__________________________________________________________________________________________________________________________________

EuropeanSafetySystemsLtd. Impress House, MansellRoad, Acton, LondonW37QHsales@e2s.com Tel:+44 (0)2087438880

www.e2s.com Fax:+44 (0)2087404200

DocumentNo. IS2425-PIssueB17-04-02Sheet2of4

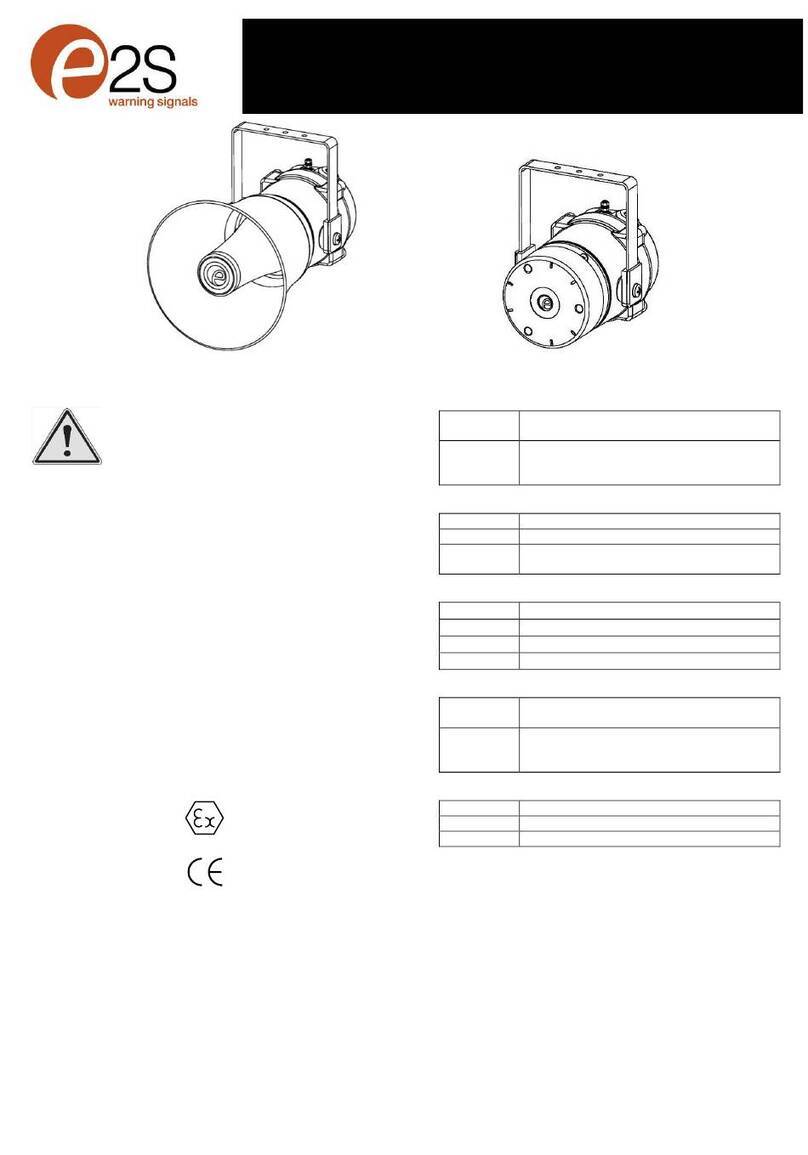

The units shouldbesecurely bolted toasuitablesurface using

the 7mm diameterboltholesin thestainlesssteelUshaped

mountingbracket(seefigure1). The angle canthen be

adjusted in the directionthat the messageisprimarily required

tocover. Thiscan beachievedbyloosening the two large

bracketscrews in theside of the unit,which allowadjustment

in steps of 18°. Oncompletion of the installation the two large

bracketadjustment screwsontheside of the unit mustbe fully

tightenedto ensurethat theunit cannot moveinservice.

7) SafetyWarning (ElectrostaticHazard)

The acoustic horn sectionis made of ABSPlastic,thereforeto

avoidapossibleELECTROSTACTIC CHARGEthe unitmust

only be cleanedwith a damp cloth.

8) Access totheFlameproofEnclosure

In order to connecttheelectrical supplycablesandto recorda

messageontotheunits,itisnecessary toremovethe

flameproof cover togain accessto theflameproof chamber. To

achieve this removethe four M6 hexagonsocket head screws

(seefigure 2)and withdrawtheflameproofcovertaking

extremecarenottodamagetheflameproofjointsin the

process.

Notethefour M6screwsareClassA4-80stainlesssteel

andonlyscrewsof thiscategorycanbeused on these

units. Itis thereforeimportant thatthesescrews and their

springwashersarekept in a safe place duringinstallation.

Oncompletionofthecable wiringinstallationtheflameproof

jointsshouldbe inspectedto ensurethat theyarecleanand

thatthey havenotbeen damagedduringinstallation.Also

checkthat theearthbondingwirebetweenthetwocasting

sectionsissecureandthe‘O’ringseal isinplace.When

replacingtheflameproof cover casting ensurethat itis square

withthe flameproof chamber castingbefore inserting. Carefully

pushthecoverin placeallowing time fortheairto beexpelled.

Only afterthecover isfullyin placeshould the four M6

Stainless SteelA4-80 coverbolts and theirspringwashers be

insertedand tighteneddown. If the coverjams while it is being

inserted, carefully remove it andtryagain.Never use the cover

boltsto forcethe cover intoposition.

9) PowerSupplySelection

Itis important that asuitable powersupplyisused torunthe

Appello’sandthat thecables usedto connecttheunits tothe

powersupply areselectedtoensurethat theyhavethe

necessary capacity.

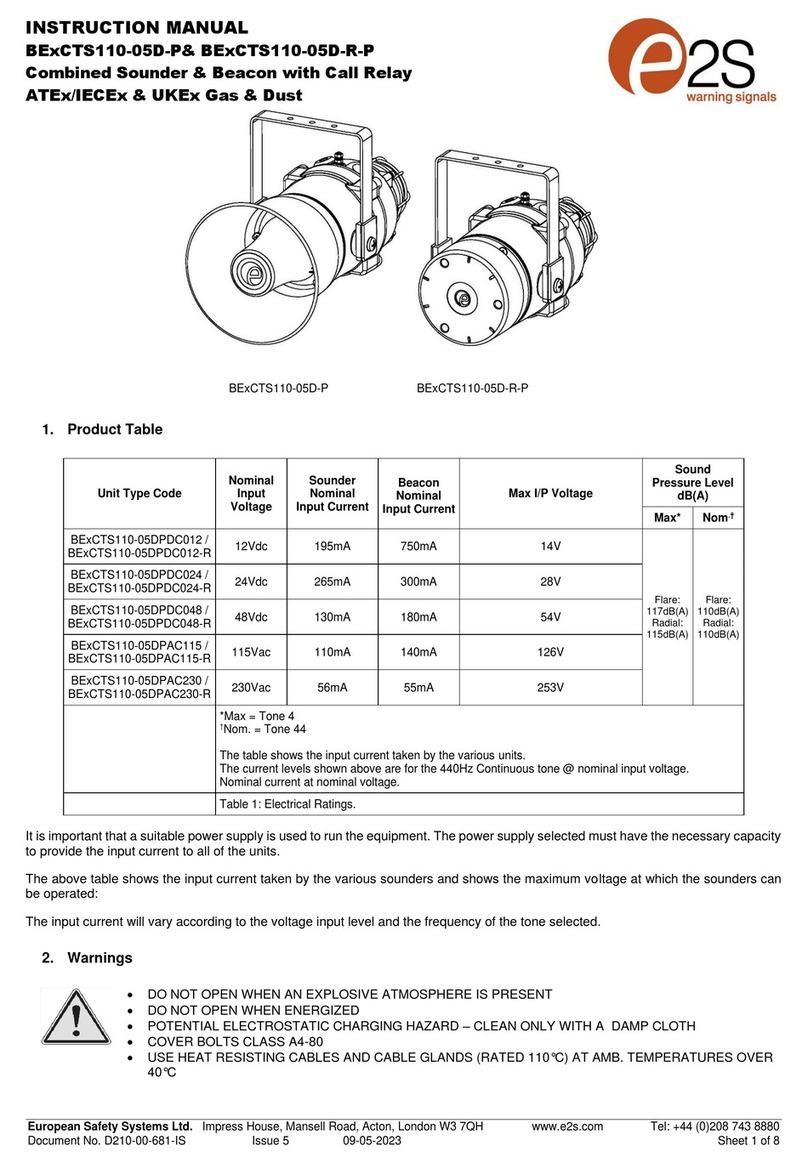

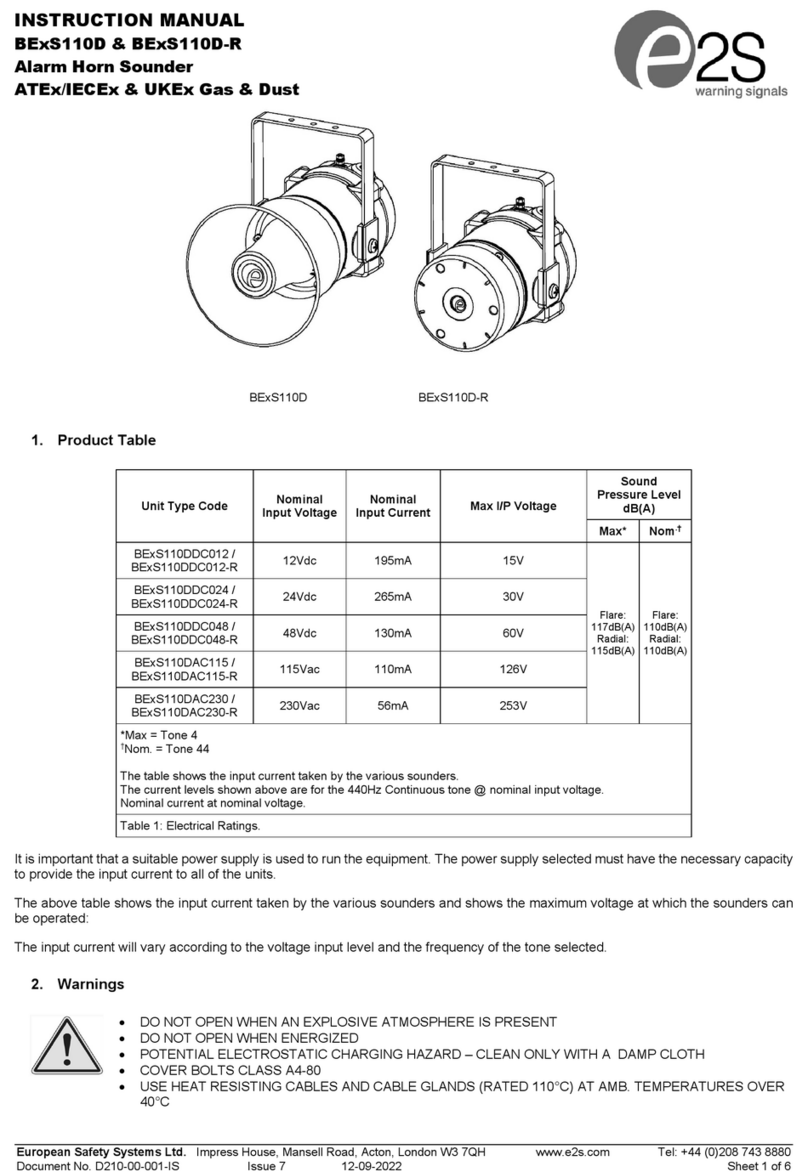

The followingtableshowstheinputcurrent taken by the

various sounderunits:-

UnitTypeInputInputMax.

VoltageCurrentI/PVolts

BExA120D24VDC 480mA30V

BExA120D230VAC45mA253V

BExA120D115VAC90mA126V

BExA110D24VDC 480mA30V

BExA110D230VAC45mA253V

BExA110D115VAC90mA126V

The input currentwillvaryaccordingtothe voltage inputlevel

and the frequencyofthe toneselected.Thecurrent values

shown abovearefor the554/440Hz tone @nominalinput

voltage. The above tablealso shows the maximum voltages at

which theunitscan beoperated.

10) CableSelection

Whenselecting the cable size consideration mustbegivento

the inputcurrentthat each unitdraws (seetableabove), the

numberofunits onthelineandthelengthofthecableruns.

The cablesizeselected musthavethe necessary capacity to

providetheinputcurrenttoalloftheAppello’s connected to

the line.

SAFETY WARNING: If the Appello’s are used athigh ambient

temperatures,i.e.over +40ºC, thenthecableentry

temperature mayexceed +70ºCand thereforesuitable heat

resisting cables mustbeused,witharatedservice

temperature of at least 95ºC.

11) Earthing

Both AC andDCAppellounitsmustbeconnectedto agood

qualityearth. The units are provided with internal and external

Figure 1

Chamber

Cover

Terminal

Pleasesee SafetyWarning

inSection 7of thismanual