Ecom EN3 User manual

Operating Instructions

The ecom-EN3 meets the requirements of the

DIN EN 50379 Part 2

Page 2 ecom-EN3

SAFTEY INSTRUCTIONS

Please observe all safety instructions in this manual carefully in order to avoid danger and

damage to people and property values.

REGULATIONS

The ecom-EN3 meets the requirements of:

- DIN EN 50379 Part 2

- VDI 4206 Sheet 1

Observe the relevant valid standards regulations and guidelines when working with the

instrument!

TARGET GROUP

This manual is intended exclusively for authorized professionals.

Symbols

DANGER

Indicates that material damage can occur.

Indicates how the hazard can be avoided.

In both cases it is stated how the danger can be avoided.

Hints

Hints are marked with an information symbol.

Text sections marked with an arrow call for an action.

WARNING

Adjustments at burners and boilers should be made only by specialists who

are familiar with these installations.

WARNING

Indicates that personal injury or even life-threatening injury may occur.

Indicates how the hazard can be avoided.

ecom-EN3

Page 3

Information on the instrument

INTENDED USE

The ecom-EN3 is designed for the following applications:

- Analysis of exhaust gases from combustion processes in combustion engines

and combustion plants in the context of control measurements

- Analysis of pressure differences in combustion engines and combustion plants

The unauthorized use leads to the exclusion of any liability claims.

LIFE EXPECTANCIES SENSORS AND BATTERY

Following life expectancies apply to sensors and battery:

- O2 sensor: approx. 4 years

- CO sensor: approx. 4 years

- Li-Ion battery: approx. 2 years

CE DECLARATION OF CONFORMITY

The product complies with the relevant directives and is therefore CE marked. The

conformity declaration can be requested from the manufacturer.

HINT

Strong electromagnetic fields can impair the function of the measuring instrument.

Make sure that the measuring instrument is not exposed to strong

electromagnetic radiation sources.

DISPOSAL

- Dispose the packaging material of the instrument in an environmentally sound manner.

- Old electrical equipment must be disposed in an environmentally sound manner by an

authorized body. On request we take back your old instrument purchased from us

and guarantee for an environmentally friendly disposal.

- Defective batteries can be dispensed both at the factory and at the collection

points of public waste disposal companies or at points of sale for rechargeable

batteries!

WARNING

The ecom

-

EN3 is explicitly NOT intended for the following applications:

- CONTINUOUS analysis of exhaust gases from combustion processes

- Use as a safety device or safety alarm device in gaseous environments

or processes

DANGER

The following substances impair the instrument´s operation:

- Solvent-containing vapours from cleaning agents

degreasers wax polishes adhesives

-

Formaldehyde

Page 4 ecom-EN3

DANGER

Electrostatic discharge!

Electrostatic discharge can lead to damage to electronic components!

Before handling the housing ensure that you are unloaded. To do

this touch a grounded component (eg water pipes radiators etc.).

WARNING

Electric shock!

Current

-

carrying components at

open housing

!

Before opening the instrument housing disconnect the

instrument from the mains supply at all poles.

WARNING The instrument is operated with a Li-Ion battery!

The replacement of the battery must be carried out only by qualified

personnel or by an ecom authorized service center.

ecom-EN3

Page 5

Page 6 ecom-EN3

Content

Information on the instrument 3

1. Instrument Design 8

1 1 ecom-EN3/-R, Transport variant aluminium-framed transport case 8

1 2 ecom-EN3-F, Transport variant professional case 9

1 3 ecom-EN3, Keyboard controls 10

1 4 ecom-EN3, Connections at the instrument 11

1 5 ecom-EN3, Option heated probe for soot measurement 12

1 6 ecom-EN3, Option hand soot pump set 13

1 7 Gas Cooler (Option) 14

1 8 Data Memory 15

1 9 ecom-EN3, Option Interfac Wi-Fi (WLAN) 16

1 10 ecom-EN3, Option interface BLE (Bluetooth Low Energy) 16

2. Measurement Preparations 17

2 1 Turn on the instrument and check the battery 17

2 2 Navigation in the menu 18

2 3 Calibration of the sensors, use of the database and fuel type selection 19

3. Carry out gas analysis 21

4. Measurement procedure gas analysis 22

4 1 Gas analysis 22

4 1 1 Adaptation of the displays for gas analysis 23

4 1 2 Positioning the probe, search the core stream 23

4 1 3 Printing measured values 24

4 1 4 CO-Overload Protcektion 25

4 2 Measurement procedure gas analysis: CO measurement 26

4 3 Measurement procedure gas analysis: O2 Check 27

4 4 Measurement procedure gas analysis: Draught measurement 27

4 5 Measurement procedure gas analysis: Flow measurement pitot tube (option) 28

4 6 Measurement procedure gas analysis: Soot Oil trace 28

4 6 1 Soot measurement 29

4 6 2 Oil trace 29

4 7 Measurement procedure gas analysis: Data processing 30

4 7 1 Create new 30

4 7 2 Memory number 31

4 7 3 Search word 32

5. Measurement procedure mean values 33

6. Measurement procedure Diagnostics 35

6 1 Fault diagnostic 35

6 2 delta-T Measurement 37

6 3 Heating Check (option) 38

6 4 4 Pa Measurement (option) 41

6 5 Pressure Tests (option) 42

6 5 1 Pressure Test 43

6 5 2 Loading Test 44

6 5 3 Tightness Test 45

6 5 4 Usage property 46

ecom-EN3

Page 7

7. After Measurement 48

7 1 Save measurement, print measurement 48

7 2 To-Dos before switching off 49

8. Control 50

9. Adjustments 51

10. Data processing 56

10 1 Storage on MM card 56

10 2 Data logger 57

10 3 Data connection to PC 58

10 3 1 Data recording with PC Software ecom-DAS NT 2 58

10 3 2 Data recording with PC Software ecom-DAS 5 59

10 3 3 Data recording with PC Software: Import and Export of Data 60

10 4 Data recording with App via WiFi 61

10 5 Data recording with App via BLE 62

11. Maintenance Tips 63

11 1 Fine dust filter 63

11 2 Gas sensors 64

11 3 Probe and tubing 64

11 4 Printer paper 65

11 5 Air leak test 66

12. Technical Data 67

Page 8

ecom-EN3

1. Instrument Design

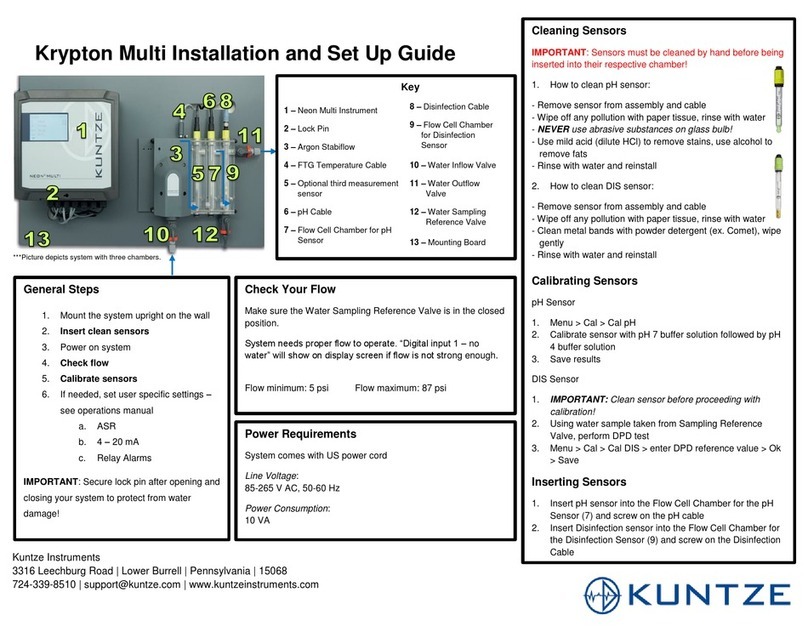

1.1 ecom-EN3/-R Transport variant aluminium-framed transport case

1

Holding clamp for

the probe

2

Graphic display

3

Slot for multi-media

card (SD)

4

onnection USB

5

onnections for Pa

pressure sensor

6

onnection pressure

7

Battery and sensors

compartment

8

onnection sampled gas

9

onnection draught

10

ondensation trap (with

peltier cooler) with fine

dust filter

11

onnection gas temperature

12

onnection air

temperature

13

Integral thermal printer

14

onnection AUX

1

2

3

4

5

6

7

8

9

10

11

12

13

14

ecom-EN3

Page 9

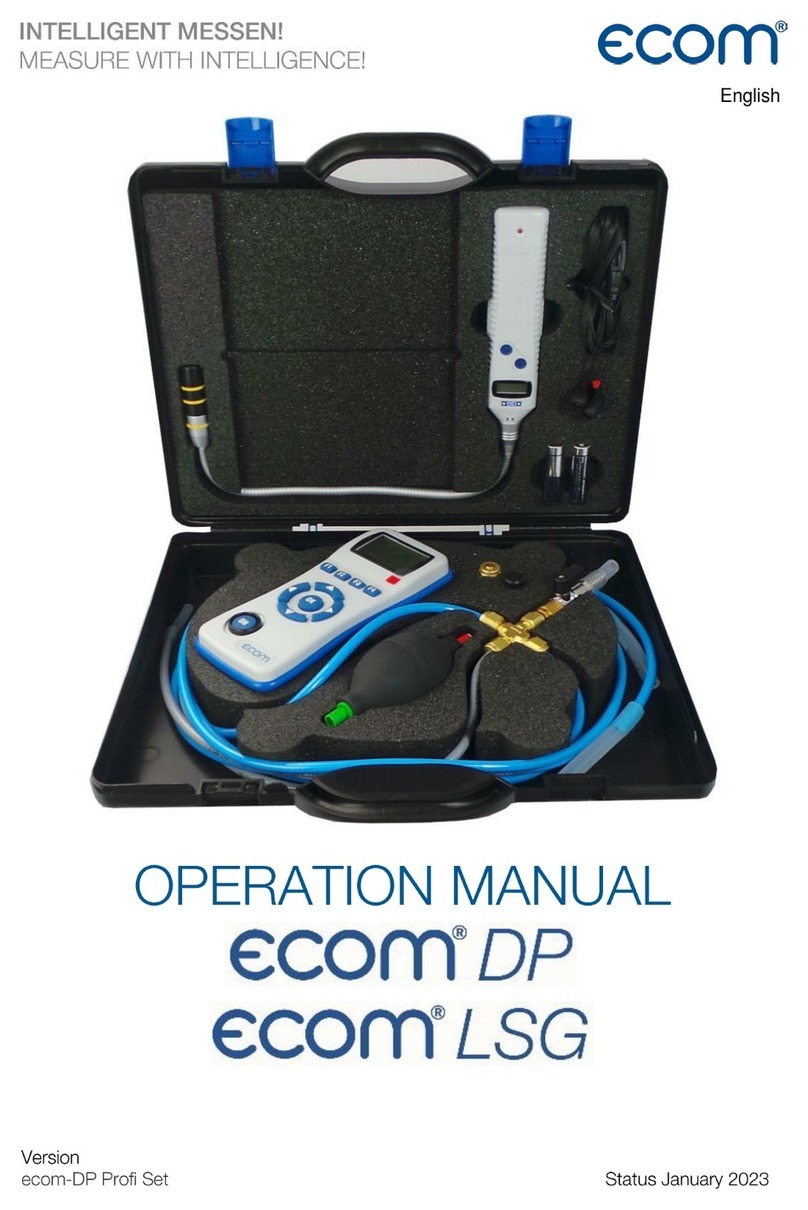

1.2 ecom-EN3-F Transport variant professional case

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1

2 3

4 5

6

7 8 9

10

11

12

13

14

Holding clamp for

the probe

Battery and sensors

compartment

Graphic display

onnection

Pressure

onnection USB

ondensation trap

(with Peltier cooler)

with fine dust filter

onnection air

temperature

onnections for Pa

pressure sensor

Integral thermal printer

onnection draught

onnection AUX

Slot for multi-media

card (SD)

onnection sampled gas

onnection gas

temperature

Page 10

ecom-EN3

1.3 ecom-EN3 Keyboard controls

5

8

9

10

11

12

1

2

3

4

6

7

1 2 3

4 5 6

7

8

9

10

11

12

onnection LED (active with

existing BT or WiFi connection)

Info LED to display the

device status

Battery LED to display the

charge state

Function key (function

shown on display)

Enter key (confirm

selection)

Print key

ES key (quit/exit menu)

ursor keys

(Up/Down/Right/Left/Scroll)

ON / OFF key

Digital flowmeter

Save key

Info key (access to control

menu)

ecom-EN3

Page 11

2 3

5 6

8

1.4 ecom-EN3 Connections at the instrument

onnection sampled gas onnection draught onnection gas temperature

onnection air temperature onnection AUX onnection Pa-Sensor

onnection pressure Slot for multi-media

card

onnection

USB

5

1

2

3

4

6

7

8

9

1

4

7 9

Page 12

ecom-EN3

1.5 ecom-EN3 Option heated probe for soot measurement

Heated probe for soot measurement

In order to perform a measurement of the soot content in the flue gas from oil firing systems,

a filter paper is introduced into the exhaust path of the probe where the soot deposits during

the measurement

On the basis of the deposited amount of soot on the filter paper (blackening), it is possible to

compare optically with a scale, which is the soot number This makes it possible to evaluate

the amount of soot in the flue gas

The filter paper is heated in the probe to prevent the flue gas from cooling too much This

cooling of the flue gas would lead to condensation of water vapour from the flue gas and will

distort the result of the measurement

Hint

As an alternative to the heated probe a hand soot pump can be used. The

possible condensation of water vapour is however not prevented with a hand

soot pump.

Hint

For further information on the procedure for soot measurement with the heated

probe please refer to chapter "4.7 Soot...Oil trace"

ecom-EN3

Page 13

1.6 ecom-EN3 Option hand soot pump set

Hand soot pump set

In order to perform a soot measurement in the flue gas from oil firing systems, a hand soot

pump can be used

By a prescribed number of suction strokes with the hand soot pump, a defined amount of flue

gas is drawn through an inserted filter paper On the basis of the deposited amount of soot

on the filter paper (blackening), it is possible to compare optically with a scale, which is the

soot number This makes it possible to evaluate the amount of soot in the flue gas

Hint

The hand soot pump is TÜV tested and characterized by high quality in its

processing and construction. This guarantees a long-term reliable function.

Hint

As an alternative to the hand soot pump a heated probe can be connected

directly to the measuring instrument. With this heated probe the possible

condensation of water vapour and thus falsification of the measuring result

can be reliably prevented.

Hint

For further information on the procedure for soot measurement with the hand

soot pump please refer to the manual for the hand soot pump set.

Page 14

ecom-EN3

2 3

1.7 Gas Cooler (option)

Hint

The ecom-EN3-F transport variant professional case is standard with a gas

cooler.

Gas outlet Gas inlet Level monitoring

ondensate

evacuation

Peltier element Fan

Exhaust gas with a temperature over the steam dew point (35 - 65 °C) is flown spiral via a

long gas path thru a surface coated metal body with good thermal conductivity The gas

radiates its heat to this metal body A Peltier element (semi-conductor cooling element) flown

by a continuous current is thermal connected with this body and with a second metal body

with cooling ribs and ventilation slots

The flow thru the Peltier element creates a heat transfer from WARM to COLD, drains the

heat of the metal body flown by gas and conveys it to the outer cooling body This heat is

conveyed thru a vertical forced ventilation to the surrounding air

The condensation issued by the heat loss of the gas drops in a receptacle and is pumped out

on request by a periodically working hose pump

Hint

When the gas cooler is active the power requirement of the instrument

increases considerably. Therefore the cooling capacity of the gas cooler in the

battery operation is reduced.

Hint

The gas cooler can be deactivated in battery operation.

To deactivate the activated gas cooler press the <Enter>

key when the measuring menu is active. Choose the menu

point "Peltier I / 0" and press the <Enter> key again.

To reactivate the deactivated gas cooler repeat the

above steps.

1

2

3

4

5

6

1

4

5 6

ecom-EN3

Page 15

1.8 Data Memory

When an SD card is inserted into the device, point measurements and data logger records

can be stored

Insert SD card as shown

°

To start point measurements or data logger records, insert the SD card as

shown in the SD card slot and let it fully engage

Hint

The SD card must have the following characteristics:

- min. card volume 32 MB - max.32 GB (UHC)

- card formatted on 16 bit FAT or FAT32

WARNING

Never pull out cards during data record - data loss and damaging of the multi-

media-card are possible!

All values of a point measurement are stored in a text file with the name "J2KDV-xx txt" The

text file is stored automatically in the main directory of the SD card

All values of a data logger record are stored in a csv file with the naming

"J2KDL-xx csv" Sequential files are automatically numbered from 0 99

The data in the text file and the csv file are stored in the same structure

You will find further information on the data format in the chapter "Technical data"

The files can be transferred to a PC using a card reader Both file types can be imported or

opened using MS Excel

Page 16

ecom-EN3

1.9 ecom-EN3 Option Interface Wi-Fi (WLAN)

If the instrument is equipped with the Wi-Fi option, this interface can be used to display the

current measured values in an App of ecom The following functions can be used in the App:

- Live display of current measured values

- Export of stored measured values as * pdf or * csv

- Activate the function "Print measured values" on the measuring instrument

- Activate the function "fresh air purge CO sensor" on the measuring instrument

Hint

For the start-up of the Wi-Fi interface and for further information on the

corresponding settings please refer to the chapter "Adjustments".

1.10 ecom-EN3 Option interface BLE (Bluetooth Low Energy)

If the device is equipped with the BLE option, this interface can be used to display the current

measured values in an App of ecom The following functions can be used in the App:

- Live display of current measured values

- Export of the stored measured values as * pdf or * csv

- Activate the function "Print measured values" on the measuring instrument

- Activate the function "fresh air purge CO sensor" on the measuring instrument

Hint

For the start-up of the BLE interface and for further information on the

corresponding settings please refer to the chapter "Adjustments".

ecom-EN3

Page 17

2. Measurement Preparations

Hint

Make sure that before each measurement

- the device has no visible defects

- the measuring system is tight (see leak test chapter 11.5)

2.1 Turn on the instrument and check the battery

The instrument is switched on with the <I / 0> key

Hint

After switching on the instrument or before starting a measurement check the

charging status of the battery.

Check the charging status of the battery in the status line and /

or in the menu "Control".

The instrument is supplied with charging power supply The instrument can also be operated

with the internal battery for an extended period of time

When recharging the battery is necessary, the instrument will emit a battery warning This is

done acoustically and via a message in the display

Hint

The battery warning is activated when the battery voltage is less than 6.5

V. Less than 6.0 V the operation with battery is no longer possible

The operation must continue via the charging power

supply.

WARNING The instrument is operated with a Li-Ion battery!

The battery must be replaced only by qualified personnel or by ecom or an

ecom authorized service center.

Page 18

ecom-EN3

2.2 Navigation in the menu

When the instrument is switched on, the start screen is displayed, followed by the main menu

Up to 5 submenus are displayed simultaneously in the main

menu Hidden submenus can be displayed by scrolling with

the arrow keys

Menu Meaning Comment

Gas analysis Perform gas analysis

Mean value Perform gas analysis with mean value calculation

Soot...Oil trace Input of soot measurement results Start soot measurement (units with soot

measurement)

Data processing Assign measurements / Data transfer only with inserted MM card

Adjustments Modify instrument adjustments

ontrol heck operation state of instrument

Diagnostics - Read-out of firing automate Only with ecom-AK

- delta-T measurement

- Heating check

- 4 Pa test

Gas analysis

Soot..Oil trace

Data processing

Adjustments

Control

Diagnostics

ecom-EN3

Page 19

2.3 Calibration of the sensors use of the database and fuel type selection

Before you can start the measurement procedures, the instrument performs the following

steps:

1 Automatic adjustment of the sensors (calibration phase)

2 Query: Use of the database

3 Query: Selection of the fuel type

Select the sub-menu "Gas analysis" and confirm with <Enter>

The instrument starts the automatic calibration of the sensors (calibration phase) This

calibration phase is completed after 60 s

Hint

Position the probe only in the exhaust pipe when the calibration phase of 60 s

has been completed!

While the calibration phase is active, the query for using the

database is displayed:

If the measured values of the subsequent gas analysis are to

be assigned to a plant or a customer, confirm the query with

"Yes"

Press the <F1> key

For the following steps see chapter "4 8 Data processing during the measurement"

If the measured values of the subsequent gas analysis are not to be assigned to a plant or to

a customer, e g for a fast control measurement, confirm the query with "No"

Press the <F1> key

Then select which fuel type is used in the combustion

To scroll through the list of fuel types stored in the

instrument, scroll up or down with the arrow keys

Select the appropriate fuel by confirming with the

<Enter> key

Do you wish to

use the data

processing?

YES

Select:

NO

Fuel type

Fuel oil

CO2max

A1

B

15.4

0.50

0.007

Select:

Page 20

ecom-EN3

The following fuel types are stored in the instrument as standard:

Fuel type CO2 max Factor A2 Factor B

Fuel oil 15,4 0,68 0,007

Natural gas 11,8 0,66 0,009

ity gas 11,7 0,63 0,011

oke oven gas 10,2 0,60 0,011

Liquid gas 14,0 0,63 0,008

WARNING

For the combustion of solid fuels (wood / pellets / wood chips) a filtering

device recommended by ecom must always be used (see illustration)!

Filter plate for combustion of solid fuels Washing bottle for combustion of solid fuels

Probe prefilter

Other manuals for EN3

1

Table of contents

Other Ecom Measuring Instrument manuals

Ecom

Ecom Ex-MX2 Installation instructions

Ecom

Ecom i.roc Ci70 -Ex Installation instructions

Ecom

Ecom B User manual

Ecom

Ecom Quad Dock Ethernet User manual

Ecom

Ecom ECOM-D User manual

Ecom

Ecom Ex-MP4 a User manual

Ecom

Ecom J2KNpro Tech User manual

Ecom

Ecom J2KNpro Tech User manual

Ecom

Ecom DP User manual

Ecom

Ecom EN3 User manual

Popular Measuring Instrument manuals by other brands

South

South Galaxy G6 user manual

Hansen

Hansen VPIF Specifications, Applications, Service Instructions & Parts

Orphee

Orphee MYTHIC 18 Service manual

steute

steute RF 96 BU SW868-NET-LDS Mounting and wiring instructions

SMC Networks

SMC Networks PME-500-TR quick start guide

lanry

lanry TF1100-EH Operation & maintenance manual