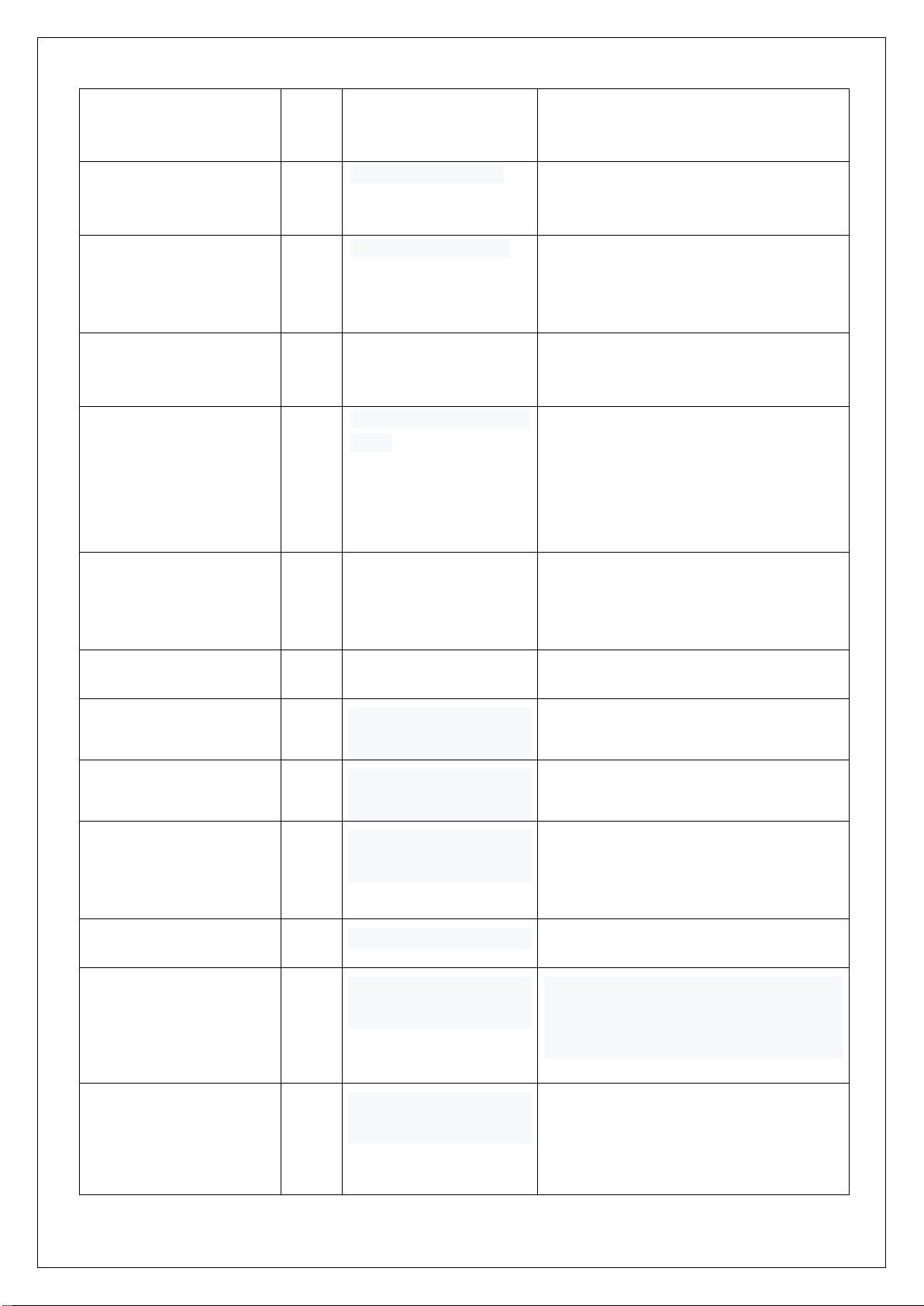

目录

1. 维修清单 .............................................................................................Error! Bookmark not defined.

a. 主要零部件概述............................................................................................................................... 0

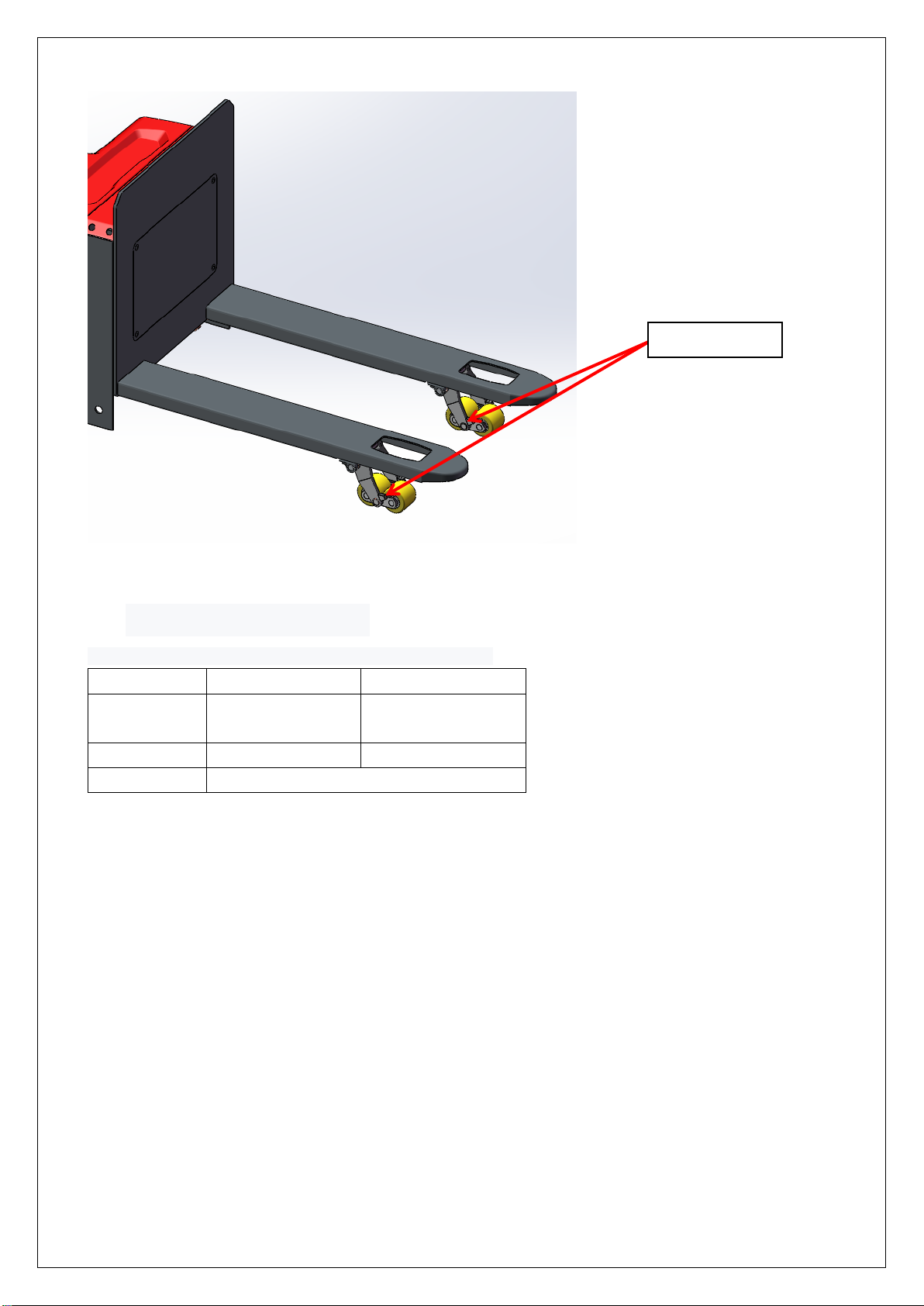

b. 润滑点 ............................................................................................................................................. 3

c. 检查再加注液压油 ........................................................................................................................... 4

d. 检查电器保险丝...............................................................................Error! Bookmark not defined.

2. 故障分析 .............................................................................................Error! Bookmark not defined.

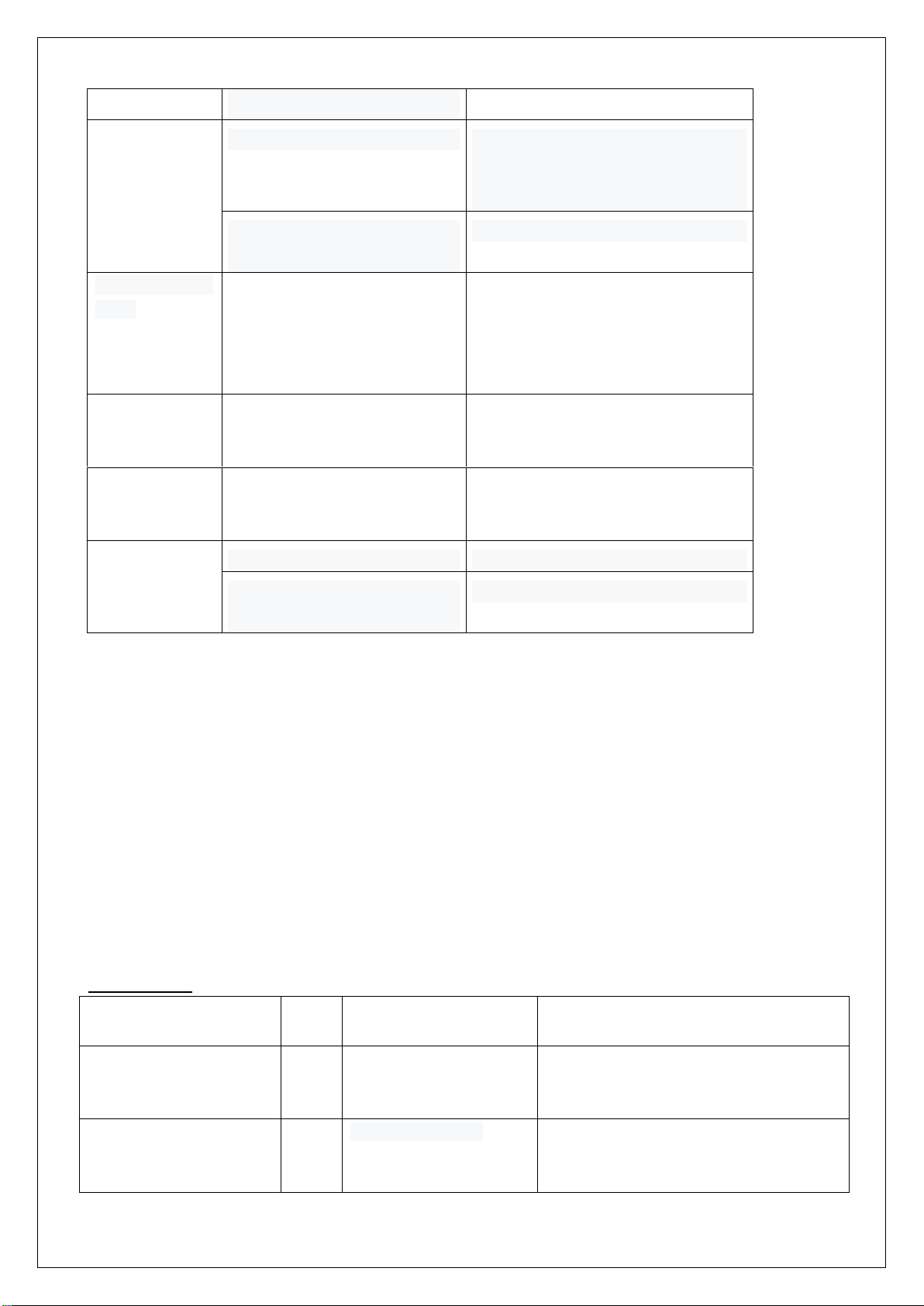

a. 常见故障分析................................................................................................................................... 5

b. 仪表故障代码显示 ...........................................................................Error! Bookmark not defined.

3. 接线/电路图.........................................................................................Error! Bookmark not defined.

a. 电路图 .............................................................................................Error! Bookmark not defined.

b. 液压回路........................................................................................................................................ 13

4. 主要零部件拆解 ..................................................................................Error! Bookmark not defined.

a. 电池刹车调整...................................................................................Error! Bookmark not defined.

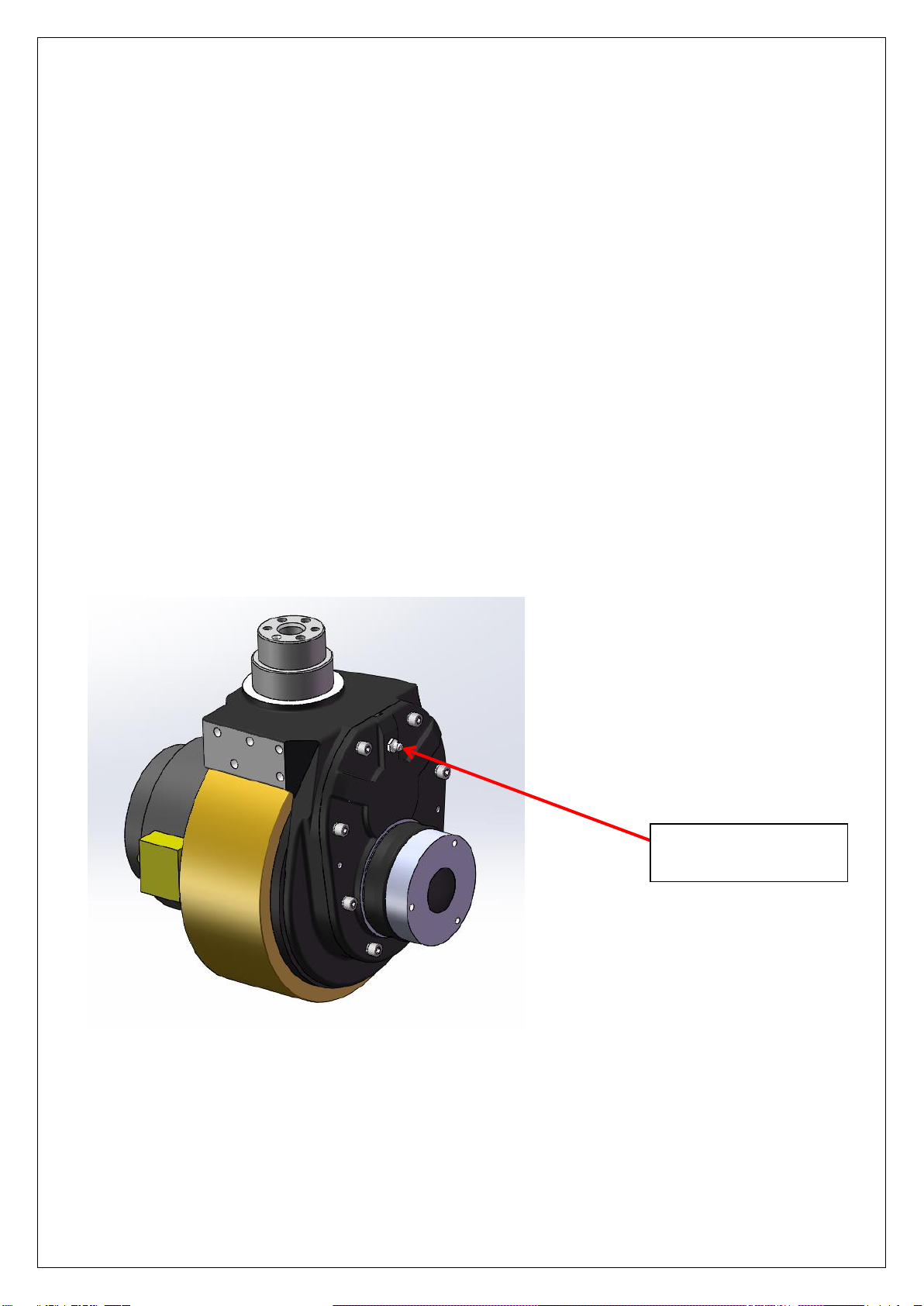

b驱动总成拆解...................................................................................Error! Bookmark not defined.

c. 驱动刹车拆解...................................................................................Error! Bookmark not defined.

d. 驱动内部齿轮 轴承 .........................................................................Error! Bookmark not defined.

e. 手柄总成..........................................................................................Error! Bookmark not defined.

f. 车架分解..........................................................................................Error! Bookmark not defined.

g. 泵站电机..........................................................................................Error! Bookmark not defined.

5. CURTIS 手持单元 ............................................................................................................................. 14

1Regular maintenance

Only qualified and trained personnel should perform maintenance work on this