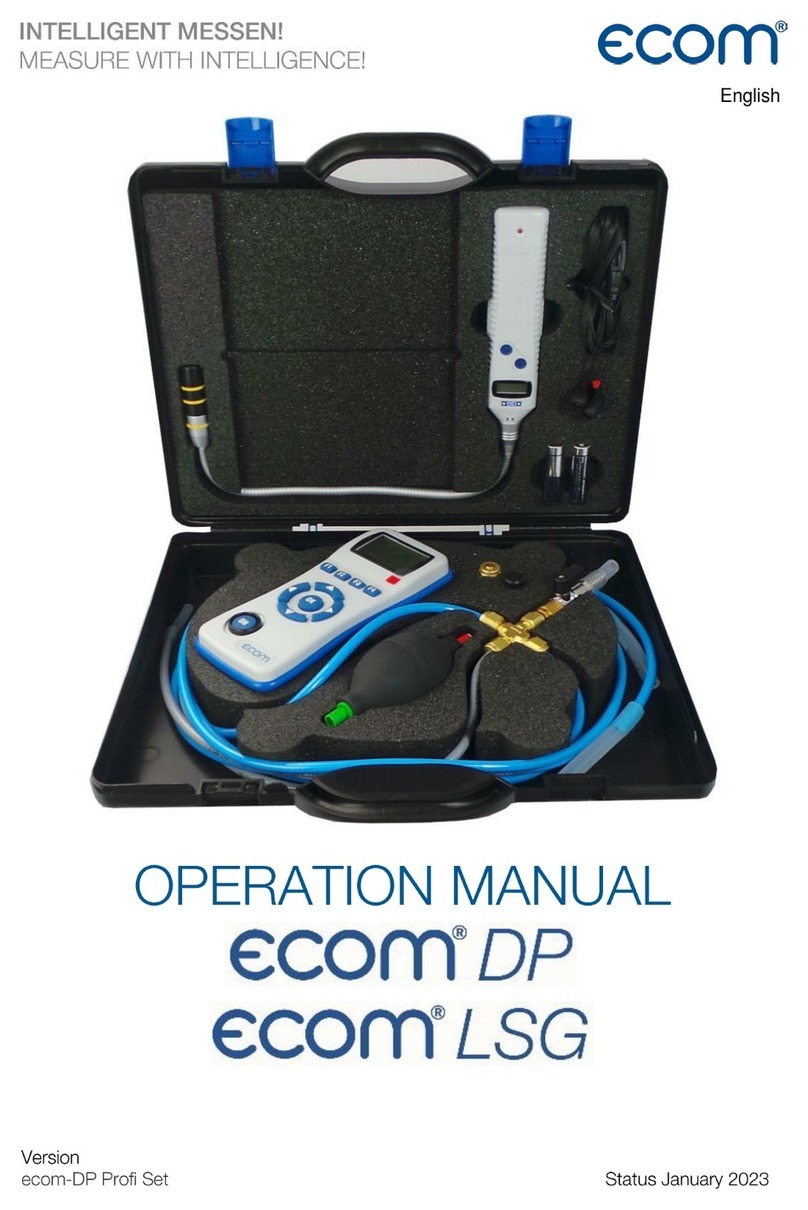

Ecom J2KNpro Tech User manual

ECOM America Ltd, 1628 Oakbrook Drive, Gainesville, GA 30507

Toll free (877) 326-6411 Phone (770) 532-3280 Fax (770) 532-3620

w w w . e c o m u s a . c o m

Quick Guide

version 3.6.2

Page 2

Thank you for choosing ECOM! Please follow the

instructions in this quick guide to get acquainted with

your J2KN Pro analyzer.

Page 3

Table of Contents Page(s)

INSTRUMENT DESIGN

J2KN Pro Base Unit……………………………………………………..4

Remote Display Unit ……………………………………………………5

Info Display………………………………………………………………..6

Filters……………….……………………………………………………….6

EMISSIONS MEASUREMENT &RECORDING

J2KN Pro Start-up…………………………………………………..…..7

Gas Analysis………....……………………………………..………………8

Capturing Data on Memory Card……………………………………9

Software Communication...................................................10

Accessories........................................................................11

CONSUMABLES

PART

PART #

DESCRIPTION

Particulate

Filter (10/PK)

3015840G

10/PK - Particulate

filter located on top

of water trap

assembly

In-line Smoke

Filter (1 EACH)

7118501H

1 EACH - Standard

3/4" in-line filter in

clear plastic casing.

NOx/SOx Filter

Media (1LB)

3014457G

1LB - NOx/SOx filter

media refill

container (purple

beads)

Thermal On-

board Printer

Paper (5/PK)

7927401H

5/PK - Printer paper

for on-board

thermal printer

Soot Test

Paper

(200/PK)

3003168G

200/PK - Round

smoke test filters for

smoke dot test

Soot Test

Chart

3002970G

Soot Test Chart with

0-9 Grayness Scale

Page 4

Instrument Design

J2KN Pro Base Unit

Ambient air

temperature

sensor

Thermocouple

connection

Main gas

connection

Draft/Pressure

connection

Draft/Pressure

connection

Water trap

drain hose

connection

On-board

printer

Filter for

IR bench

(if applicable)

Remote Display

Unit

(see next page)

Power cord

socket

Info display

ON / OFF

button

Analogue

inputs

(optional)

Auxiliary

temperature

connections

Nox/SOx

filter for

CO sensor

Pitot tube

connections

(optional)

Data cable

connection

(used by ECOM

personnel only)

Under case

(optional)

Trolley w/ wheels

(optional)

Heated line power

supply connection

(optional)

Fresh Air

Bypass Switch

(Pro IN only)

Page 5

J2KN Pro Remote Display Unit

Escape

Note: All keypad buttons

are used for input of num-

bers 0-9 and decimal point

OK

(press to confirm)

Up/Down/Right/Left

and Scroll

Capture data

Press to add

custom text to printout

(Press F2 to

print normally)

ON/OFF

Display

Backlight

ON/OFF

Function Keys

(See 8.1 Gas Analysis)

Memory card slot

LCD display

screen

USB

connection

Data cable sockets

(used by ECOM per-

sonnel only)

WiFi antenna

(If your antenna has a

pink band, it is

Bluetooth)

Air temperature

connection

(not an antenna)

Page 6

Info display

Filters

Particulate filter (water trap filter)

Unscrew the cover of the water trap and check the particu-

late filter for grayness. Change the filter when it is dark gray.

Tip: use the elbow piece as a reference since it is dark gray.

In-line smoke filter

The round in-line smoke filter should be checked periodically

for grayness. Change the filter when it is dark gray. Tip: use

the elbow piece as a reference since it is dark gray.

NOx/SOx filter

The CO sensor has an independent gas path (see 4. Gas

Path Diagram) which includes a potassium permanganate

chemical filter for filtering SO2 and NOx from the gas sample.

Color change: purple -> brown -> grey-> white

Filter media should be changed once it has turned grey!

2.24

ltr /

min

Main pump is running

Fresh air valve is open

CO purging is running

Gas cooler ready for use

Heated line ready for use

Heated head ready for use

Probe heating is switched on

Gas flow

(liters per minute)

Radio mode

Battery operation

Calibration phase

läuft

Elbow piece

Particulate filter

In-line smoke filter

Page 7

J2KN Pro Start-up

Make sure the probe is in fresh air when you

turn on the J2KN Pro.

1. Switch on the J2KN base unit and the remote control

unit. The Main Menu is displayed with 8 sub-menus:

- Gas analysis View gas readings & calculations

- Averaging Perform averaging tests

- Draft/Pressure Calibrate pressure sensor

- Soot Test Perform soot/smoke density test

- Automatic meas. Data logging onto memory card

(Pro Easy & IN) and set up auto-

matic test cycles (Pro IN only)

- Adjustments Modify J2KN settings

- Control Diagnostic info/Calibration mode

- Diagnostics (Only used with ECOM AK tool)

2. Select Gas Analysis and press <OK>

3. Press Up/Down to select Fuel Type

and press <OK>

1. Analyzer will complete auto-zeroing

of all sensors, except the O2 sensor

which is calibrated to 20.9%

Fuel type

Gas-Natural

CO2max A1 B

11.7 0.35 0.006

Select: (

Radio Link

Quality Indicator

Battery Charging

Indicator

Display contrast:

Lighten F1

Darken F2

Gas analysis

Averaging

Draft/Pressure

Soot Test

Automatic meas.

Adjustments

Control

Diagnostics

Page 8

Gas Analysis

If you change testing environments, let the

analyzer acclimate to the new ambient envi-

ronment, then power down and restart.

After the 1-minute auto-zeroing phase, the instrument switches

to Gas Analysis mode. The measurement values can be viewed

on 3 display pages: a zoomed in 4-line display and 2 full 9-line

displays. All line items are user-selectable (see Display Values

below). Press Up/Down to scroll between the pages.

Bypass Switch (Pro IN)..Turn on/off fresh air bypass to purge

Info Screen (Pro Easy)....View diagnostic info on Control screen

Quick Print............Prints on-screen measurement values

CO Bypass.............Manually turn on/off CO bypass pump

Display Lines.......Choose measurement values to display by

pressing F4 then Up/Down/Right/Left

To change F1 hotkey from default, go to

Adjustments > Internal > F1 Hotkey

Turn on CO bypass pump to protect CO

sensor from high concentrations

Pump automatically activates at 4000ppm!

To change F4 hotkey from default, go to

Adjustments > Internal > F4 Hotkey

Edit Display

Lines

<F4>

Control Screen (Pro Easy)

Purge Valve On/Off (Pro IN)

<F1>

F1:

F2:

F3:

F4:

Tip: To apply O2 correction, go

to Adjustments>Ref. O2 and input

your O2 correction % value. Then

go to Adjustments>Unit & change

unit to ppm %O2 corrected.

Quick Print

<F2>

CO Bypass

Pump ON/OFF

<F3>

O2 8.2 %

CO 431 ppm

NO 126 ppm

NO2 65 ppm

Gas Analysis 25.11.07

Tip: If you are in a

cold environment, you

may need to use a

heated probe. Go to

Adjustments>Internal

‘>Probe Heating>F1 to

‘’’ turn on and off.

Page 9

Capturing Data on Memory Card (2GB max)

Data Logging in Timed Intervals

1. Go to Automatic Meas. > Save to MM

Card. This is the time interval that each

data point is recorded to the memory card

(min. 1sec, max 255sec). Input desired

amount in seconds and press OK.

2. Select Datalogger > “Start dl? Are you

sure?” > Press F1

3. Analyzer is now in Datalogging mode. The

blinking disk in the top right corner indicates that the analyzer

is currently logging data. Press to return to the main menu

and select Gas Analysis to view real-time measurements.

4. To complete data logging and save the file, press to return

to the main menu, go to Automatic Meas. > Datalogger >

“Finish dl? Are you sure?” > Press F1.

OR

Capturing Data Snapshots On-Demand

1. Go to Automatic Meas. > Save to MM Card and input 255.

2. Select Datalogger > “Start dl? Are you sure?” -> Press F1

3. Press to return to the main menu and go to Gas Analysis

to view real-time measurements.

4. Press 5 (disk symbol). You will see an X over the disk icon

in the top right corner. This is normal and expected.

5. When you are ready to capture the first data point, press 5

(disk symbol), wait 2 seconds, and press 5again. The

data point was captured during the 2 second interval.

6. Repeat step 5 for all desired data points.

7. To complete data collection and save the file, press to

return to the main menu, go to Automatic Meas., select

Datalogger -> “Finish dl? Are you sure?” -> Press F1.

Each data file will be saved separately as J2KDL-00, J2KDL-01, etc. Open in

Microsoft Excel. You can also import the data from the SD card into ECOM’s

free DAS 5 software to create formal reports.

Page 10

Software Communication

If you need help with installation or operation of your DAS

or e-Comply software, please consult the User Manual for your

software product. If you are having trouble communicating

from the analyzer to a computer, please check the following:

Adjustments > Internal > RF Connect

Make sure it is in Remote setting.

Adjustments > Internal > USB

For both DAS and e-Comply, make sure the Baud rate is

38400 and the Protocol is Enhanced.

Adjustments > Internal > WLAN (if applicable)

If you have WiFi communication problems, refresh the WiFi

signal by selecting Auto Connect > F1. You will see the IP

address dash out and come back again. Note: You can’t con-

nect to both the software and mobile app simultaneously.

Adjustments > Internal > Bluetooth (if applicable)

For both DAS and e-Comply, make sure the Baud rate is

9600 and the Protocol is Enhanced. To reset the Bluetooth

signal on your computer, right-click on > Show Bluetooth

Devices > Right-click on BT connection> Remove Device. Now

click Add a Device and re-connect to the analyzer. PIN=1234

If communication issues persist, re-sync the remote & base

1. Place remote unit into cradle. Go to Adjustments >

Internal > RF Connect and select Standard.

2. The base and remote are now synced.

3. Change the RF Connect setting back to Remote.

4. The remote can now be used as normal.

If all else fails, do a hard reset of the analyzer:

1. Power down the analyzer.

2. Disconnect analyzer from AC power.

3. Open the battery drawer and disconnect the lead from the

battery (white plastic clip). Wait at least 1 minute.

5. Reconnect the battery, reconnect the power cord, and

restart analyzer. You have just completed a hard reset.

Page 11

Accessories

e-Comply Testing Software

Part no. 9038001H

(Records mass emissions in

g/bhp-hr, lbs/hr, & tons/year)

Calibration Gas Kits

Part no. available upon request

Probe Shield

Part no. 3025006G

(Recommended for high temp

applications to protect grip)

15ft/30ft Heated Sample Line

Part no. 7952501H

(Custom lengths available

from 0 to 100ft)

Tail Pipe Probe Assembly

Part no. 7126631H

(Recommended for tail pipes

when inserting 180into stream)

Flex-Tip Probe Assembly

Part no. 7129601H

(Recommended for hard-to-

access sampling ports)

Page 12

RUGGED.RELIABLE.ACCURATE.

ECOM AMERICA LTD

1628 OAKBROOK DRIVE

GAINESVILLE,GA 30507

TOLL FREE (877) 326-6411

PHONE (770) 532-3280

FAX (770) 532-3620

ecom.info@ecomusa.com

w w w . e c o m u s a . c o m

Other manuals for J2KNpro Tech

5

Table of contents

Other Ecom Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Endress+Hauser

Endress+Hauser Liquiline System CA80TP Brief operating instructions

Minebea

Minebea CSD-401 instruction manual

Catalyst

Catalyst AirCom UWB Analyzer user manual

WILDLIFE

WILDLIFE 265A quick start guide

Keysight

Keysight NFA Series Performance Verification and Calibration Guide

Panametrics

Panametrics DigitalFlow GM868 Service manual