3

Content / Sommaire / Содержание / Зміст / Мазмұны /

English

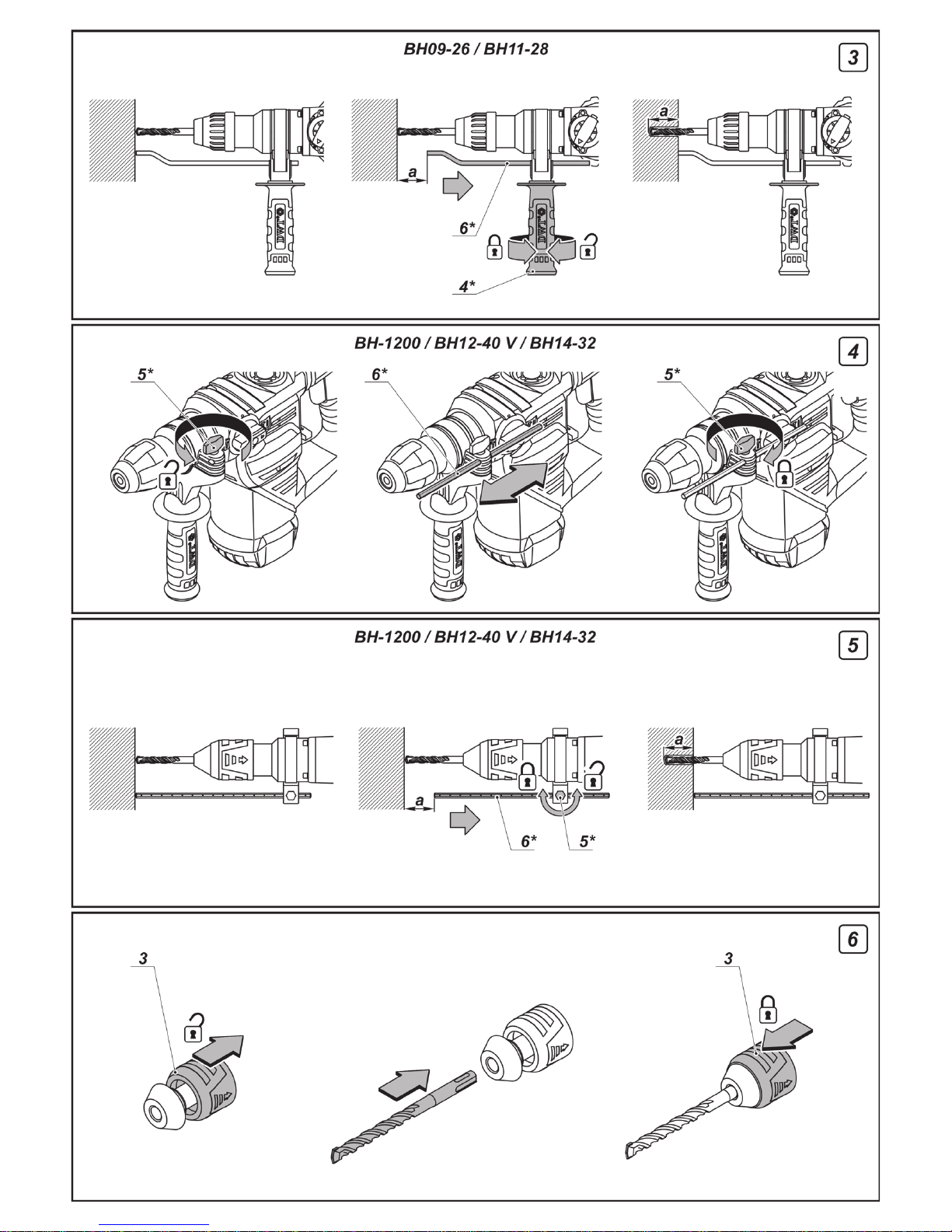

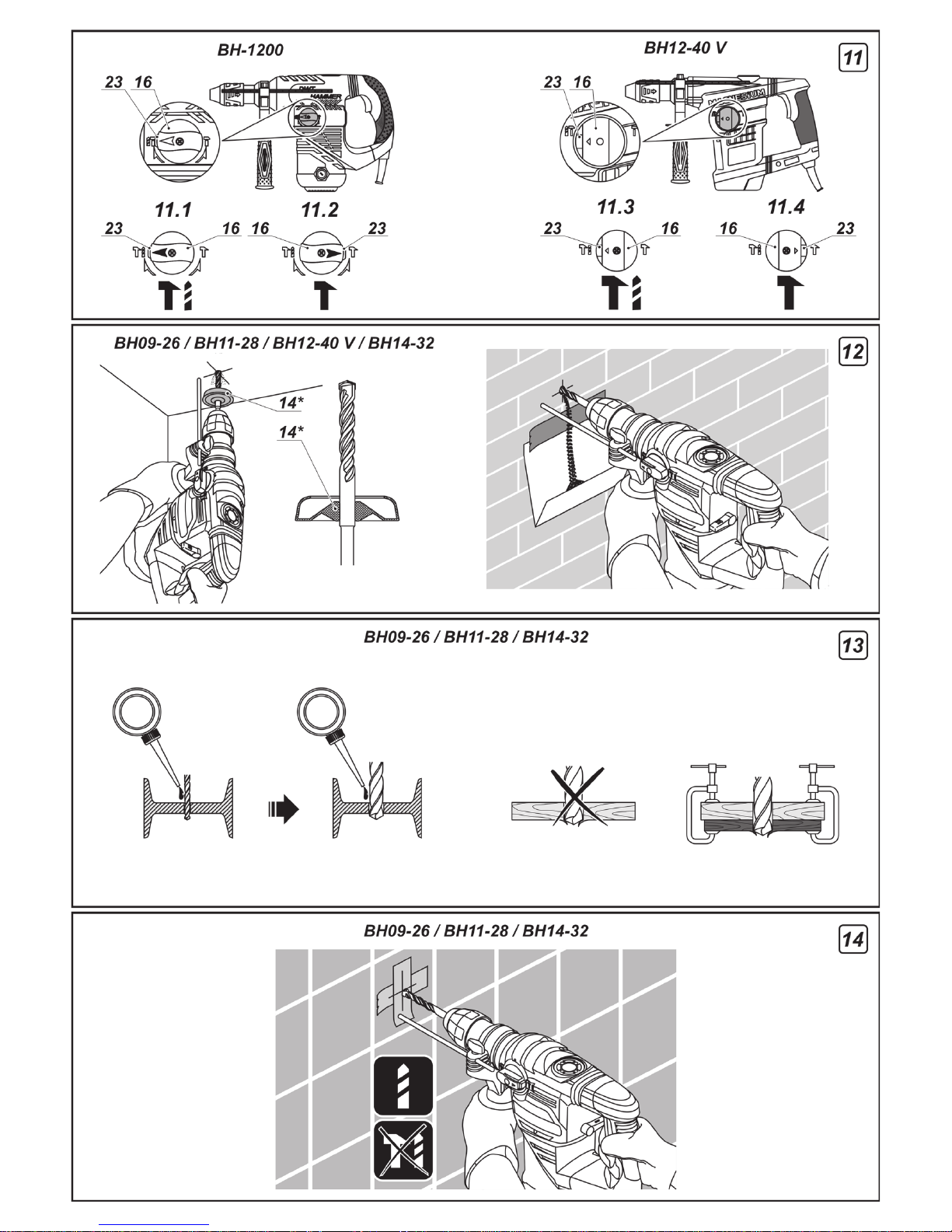

Explanatory drawings ............................................................................................................. pages

General safety rules, instructions manual ............................................................................. pages

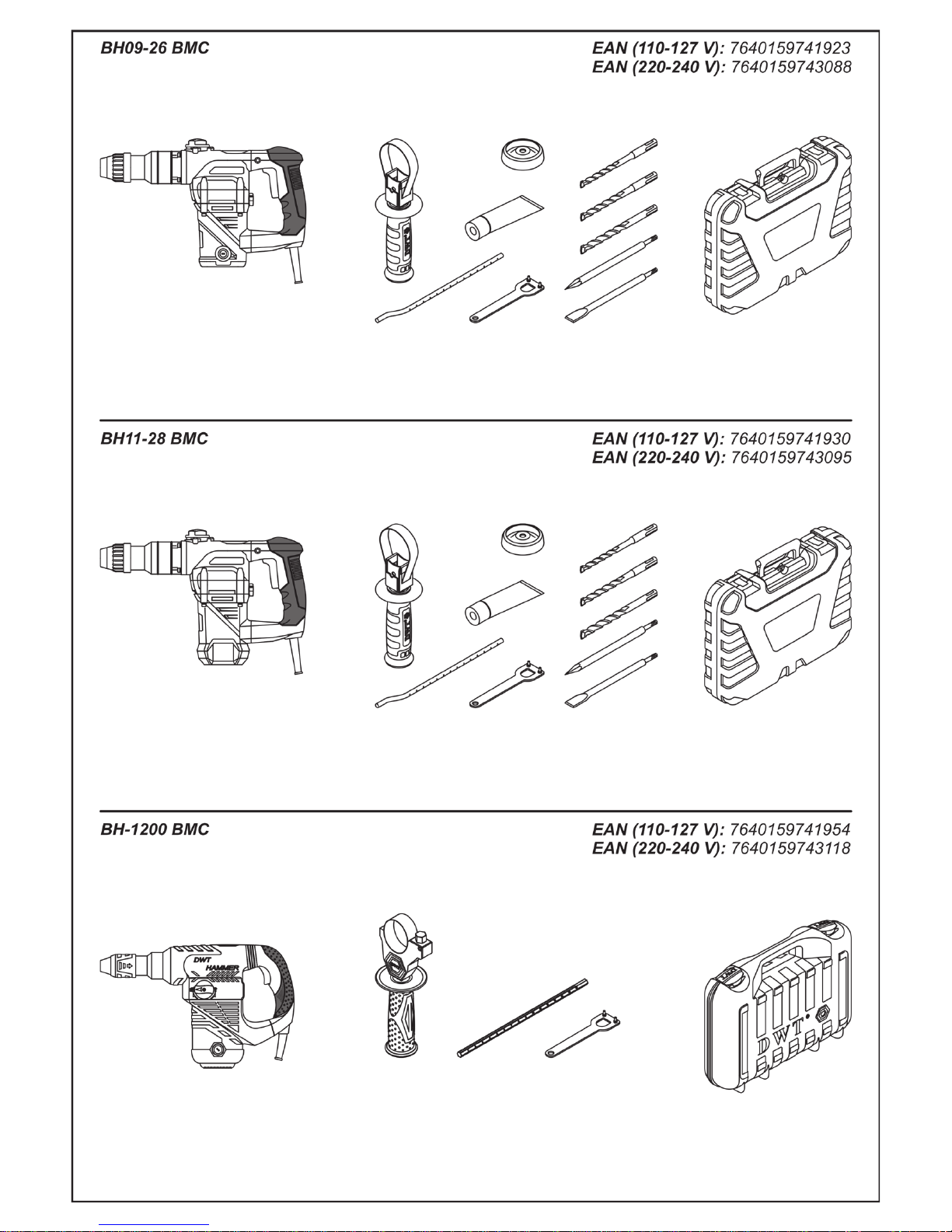

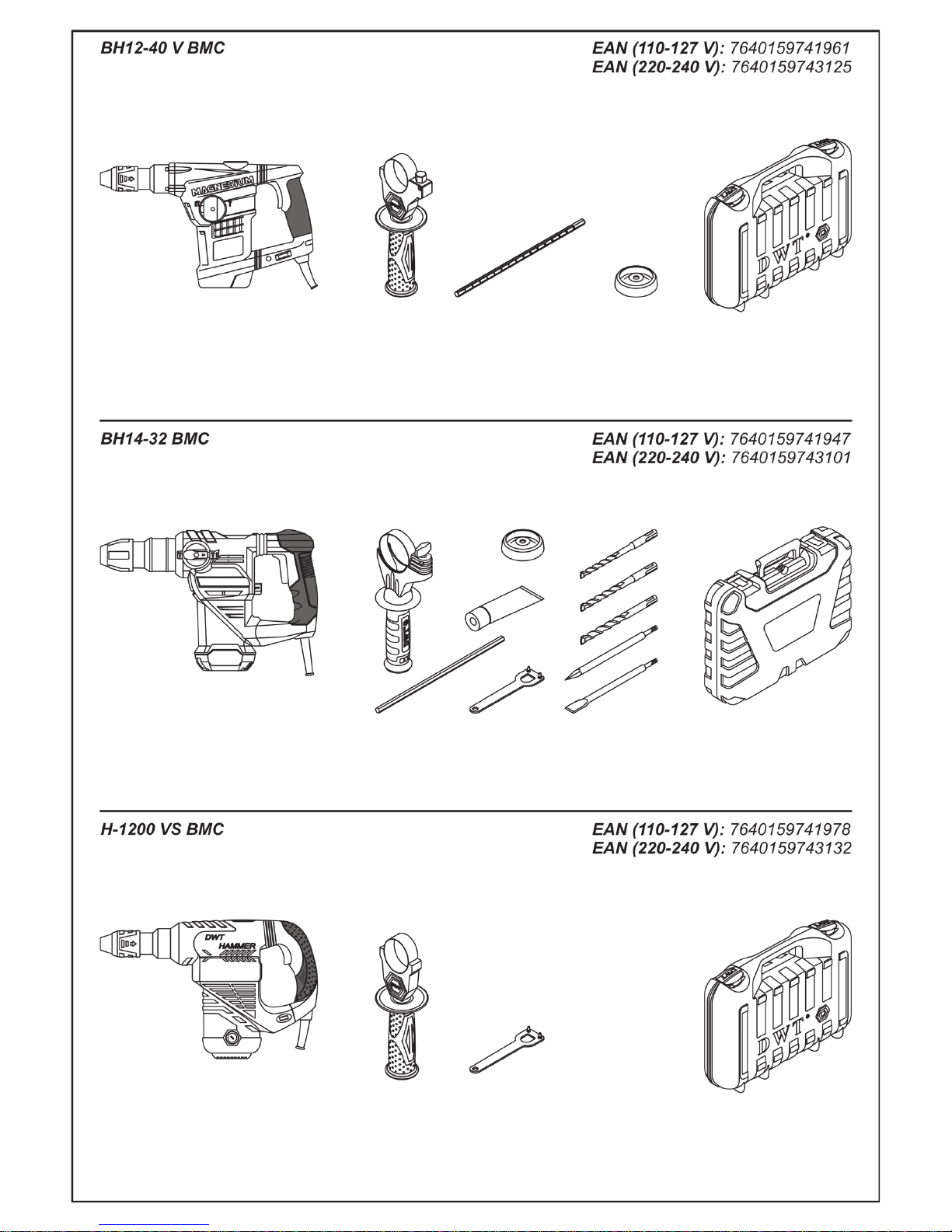

Parts diagrams ...................................................................................................................... pages

Service centres ...................................................................................................................... pages

DWT warranty .......................................................................................................................... page

Warranty card and service cards ........................................................................................... pages

4 - 10

11 - 17

52 - 61

62 - 66

67

80 - 82

Français

Dessins explicatifs .................................................................................................................. pages

Recommandations générales de sécurité, mode d'emploi .................................................... pages

Schéma des pièces ............................................................................................................... pages

Centres d'assistance ............................................................................................................. pages

Garantie DWT .......................................................................................................................... page

Garantie coupon et cartes de service .................................................................................... pages

4 - 10

18 - 24

52 - 61

62 - 66

68

80 - 82

Русский

Пояснительные рисунки .............................................................................................. страницы

Общие указания по ТБ, инструкция по эксплуатации ............................................ страницы

Схемы запчастей ........................................................................................................ страницы

Сервисные центры ..................................................................................................... страницы

Гарантия DWT .............................................................................................................. страница

Гарантийный талон и сервисные талоны .............................................................. страницы

4 - 10

25 - 31

52 - 61

62 - 66

69

80 - 82

Украïнська

Пояснювальні малюнки ...................................................................................................сторінки

Загальні вказівки по ТБ, iнструкція з експлуатації ..................................................... сторінки

Схеми запчастин ............................................................................................................ сторінки

Сервісні центри .............................................................................................................. сторінки

Гарантія DWT ................................................................................................................. сторінки

Гарантійний талон i сервісні талони ...........................................................................сторінки

4 - 10

32 - 38

52 - 61

62 - 66

70 - 75

80 - 82

Қазақ тілі

Түсіндіргіш әлеміштер ....................................................................................................беттер

Жалпы қауіпсіздік жөніндегі ұсыныстар, пайдалану нұсқаулығы ................................... беттер

Бөлшектер тәсімі ........................................................................................................... беттер

Қызмет орталықтары ................................................................................................... беттер

DWT кепілдігі .......................................................................................................................... бет

Гарантиялы талон және қызмет көрсету карталары ...............................................беттер

4 - 10

39 - 45

52 - 61

62 - 66

76

80 - 82

.........................................................................................................................

...................................................................................................

...........................................................................................................................

...............................................................................................................................

.................................................................................................................................

........................................................................................................

4 - 10

46 - 51

52 - 61

62 - 66

77

80 - 82