1.

Safety guidance

1.1

Operators must read all warning signs and instructions on the stacker

before use.

1.2

Do not operate this stacker unless you are familiar with it, have been

professionally trained in its operation and functionality, and are also

authorized to do so.

1.3

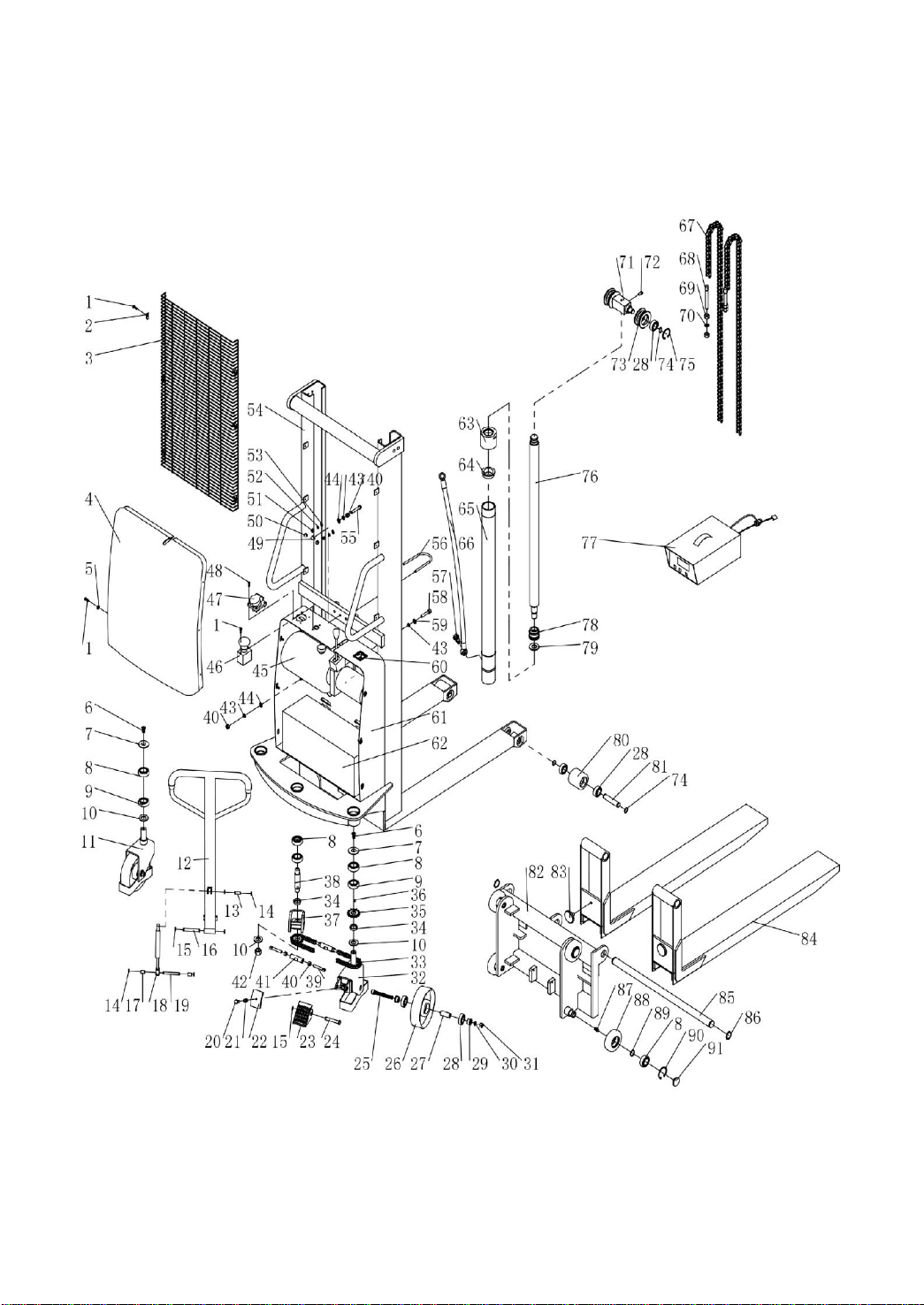

Do not operate this stacker unless you have checked its condition. Give

special attention to the chain, the wheels, the handle, the guide frame, the

pilot wheel, the mast, battery, etc.

1.4

Do not use it on sloped ground or in an explosive or dangerous

environment.

1.5

Do not ever lift people on the forks.

1.6

While the forks are elevated it is prohibited for anyone to stand under

the forks or pass through the forks.

1.7

The operator should use gloves for protection.

1.8

Do not move the stacker when the goods are lifted to a height of more

than 11.8 in.

1.9

When the goods are lifted, people should stay clear from the forks by

at least 2 feet.

1.10

Evenly distribute the weight of goods onto both forks, do not use only

one fork. The center of gravity of the goods should be in the middle of the

two forks on the load center of 24”.

1.11

Do not overload maximum capacity.

1.12

Before using or charging it you must check battery fluids, if it is

insufficient, please fill with distilled water ONLY.

1.13

Charge the equipment in a dry and ventilated location, and far away

from heat.

1.14

Always keep the forks in the lowest position if not in use.

1.15

The operator should always be responsible and careful when

operating the stacker.