European Safety Systems Ltd. Impress House, Mansell Road, Acton, London W3 7QH www.e2s.com Tel: +44 (0)208 743 8880

Document No. D190-00-101-IS Issue 3 28-11-2022 Sheet 3 of 8

5) Specific Conditions of Installation

ATEx/IECEx & UKEx Installations:

The cable entries have two M20 x 1.5 – 6H entry thread and a

single ½” NPT thread. If the installation is made using cable

glands, only suitably rated ATEx/IECEx or UKEx certified cable

glands must be used. They must be suitable for the type of

cable being used and also meet the requirements of the

current installation standards EN 60079-14 / IEC60079-14.

If the installation is made using conduit, openings must have a

sealing fitting connected as close as practical to the wall of the

enclosure, but in no case more than the size of the conduit or

50mm, whichever is the lesser.

Any unused cable entries must be closed with suitably rated

and UKEx certified blanking plugs.

For high ambient temperatures the cable entry temperature

may exceed 70ºC or the cable branching point temperature

may exceed 80ºC and therefore suitable heat resisting

cables and cable glands must be used, with a rated service

temperature at least as stated below:

NEC / CEC Installations:

The cable entries have two M20 x 1.5 – 6H entry thread and a

single ½” NPT thread. If the installation is made using cable

glands, only suitably rated and UKEx certified cable glands

must be used. They must be suitable for the type of cable

being used and also meet the requirements of the current

installation standards for NEC & CEC.

If the installation is made using conduit, openings must have a

sealing fitting connected within 18” of enclosure.

Any unused cable entries must be closed with suitably rated

and certified blanking plugs.

All Installations:

The plastic horn is not anti-static and the metallic enclosure has a

non-conductive coating. These may generate an ignition-capable

level of electrostatic charges under certain extreme conditions. The

user should ensure that the equipment is not installed in a location

where it may be subjected to external conditions that might cause a

build-up of electrostatic charges on non-conducting surfaces.

Only the explosionproof cover is to be used for access to the

enclosure for installation, service and maintenance.

6) Specific Conditions for Safe Use

Flameproof threaded joints and cemented joints are not permitted to

be repaired.

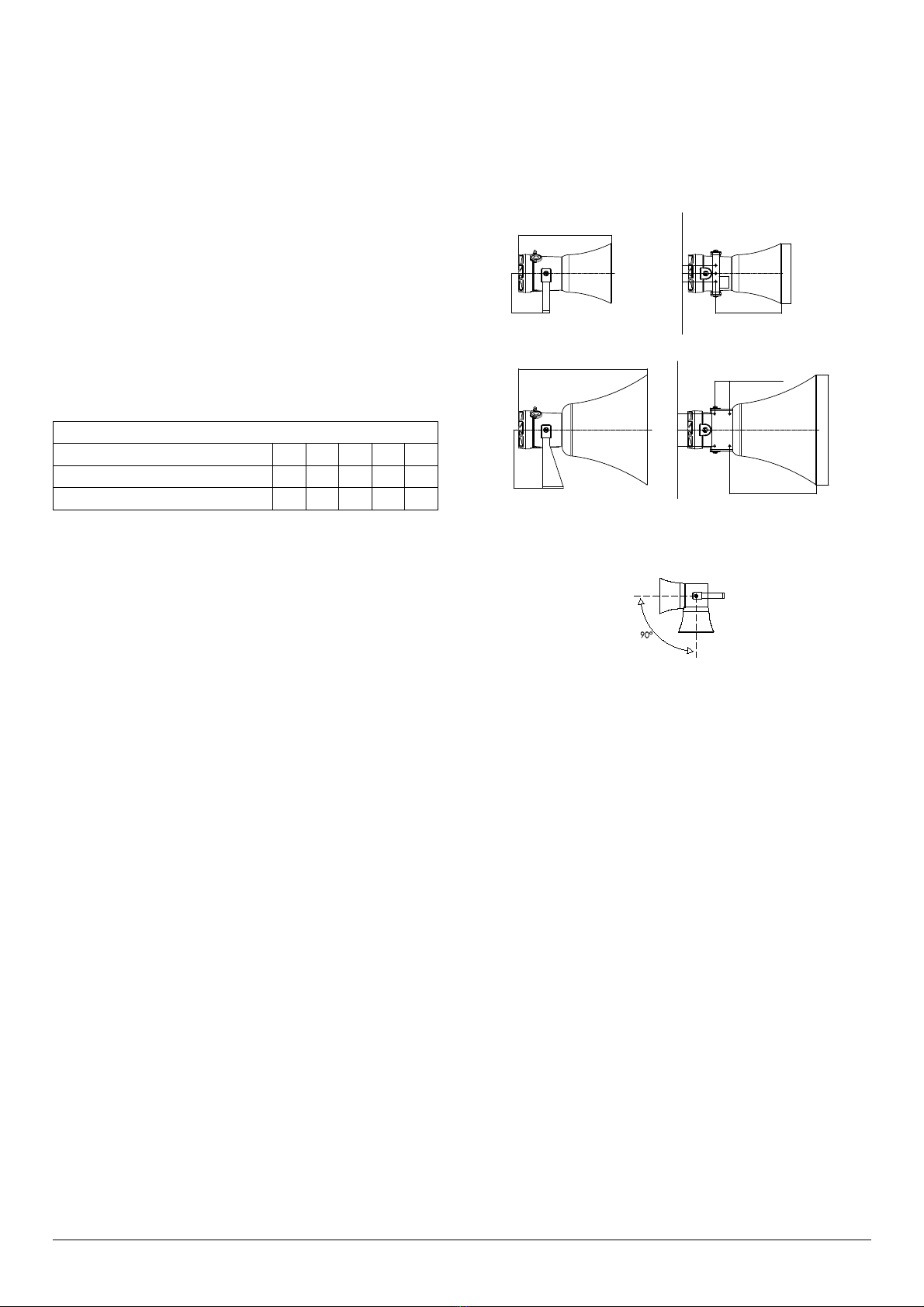

7) Product Mounting and Access

7.1 Mounting

The D1x Alarm Horn may be secured to any flat surface using at

least two of the three or four 7mm fixing holes. The enclosure

provides IP66 protection and is suitable for installation in

exterior locations providing it is positioned so that water cannot

collect in the horn, and the cable entry is sealed.

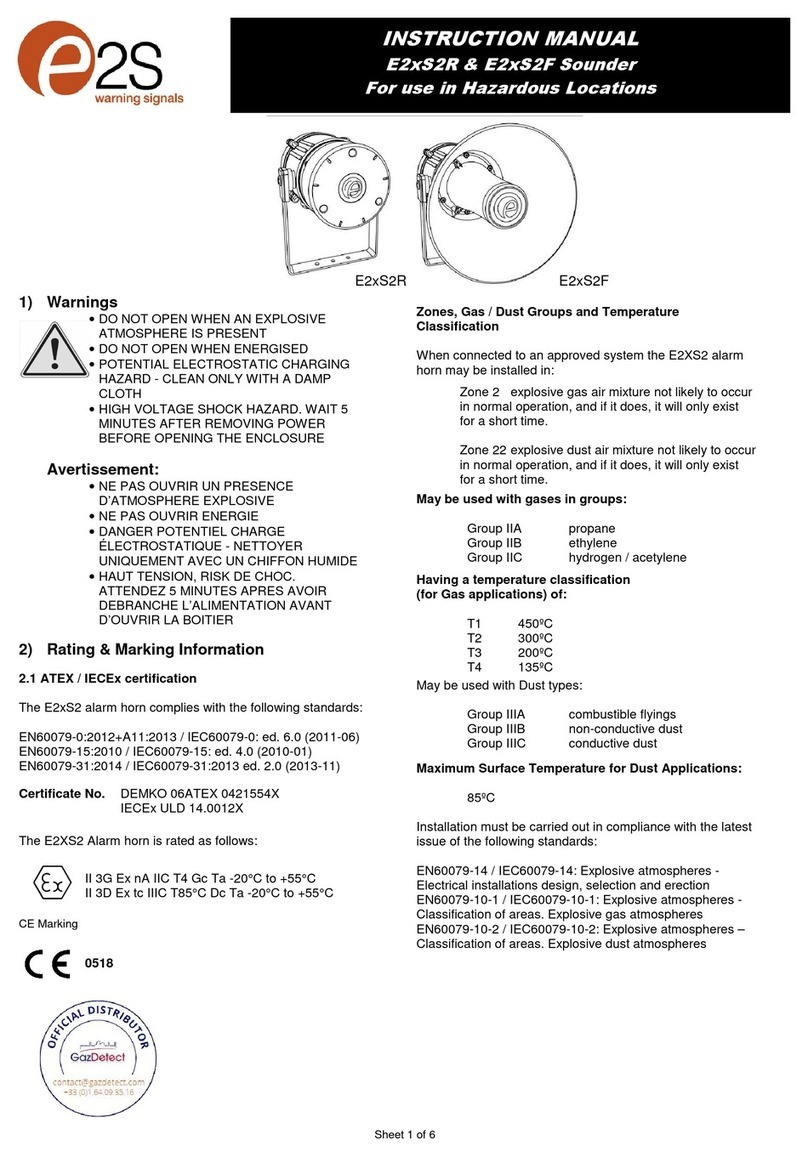

145 [5.71 in.]

30 [1.18 in.]30 [1.18 in.]

236.9 [9.33 in.]

219.6 [8.64 in.]

335.9 [13.23 in.]

314.5 [12.38 in.]

403.2 [15.87 in.]

465.9 [18.34 in.]

55 [2.17 in.]

59 [2.32 in.] 59 [2.32 in.]

215 [8.46 in.]

Fig 1: Mounting Locations

The Equipment must not be installed with the horn facing upwards

of horizontal.

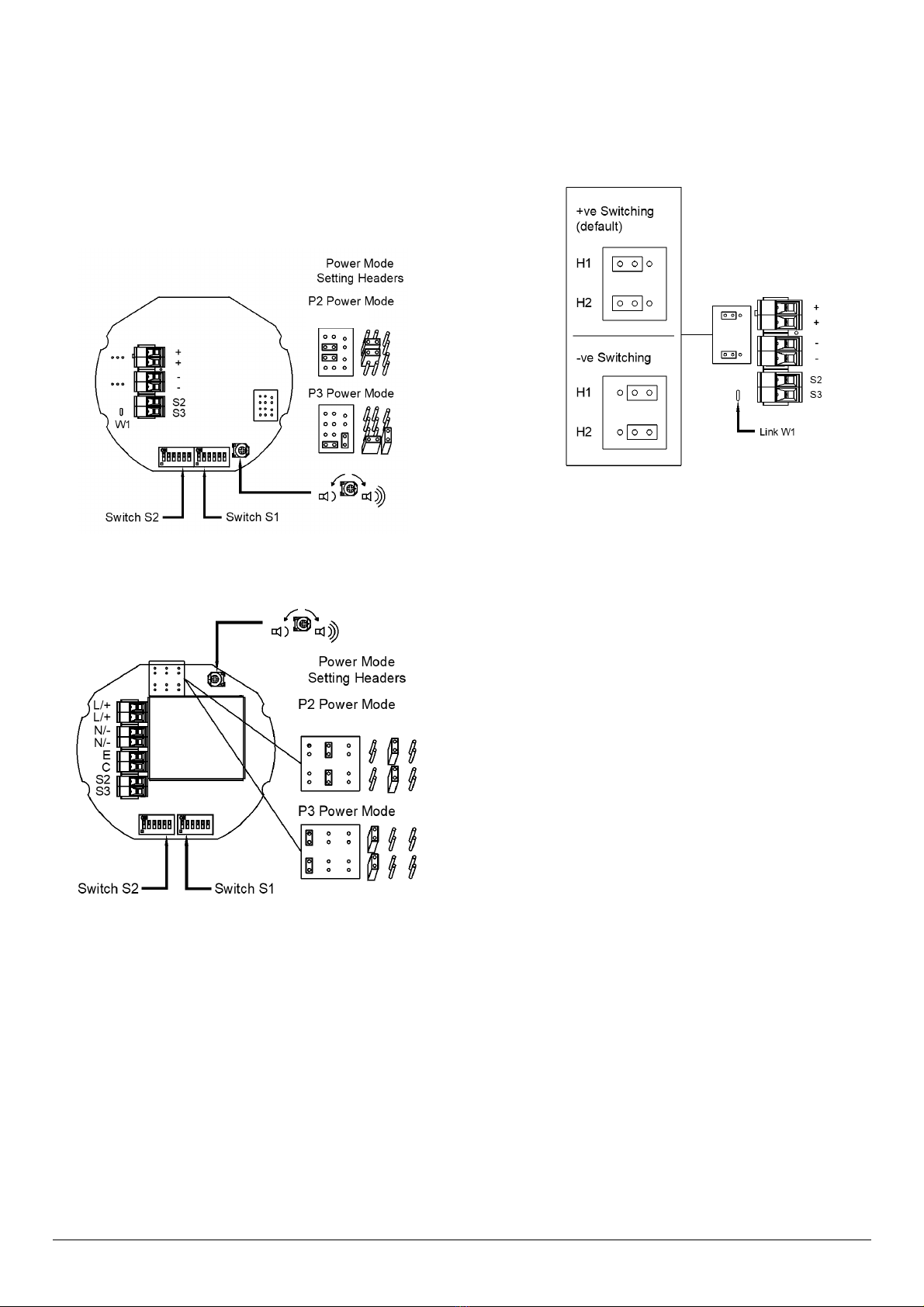

7.2 Installation procedure

a. Secure the D1x unit to a flat surface via the three 7mm

fixing holes in the mounting bracket.

b. Remove the explosionproof cover of the alarm horn by

unscrewing it, taking care not to damage the

explosionproof threads in the process (Refer to section

7.4).

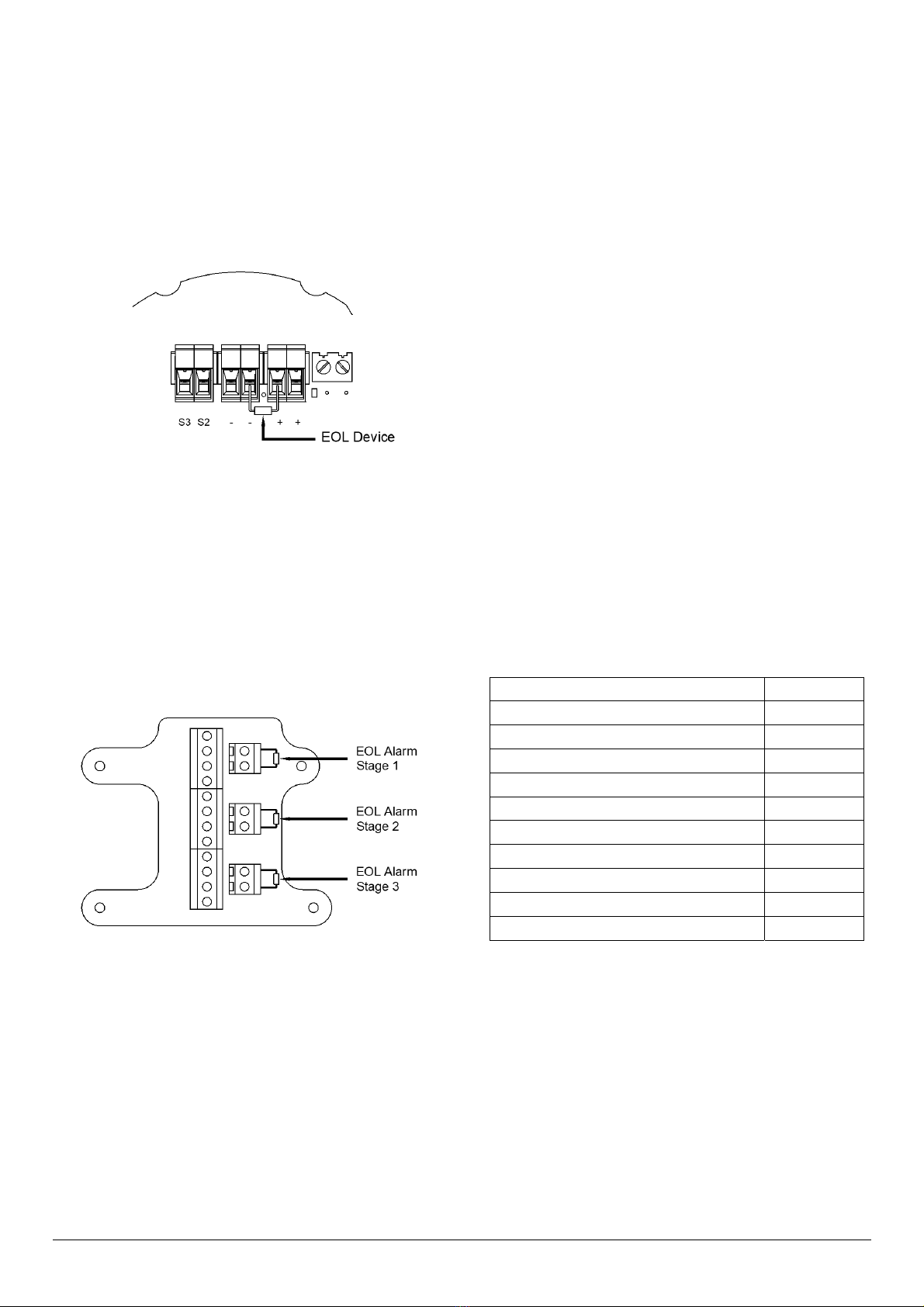

c. Fit an M20/NPT suitably rated cable gland or conduit entry

into the hole in the enclosure and connect the field wiring

to the appropriate alarm horn terminals as shown in D190-

06-005 (AC) or D190-06-001. (DC). The power supply

terminals are duplicated so that units may be connected

in parallel. An end of line monitoring resistor may be fitted

to DC units only (see section 10). If the second and third

M20/NPT entries are not used, suitably rated stopping

plugs must always be fitted.

d. Replace the explosionproof cover of the loudspeaker,

taking care not to damage the explosionproof threads.

Tighten fully.

7.3 Hornless Variants

The D1x Sounder is also available as a variant with no horn fitted

in the factory. The Horn threaded nose portion has a fitment

thread of 1-3/8” – 18 UNF (to BS1580 or ANSI B1.1). The

customer is responsible for sourcing and correctly fitting a suitable

horn that meets all of the relevant safety requirements.

Minimum Ratings of Cables & Cable Glands

Max Ambient Temp (°C) 55 60 65 70 75

D1xS2

DC024-A Min. Rating (°C) 70 75 80 85 90

D1xS2-AC230-A Min. Rating (°C) 70 75 80 85

Table 2: Min. Ratings of Cables & Cable Glands.

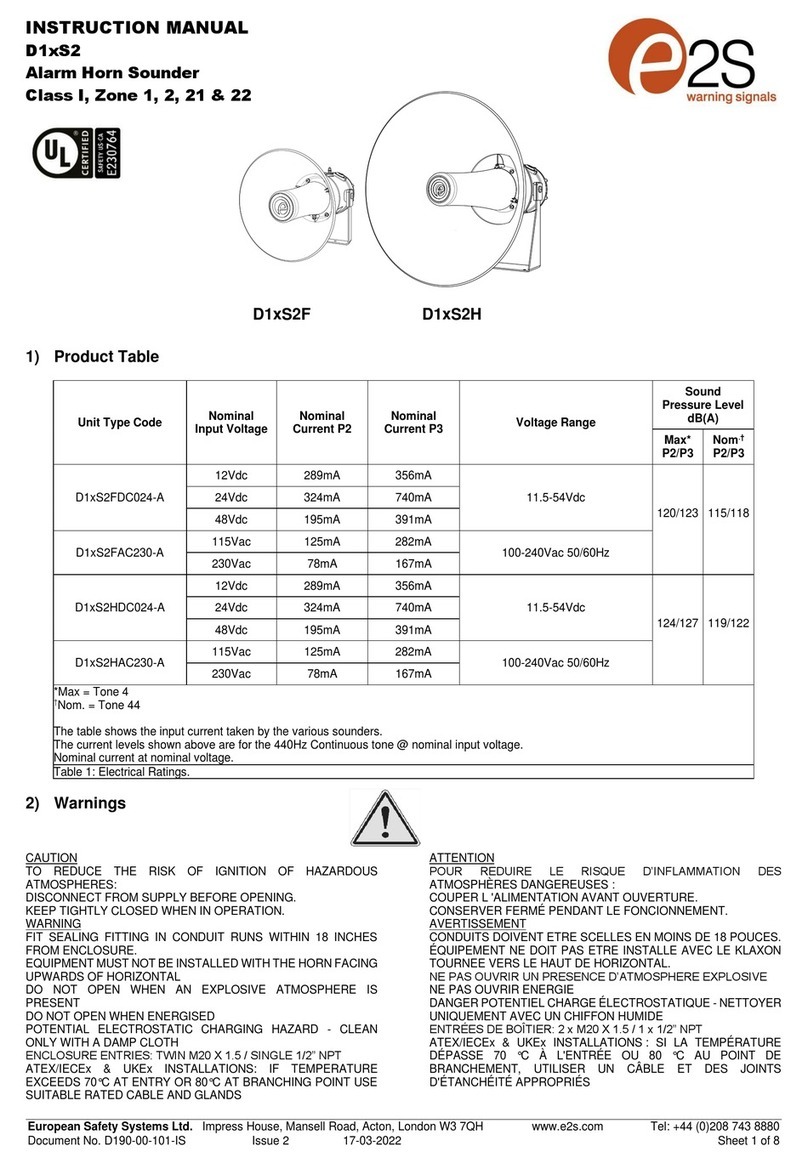

D1xS2F

D1xS2H