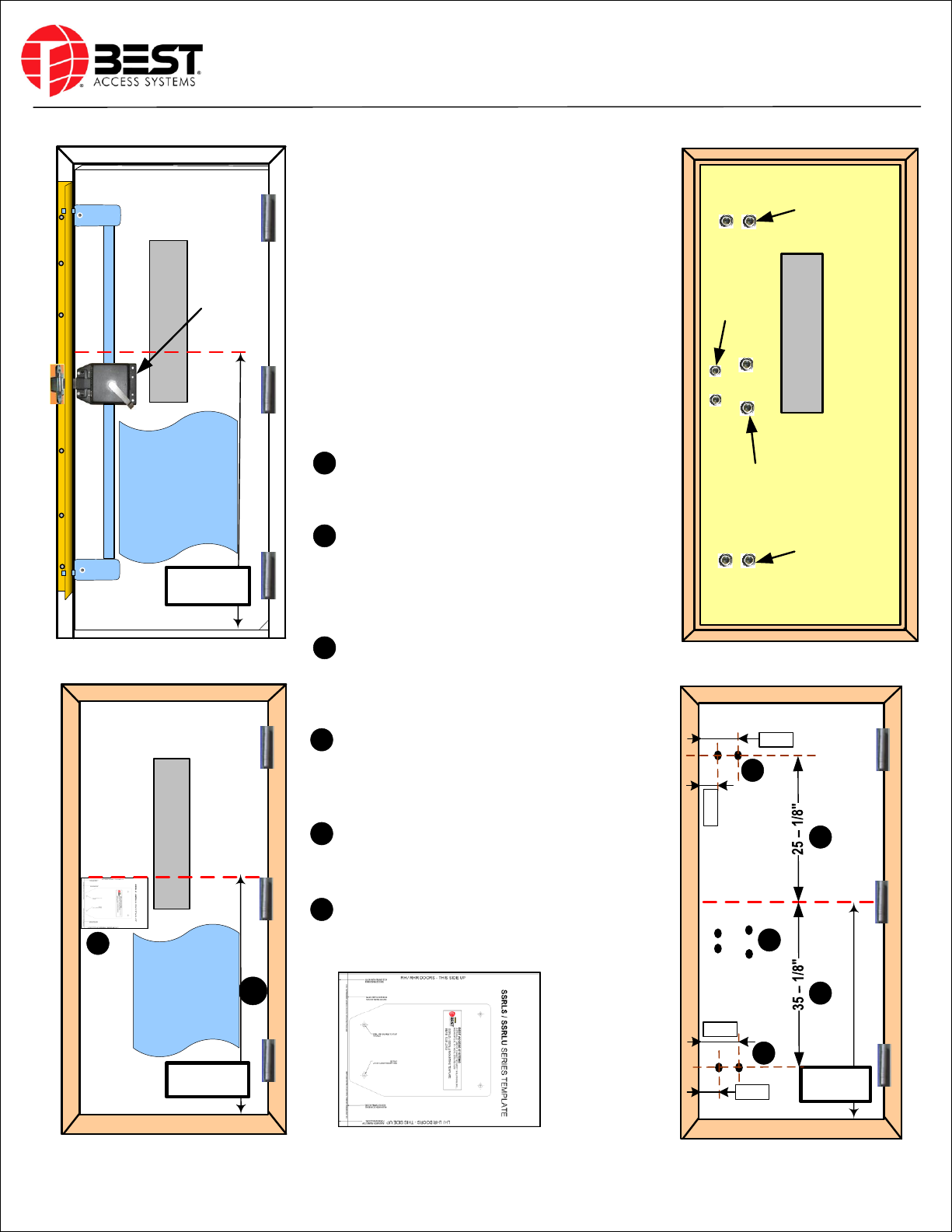

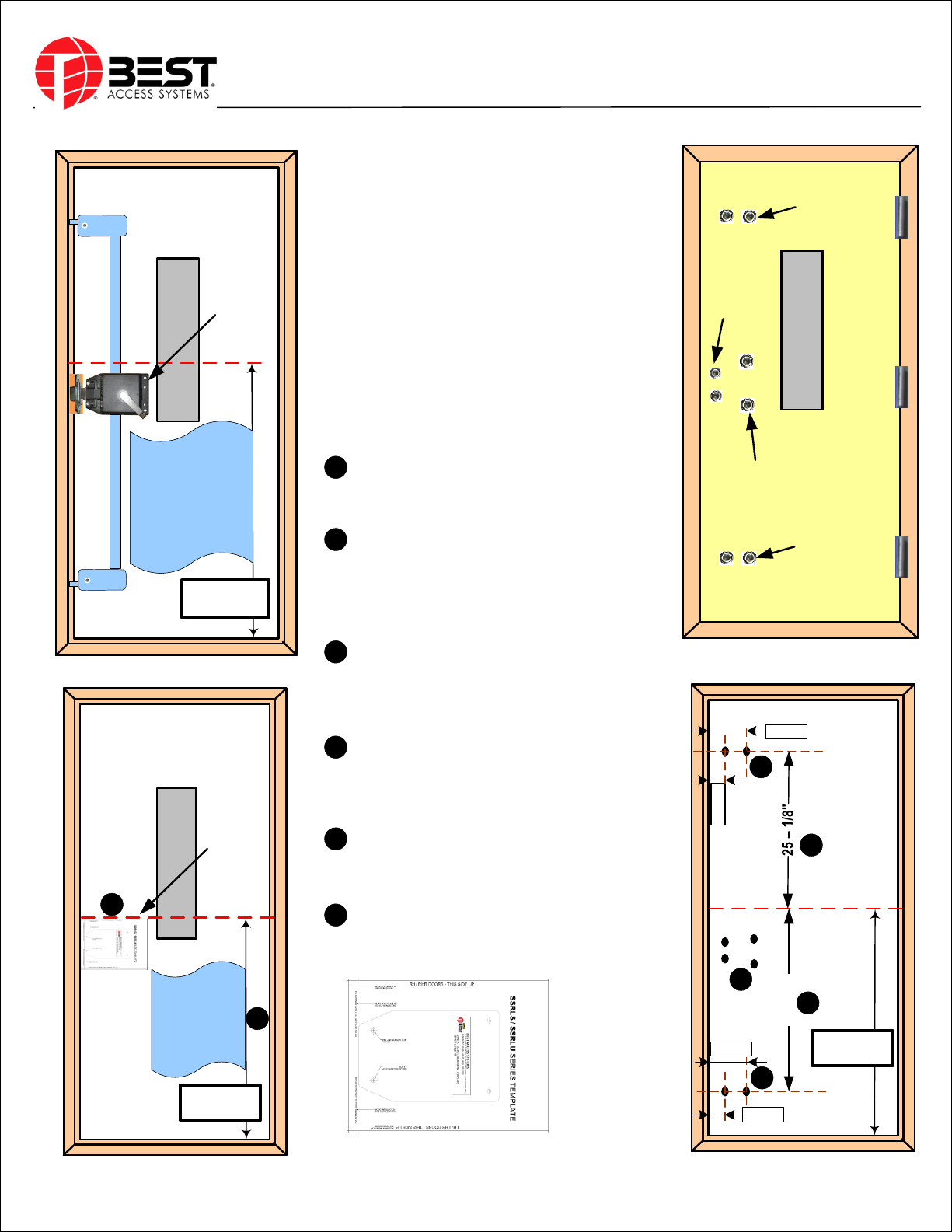

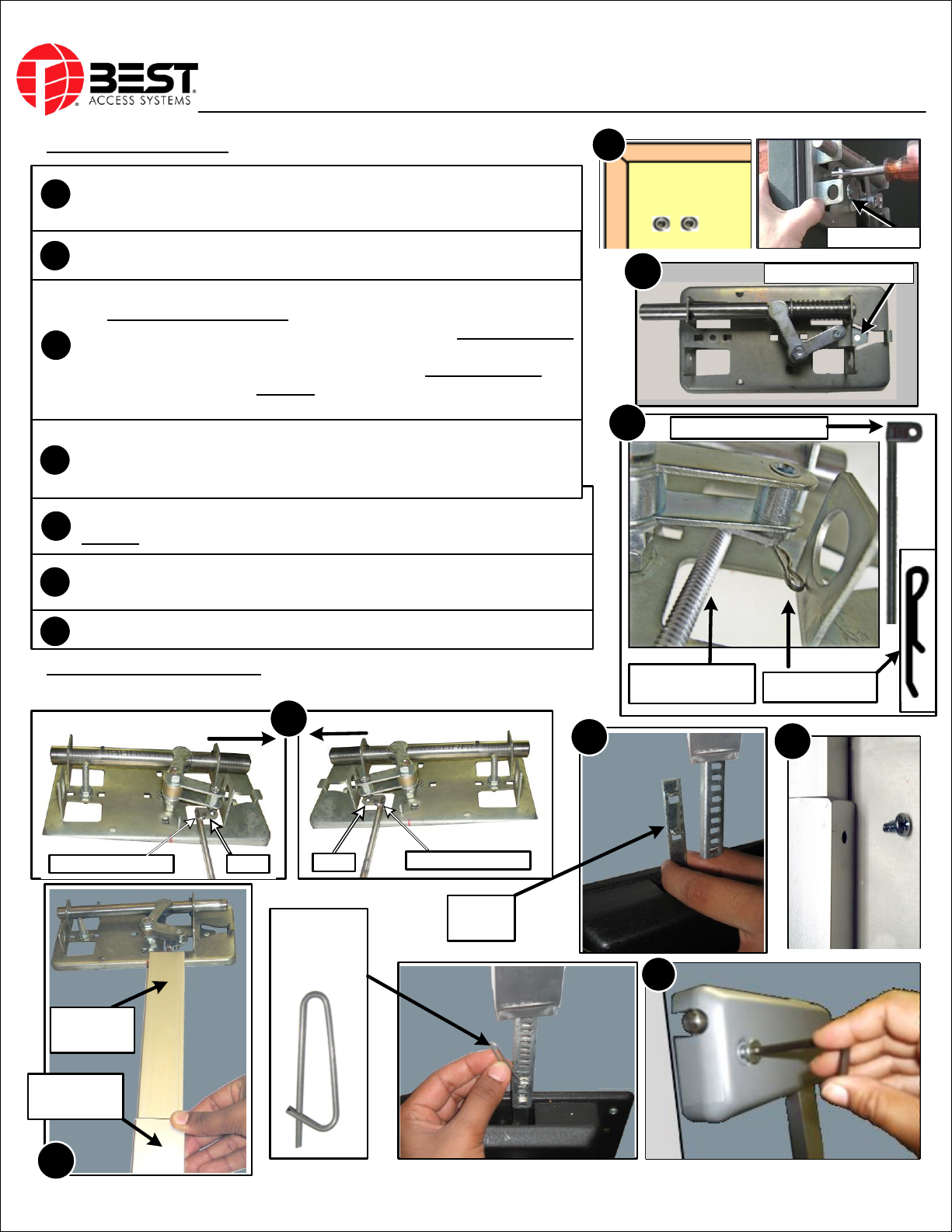

OUT SWING MODEL

Installation Instructions

INS SSRLS_SSRLU-3 v10.2.vsd Created: 5-14-2018 Revised: 5-14-2018 Page 2

44"

(suggested)

Select a height

which is

comfortable

for users

Select a height

which is

comfortable

for users

44"

(suggested)

Select a height

which is

comfortable

for users

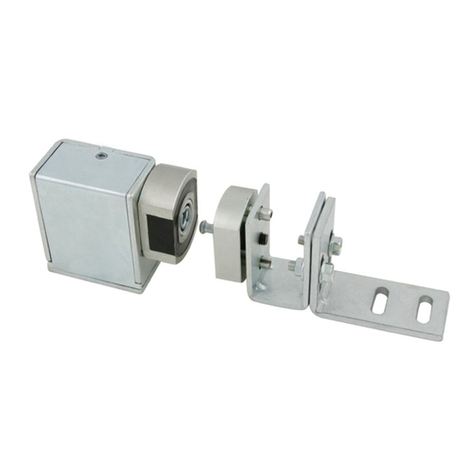

OUT-SWING MODEL

Upper Module

Lower

Module

Channel

Main Lock

Body

Bolt

Extended

Aluminium Angle

44"

(suggested)

Select a height

which is

comfortable

for users

OUT-SWING MODEL

Upper Module

Lower

Module

Channel

Main Lock

Body

Bolt

Extended

Aluminium Angle

The locksets are handed. When unlocked, the lever should

always point upward at a 45° angle.

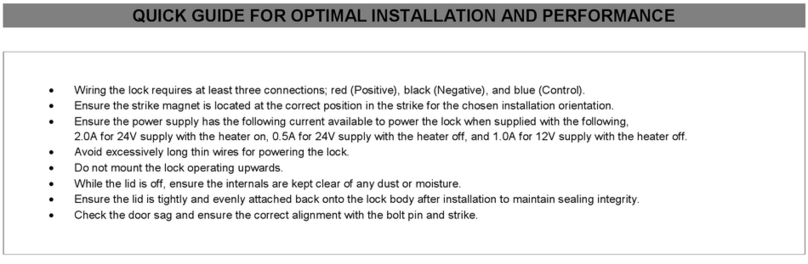

3- Point Horizontal Lock Installation

DOOR MARKING & DRILLING:

IMPORTANT: Make sure the door swings free and smooth before

you begin the installation. Remove all old locks, exit devices, any

slide bolts or other hardware & brackets. Make sure any exposed

holes left from previous hardware are completely covered after

installation.

Make any adjustments to make the door swing FREELY before

you start marking and installing.

1) Mark a horizontal reference line on the corridor side of the

door, at a height of 44" from the bottom of the door (not

floor). Extend the line to the hinge side of the door.

2) Line up the template with the horizontal reference line and

the door edge then tape it to the door. Please refer the

cardboard template to mark and drill the holes. Drill (4) 3/8"

through holes (TIP: Start with 1/8"). Make sure you drill

level.

3) Select a location for the height of the top module

(suggested at a height of 25-1/8" from the horizontal

reference line). Mark a horizontal line approx. 12" from the

lock edge of the door. Make sure the line is level.

4) Select a location for the height of the bottom module

(suggested at a height of 35-1/8" from the horizontal

reference line). Mark a horizontal line approx. 12" from the

lock edge of the door. Make sure the line is level.

5) Draw two vertical lines, one at a distance of 1-½” and

another at a distance of 4-½” from door edge on the top and

bottom horizontal module lines.

6) Punch the center point at vertical and horizontal lines

intersect as shown. Drill pilot holes first. Drill (2) top holes

and (2) bottom holes of 3/8" dia. through the door.

A

CORRIDOR SIDE OF THE DOOR

Stamped Washer

Stamped Washer &

Carriage Bolt Assly.

B

ROOM SIDE OF THE DOOR

44"

(suggested)

Cardboard

Template

OUT-SWING MODEL

Reference Line

A

44"

(suggested)

OUT-SWING MODEL

Reference Line

C

D

EC

D

E

E

1-½”

Stamped Washer

1-½”

4-½”

4-½”

E

SSRLS / SSRLU

Cardboard Template

CORRIDOR SIDE OF THE DOOR ROOM SIDE OF THE DOOR

B

Cardboard

Template

B

Select a height

which is

comfortable

for users

Carriage

Bolt &

Washer

Assly.