Pre-installation data sheet Duravit No. 1_22.03.1

Pre-installation

INSTALLATION LOCATION / INSTALLATION ROOM

> Make sure that the installation location fulfils the following criteria

Doors / external

access

• Ensure that doors or other access openings are

large enough to accommodate transport dimen-

sions, keeping in mind the weight and need for

sufficient manoeuvring room.

Required area • Allow for enough space around the tub for the in-

stallation.

Floor • Completely level.

• At a right angle to the wall.

• Note the overall strength of the floor structure

including the floor finish.

• There must not be any underfloor heating under

the tub.

• Install tubs after the tiles. (Top edge of finished

floor).

• Depending on the combination of tub and whirl

system it is possible that system components may

protrude beyond the edge of the tub. We there-

fore recommend installation in a support frame.

• Tolerances for acrylic: As a result of the manu-

facturing process, deviations from the nominal

dimensions may occur within the limits specified

in the DIN 198 standard. Please take this into

account in your planning.

Wall • Tiled.

• At a right angle to the tub.

• Completely straight.

• Note the overall strength of the wall structure

including the wall finish.

WATER INSTALLATION

NOTE

Bathtubs without overflow will overflow into the room.

> If a bathtub is installed without an overflow, a floor drain must be

installed to protect the building against overflow water in accordance

with DIN 1986-100.

NOTE

A pipe interrupter is absolutely essential for tubs with a base inlet (DIN

EN 1717).

> Comply with assembly scheme.

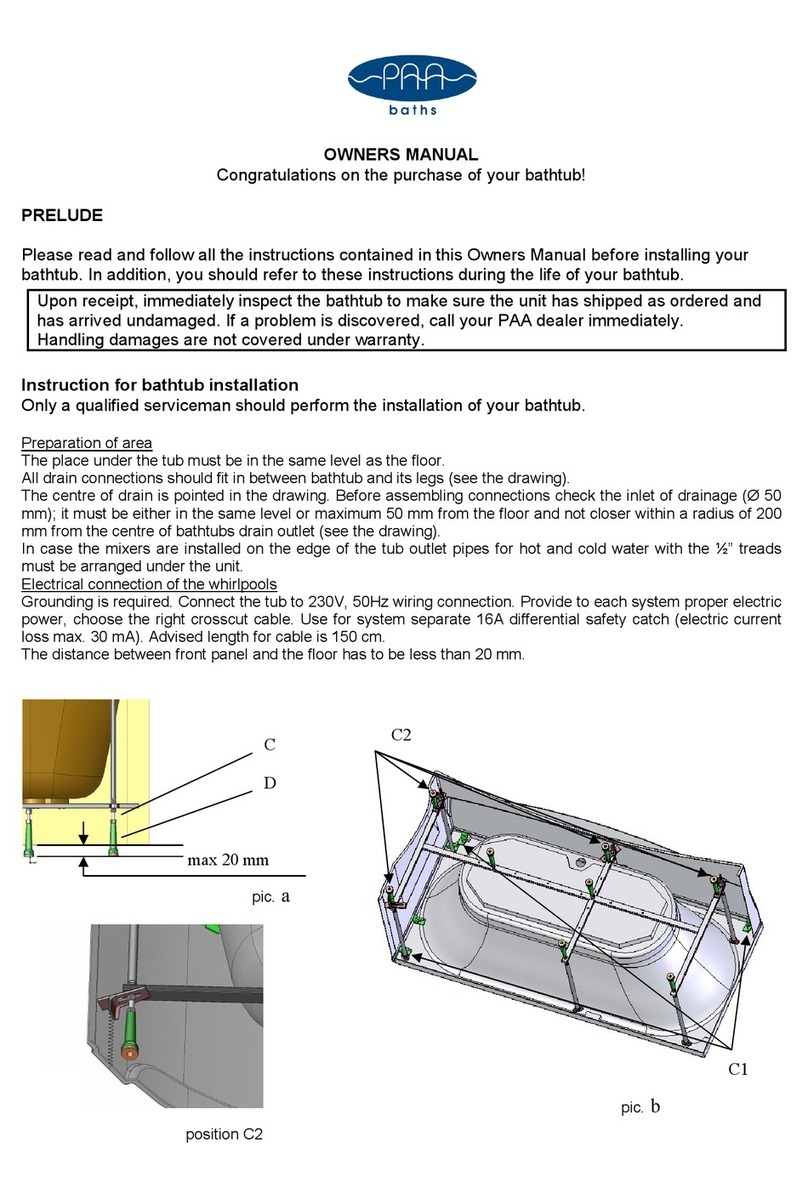

Seitenansicht

Lateral view

150

>

=

Gezeichnet

Drafted

Ge ndert

Modified

Gepr ft

Certified

Datum

Date Name Ma§stab

Scale

Name

Bezeichnung

Description

Artikel-Nr.

Model-No.

Technische Verbesserungen und optischeVernderungen an den abgebildeten Produkten behalten wir uns vor.

We reserve the right to make technical improvements and enhance the appearance of the products shown.

1:20

1:10

1:5

X

# W-T-

Allgaier

000000 - 00 - 0

08.10.13

000000

Schematische Zeichnung mit Rohrunterbrecher

Zeichnung

Drawing

Spezial Ab-und berlaufgarnitur mit Bodenzulauf

fr Badewanne

Special waste and overflow with base inlet

for bathtubs

WLT

08.10.13

Water connection

• Connections for the water supply and drains must be in compliance

with the currently valid standards and public regulations.

• Position the water drain (DN 50) flush to the mounting surface or out of

the wall directly above the mounting surface; see drawing for recom-

mended area.

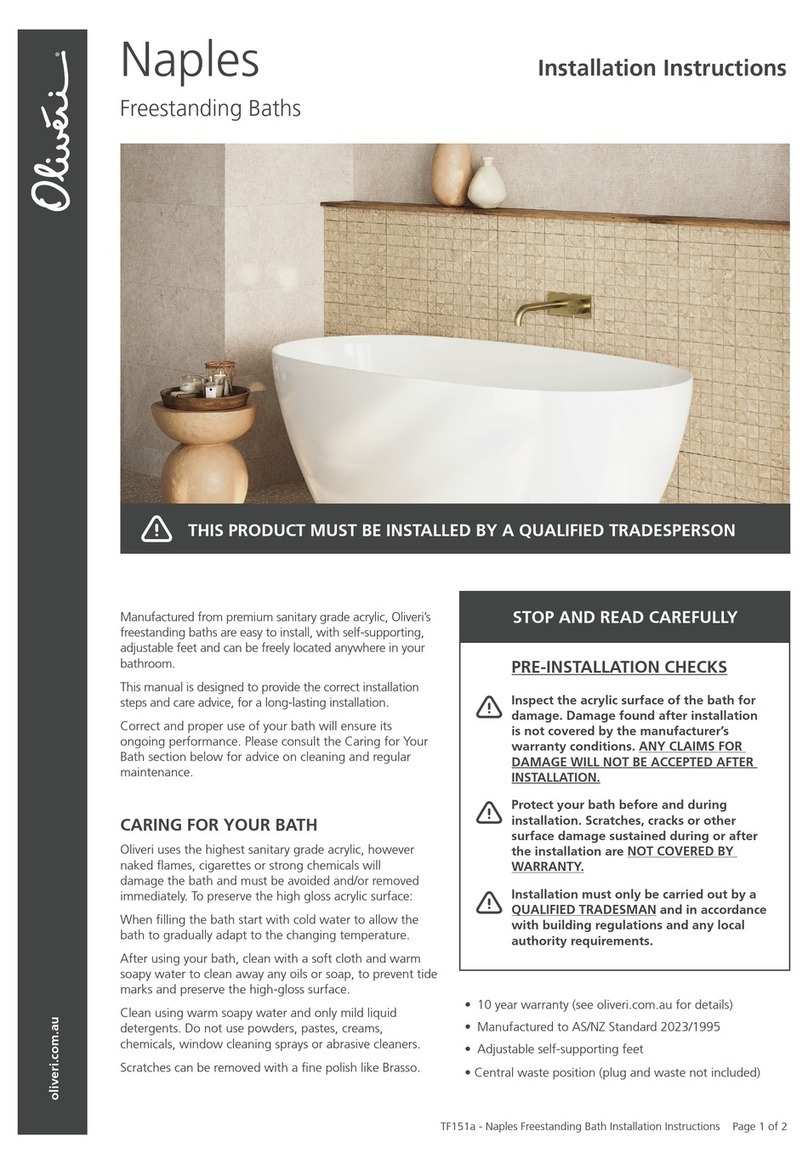

MAINTENANCE OPENINGS AND AIR SUPPLY

NOTE

It is recommended to install the tub with a removable bathtub panel due

to the improved maintenance options.

Tiling the tub

The following maintenance openings must be provided:

• Cable-driven waste and overflow 200 x 200 mm

• Units 500 x 500 mm

(Please see the section on “Maintenance openings”)

• Provide an opening in the panel for the air supply with an effective area

of approx. 15 cm2(e.g. 3 x 5cm or 2 x 7.5cm).

Tub with a panel

• The panel must be removed for maintenance, and with a seamless pan-

el, the tub must be removed from the wall. Your plans should therefore

include a clearance in front of the tub.

• The air supply for the whirl system (ventilation grille/ventilation slot)

must not be covered.

ELECTRICAL INSTALLATION

DANGER Risk of fatal electric shock

> Disconnect the power supply while working on the electrical

components.

> The device must be earthed. Earthed appliances must be permanently

connected to fixed wiring.

> Connect the device only to the designated electrical cable.

> NEVER touch the power supply line with wet hands.

Pre-installation

> Lay a permanent power supply line which must be on a separate

circuit.

• The device itself does not have electrical leakage protection func-

tion. The device must be supplied through a residual current device

(RCD) with a rated residual operating current not exceeding 30 mA.

• Means for disconnection must be incorporated in the fixed wiring

in accordance with the wiring rules and have a contact separation

in all poles that provides full disconnection under overvoltage cat-

egory III conditions outside the prescribed protection zones (0 – 2).

• Leave 3000 mm of the supply line exposed.

> Lay an equipotential bonding cable:

• Leave 3000 mm of cable exposed.

> Select a supply line cross-section based on the connected load on the

identification plate (2.5 mm – 4 mm).

> Confirm that the grounding wire is 10 mm (⅜ ”) longer than the L and

N wire.

> Install a circuit breaker.

3