Silhouette/Series E & V by Draper

Page 2 of 5

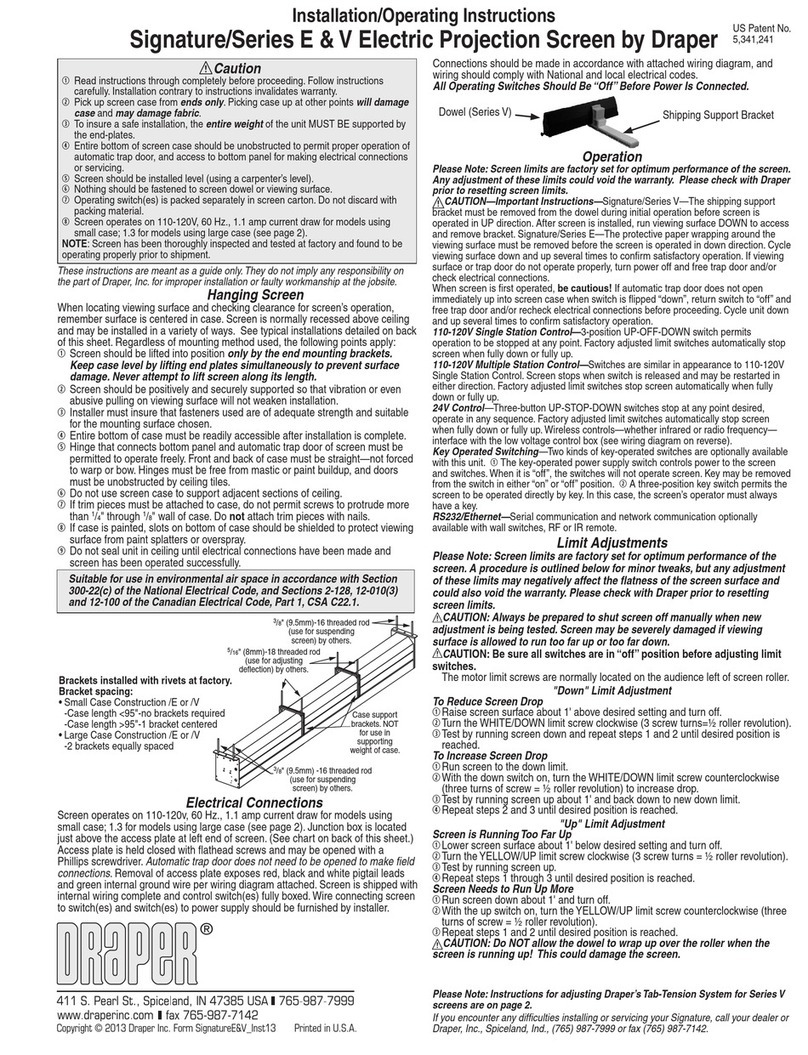

Removing Case Fascia

Caution: When removing or reattaching fascia, do not handle fascia

by unpainted ends.

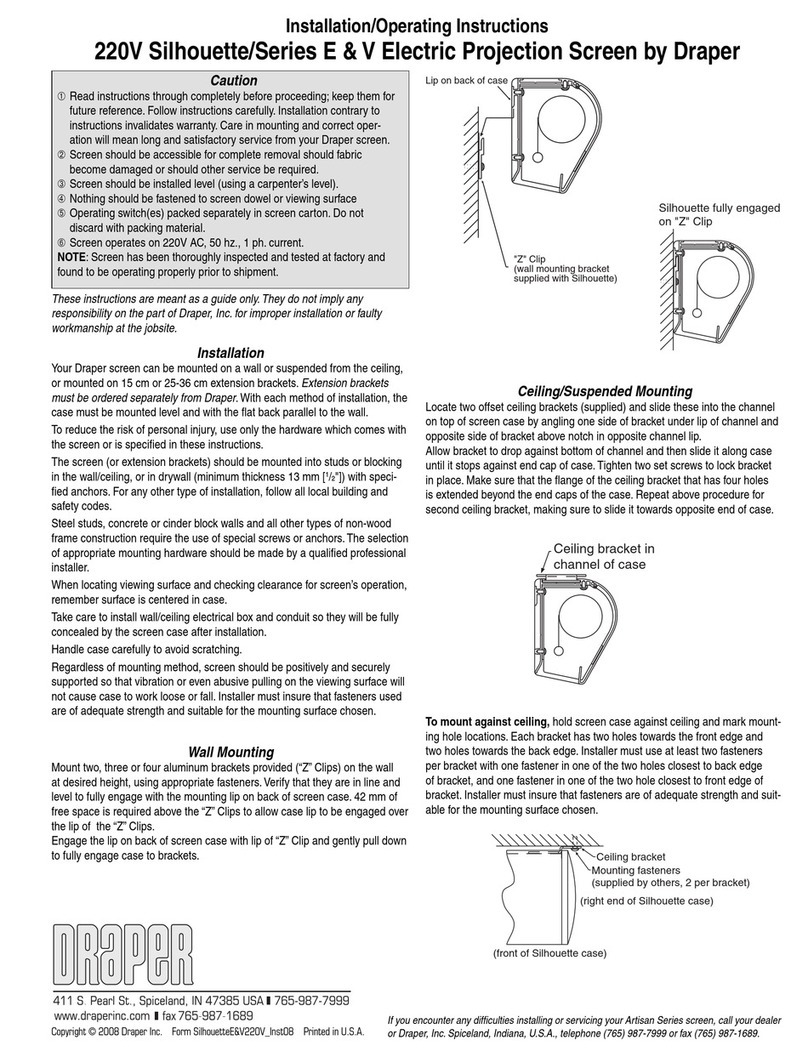

Case fascia is removable to access roller assembly. To remove fascia, depress

outward the spring lip located inside lower front corner of screen case and

pull lower corner of fascia outward. Repeat this at right end of case. Support

fascia from center and rotate lower front edge upward approximately 40° to

disengage the Roll-Lok hinge at the top front of screen case. Fascia can now

be completely removed from case.

To install fascia, generally reverse instructions above making sure the Roll-

Lok hinge is completely engaged before rotating fascia down towards the

closed position. Depress spring clips outward, push lower corners of fascia

inward until lips of spring clips hook behind fascia.

Please Note: Be sure the clips are completely up against the ends of the

fascia.

Electrical Connections

Screen operates on 110-120V, 60 Hz., 1.1 amp current draw. Duty Cycle: ON

28 seconds/OFF 4 minutes.

Junction box is located at left end of screen. It is accessible through front

of screen case after fascia is removed (see instructions above for removing

fascia).

Electrical supply wires can enter through the back or top of case. For top

entry, remove plug from top conduit hole and snap plug into hole on back side

of case.

Junction box contains red, black, and white pigtail leads and green internal

ground wire per wiring diagram attached.

If optional low voltage control or video interface control is specified, please

refer to wiring diagrams on pages 4-5.

Wall or ceiling electrical box should be installed so as to be fully concealed by

screen case after installation.

Screen is shipped with internal wiring complete and control switch(es) fully

boxed. Wire to connect screen to switch(es) and switch(es) to power supply

should be furnished by installer. Please Note: Screen must be installed in

accordance with the requirements of the Local Building Codes, the Cana-

dian Electrical Code (CEC), CAN/CSA C22.1 and the National Electric Code

(NEC), NFPA 70. An appropriate disconnect device shall be provided as part

of the building installation.

All operating switches should be “off” before power is connected.

Plug-in power cord option available on units with built-in low voltage controller.

For Reconfiguration/Conversion of Non-detachable Power Cord to

Field Wiring for Models SLE-28, SLE-30, SLV-28 and SLV-30 Only:

1Disconnect cord plug from outlet.

2Remove junction box cover.

3Disconnect wire nut connections from black, white and green wires.

4Remove power cord and strain relief.

5Connect the black from motor to "hot" supply wire.

6Connect white wire from motor to "neutral" supply wire.

7Connect green/yellow ground to "ground" supply wire.

8Replace junction box cover.

Operation

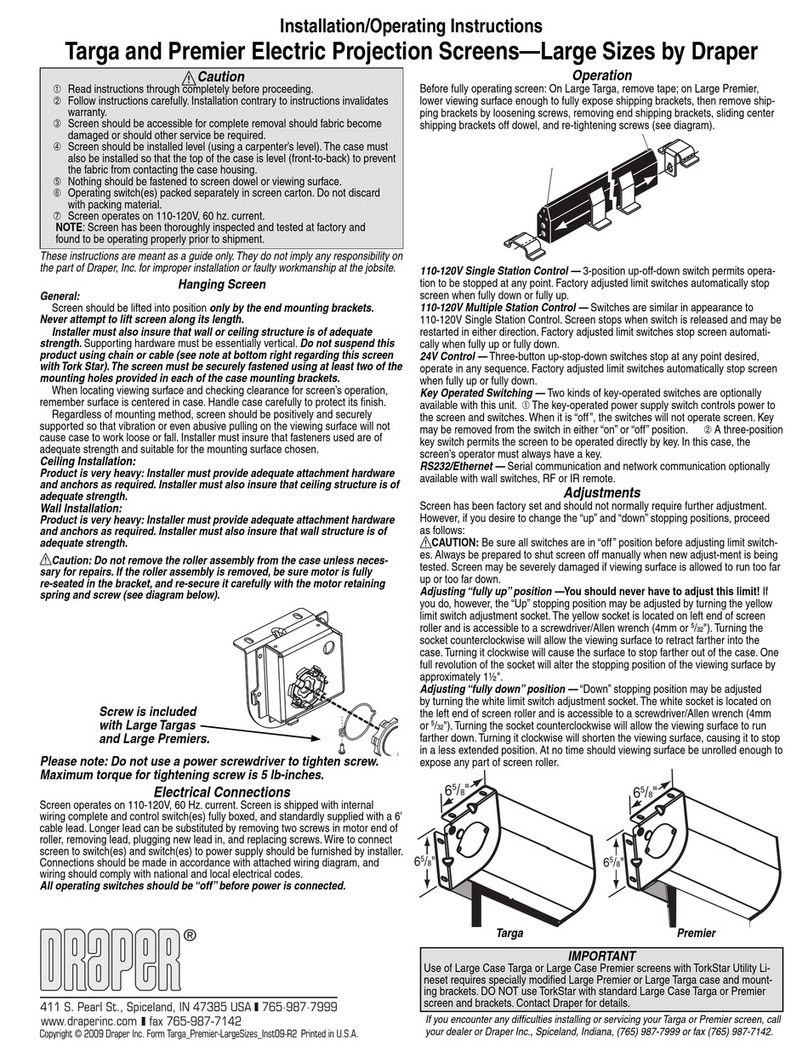

Before operating screen, remove any shipping brackets or tape securing fab-

ric and dowel to the roller. If viewing surface hangs out of case 8" or 9", tape

has probably been broken by rough handling in shipment, allowing surface to

“unwrap” one turn off the roller. Manually wrap fabric back around the roller

without turning the roller itself.

When screen is first operated, be cautious! Cycle unit down and up several

times to confirm satisfactory operation.

110-120V SINGLE STATION CONTROL—3-position UP-OFF-DOWN switch

permits operation to be stopped at any point. Factory adjusted limit switches

automatically stop screen when fully down or fully up.

110-120V MULTIPLE STATION CONTROL—Switches are similar in ap-

pearance to 110-120V Single Station Control. Screen stops when switch

is released and may be restarted in either direction. Factory adjusted limit

switches stop screen automatically when fully down or fully up.

24V MULTIPLE STATION CONTROL—Three-button UP-STOP-DOWN

switches stop at any point desired, operate in any sequence. Factory adjusted

limit switches automatically stop screen when fully down or fully up.

110-120V & 12V VIDEO INTERFACE CONTROL—Allows screen to be con-

trolled by a trigger signal—when the signal comes on, the screen descends

automatically. Two versions: Model VIC115 integrates screen operation with

a DRAPER video projector lift or a video projector or tuner with a 110-120V

switch outlet. Model VIC12 interfaces with a 12V switch outlet. Both available

with an override switch (VIC–OS), permitting independent operation. VIC–OS

not available with factory installed VIC115 & VIC12.

KEY OPERATED SWITCHING—Two kinds of key-operated switches are

optionally available with this unit.

1The key-operated power supply switch controls power to the screen and

switches. When it is “off”, the switches will not operate screen.

Key may be removed from the switch in either “on” or “off” position.

2A three-position key switch permits the screen to be operated directly by

key. In this case, the screen’s operator must always have a key.

RS232/ETHERNET—Serial communication and network communication

optionally available with wall switches, RF or IR remote.

PLUG & PLAY

TM

—Provided with handheld IR remote control transmitter and

10' (3m) cord. No wiring necessary except to connect to RS232. Screen is

equipped with a handheld remote or 3-position operating switch (see below).

Three positions (up-off-down) permit operation to be stopped at any point.

Factory adjusted limit switches automatically stop screen when fully down or

fully up.

.draperinc.com (765) 987-7999

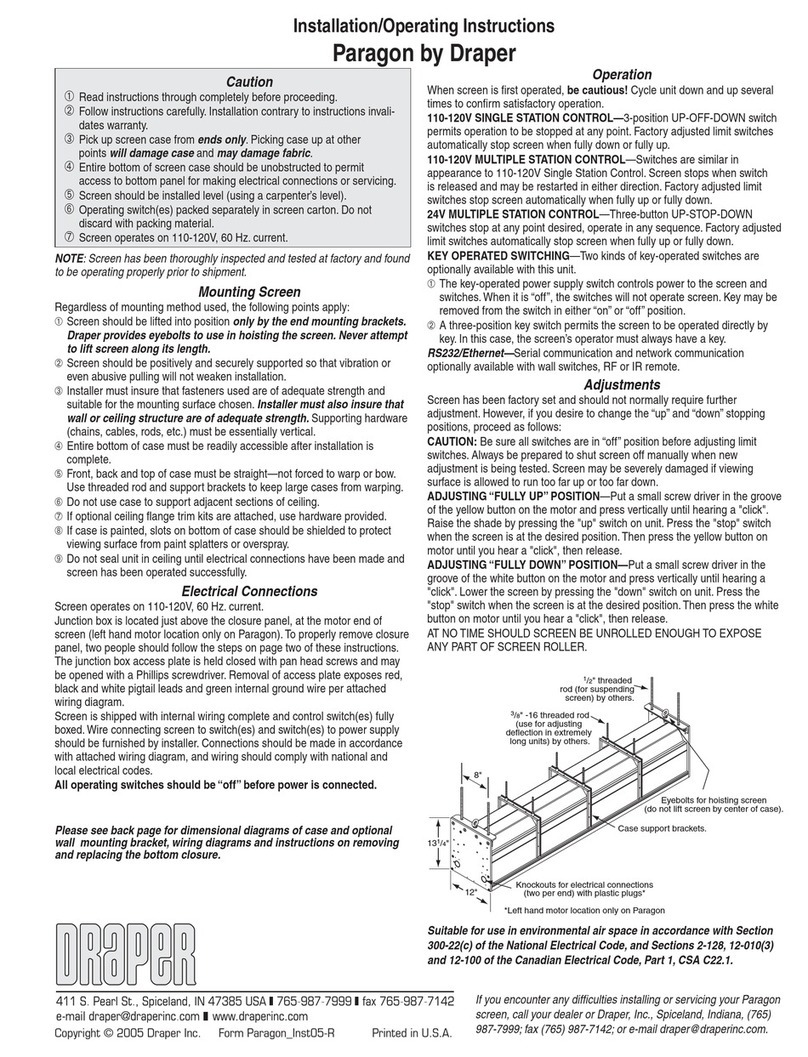

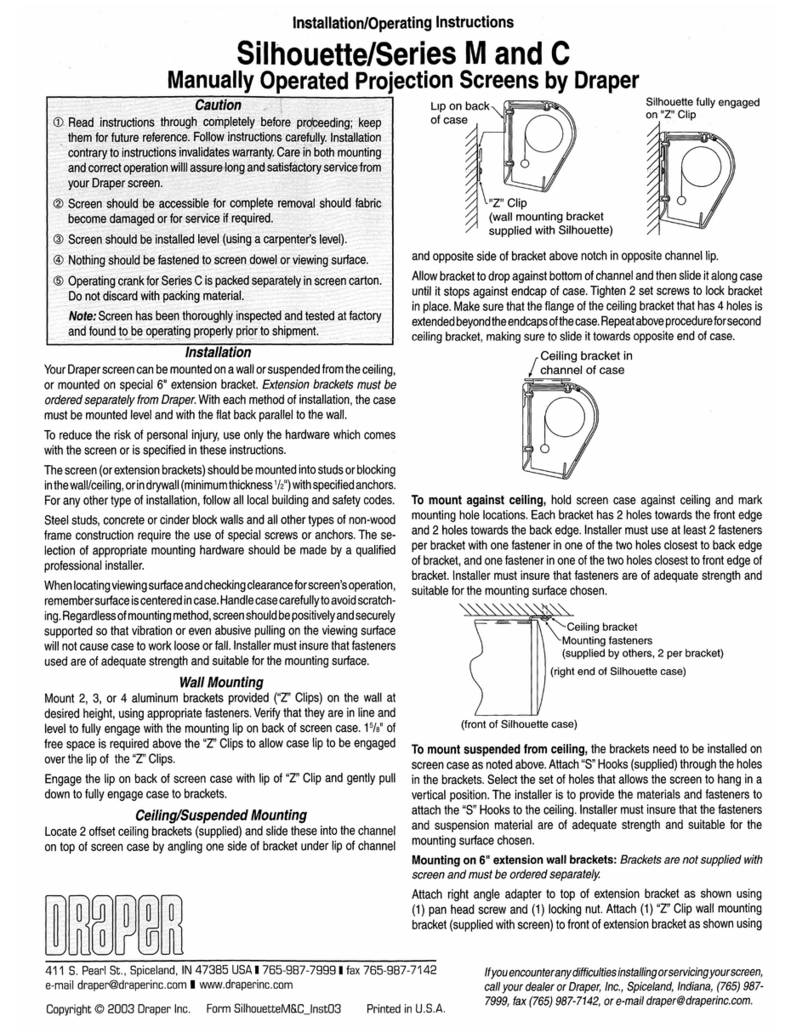

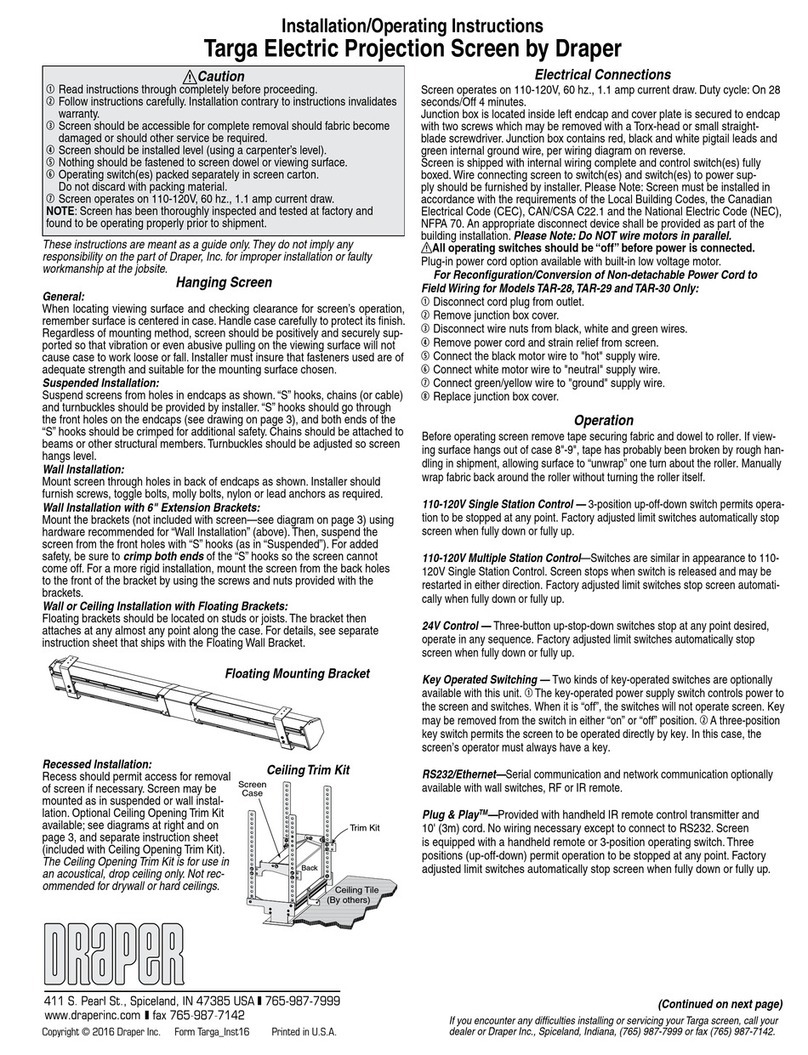

Extension Wall Brackets

6" or 10"-14" Extension Wall Brackets are needed to mount Silhouette

extended from wall. Wall Brackets are not supplied with screen and must be

ordered separately. Specify “Silhouette Extension Wall Brackets”.

1Mount the Wall Brackets to the wall, making sure they are level and verti-

cally plumb. Installer must insure fasteners (not included) are of adequate

strength and suitable for chosen mounting surface.

2Attach hanging bracket to wall bracket as shown.

3Attach (1) “Z” Clip and (1) Support Plate (supplied with screen) to hanging

bracket as shown.

4Engage the lip on back of screen case with lip of “Z” Clip and gently pull

down to fully engage case to brackets.

5Install hook bracket as shown making sure the two tabs of this bracket

hook over the case extrusion.

6Install #10-24 hex head screw through hook bracket, hanging bracket, and

support plate as shown.

Hook

Bracket

CB ¼"-20 x 1¾" Z Keg,

Flat Washer,

¼"-20 Nylock Nut

#10-24 x

7

/

8

"

Phillips Pan Head

Screw, Nylock Nut

#10-24 x ½"

Hex Head Screw

Z Clip

Wall

Bracket

Support

Plate

Hanging

Bracket

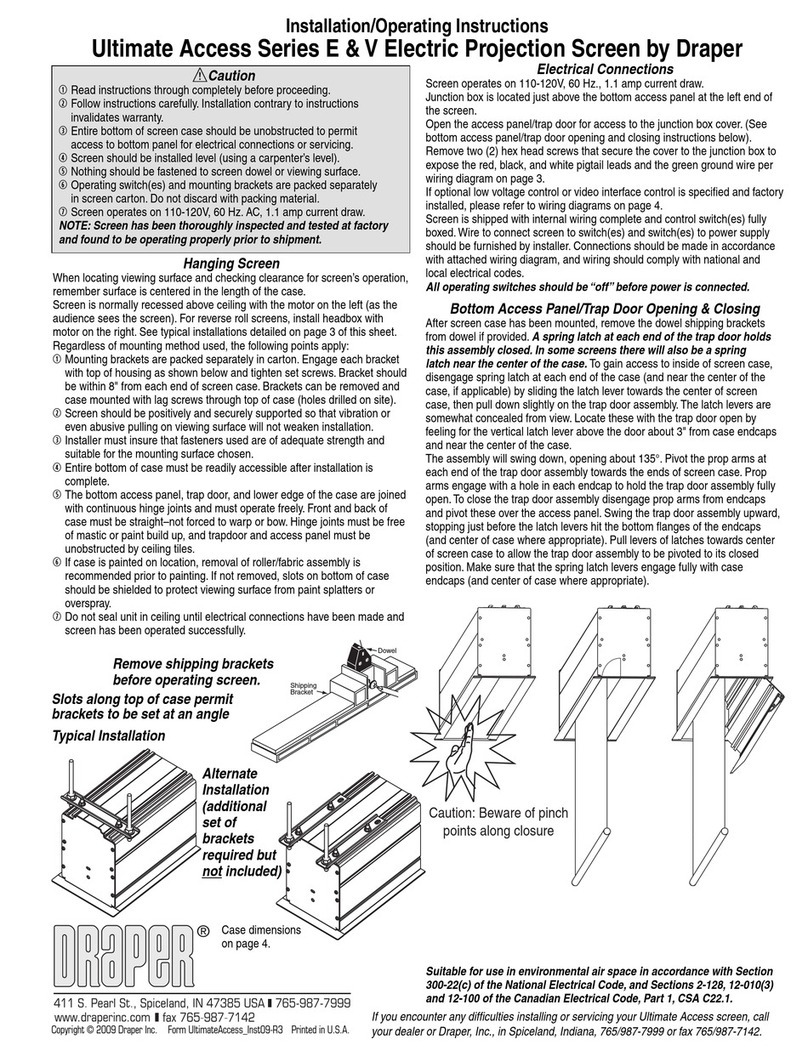

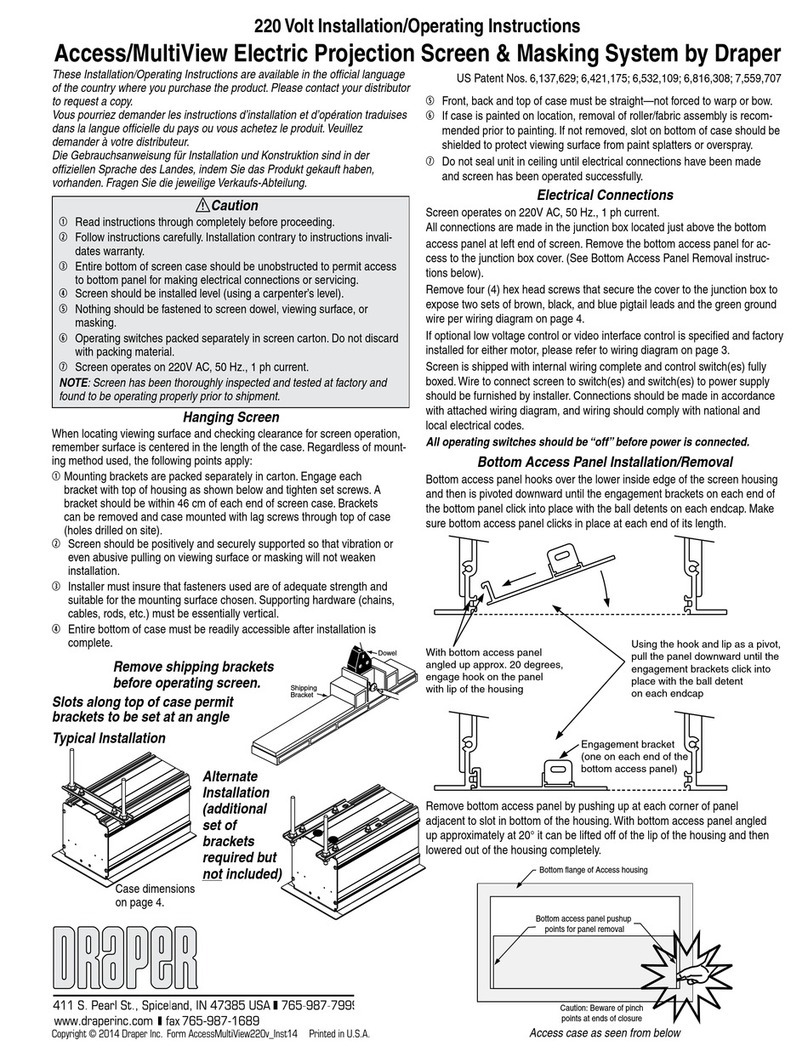

Caution: Do not remove the roller assembly from the case unless neces-

sary for repairs. If the roller assembly is removed, be sure motor is fully re-

seated in the bracket. If mounting style incorporates a retaining spring (left

below), be sure the retaining spring is reinstalled.