Ecom EN2 User manual

Operating Instructions

Intelligent analysis!

Page 2 ecom-EN2

Index Page

Important Hints 3

1. Instrument Design 5

2. Remote monitor ecom-R 7

3. Gas Cooler (option) 9

4. Power Supply 10

5. Data Memory 10

6. Instrument Start 11

7. Input or Selection of combustion plants 13

8. Flue Gas Analysis

8.1. Gas analysis 16

8.2. CO measurement (gas path check) 19

8.3. O

2

check 20

8.4. Draught measurement 20

8.5. Flow measurement (Option) 21

8.6. Soot dot...Oil trace 22

8.7. Measurement record and printout 23

8.8. After Measurement 24

9. Mean Value Measurement 25

10. Adjustments 27

11. Control 31

12. Data Processing

12.1 Communication 32

12.2. Data logger 33

12.3. Data logging with DASNT2 34

12.4. Data processing with DAS5 34

12.5. Data processing with Remote Display App 35

13. Diagnostics

13.1. Fault diagnostic 36

13.2. delta-T measurement 38

13.3. Heating check (Option) 38

13.4. 4 Pa measurement (Option) 42

13.5. Pressure Tests (Option) 43

14. Maintenance Tips 50

15. Technical Data 53

16. FAQ 54

ecom-EN2 Page 3

Important Hints

The ecom

-

EN2 meets the requirements

of the DIN EN 50379 Part 2.

Observe the following minimum times in order to

get correct measurement values:

- 1 min. for sensors calibration at fresh air

- 2 min. for stable measurement values

The following subst

ances impair the instr

u-

ment´s operation:

- Solvent-containing vapours as:

- cleaning agents

- degreasers

- wax polishes

- adhesives

do contain

- Formaldehyde

Adjustments at burners and boilers

should be made only by specialists

who are familiar with these installations.

1. Charge the internal

battery

regularly.

(an unused analyser should be charged at least 1 x per month)!

2. Never store the unit with a discharged battery!

The ecom

-

EN2 should not be used for

continuous emission control!

Page 4 ecom-EN2

Do not lock fresh air opening

for fresh air pump!

Fresh air opening

ecom-EN2 Page 5

1. Instrument Design

Connection air

temperature

Slot for multi-

media card

Connections for

Pa pressure sensor

Connection gas

temperature

Connection

USB

Condensation trap

(with peltier cooler)

with fine dust filter

Connection

sampled gas

Connection

draught

Connection

pressure

Connection

AUX

Integral

printer

Battery and

sensors com-

partment

Graphic

display

Optical flow

control

Connection

charger

Page 6 ecom-EN2

Keyboard

ESC key

(quit/

exit menu)

In the input mode, the keys are

used for numerical inputs

Enter key

(confirm

selection)

Cursor keys

(Up/Down/Right/

Left/Scroll)

Values

recording

Print key

(access to

printing menu)

ON / OFF

key

Info key

(access to

control menu)

Function keys

(function shown on

display)

ecom-EN2 Page 7

2. Remote monitor ecom-R

Connection with ecom-EN2

(the ecom-R is only connectable with one ecom-EN2)

Program connection:

-switch on ecom-EN2 (only one instrument with Bluetooth near

the ecom-R )

-choose at the ecom-EN2 in menu „Adjustments/Internal/

Bluetooth“ the „ enhanced Protocol“

-switch on ecom-R (hold the red key approx. 1 s).

-hold the red key (approx. 5 s) until „Unpair:“ appears

-switch on ecom-R (programming will be done automatically)

-if there is no connection (READY does not appear at right bottom of

the display), switch ecom-R off and on again

Operating

ecom

-

EN2 must have Bluetooth option!

(possible data transfer distance approx. 10 m)

Change display:

Choose line

Adjust line

Store adjustment

Break off adjustment

Change display

Start printout

Choose display

Switch on/off ecom-R

(hold approx. 1 s)

READY = Connection exists

CALIB = EN2 in calibration phase

WAIT = Searching for connection

Battery voltage

Change functions

CO switch-off

Page 8 ecom-EN2

Battery Change

-open battery box (operate unlocking)

-take out used batteries

-put in new batteries (respect polarity)

-close battery box

Important: Always dispose of used batteries and accumulators in

official recycling containers only (e.g. in battery shops).

Model with integrated air temperature sensor

If there is no air temperature sensor connected at the ecom-EN2,

then the air temperature sensor of the ecom-R supplies the meas-

ured values.

Battery box

Batteries 1,5 V AA or

Batteries 1,2 V AA

Unlocking

Air temperature sensor

ecom-EN2 Page 9

3. Gas Cooler (option)

Exhaust gas with a temperature over the steam dew point (35 - 65

°C) is flown spiral via a long gas path thru a surface coated metal

body with good thermal conductivity. The gas radiates its heat to this

metal body. A Peltier element (semi-conductor cooling element)

flown by a continuous current is thermal connected with this body

and with a second metal body with cooling ribs and ventilation slots.

The flow thru the Peltier element creates a heat transfer from WARM

to COLD, drains the heat of the metal body flown by gas and con-

veys it to the outer cooling body. This heat is conveyed thru a vertical

forced ventilation to the surrounding air.

The condensation issued by the heat loss of the gas drops in a re-

ceptacle and is pumped out on request by a periodically working

hose pump.

By accumulator operation, the Peltier cooler can be switched off.

In the measurement menu press hereto <Enter>, select the menu

point „Peltier I/0“ and press again <Enter> (for Peltier cooler switch

on, just repeat this procedure).

Fan

WARM

COLD

Peltier

element

Gas

outlet

Gas inlet

Level

monitoring

Condensate

evacuation

The power needs

of the gas cooler being high,

the cooling performance shall be reduced

by accumulator operation!

Page 10 ecom-EN2

4. Power Supply

The ecom-EN2 comes with an external charger. The analyser can

also be powered via the internal accumulator for a while (6 V; 3.8

Ah). The accumulator recharge should be started when the instru-

ment requires to (acoustical warning and display indication). The

accumulator charging stand can be checked looking at the voltage

indication on the display (menu "Control" - Info key). The battery

warning is activated when the value „Accu“ is smaller than 5.7 V.

By 5.4 V the power operation via battery is no more possible; the

instrument must be further powered via the external charger.

5. Data Memory

The multi-media card enables the storage of punctual measure-

ments; the gathered values are written in a text file (J2KDV.txt). Data

format information is to be found in the appendix. The files can be

transferred to a PC via a card reader.

The following conditions must be fulfilled for using a multi-media

card:

- min. card volume 32 MB - max.32 GB (UHC)

- card formatted on 16 bit FAT or FAT32

- SD cards from SanDisk recommended

- PC with card reader

Used accumulators can either be returned

to us or brought to recycling stations of

public waste disposal companies

respectively to stores selling accumulators!

ecom-EN2 Page 11

Card insert

Insert the multi-media-card as shown.

Take care that the card does not stand

out and that it well hooks on.

6. Instrument Start

Never pull out cards during data record

- data loss and damaging of the

multi-media-card are possible!

Always position the probe in the exhaust pipe once

the calibration phase is over!

Always use a filtering system as per our recommend

a-

tion for combustion plants

firing solid combustibles!

ecom

-

EN2 with

filtering plate

ecom

-

EN2 with

washing bottle

Page 12 ecom-EN2

Once the instrument is switched on (key

<I/0>), the main menu is displayed.

6 sub-menus with the following func-

tions (non-visible sub-menus can be

called up while scrolling with the cursor

keys) are displayed:

- Gas analysis : Perform gas analysis

- Soot...Oil trace : Input of soot measurement results

- Data processing : Assign measurements / Data transfer

(only by inserted MM card)

- Adjustments : Modify instrument adjustments

- Control : Check operation state of instrument

- Diagnostics : Read-out of firing automate

(only in connection with ecom-AK) /

delta-T measurement / Heating check /

4 Pa test

To perform measurements, select with

the cursor keys the sub-menu "Gas

analysis" and confirm with <Enter>.

The instrument starts a 1- minute cali-

bration phase and it enquires if you wish

to use the data bank. If you want to

assign the sampled data to a specific

plant, so press <F1> (<F4> = no:

measurement will be performed without

assignment).

Fuel types acc. to 1

st

BImSchV

Fuel oil (B)

Natural gas (B)

City gas (B)

Coke oven gas (B)

Liquid gas (B)

Use the cursor keys to select the de-

sired fuel type and confirm with <En-

ter>.

Gas analysis

Soot..Oil trace

Data processing

Adjustments

Control

Diagnostics

Fuel type

Fuel oil (B)

CO2max

A1

B

15.4

0.50

0.007

Select: ↑↓

↑↓↑↓

↑↓

↵

↵↵

↵

Do you wish to

use the data

processing

JA

Auswählen:

<

↵

↵↵

↵

>

!

NEIN

ecom-EN2 Page 13

7. Input or selection of combustion plants

To call up plant data already recorded or to create a new file, the

following possibilities are available:

Create new (is automatically selected

by first use of a MM card): To create a

new file, a numerical number should be

assigned.

Select „Create new“ and confirm with

<Enter>. Input a random number (max.

16 figures) using the keyboard:

- use the cursor keys <Up/Down/Right/Left> to select

the figure (selected figure outlined by a black background)

- press <Enter> to accept the figure (press <F2> to delete

the last figure if needed)

- repeat this procedure until the desired number is complete.

Example: "25.09.2009"

Tip: We suggest a date-related input to easily find the data

record later on via the search function.

After confirming with <F1> it is possible to enter a text via the key-

board (max. 6 lines with 20 characters each) which is printed out and

can be used for data processing purposes. Proceed as follows:

- select text line 1 using the cursor keys <Up/Down> and

confirm with <Enter>

- select with <F3> the keyboard mode (4 keyboard modes

are available)

- select with the cursor keys <Up/Down/Right/Left> the desired

character (selected character outlined by a black background)

- press <Enter> to accept the character (press <F2> to delete the

last character)

- repeat this procedure until the desired text is complete.

Selection upon:

Search word

Memory number

Create new

Quit with: ESC

Page 14 ecom-EN2

- proceed as follows to correct a character:

- press <F4> to interrupt the character selection

- use the cursor keys <Right/Left> to select the

character requiring correction

- activate with <F4> the character selection and correct character

- return with <F1> to character selection and call up next line for

process

The input is closed with <ESC> and the next available data record is

activated. Press <ESC> to return to the gas analysis menu.

Memory number: For check of the

plant already stored in the instrument,

the selection upon record number is

most appropriate.

Select „Memory number“ and confirm

with <Enter>. Input a random data rec-

ord number:

Example: "3" for data record number 3

- Press <Enter> once the input is completed to call up said data

record number. The cursor keys <Up/Down> enable the check of

the record numbers.

- Press <F1> to select the first record number and <F2> for the last.

- Press <F4> to delete the content of the selected record number.

- Press <Enter> to activate the record number.

- Finally press <ESC> to start the gas analysis.

Search word

Memory number

Create new

Selection upon:

Quit with: ESC

Input number

3

Please use the

numerical keys!

ecom-EN2 Page 15

Search word: If the plant code is known, it is possible to find the

plant data stored with help of a search machine.

Select hereto "Search word" and confirm with <Enter>. Using the

software keyboard, input at least 3 connected figures of the plant:

Example: "25.09" for plant code 25.09.2009

After input completion, press <F1> to

start the search. All files matching this

code will be filtered. The resulting selec-

tion can be scrolled using the cursor

keys (F1 for selection start, F2 for selec-

tion end). Once found, activate the de-

sired data record with <Enter>. The last

measurement on this plant can be

viewed pressing <Enter> / „View

memory“ / <Enter>. All measured and

calculated values can be called up on 5

display pages, using the cursor keys to

step thru.

Press <ESC> to escape the previous measurement data and the

recording of the current data can start.

Measurement available

Memory number 1

25.09.2009

Memory number 1

25.09.2009

12:15 25.09.09

O2 value in air

O2 value in air 12:15 25.09.09

Memory number 1

O2

19.5

%

CO

3

ppm

Draught

0.01

hPa

dT-measurement

dT-measurement 12:15 25.09.09

Memory number 1

T1

70.4

°C

T2

56.3

°C

dT

14.1

°C

Soot..Oil trace

Soot..Oil trace 12:15 25.09.09

Memory number 1

Boiler temp. : 65°C

1.Soot meas. : 0.5

2.Soot meas. : 0.3

3.Soot meas. : 0.7

Oil trace : NEIN

Gas analysis 12:15 25.09.09

Memory number 1

O2 3.2 %

CO2 13.1 %

CO 0 ppm

Eff. 92.5 %

Losses 7.5 %

Exc. air 1.18

T.Gas 184 °C

T.Air 20 °C

CO measurement 12:15 25.09.09

Memory number 1

O2

17.5

%

CO 0%

738

ppm

CO

123

ppm

Exc. air

7.00

Page 16 ecom-EN2

8. Flue Gas Analysis

8.1. Gas analysis

After the 1-minute calibration phase, the instrument switches over to

the measurement mode. The gas measurement values can be

viewed on 4 display pages. Use the cursor keys to scroll the pages.

Pressing <F1> enables to switch, from the values display, to a menu

point selected before or on „Standby“ (see chapter Adjustments).

Possible menu points are: Soot...Oil trace, Data processing, View

memory, Display values, Fuel type, Efficiency (K), Internal, Adjust-

ments. Furthermore you can switch back from any random menu

point to the values display with <F1>.

Press <F2> to print out the values simultaneously to their recording

in the intermediate memory.

Press <F3> to cut the CO sensor from the gas path so that it is pro-

tected against too high concentrations.

Pressing <F4> also enables to switch, from the values display, to a

menu point selected before or on „Standby“ (see chapter Adjust-

ments). Possible menu points are: Soot...Oil trace, Data processing,

View memory, Display values, Fuel type, Efficiency (K), Internal,

Adjustments (back to values display with <F1>).

Hotkey

Key <F1>

Re

-

calibrate the instrument after each

measurement (after one hour at the latest)

to keep the accuracy of the results!

Hotkey

Taste <F4>

Store and print

values

key <F2>

Switch

-

off CO

sensor

key <F3>

Symbol

cooler

ON/OFF

O2

3.2

%

CO2

13.1

%

T.Gas

184

°C

T.Air

20

°C

BImSchV

ecom-EN2 Page 17

The position of the measured and calculated values (gas analysis

sub-menu) on the display pages is free selectable. For alteration of

the existing succession, proceed as follows:

- Press <Enter> / „Display values“ / <Enter> to activate the

function

- select line with cursor keys (Up/Down)

- select desired parameter with cursor keys (Right/Left)

- repeat procedure until desired layout is completed

- Press <Enter> to deactivate the function

Connect the sampling tubing on the instrument to the plug „Connec-

tion gas“. Position the sampling probe in the exhaust channel, so that

the thermocouple is fully surrounded with the gas (see drawing).

Perform the measurement in the core stream of the exhaust gas

channel (probe placed in the hottest gas temperature area). A trend

indication for T.Gas easies the core stream search. As long as the

display shows an arrow in upwards direction, the measured tempera-

ture increases, it means the probe tip moves towards the core

stream center. If an arrow in downwards direction is displayed, it

means you move the probe away from the core stream and the tem-

perature sinks. If no temperature change is shown for at least 3 sec-

onds, so the trend indication will disappear.

Core stream search

Gas stream

Protection bow

Probe tip

O2 3.2 %

CO2 13.1 %

CO 0 ppm

Eff. 92.5 %

Losses 7.5 %

Exc. air 1.18

T.Gas 184 °C

T.Air 20 °C

BImSchV

Page 18 ecom-EN2

CO

2

, efficiency, losses, excess air and dew point are calculated val-

ues. They can only be calculated if realistic values for the basic pa-

rameters like O

2

and the temperatures are available. It must be as-

certained that:

O

2

< 20,5 % and T.Gas - T.Air > + 5 °C

are given. The dew point can only be calculated accurately if, in the

menu "Adjustments", the current barometric air pressure value has

been inputted. If the gas temperature falls below the dew point (be-

tween 25 and 65 °C), so efficiency will be calculated with condensa-

tion gain. In this case a (K) is displayed after „Efficiency“.

Correct measurement values are displayed first after a short delay,

necessary for the gas transport and the build-up of a stable electro-

chemical reaction to the sensors. This time period lasts approx. 1 to

1.5 minute. For recording, printout and evaluation, wait until the val-

ues do not change anymore. If deviations higher than 2 ppm still

occur by the gas values, they can be due to unstable pressure condi-

tions in the exhaust channel.

If the measurement values are stable

and the results can be printed out, press

the key <Record> (disk symbol) to

transfer the values in the intermediate

memory (caution: store separately gas

analysis, CO, O

2

check and draught

measurements). They will be kept there

for a later printout and, if need be, for a

final data record storage.

If a printout of the values should be made simultaneously to the in-

termediate recording, so press <F2> (the complete content of the

intermediate memory will be printed).

Measurement stored in

intermediate memory

O2 3.2 %

CO2 13.1 %

CO 0 ppm

Eff. 92.5 %

Losses 7.5 %

Exc. air 1.18

T.Gas 184 °C

T.Air 20 °C

BImSchV

ecom-EN2 Page 19

The CO sensor is protected against overload thanks to an internal

programme. If the 4000 ppm limit value is exceeded, so a purging

pump is activated which provides the sensor with fresh air. After

sufficient purging time (X behinds CO disappears) the sensor can be

reintegrated into the measurement system with <F3> (if you choose

„Yes“ at „Adjustments“ / „Internal“ / „CO-Automatic“ the CO

sensor switches to measurement automatically). The sensor can

also be manually be excluded from the measurement system with

<F3>.

8.2. CO Measurement (gas path check)

The gas channel check, called also CO measurement, is used for the

technical check of gas-fired plants in regards of safety aspects.

Hereby the CO concentration in the gas channel is measured after

the flow safety device and calculated on an undiluted value (oxygen

rest content in flue gas = 0%). As the gas conditions after the flow

safety device are no more homogeneous because of the flow in of

secondary air and consequently the core stream measurement can

be erratic, the analysis of the exhaust gas is performed along the

totality of the exhaust pipe diameter. A multi-hole probe (optional

accessory) is hereby used as sampling probe.

The calculated value shown on the line

„CO 0 %“ corresponds to the measured

CO concentration supposed the oxygen

content would amount 0% by the same

exhaust gas volume. It is consequently

the undiluted CO content in exhaust

gas. If the values indication is stable,

press <Record> to store the result in

the intermediate memory. If a printout of

the values should occur simultaneously

to the recording in the intermediate

memory press <F2> (the complete con-

tent of the intermediate memory will be

printed out).

Measurement stored in

intermediate memory

O2

17.5

%

CO 0%

738

ppm

CO

123

ppm

Exc. air

7.00

CO

-

Messung

Page 20 ecom-EN2

8.3. O

2

check

This measurement is performed by room-independent plants like

gross calorific value plants. It is determined if exhaust gas flows into

the combustion air (O

2

content drops down / CO content can be pre-

sent) and herewith influence on the combustion quality.

For this analysis, a special multi-hole

probe (optional accessory) should be

used. If the value indicated is stable,

press <Record> to store the value in

the intermediate memory. If a printout of

the values should occur simultaneously

to the recording in the intermediate

memory, press <F2> (the complete

content of the intermediate memory will

be printed out).

8.4. Draught Measurement

A trend indication for the draught conditions in the exhaust channel

can already be viewed during the gas analysis. Nevertheless the

value for the chimney draught will not be stored together with the gas

values while pressing <Record> because the differential pressure

sensor tends to drifts because of its sensibility.

For an exact measurement, it is consequently advised to re-calibrate

this sensor just before sampling and documenting the value.

The display shows the current value as

well as the recommendation to re-set

the zero point of the sensor. Disconnect

the draught hose from the instrument for

a short moment and press <F4>. The

sensor is herewith re-calibrated.

O2 value in air

O2

19.5

%

CO

3

ppm

Draught

0.01

hPa

O2 val. in air

Measurement stored in

intermediate memory

Pressure

Draught

-0.12

hPa

Recorded value:

--

.

--

hPa

Other manuals for EN2

2

This manual suits for next models

1

Table of contents

Other Ecom Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

ANDERSON-NEGELE

ANDERSON-NEGELE FMQ operating manual

BURG WATCHER

BURG WATCHER ProfiScale CROSS operating instructions

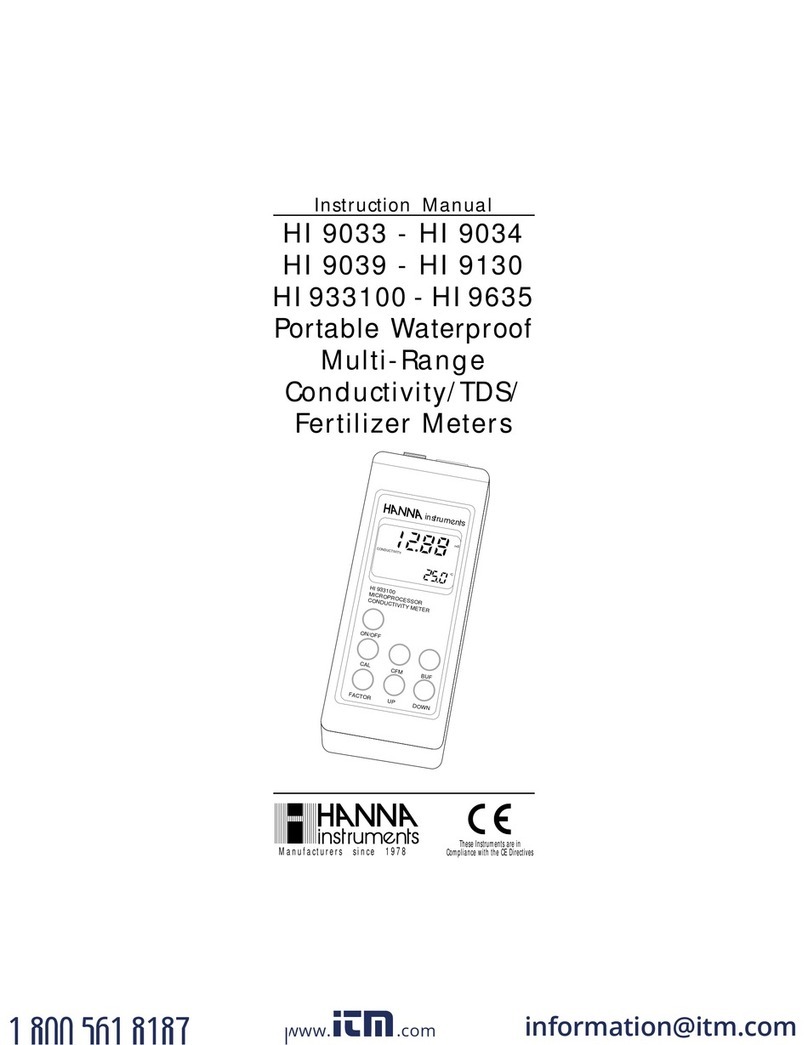

Hanna Instruments

Hanna Instruments HI 9033 instruction manual

PCE Health and Fitness

PCE Health and Fitness PM 3 user manual

Hanna Instruments

Hanna Instruments HI 99161 instruction manual

Tunix

Tunix EO-250 instruction manual