__________________________________________________________________________________________________________________________________

EuropeanSafetySystemsLtd. Impress House, MansellRoad, Acton, LondonW37QHsales@e2s.com Tel:+44 (0)2087438880

www.e2s.com Fax:+44 (0)2087404200

DocumentNo. IS2427-PIssue B17-04-02 Sheet2of 4

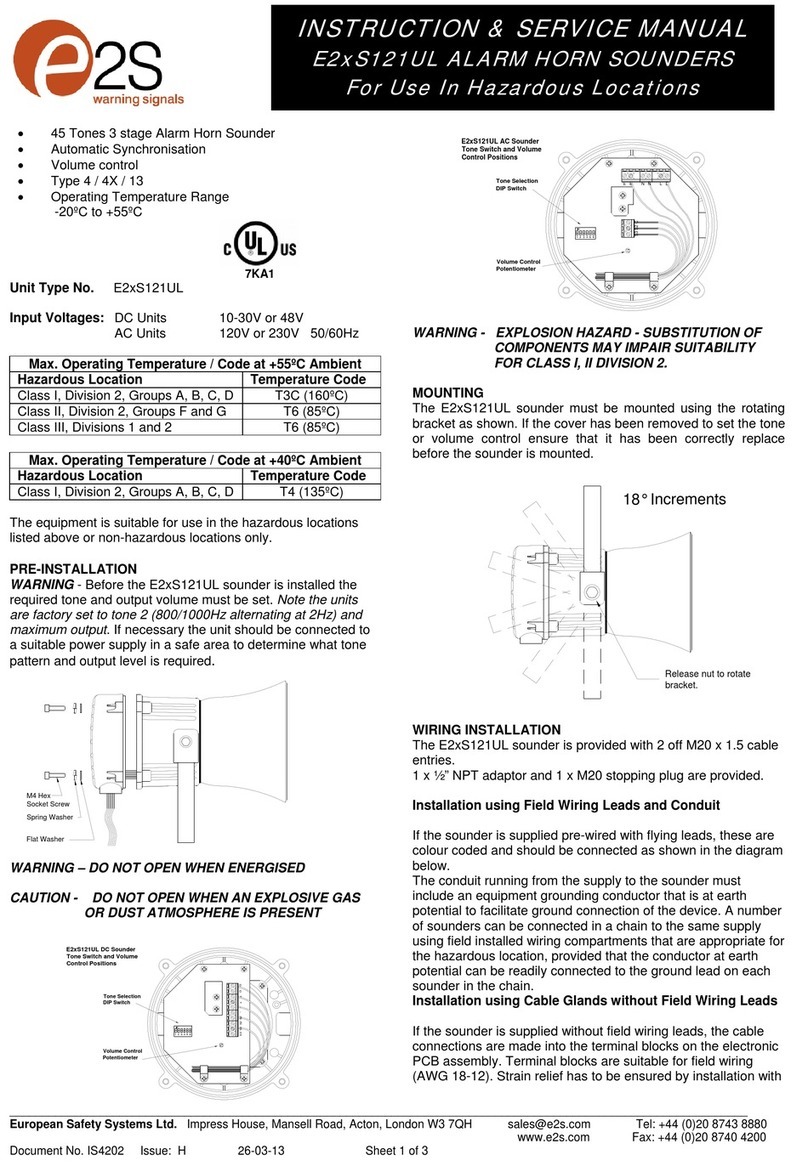

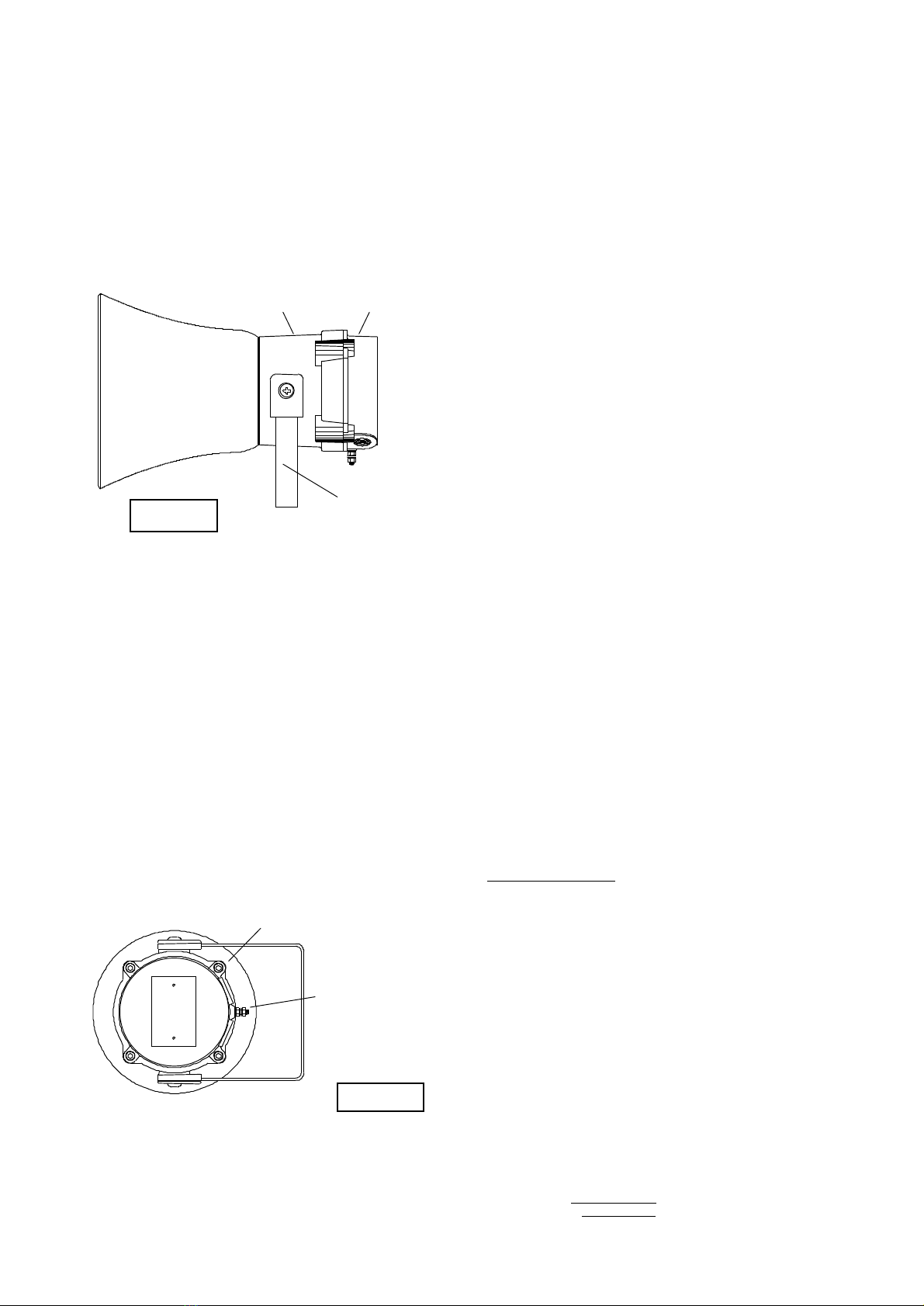

TheSontelsshouldbesecurely boltedtoasuitablesurface

usingthe7mmdiameter boltholesinthe stainlesssteelU

shapedmountingbracket(see figure1). Theanglecan then be

adjusted in the direction thatthe sound is primarily required to

cover. Thiscan beachieved by looseningthetwolarge bracket

screws in the side of the unit, whichallow adjustment in steps

of18°.On completion of the installation thetwolarge bracket

adjustment screws onthe sideof theunit must befully

tightenedto ensurethat theunit cannot moveinservice.

7) SafetyWarning (ElectrostaticHazard)

The acoustic horn sectionis made of ABSPlastic,thereforeto

avoidapossibleELECTROSTACTIC CHARGEthe unitmust

only be cleanedwith a damp cloth.

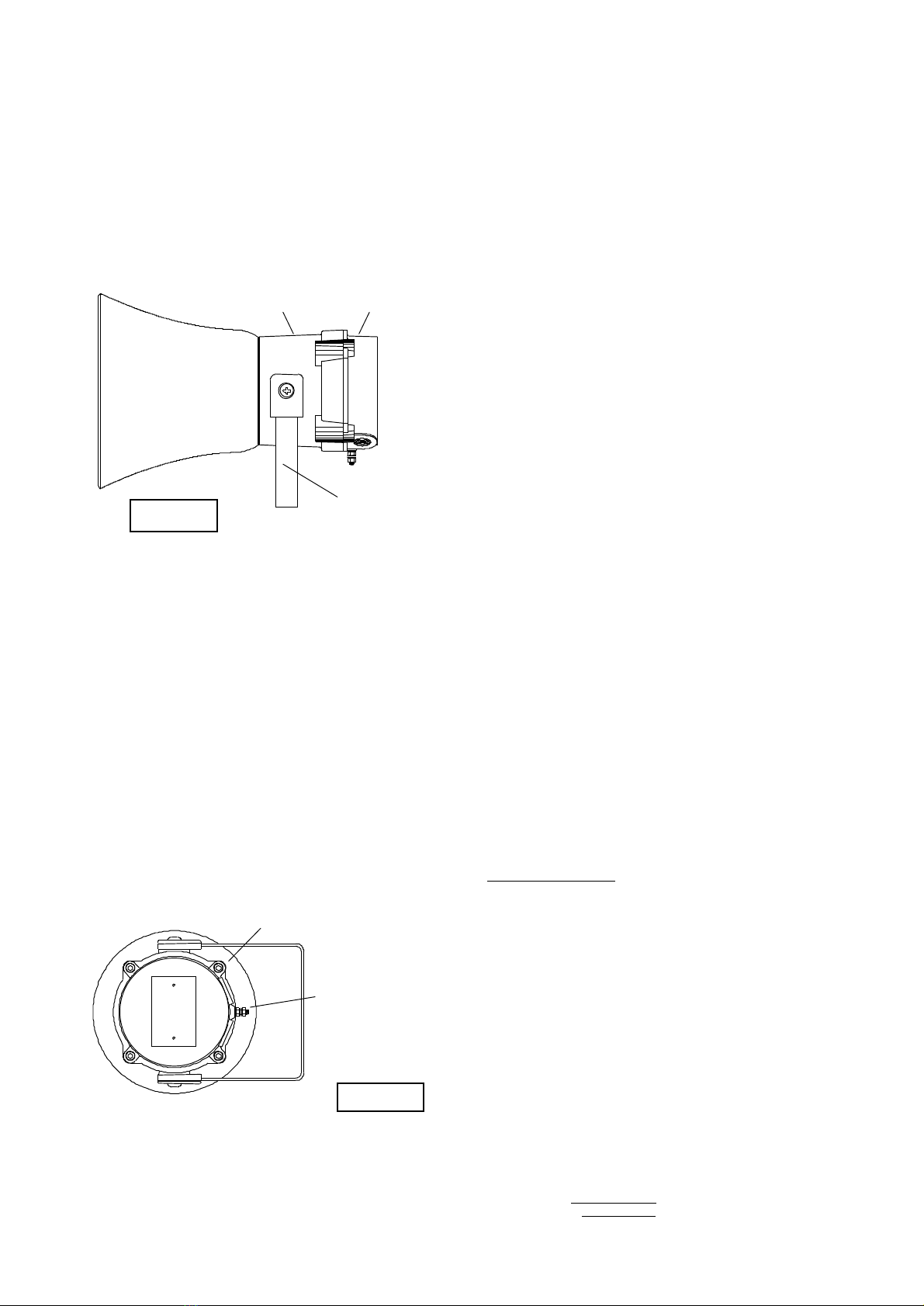

8) Access totheFlameproofEnclosure

Inorder to connect theelectrical supply cableandthe

telephonelinecabletotheSontelit isnecessarytoremovethe

flameproof cover togain accessto theflameproof chamber. To

achieve this remove thefour M6 hexagonsockethead screws

(seefigure 2)and withdraw theflameproof covertaking

extremecarenottodamagetheflameproofjointsin the

process.

Notethefour M6screwsareClassA4-80stainlesssteel

andonlyscrewsof thiscategorycanbeused on these

Sontels. Itis thereforeimportant that thesescrews and their

springwashersarekept in a safe place duringinstallation.

Oncompletionof thecable wiring installationtheflameproof

jointsshould be inspectedto ensurethat theyarecleanand

thatthey havenotbeendamagedduring installation.Also

checkthat theearthbonding wirebetween thetwocasting

sectionsissecureandthe‘O’ringseal isinplace.When

replacingtheflameproof cover casting ensurethat itis square

withthe flameproof chamber castingbefore inserting. Carefully

push thecoverin placeallowing timefor theair to be expelled.

Only afterthecover is fullyin placeshould the fourM6

StainlessSteelA4-80coverbolts and theirspringwasherbe

insertedand tighteneddown. If the coverjamswhile it isbeing

inserted, carefully remove it andtry again.Never use thecover

boltsto force the cover intoposition.

9) PowerSupplySelection

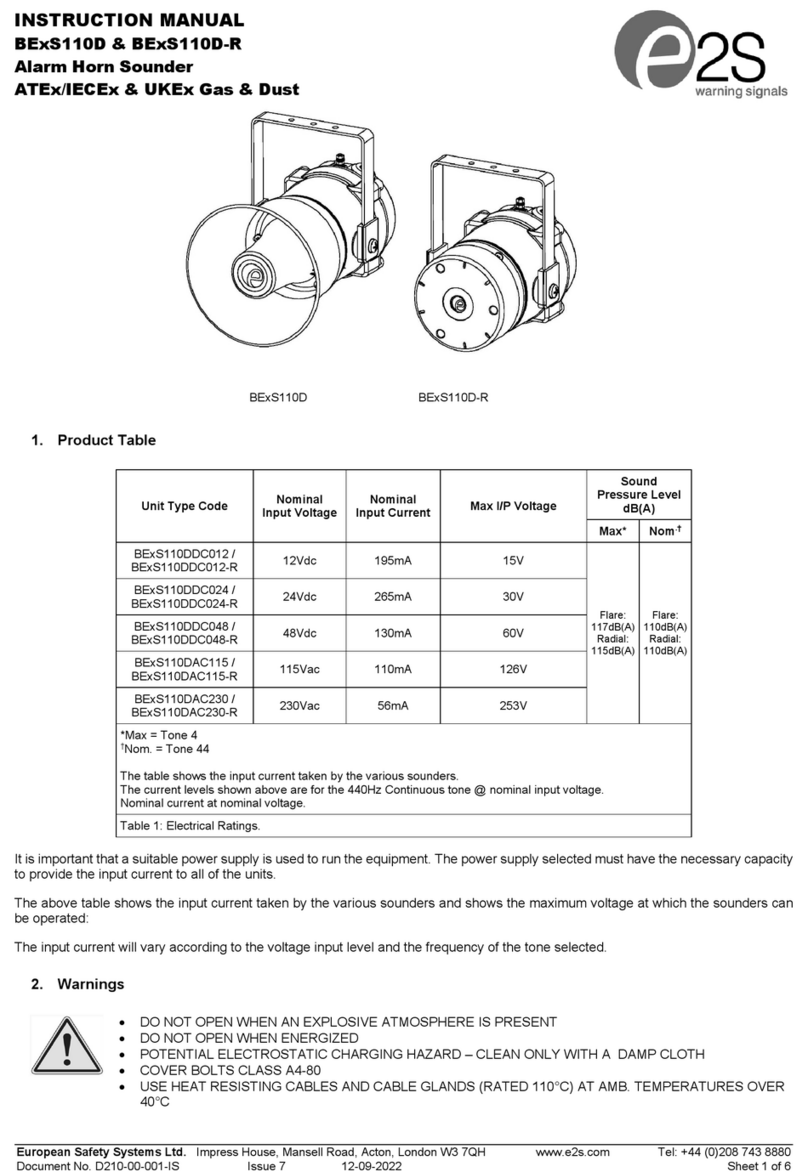

Itis important that asuitable powersupplyisused torunthe

Sontels.

The followingtableshowstheinputcurrent taken by the

various units:-

UnitTypeInputInputMax.

VoltageCurrentI/PVolts

BExTS110D230VAC56mA264V

BExTS110D110VAC93mA121V

BExTS110D115VAC110mA126V

The input currentwillvaryaccordingtothe voltage inputlevel

and the frequencyofthetoneselected.The current levels

shown abovearefor the 440Hz Continuoustone@nominal

input voltage.Theunitshaveaswitching voltageregulator

circuit andthereforethe input current levelwill decrease

slightly astheinputvoltagein increasedand willincrease

slightly astheinput voltageisreduced.

The abovetable also showsthemaximum voltagesat which

the sounderscanbe operated.

10) CableSelection

Whenselecting the cable size consideration mustbegivento

the inputcurrentthateach unit draws(seetable above), and

the length ofthe cableruns.

SAFETY WARNING: IfthehighoutputBExTS110Dunitsare

used athighambienttemperatures,i.e. over+40ºC, then the

cable entrytemperature mayexceed +70ºCand therefore

suitable heat resistingcablesmustbeused, witharated

service temperatureofat least 95ºC.

11) Earthing

The Sontelunits mustbeconnectedtoagood quality earth.

The unitsareprovidedwithinternal and externalearthing

terminalswhicharebothlocatedonthe terminalchamber

sectionoftheunit (seefigures 2and3).

Figure 1

PleaseseeSafetyWarning

in Section7ofthismanual

Chamber

Cover

Terminal