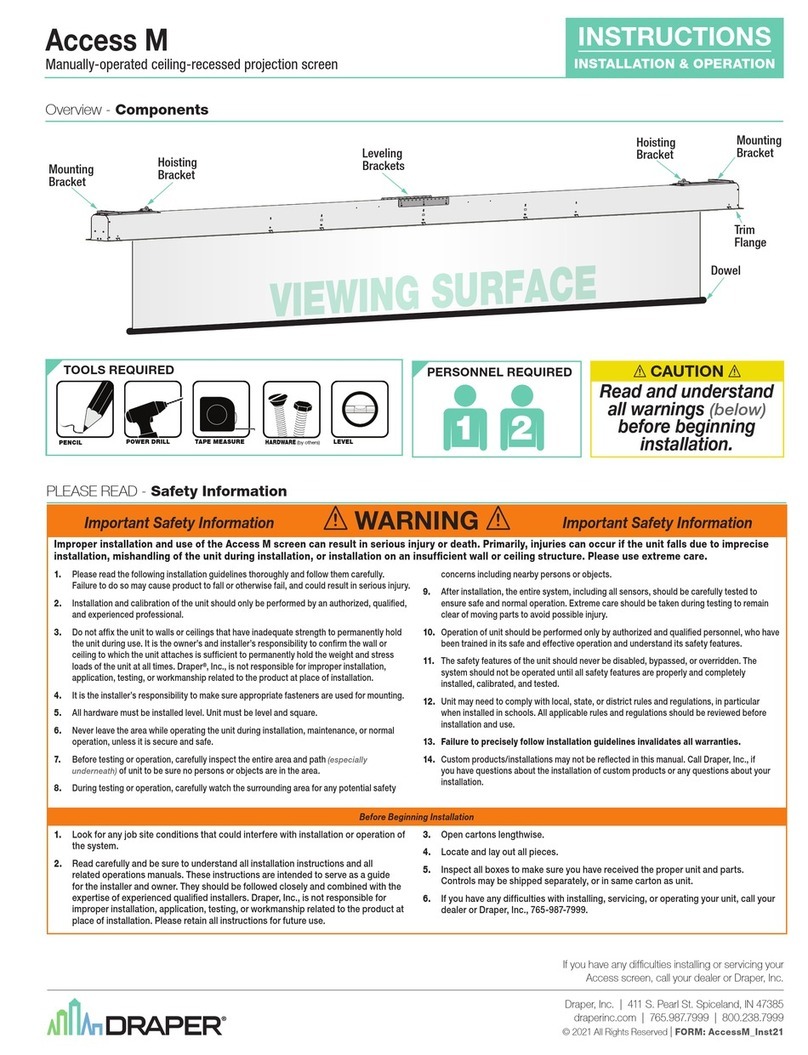

Locking screw

Wall bracket*

Angle adapter*

Extension

bracket

*Supplied with screen

Silhouette/Series E & V by Draper Page 2 of 4

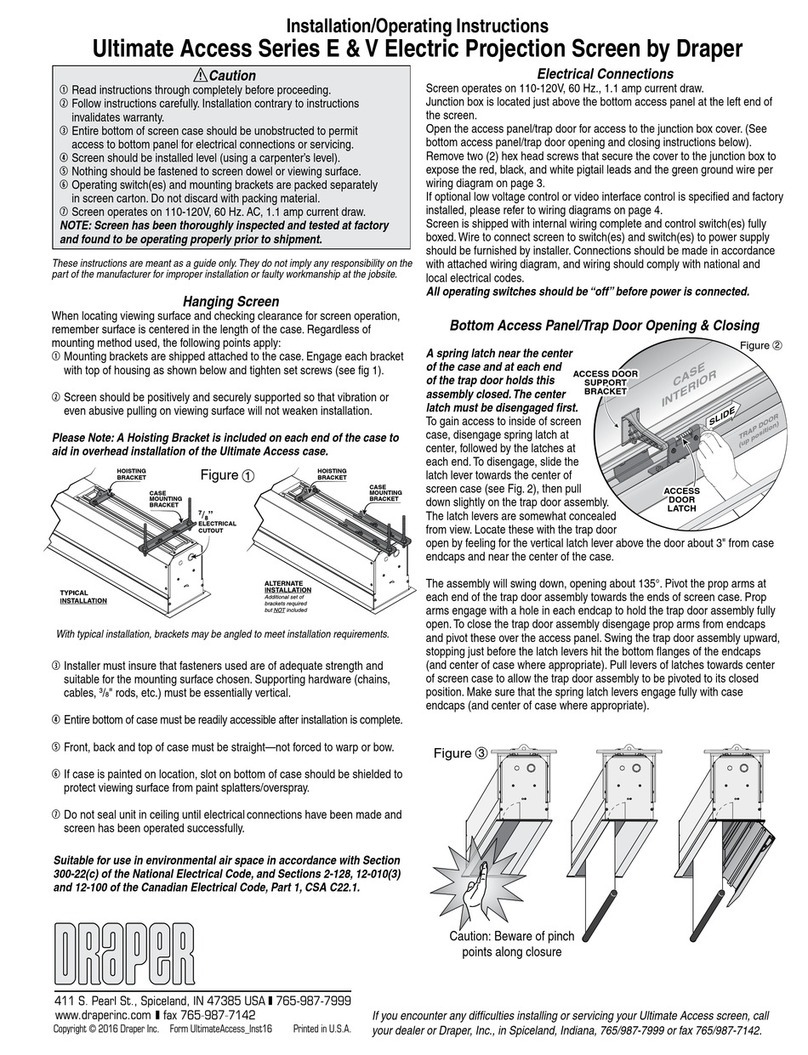

Removing Case Fascia

Case fascia is removable to access roller assembly. To remove fascia,

depress outward the spring lip located inside lower front corner of screen

case and pull lower corner of fascia outward. Repeat this at right end of

case. Support fascia from center and rotate lower front edge upward

approximately 40° to disengage the Roll-Lok hinge at the top front of

screen case. Fascia can now be completely removed from case.

To install fascia, generally reverse instructions above making sure the Roll-

Lok hinge is completely engaged before rotating fascia down towards the

closed position. Depress spring clips outward, push lower corners of fascia

inward until lips of spring clips hook behind fascia.

Electrical Connections

Screen operates on 110-120v, 60 Hz. current.

Junction box is located at left end of screen. It is accessible through front of

screen case after fascia is removed. (See instructions above for removing

fascia.)

Electrical supply wires can enter through the back or top of case. For top

entry, remove plug from top conduit hole and snap plug into hole on back

side of case.

Junction box contains red, black, and white pigtail leads and green internal

ground wire per wiring diagram attached.

If optional low voltage control or video interface control is specified and

factory installed, please refer to wiring diagram on page 3.

Wall or ceiling electrical box should be installed so as to be fully concealed

by screen case after installation.

Screen is shipped with internal wiring complete and control switch(es) fully

boxed. Wire to connect screen to switch(es) and switch(es) to power supply

should be furnished by installer. Connections should be made in accor-

dance with attached wiring diagram, and wiring should comply with national

and local electrical codes.

All operating switches should be “off” before power is connected.

Operation

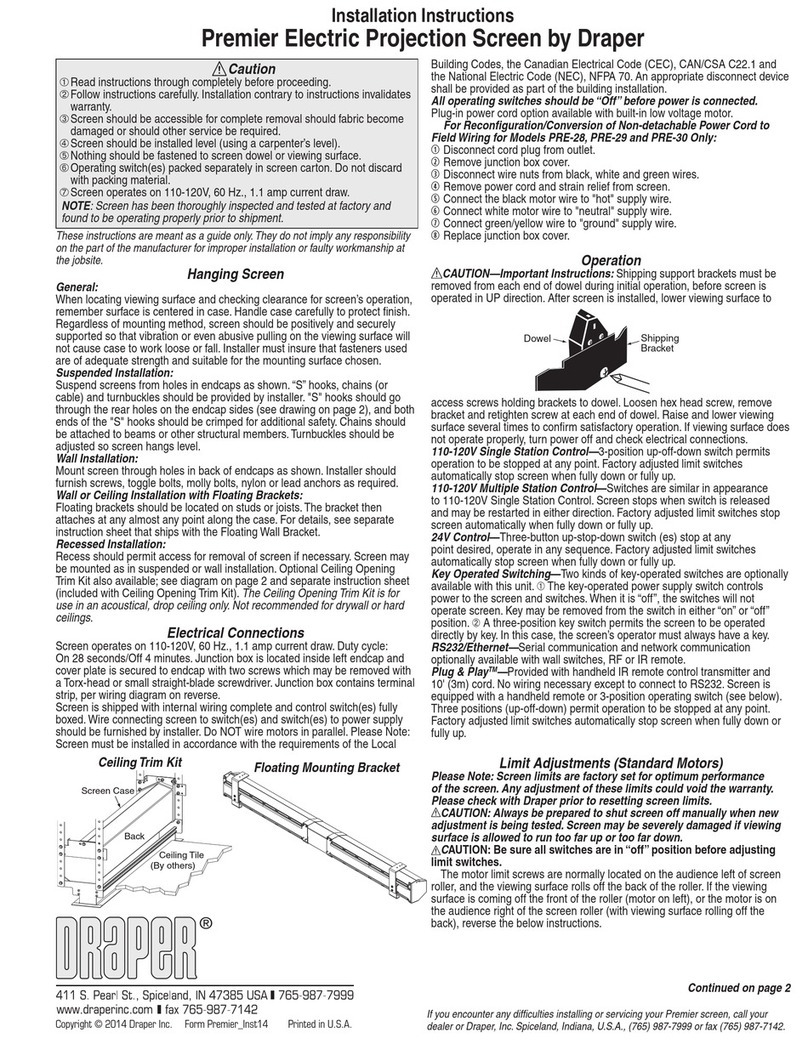

Before operating screen, remove any shipping brackets or tape securing

fabric and dowel to the roller. If viewing surface hangs out of case 8" or 9",

tape has probable been broken by rough handling in shipment, allowing

surface to “unwrap” one turn off the roller. Manually wrap fabric back around

the roller without turning the roller itself.

When screen is first operated, be cautious! Cycle unit down and up several

times to confirm satisfactory operation.

110-120v SINGLE STATION CONTROL—3-position UP-OFF-DOWN switch

permits operation to be stopped at any point. Factory adjusted limit switches

automatically stop screen when fully down or fully up.

110-120v MULTIPLE STATION CONTROL—Switches are similar in

appearance to 110-120v Single Station Control. Screen stops when switch

is released and may be restarted in either direction. Factory adjusted limit

switches stop screen automatically when fully up or fully down.

24v MULTIPLE STATION CONTROL—Three-button UP-STOP-DOWN

switches stop at any point desired, operate in any sequence. Factory

adjusted limit switches automatically stop screen when fully up or fully

down.

110-120v & 12v VIDEO INTERFACE CONTROL—Allows screen to be

controlled by a trigger signal—when the signal comes on, the screen

descends automatically. Two versions: Model VIC115 integrates screen

operation with a DRAPER video projector lift or a video projector or tuner

with a 110-120v switch outlet. Model VIC12 interfaces with a 12V switch

outlet. Both available with an override switch (VIC–OS), permitting

independent operation. VIC–OS not available with factory installed VIC115

& VIC12.

KEY OPERATED SWITCHING—Two kinds of key-operated switches are

optionally available with this unit.

➀The key-operated power supply switch controls power to the screen and

switches. When it is “off”, the switches will not operate screen.

Key may be removed from the switch in either “on” or “off” position.

➁A three-position key switch permits the screen to be operated directly by

key. In this case, the screen’s operator must always have a key.

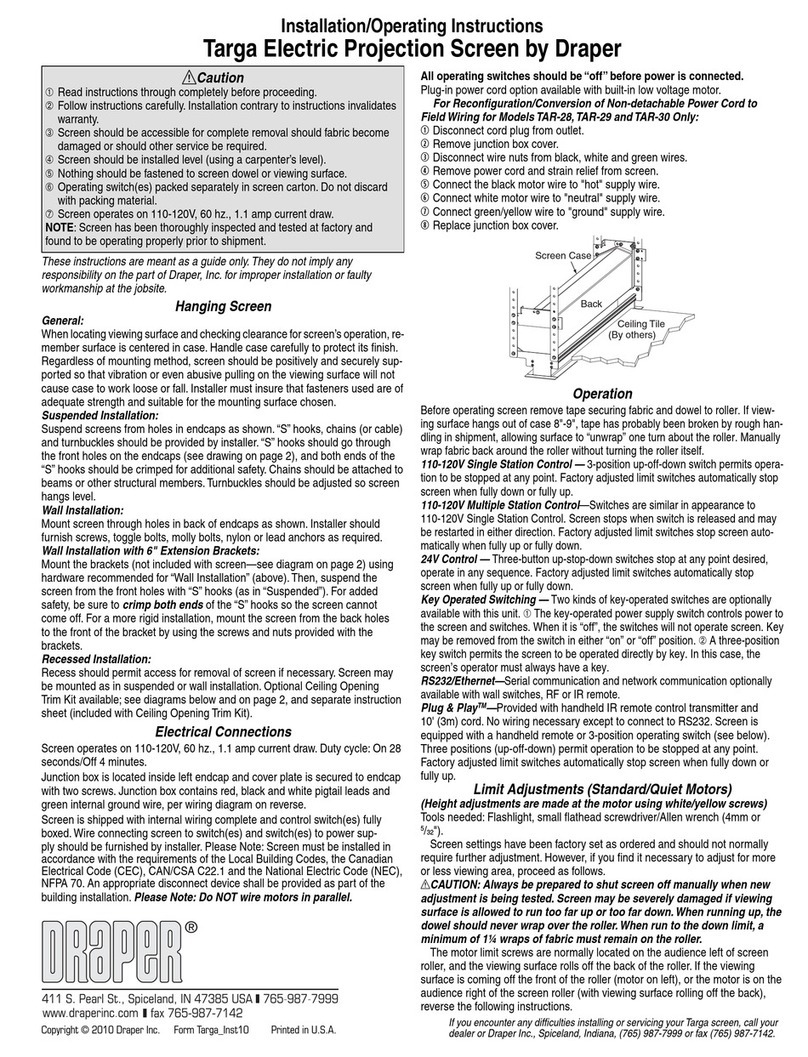

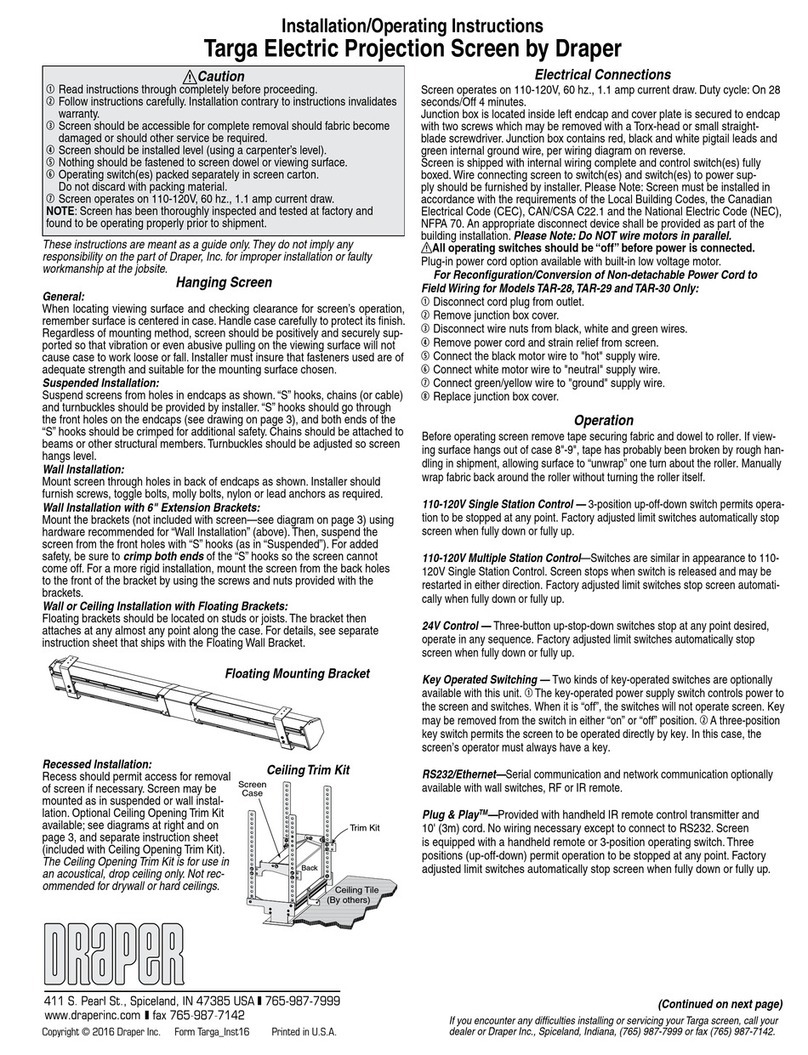

Angle adapter

Wall bracket

Extension Arm

Front view of assembled

extension bracket

90˚

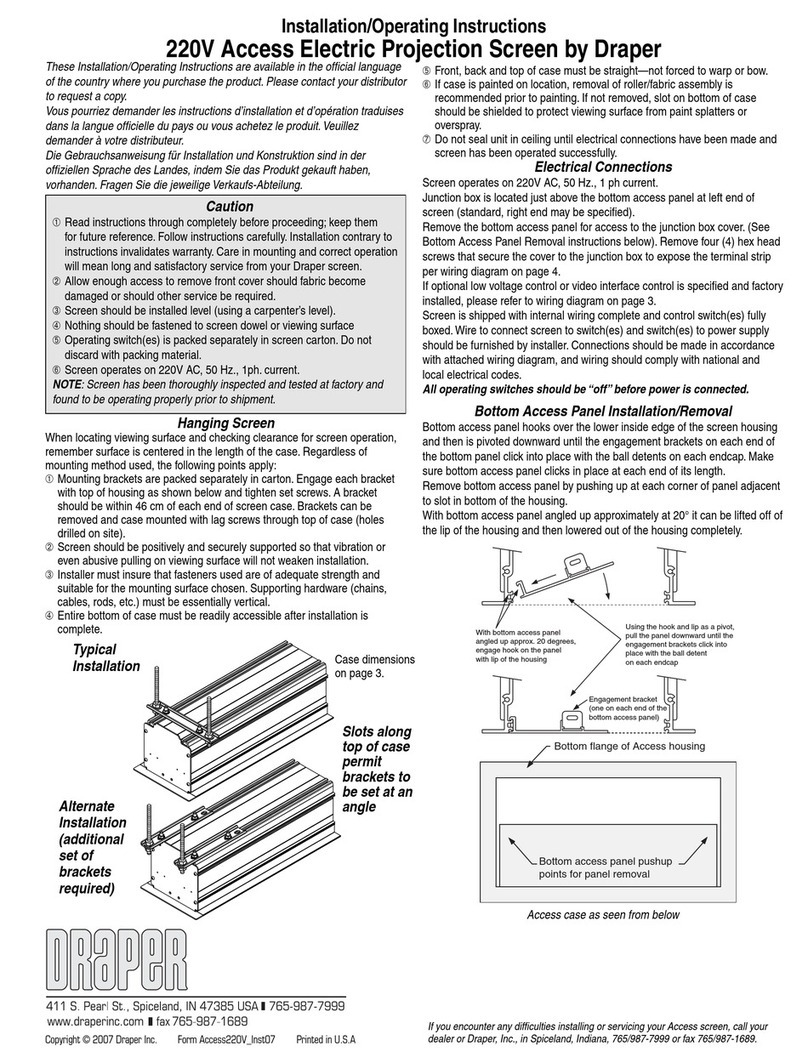

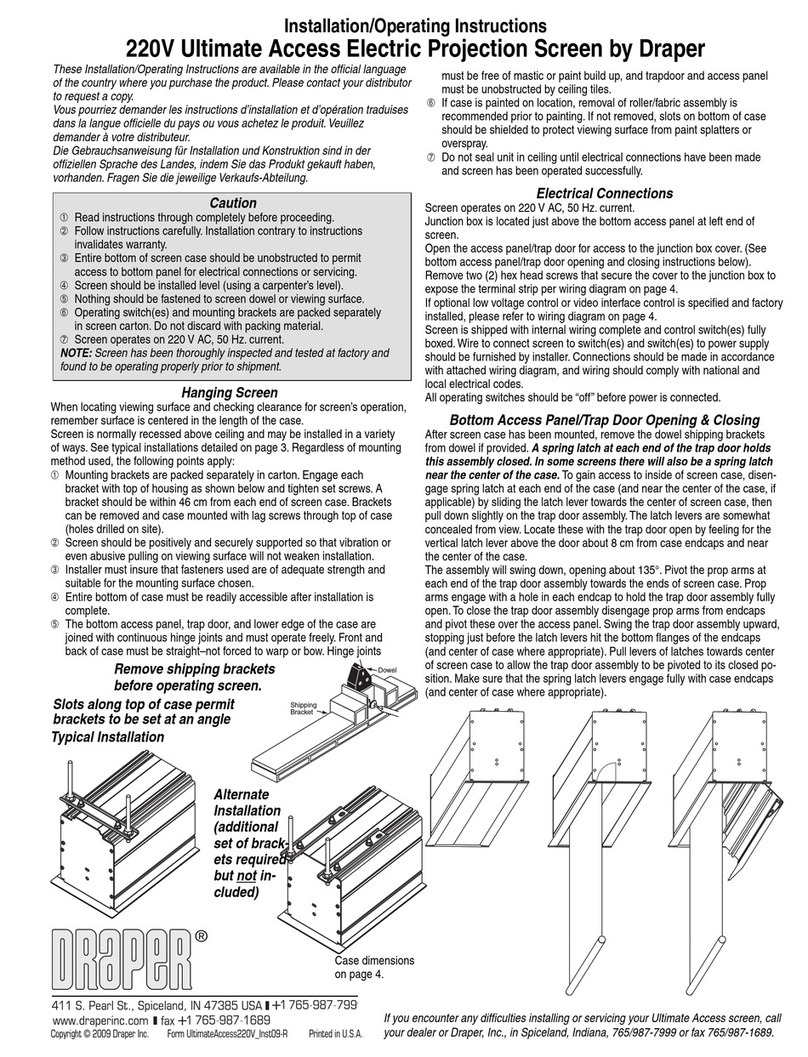

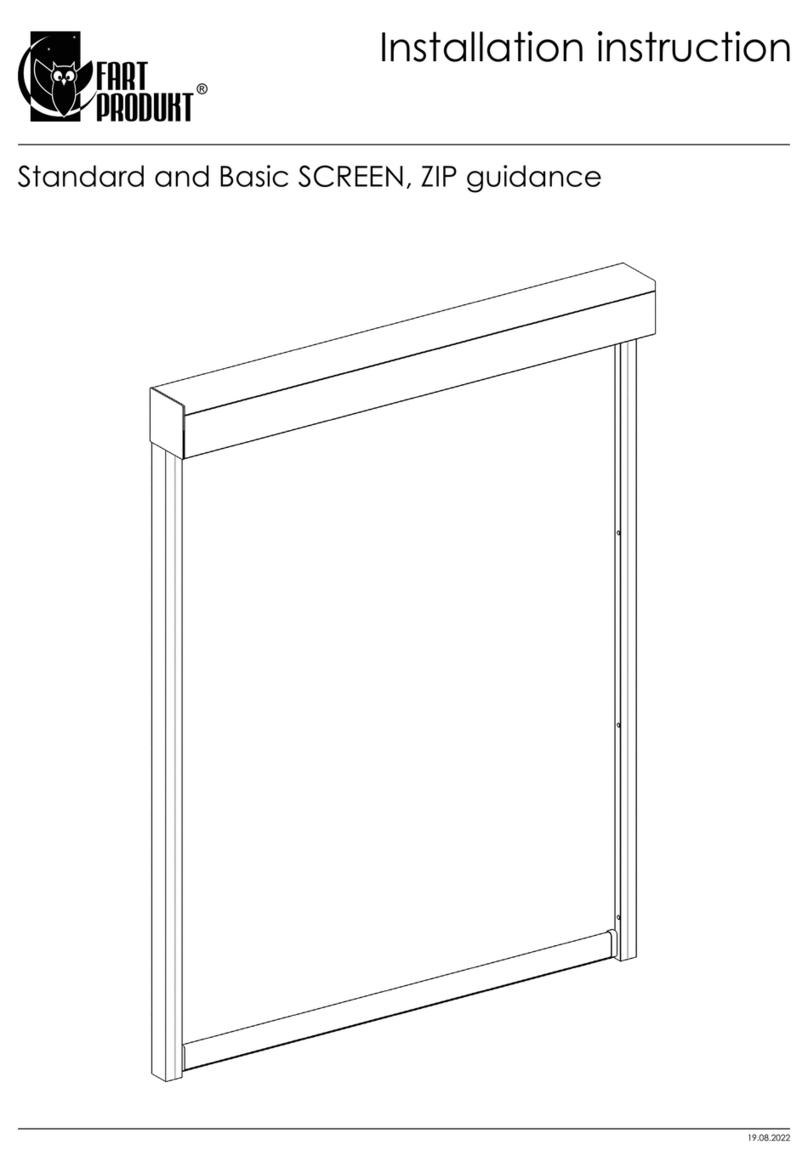

To mount suspended from ceiling, the brackets need to be installed on

screen case as noted on page 1. Attach “S” Hooks (supplied) through the

holes in the brackets. Select the set of holes that allows the screen to hang

in a vertical position. The installer is to provide the materials and fasteners

to attach the “S” Hooks to the ceiling. Installer must insure that the fasteners

and suspension material is of adequate strength and suitable for the

mounting surface chosen.

Mounting on 6" extension wall brackets:

Special 6" extension brackets

are needed to mount Silhouette extended from wall. Brackets are not

supplied with screen and must be ordered separately. Specify “Silhouette

Extension Brackets”.

Attach right angle adapter to top of extension bracket as shown using (1)

pan head screw and (1) locking nut. Attach (1) “Z” Clip wall mounting

bracket (supplied with screen) to front of extension bracket as shown using

(1) pan head screw and (1) locking nut. (Make sure “Z” Clip is oriented 90°

to angle adapter.)

Wall mount the extension brackets to wall, making sure they are level and

vertically plumb. Installer must insure fasteners are of adequate strength

and suitable for chosen mounting surface. Back out the top stop screw until

it is flush with front side of angle adapter.

Engage the lip on back of screen case with lip of “Z” Clip and gently pull

down to fully engage case to brackets. Screw in stop screw on each bracket

to lock screen case in place.