Content

1.The General Introduction.............................................................................................1

2. Proper use ........................................................................................................................ 2

3.Introduce of the product .............................................................................................. 3

3.1Product overview ............................................................................................................. 3

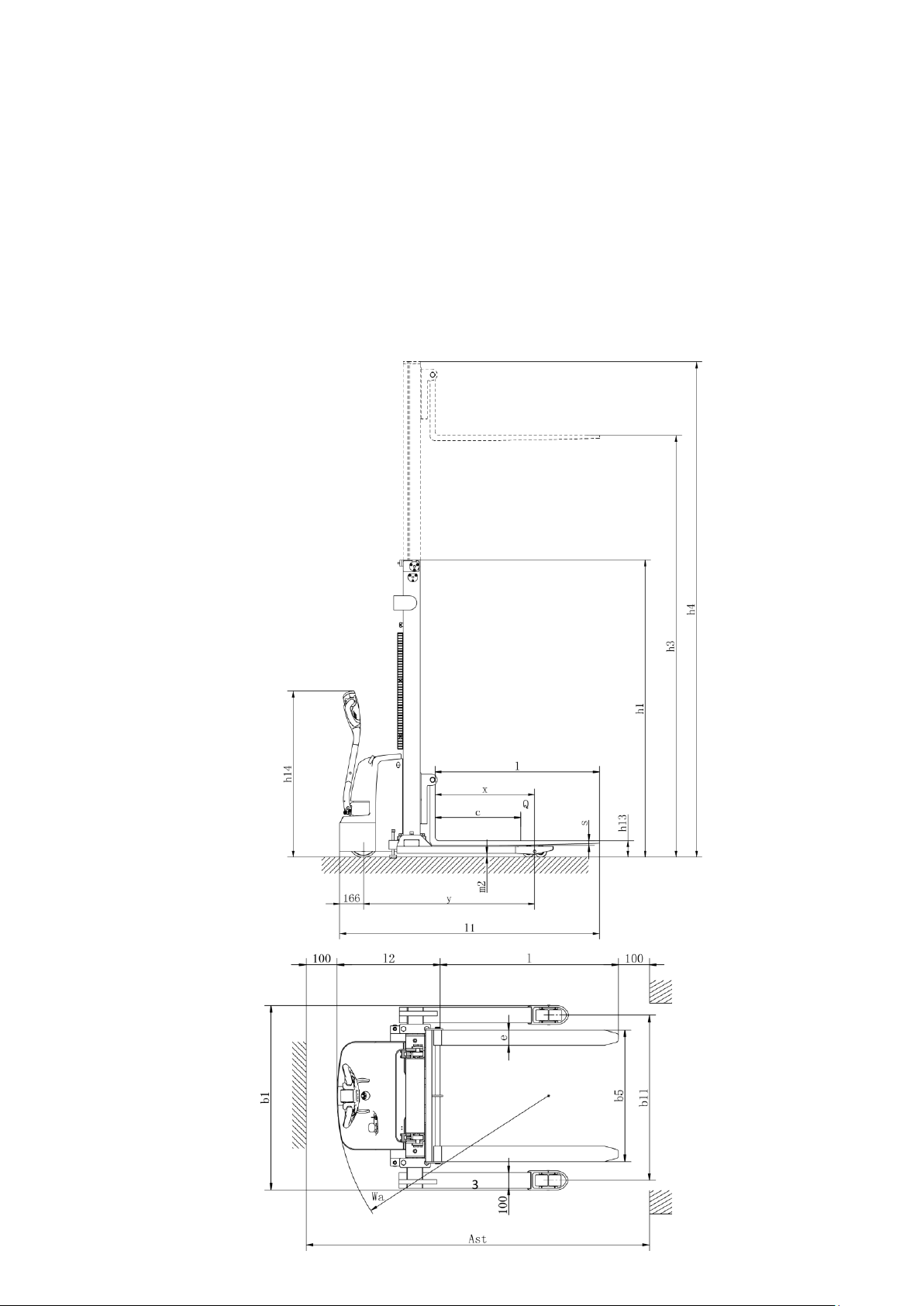

3.2Model parameters............................................................................................................. 3

4.Operating principle........................................................................................................5

5. Operating principle .......................................................................................................6

5.1Running system.................................................................................................................. 6

5.2 Steering system................................................................................................................. 6

5.3 Brake structure and brake schematic diagram. ................................................... 6

5.4 Operating System............................................................................................................. 8

5.5 Electric System.................................................................................................................. 8

5.6 Hydraulic principle.......................................................................................................... 8

6. Electrical schematic diagram.....................................................................................9

7. Hydraulic Scheme ....................................................................................................... 10

8.Operating Instruction................................................................................................. 11

8.1 Start, run and parking: .................................................................................................11

8.2The using of emergency power safety switch ......................................................11

8.3 The use of Horn and reversing Horn ......................................................................12

8.4 Battery capacity indicator...........................................................................................12

8.5Operation............................................................................................................................12

9.Maintenance and care instructions ....................................................................... 13

W1 = Every 50 work hours, but at least once a week..............................................14

10.Safety Caution ............................................................................................................. 21

10.1 General rule ...................................................................................................................21

10.2 Storage and transportation......................................................................................21

10.3 Check before using......................................................................................................22

10.4Safety operation regulation......................................................................................22

11.Service Manual ........................................................................................................... 26

12.After Sales Service..................................................................................................... 28