PSS®7000 Twin Pack Series

Self-contained breathing apparatus Instructions for Use

i

PSS®is a trademark of Dräger 3356970 (A3-D-P)

For Your Safety

The Dräger PSS®7000 Twin Pack Series of Self Contained Breathing

Apparatus (SCBA) incorporates a preset and sealed pressure reducer. Correct

operational condition is only valid when the pressure reducer is serviced and re-

sealed by Dräger.

●Use of this SCBA requires wearer training and observance of this

Instruction for Use.

●Use the SCBA only for the purpose specified in this Instruction for Use

under Description and Intended Use.

●Use and maintenance of the SCBA requires knowledge and compliance

with National Regulations, Laws, and Standards, governing the use of

respiratory protection apparatus in the country of use.

●Only trained competent personnel should inspect and service the SCBA at

regular intervals and a record kept of such inspections and service.

●Only trained and competent personnel should carry out the inspection and

charging of the associated compressed air cylinders.

●Dräger recommends that a Service Contract be arranged with the Dräger

Branch or Agent.

●Contact Dräger for details of Wearer Training, Service Training Courses

and Service Contracts.

●Use only original Dräger Spare Parts for service and maintenance.

●Use only original Dräger Test Equipment for service and maintenance.

●Notify Dräger if there is a component fault or failure.

Definitions of Alert Icons

Alert icons are used in this document to provide and highlight text that requires

a greater awareness by the user. A definition of the meaning of each icon is as

follows:

!

WARNING

!

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION

i

i

Indicates a potentially hazardous situation which, if not avoided, could

result in physical injury or damage to the product or environment. It

may also be used to alert against unsafe practices.

NOTICE

Indicates additional information on how to use the product.

Liability Statement

Responsibility for reliable function of the equipment transfers to the owner or

operator when the equipment is serviced, or repaired by untrained personnel,

or when used in a manner not conforming to its intended use.

Description

The Dräger PSS®7000 Twin Pack Series of SCBA incorporates a special

mounting bracket arrangement with locking mechanism, that is attached to the

backplate, providing a secure support for the range of Dräger Twin Cylinder

Packs.

The standard PSS®7000 height adjustable and articulating carrying system

provides greater performance, comfort and ease of use, resulting in reduced

wearer fatigue.

The backplate of the carrying system incorporates a sliding height adjustable

shoulder yoke that has three preset height settings. A flexible pivot joint, located

at the base of the backplate, is in line with the hip of the SCBA wearer. The pivot

joint moves in response to the twisting and bending of the wearer, improving the

weight distribution, the freedom of movement and increased manoeuvrability for

the wearer.

Refer to the specific Instructions for Use for the operation, control and testing of

the electronic monitoring unit, i.e. Bodyguard.

Intended Use

The Dräger PSS®7000 Twin Pack Series of SCBA, when used with approved

lung demand valve and associated face mask, and compressed air Dräger Twin

Cylinder Packs, provides the wearer with respiratory protection when working in

a contaminated, or oxygen deficient gaseous atmosphere.

Working duration of the SCBA is dependent on the capacity (volume) of the

selected Twin Cylinder Pack, and of course the breathing rate of wearer.

Use in potentially explosive atmospheres

The PSS®7000 Series is type tested as suitable for use in potentially explosive

atmospheres. Electronic sub-assemblies are ATEX certified.

All combinations are suitable for use in hazardous areas up to and including

zone 0 and zone 20.

Approvals

The European standards, guidelines, and directives according to which this

product is approved are specified in the declaration of conformity (see

declaration of conformity or www.draeger.com/product-certificates).

Technical Data

High Pressure Connection:

300bar

Standard G5/8 as per EN 144-2.

Whistle Warning Unit

Preset by Dräger to begin activation between 60bar to 50bar.

Compressed Air Cylinders

2 × 3.4L, 2 × 4.3L, 2 × 6L or 2 × 6.8L capacity cylinders (300bar) are available

in carbon-composite and full composite materials. Contact Dräger for details.

!

CAUTION

When working in a confined space using SCBA fitted with twin cylinder

configuration, it is essential to consider possible restriction to a wearer.

Preparation for Use

The following procedures must be performed before release of the apparatus

for operational use.

i

i

NOTICE

The pressure gauge face may be fitted with a thin flexible protective

covering. This covering must be removed before first use.

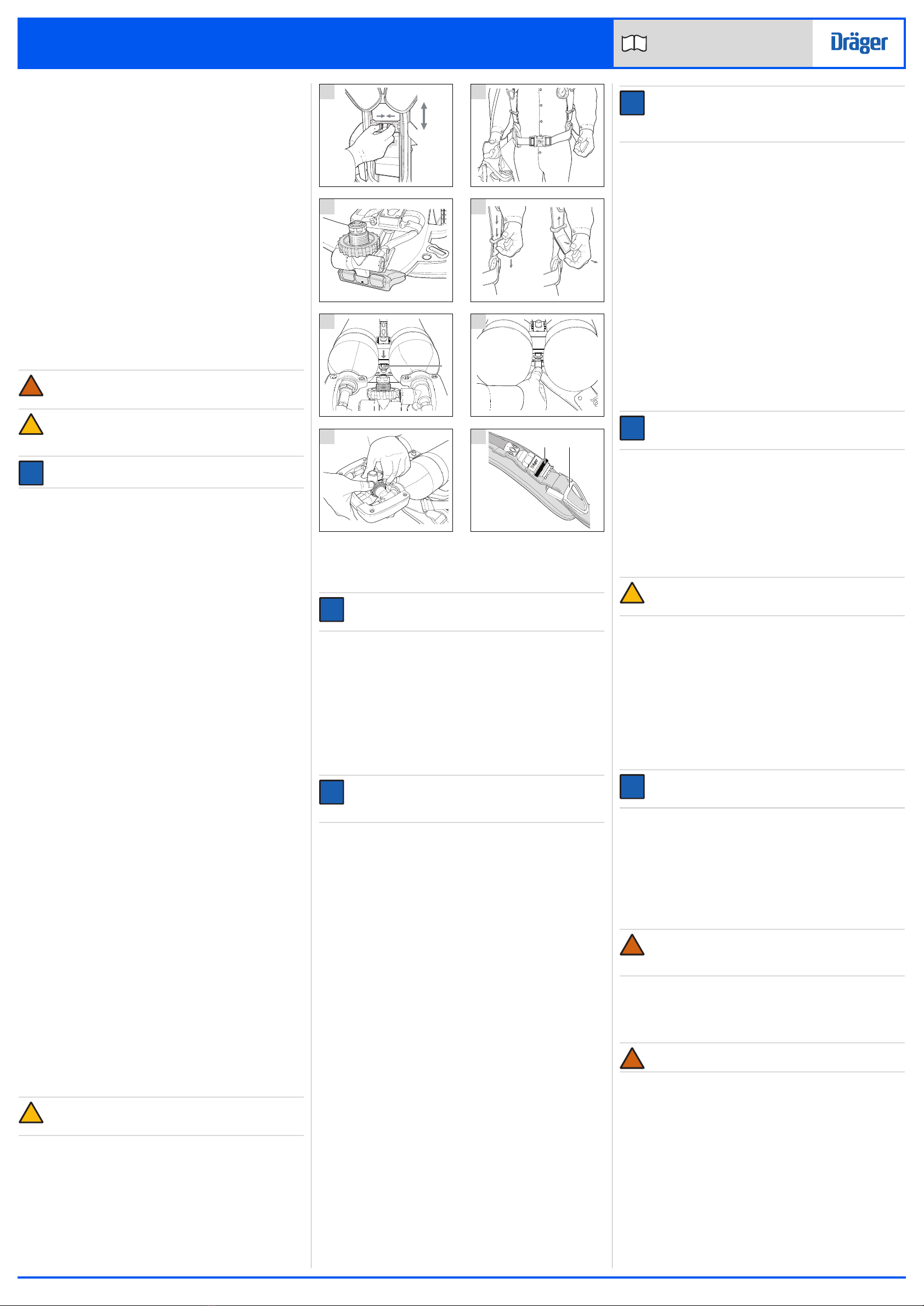

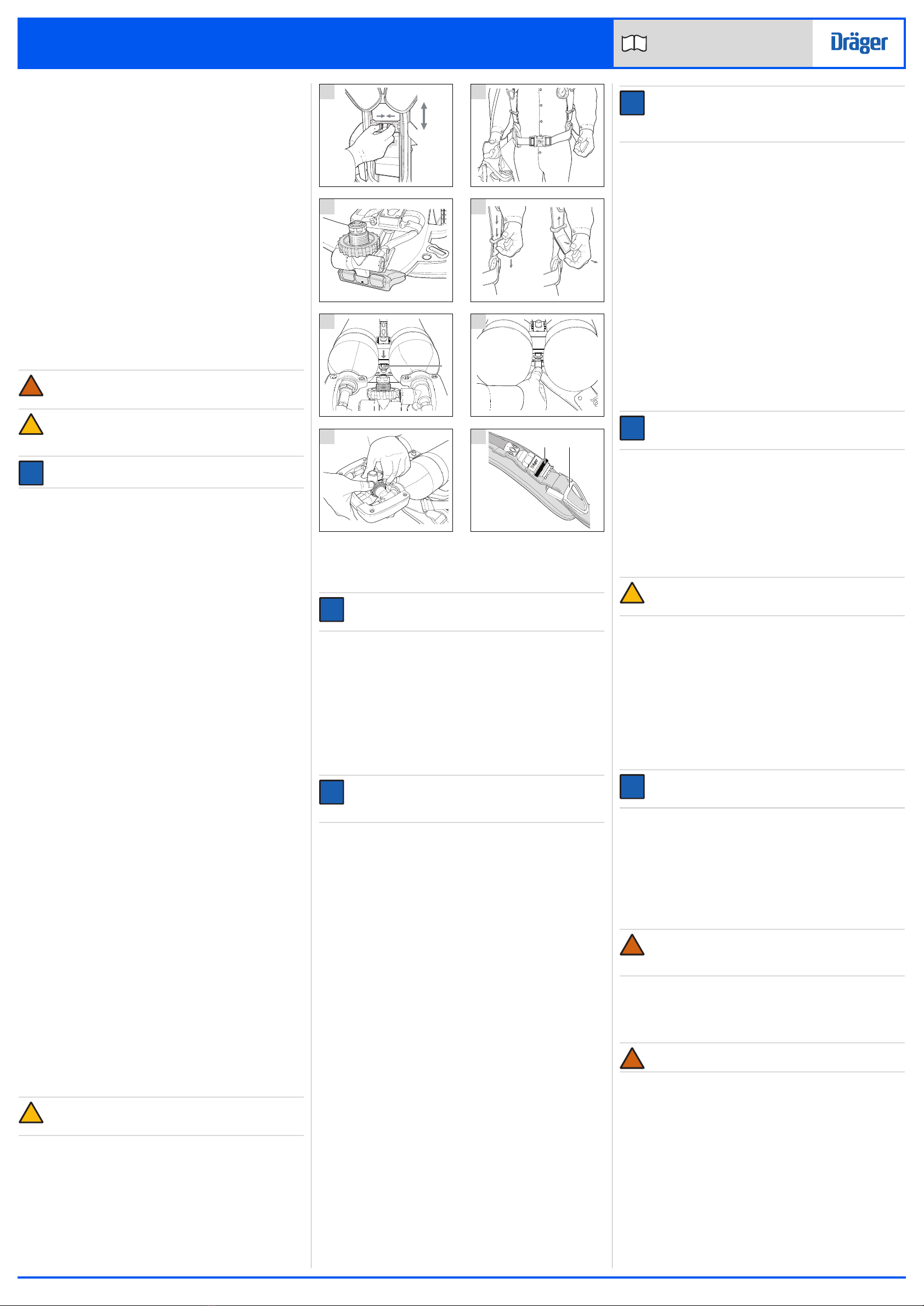

Height adjustment

The carrying system length can be adjusted, and set, at the shoulder yoke, to

suit the torso length of the wearer. Three settings, marked on the set, are

available, i.e. Short (S), Medium (M) and Long (L). To set the torso length, follow

these instructions.

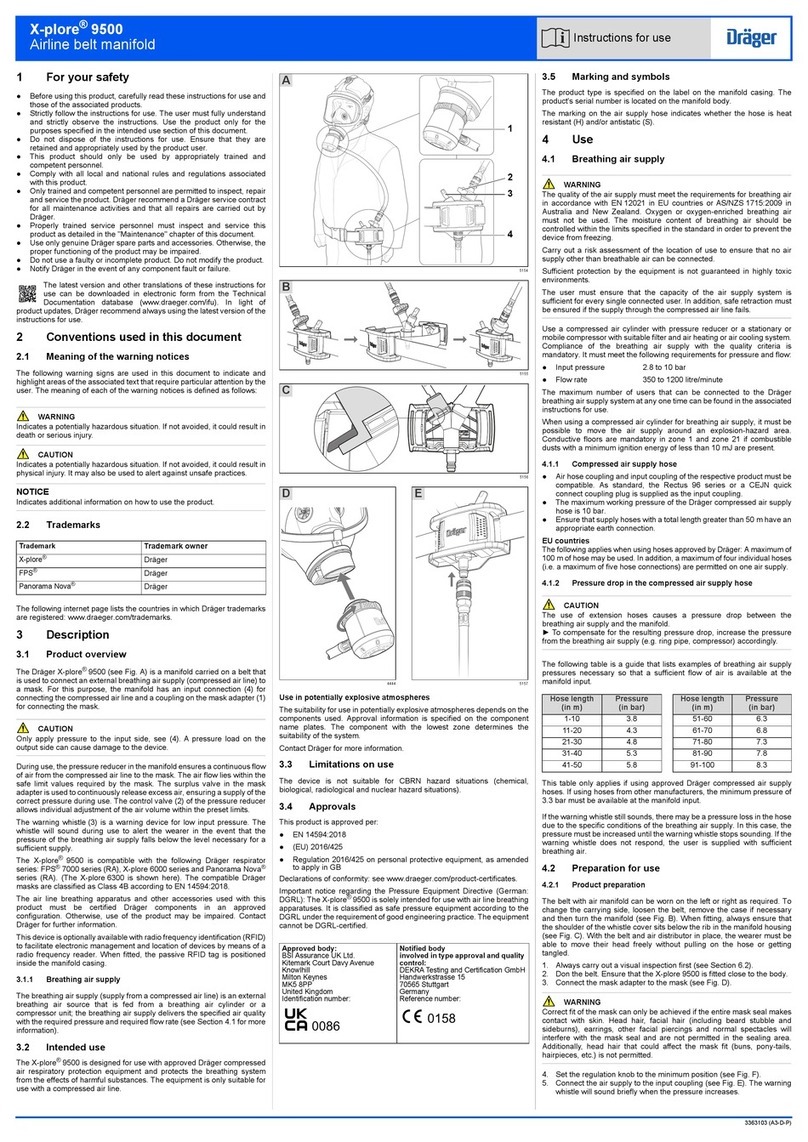

Refer to Fig 1.

i

i

●Lift the apparatus into the vertical position.

●Simultaneously press the two spring loaded buttons to unlock the shoulder

yoke. Slide the yoke in the required direction, then release the buttons.

Continue sliding the yoke until the buttons engage and lock the yoke in the

required position, i.e. S, M, or L.

NOTICE

When the set is being worn, and with the adjusting straps extended

(loose), adjustment of the yoke height may be performed by a support

person.

Fitting the Twin Cylinder Pack

●Inspect and check that the threads of the valve port, and the reducer hand

wheel, are not damaged. Check that the O Ring seal, of the high pressure

(HP) connector of the reducer, is in position and not damaged. Check that

the bore to the sintered filter, in the HP connector of the pressure reducer,

is clean and free from dirt and contamination.

●Lay down the carrying frame of the SCBA horizontally and locate the

pressure reducer to the start position as shown in Fig 2.

Refer to Fig 3.

●Lift the twin pack (horizontally) by the valve end handle, and dome end of

cylinder. Align the pack centrally over the carrying frame with the handle

towards the pressure reducer. Lower the twin pack to the SCBA and, with

the fingers of the hand at the handle end, lift the reducer through the inside

of the handle. At the same time locate the locating pin (1), valve end of the

pack into the guide at the bottom support and also locate the top locating

pin to the spring plate of the top support. Press and hold down the pack to

open the spring plate and then slide the twin pack towards the reducer until

an audible ‘Click’ is heard. This indicates that the top locating pin has

located in the top support. This completes the assembly of the twin pack to

the backplate.

●Check that the top and bottom locating pins of the twin pack are correctly

located and that the twin pack is securely attached to the SCBA.

Refer to Fig 4.

●Lift and twist the reducer assembly to align the hand wheel with the port of

the valve. Screw the hand wheel of the reducer (clockwise) to the port of

the valve until an initial restriction is felt. Continue turning the hand wheel,

using only the thumb and index finger, until a definite metal to metal contact

is achieved – Do Not use tools or over tighten.

Pre-Operational Checks

Connecting the LDV to the SCBA

●For breathing apparatus with a medium-pressure coupling for the lung

demand valve, disconnect and then reconnect the male coupling. To

connect, press the male coupling into the female coupling until an audible

click is heard. If there is any difficulty disconnecting or connecting, see the

troubleshooting information.

Refer also to the Instructions for Use provided with the Lung Demand Valve.

i

i

NOTICE

i

i

The following tests will verify the integrity of the assembly. These

instructions refer to an SCBA fitted with a mechanical pressure gauge.

Refer to the appropriate Instructions for Use provided for variants, e.g.

Bodyguard.

High Pressure (HP) Leak and Whistle Warning Test

●Positive Pressure type LDVs only (type A, AE or ESA) – Press the reset

button of the LDV to ensure that the positive pressure facility is ‘Off’.

●Slowly and fully ‘open’ the cylinder valve by rotating the hand wheel of the

valve (anticlockwise) until a resistance is felt. During pressurisation of the

system, a momentary sounding of the whistle warning unit will occur. Check

the pressure reading of the cylinder contents (pressure) gauge.

●‘Close’ the cylinder valve by rotating the hand wheel of the valve clockwise

until a resistance is felt. When fully closed, immediately check the pressure

reading of the contents gauge.

●After one minute, again observe the contents gauge and then ‘reopen’ the

cylinder valve – the pointer of the gauge must not show an increase in

pressure reading of more than 10bar (10bar is acceptable) – i.e. one radial

marking on the gauge face.

●Continue to the Whistle Warning Unit Check.

●While holding the contents gauge in one hand, slowly ‘close’ the cylinder

valve fully until a resistance is felt.

○A, AE and ESA type LDVs – Cover the outlet port of the LDV with the

palm of the hand. Press the centre of the rubber cover to switch ‘On’

the positive pressure. Slowly vent the system by carefully lifting the

palm of the hand from the outlet of the LDV to maintain a slow decrease

in pressure.

○N type LDVs – Slowly vent system by carefully pressing the centre of

rubber cover.

●Observe the contents gauge as the pressure decreases. The whistle should

begin to operate and sound between the following pressures: 60bar to

50bar.

NOTICE

!

Should the whistle not sound at the preset pressure, return the SCBA

to Dräger Service

●When the system is exhausted of air, activate the reset feature of the LDV

(A, AE and ESA type LDVs) to ensure that the positive pressure facility is

‘Off’.

Connecting LDV to the face mask

●Fully extend (open) the straps of the head harness of the face mask. Refer

also to the Instructions for Use provided with the face mask.

Use

Putting on the SCBA

CAUTION

i

i

This device may only be worn by expert personnel who have been

thoroughly trained in the correct use of the device.

●If necessary, adjust and set the yoke to the required Wearer Height.

●Loosen the shoulder straps and waist strap and hang the unit over your

body. Take the weight of the system on your shoulders by pulling the

shoulder straps. Do Not tighten. Check that both the shoulder pads are not

twisted.

●Close the waist strap buckle. Pull the ends of the waist strap forwards

(Fig 5), until the strap padding fits securely and comfortably over your hips.

Tuck the strap ends between your body and the hip pads.

●Pull down the shoulder straps until the device rests securely and

comfortably on your hips. Do Not over-tighten. Pull the strap retainers down

to secure the strap ends (Fig 6).

●Fully loosen the head straps of the face mask. Place the neck strap over

the back of the neck.

●Activate the reset feature of the LDV to ensure that the positive pressure

facility is switched Off.

NOTICE

Refer to the appropriate Instruction for Use provided with any variants,

e.g. Bodyguard.

●Open (anticlockwise) the cylinder valve slowly but fully to pressurise

system. Check the content gauge.

Putting on the face mask

Refer to the Instructions for Use provided with the face mask.

!

In Use

●Regularly take a reading of the content gauge to check the pressure

remaining in the twin cylinder pack.

WARNING

!

Leave the hazard area by the shortest route once the whistle warning

unit sounds. It is recommended that the wearer should be in a safe area

before the whistle begins to sound.

●Once established in a safe area Check In with the BA control personnel.

After Use

Removal of the apparatus

WARNING

Do Not remove the apparatus until in a safe area, clear of hazard.

●Lift and pull forward on each of the bottom buckles of the straps of the face

mask – extending the straps. When the seal to the face is broken, activate

the reset feature of the LDV (PP only) to ensure that the positive pressure

facility is Off. Continue to remove the face mask. Breathe normally. Leave

the face mask hanging around the neck from the neck strap.

●Close the cylinder valve (clockwise) until a resistance is felt, i.e. the valve

is fully closed. Depress the centre of the rubber cover of the LDV to exhaust

the air from the system. Activate the reset feature of the LDV (A, AE and

ESA types only) to switch Off the positive pressure.

●Open the waist belt buckle to release the waist belt. Lift the shoulder strap

ends to release the strap retainers (Fig 6) and then lift the shoulder strap

buckles to loosen the straps.

●Remove the neck strap of the face mask from around the back of the neck

and then remove the SCBA from the shoulders. Place the SCBA down

carefully at a safe location. Do Not drop the SCBA.