1

Manual

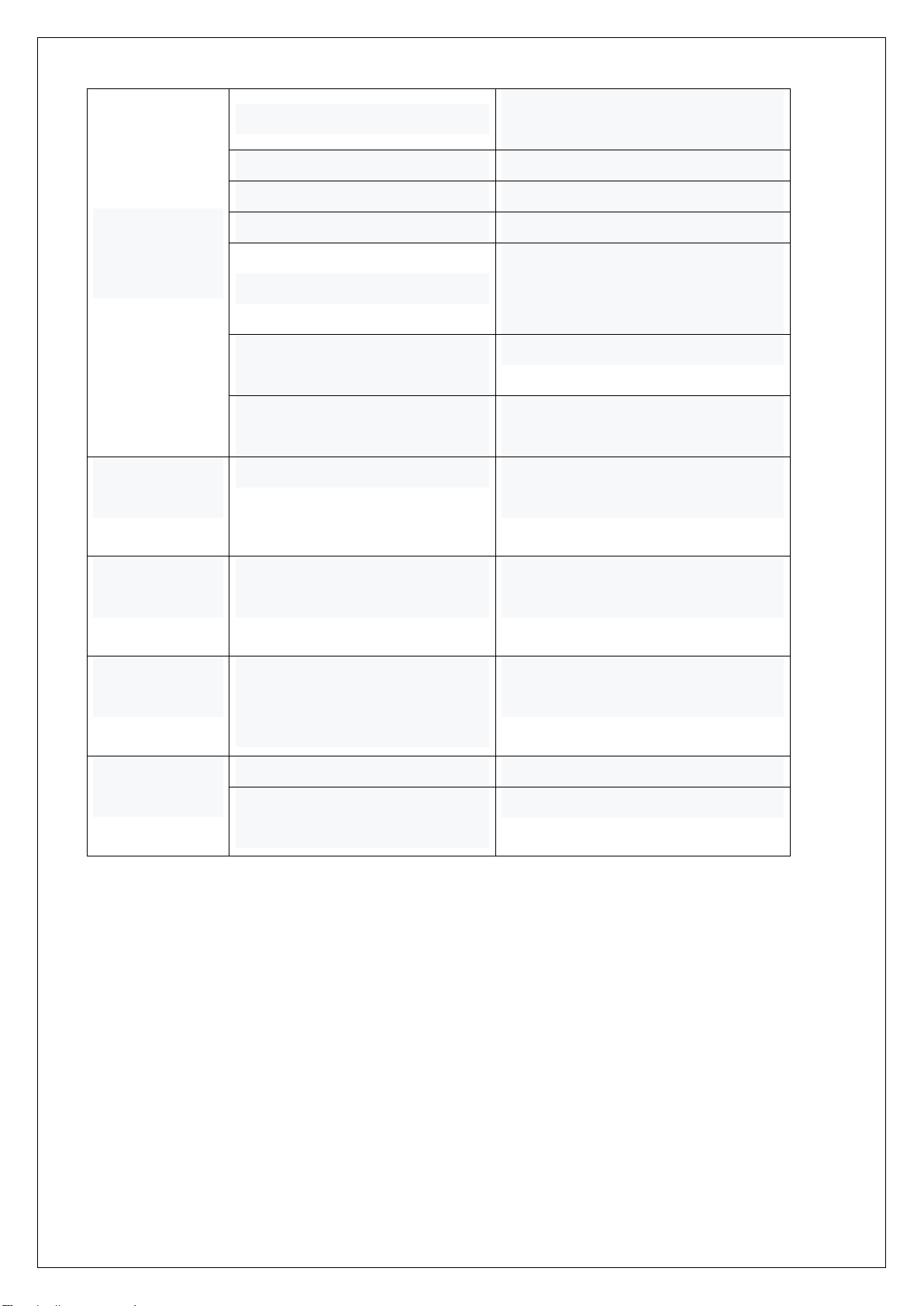

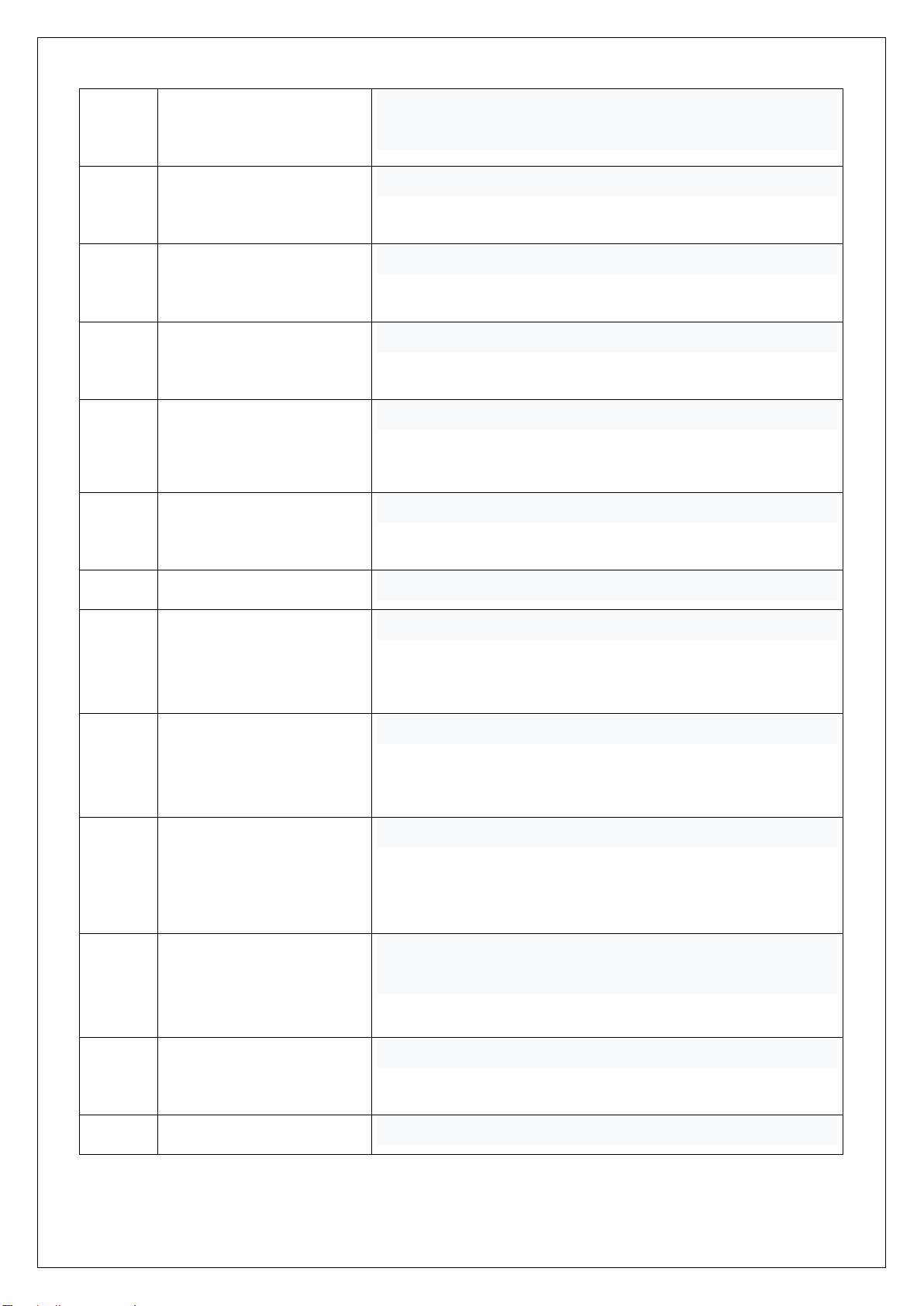

1. Maintenance List........................................................................................................................................................................................ 2

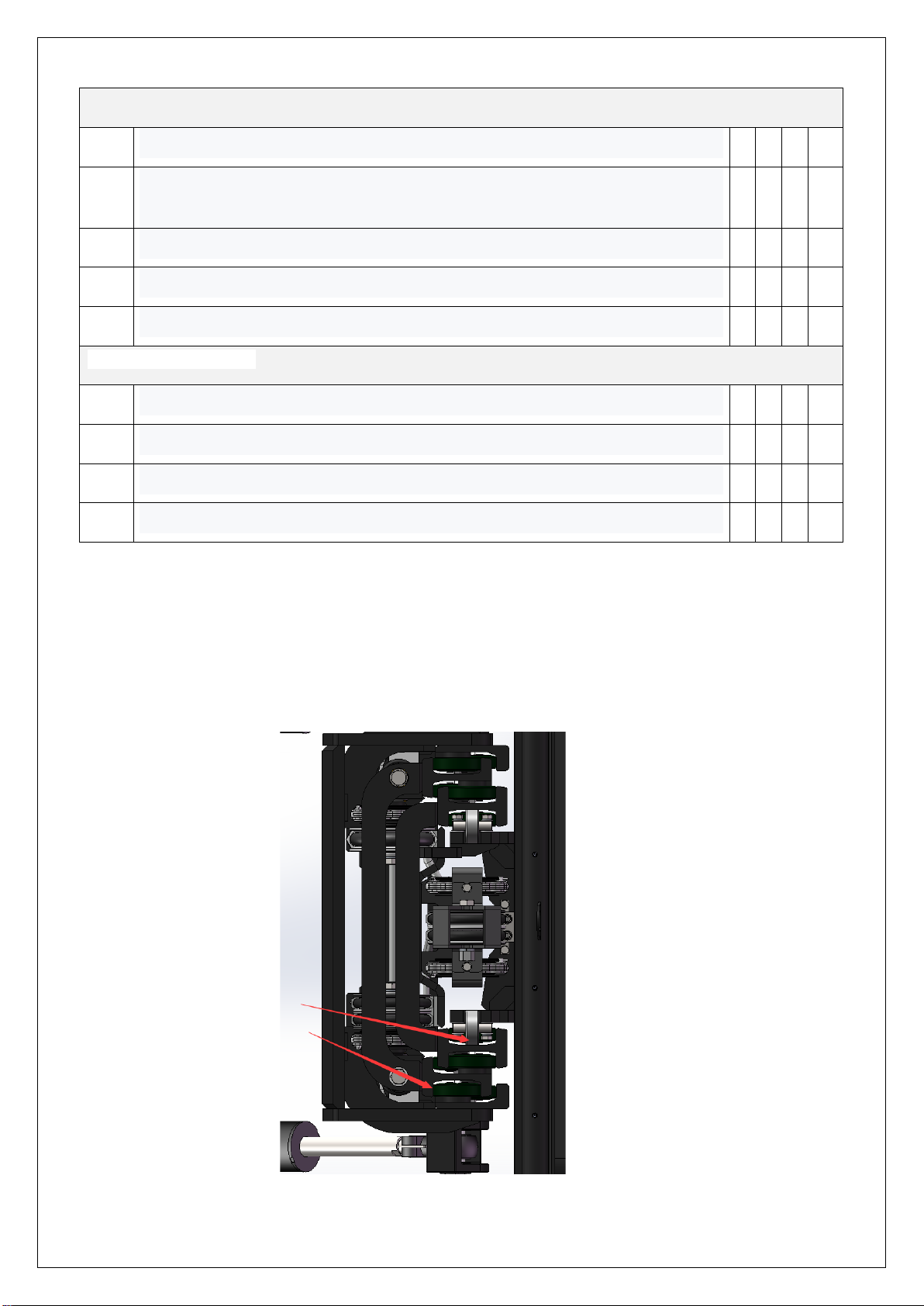

a. Overview of main components ........................................................................................................................................................2

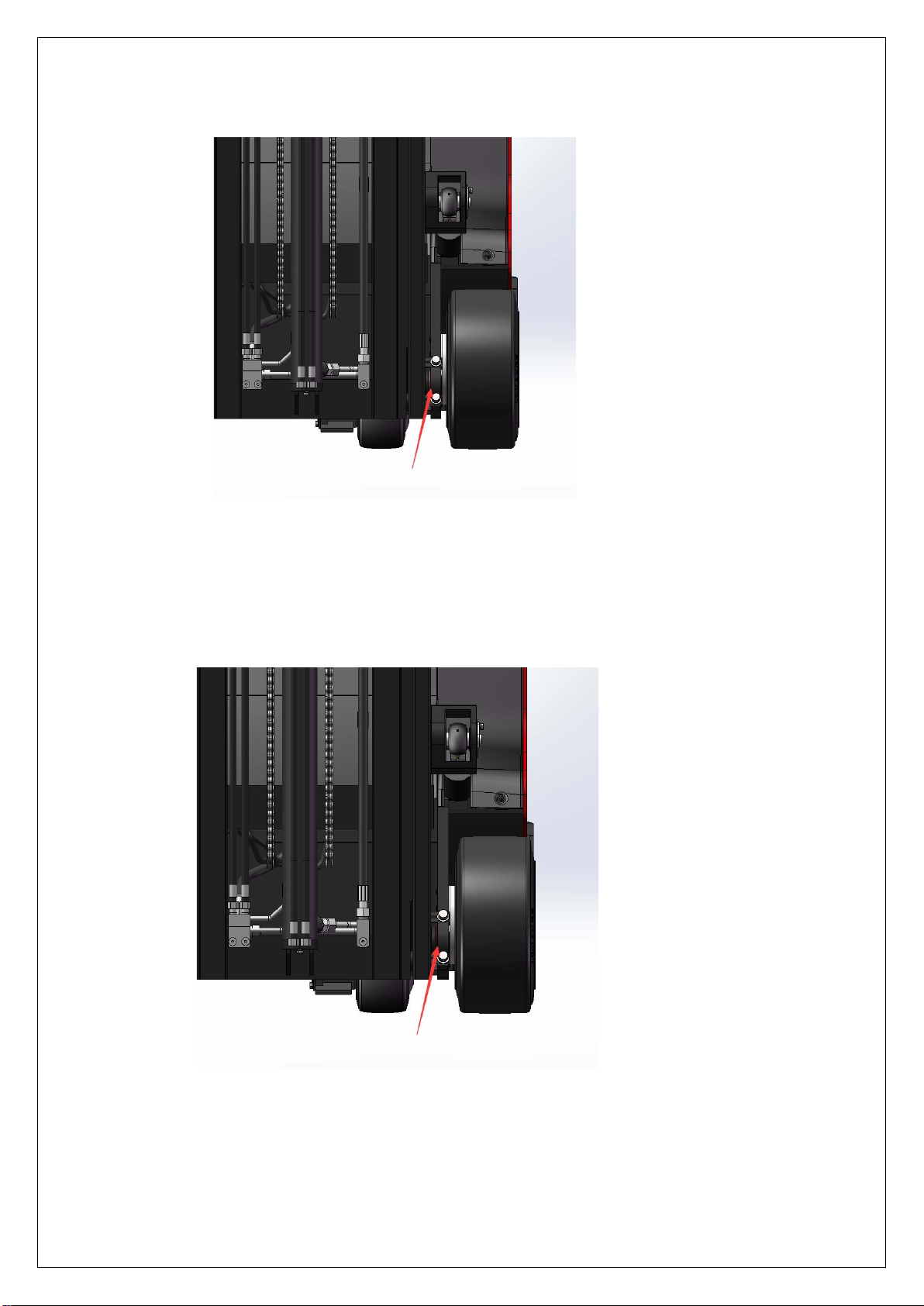

b. Lubrication point ....................................................................................................................................................................................3

c. Check and refill hydraulic oil.............................................................................................................................................................4

d. Check the fuse ..........................................................................................................................................................................................5

2. Fault Analysis................................................................................................................................................................................................ 5

a. Common Fault analysis......................................................................................................................................................................7

b. The fault code is displayed .................................................................................................................................................................8

3. Wiring/circuit Diagram.............................................................................................................................................................................9

a、Schematic diagram and wiring diagram.............................................................................................................................................10

b、Hydraulic circuit ....................................................................................................................................................................................11

4. Main parts disassembling ....................................................................................................................................................... 12

a. Battery brake adjustment.................................................................................................................................................... 12

b Drive assembly disassembly............................................................................................................................................... 13

c. Drive brake disassembly ...................................................................................................................................................... 14

d. Drive internal gear bearings............................................................................................................................................... 15

e. Handle assembly...................................................................................................................................................................... 16

f. Frame breakdown ................................................................................................................................................................... 18

g. Pump station motor ................................................................................................Error! Bookmark not defined.4

5、CURTIS Handheld Unit...............................................................................................................................................................................25