_______________________________________________________________________________________________________________________________

European Safety Systems Ltd.

Impress House, Mansell Road, Acton, London W3 7QH [email protected] Tel: +44 (0)208 743 8880 www.e2s.com Fax: +44 (0)208 740 4200

Document No. D199-00-411-IS-SC Issue 4 24-02-2021 Sheet 3 of 6

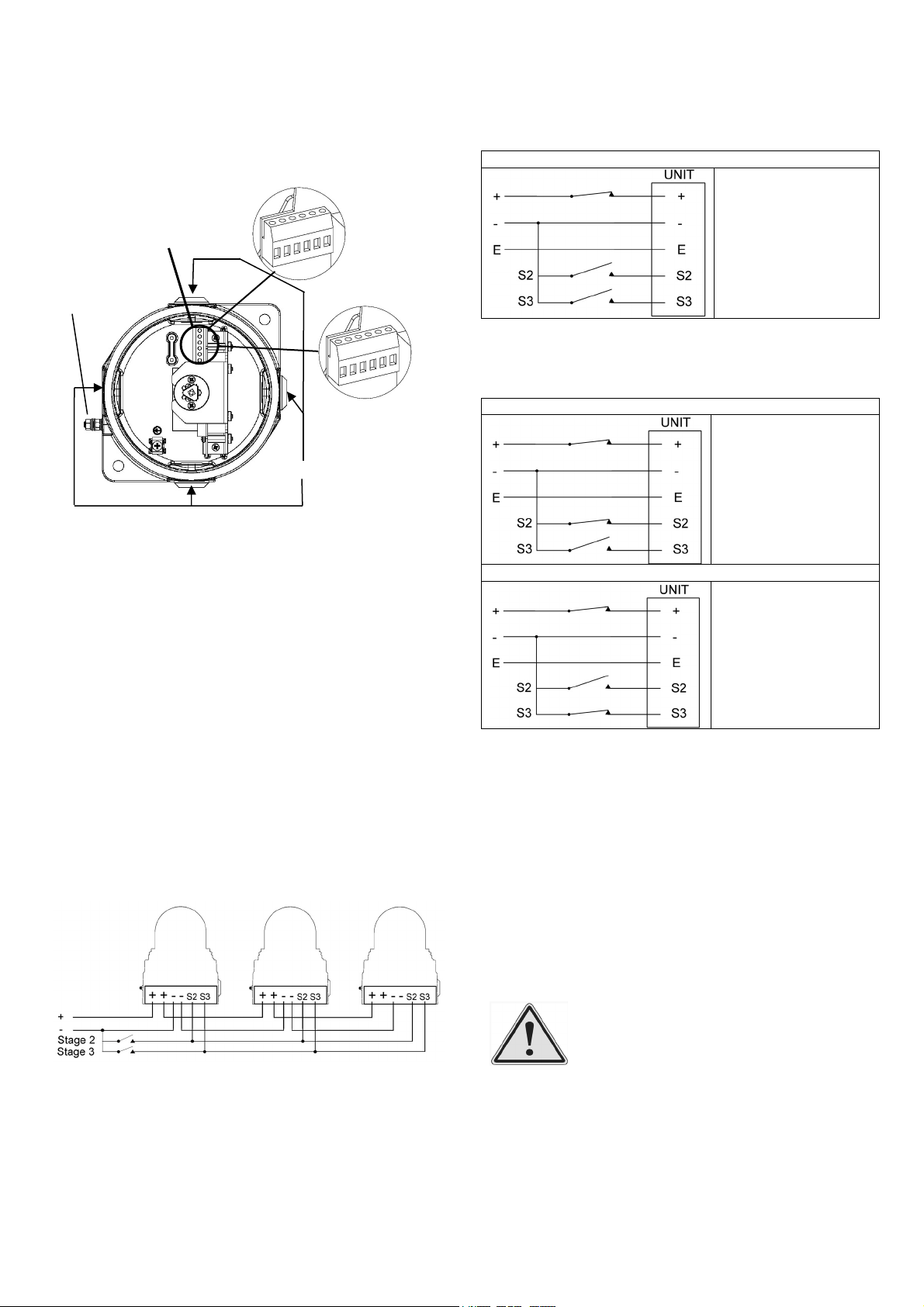

Fig. 2: Accessing the Explosion proof Enclosure

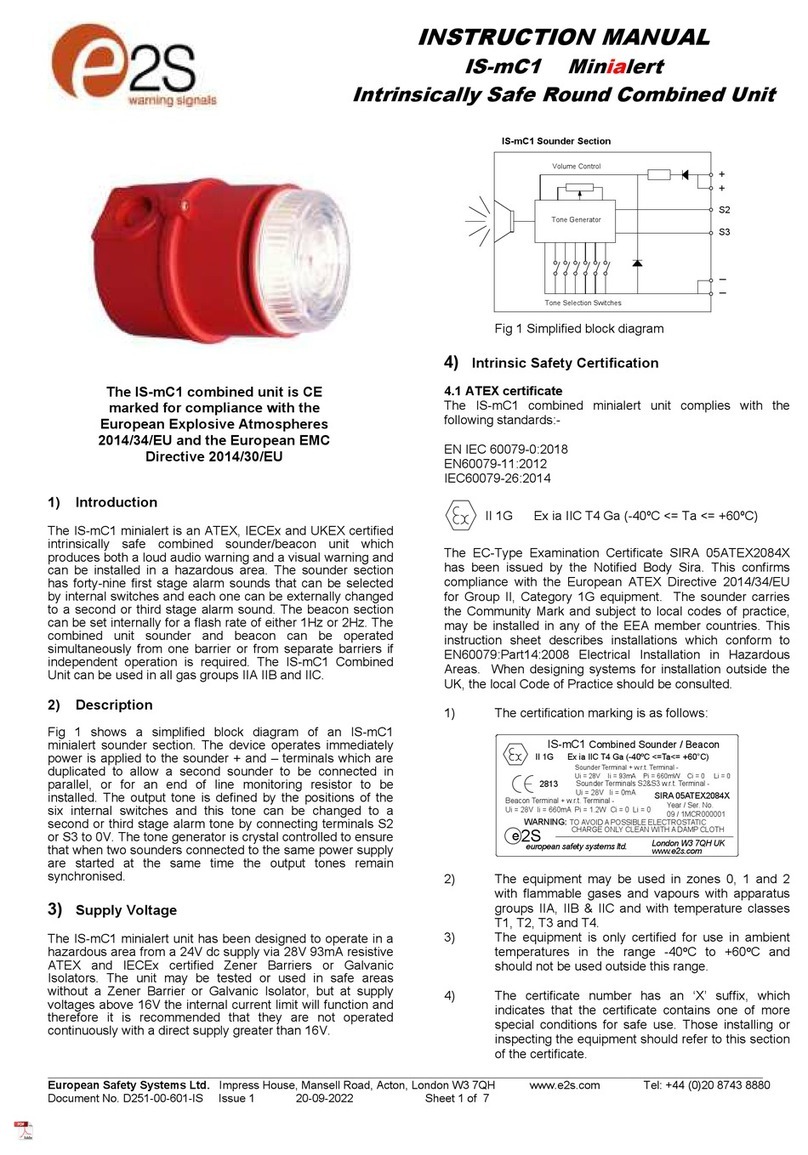

On completion of the installation the flameproof threaded joint

should be inspected to ensure that they are clean and that

they have not been damaged during installation. Flameproof

threaded joints are not intended to be repaired. Also check

that the ‘O’ ring seal is in place. When fitting the flameproof

cover ensure the thread is engaged correctly. Fully tighten

the cover all the way, ensure no gap is visible between the

cover and base of the beacon enclosure. Tighten the M4

grub screw.

8) Power Supply Selection

It is important that a suitable power supply is used to run the

beacons. The power supply selected must have the

necessary capacity to provide the input current to all of the

beacons

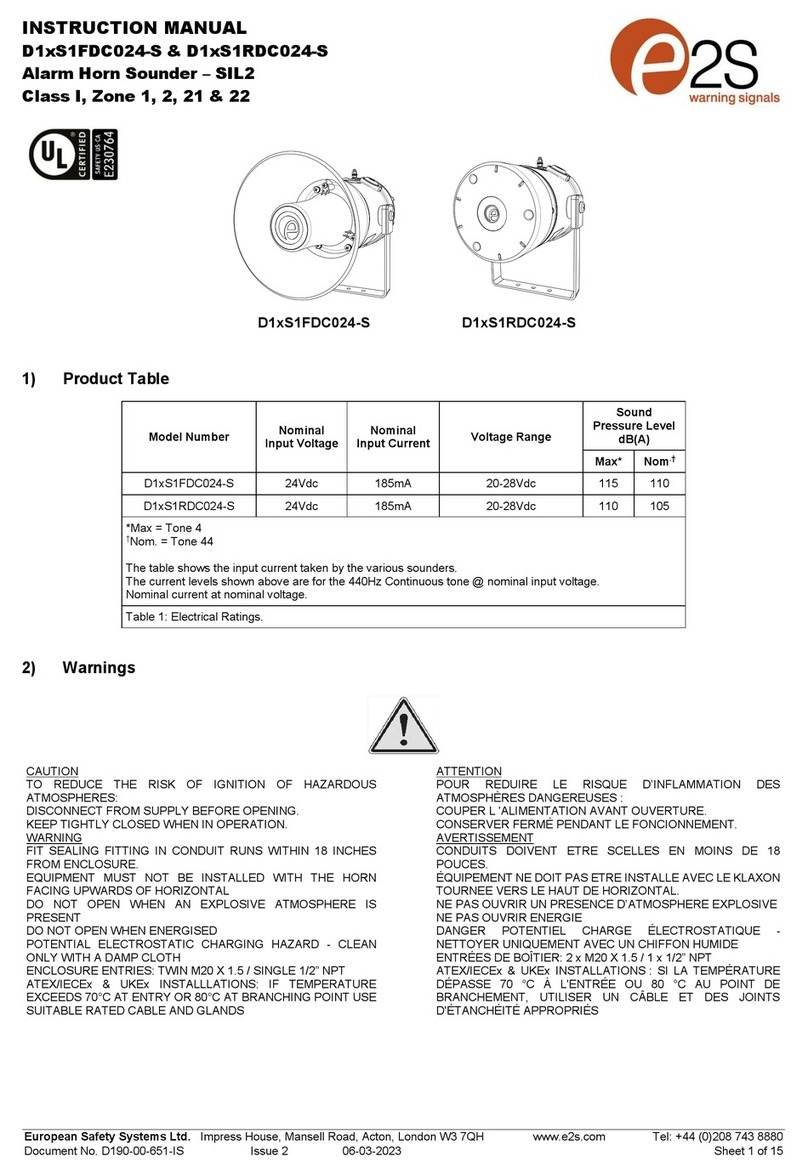

The following table shows the input current taken by the

various beacons:

The equipment has been tested for supply voltage variation

of -30% / +25% according to DNVGL-CG-0339.

9) Selection of Cable, Cable Glands, Blanking

Elements & Adapters

When selecting the cable size, consideration must be given

to the input current that each unit draws (see table above),

the number of beacons on the line and the length of the cable

runs. The cable size selected must have the necessary

capacity to provide the input current to all of the beacons

connected to the line.

For ambient temperatures over +40ºC the cable entry

temperature may exceed +70ºC and therefore suitable heat

resisting cables and cable glands must be used as per table

below

STExB2LD2

Ambient

Temp. 45ºC 50ºC 55ºC 60ºC 65ºC 70ºC

Min. Rating of

cables and

cable glands

85ºC 90ºC 95ºC 100ºC 105ºC 110ºC

The cable entries have an M20 x 1.5 – 6H entry thread. If the

installation is made using cable glands, only suitably rated

and ATEX / IECEx certified cable glands must be used. They

must be suitable for the type of cable being used and also

meet the requirements of the current installation standards

EN 60079-14 / IEC60079-14.

Any unused cable entries must be closed with suitably rated

and ATEX / IECEx certified blanking plugs.

If the installation is made using conduit, openings must have

a sealing fitting connected as close as practical to the wall of

the enclosure, but in no case more than the size of the

conduit or 50mm, whichever is the lesser.

If a high IP (Ingress Protection) rating is required then a

suitable sealing washer must be fitted under the cable glands

or blanking plugs. A minimum ingress protection rating of

IP6X must be maintained for installations in explosive dust

atmospheres.

For combustible dust applications, the cable entry device and

blanking elements shall be in type of explosion protection and

shall have an IP 6X rating.

The STEx Beacon Range can be supplied with the following

types of adapters:

M20 to ½” NPT

M20 to ¾” NPT

M20 to M25

It is important to note that stopping plugs cannot be fitted

onto adapters, only directly onto the M20 entries.

Any other adapters used must be suitably rated and ATEX /

IECEx certified adapters.

10) Earthing

Both AC and DC beacon units must be connected to an earth

according to EN/IEC 60079/14. The units are provided with

internal and external earth terminals which are both located

on the terminal chamber section of the unit

Internal earthing connections should be made to the Internal

Earth terminal in the base of the housing using a ring crimp

terminal to secure the earth conductor under the earth clamp.

The earth conductor should be at least equal in size and

rating to the incoming power conductors.

External earthing connections should be made to the M5

earth stud, using a ring crimp terminal to secure the earth

conductor to the earth stud. The external earth conductor

should be at least 4mm² in size.

Type No.

STExB2LD2

Flash Modes

Nominal Current

Nominal Voltage Steady High

Powe

Steady Low

Powe

Flashing

1Hz

24Vdc 240mA 134mA 110mA

M4 x 12mm

Grub Screw

Lid

Moulding

O-Ring