EVCOS.p.A.|EV3271/EV3281|Instructionsheetver.1.0|Code1043271E103|Page2of2 |PT05/22

13

r4 0.0 setpoint offset in energy saving 0... 99 °C/°F

14

r5

0

cooling or heating operation

0 = cooling

1 = heating

15

r6

0.0

setpoint offset in overcool-

ing/overheating 0... 99 °C/°F

16

r7 30 overcooling/overheating duration 0... 240 min

17

r8

0

DOWN key additional function

0 = disabled

1 = overcooling/overheating

2 = energy saving

18

r12

0

position of the r0 differential

0 = asymmetric

1 = symmetric

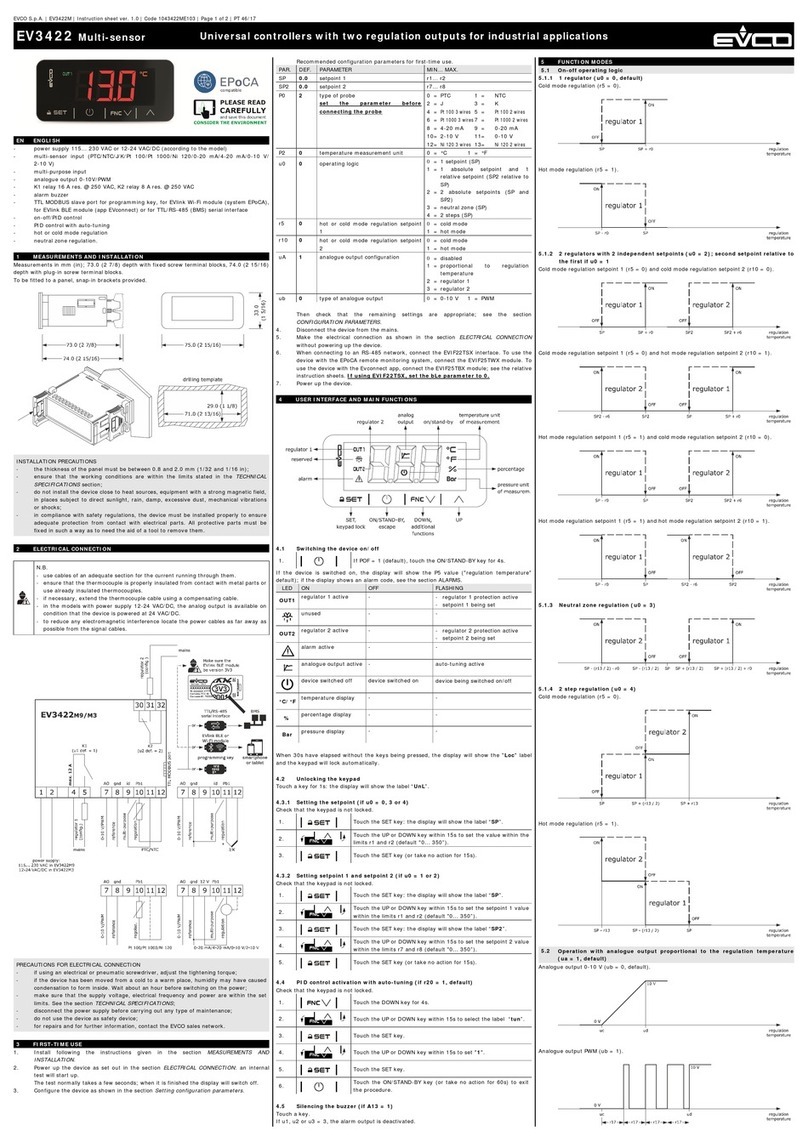

N. PAR. DEF. COMPRESSOR MIN... MAX.

19

C0

0

compressor on delay after pow-

er-on 0... 240 min

20

C2

3

compressor off minimum time

0... 240 min

0 = protection against mains

voltage fluctuations dis-

abled

21

C3 0 compressor on minimum time 0... 240 s

22

C4

10

compressor off time during cabi-

net probe alarm 0... 240 min

23

C5

10

compressor on time during cabi-

net probe alarm 0... 240 min

24

C6

80.0

threshold for high condensation

warning 0... 199 °C/°F

differential = 2 °C/4 °F

25

C7

90.0

threshold for high condensation

alarm 0... 199 °C/°F

26

C8 1 high condensation alarm delay 0... 15 min

27

C10

0

compressor hours for service

0... 999 h x 100

0 = disabled

28

C14

190

mains voltage threshold below

which the compressor is not

switched on

95... 260 V

the device attempts to switch

on every 30 s

29

C15

180

mains voltage threshold below

which the compressor is switched

off

95... 260 V

if satisfied C17 time

30

C16

260

mains voltage threshold above

which the compressor is not

switched on or switched off

95... 260 V

if satisfied C17 time

the device attempts to switch

on every 30 s

31

C17

5

consecutive duration of the per-

manence of the mains voltage

outside the thresholds C15 and

C16 due to the compressor being

switched off

0... 60 s

32

C18

5

consecutive number of failed

compressor starts due to the

mains voltage outside the

thresholds C14 and C16 such as

to cause the forced start-up of

the compressor

0... oo

0 = protection against mains

voltage fluctuations dis-

abled

oo= the device never makes

the forced start-up of

the compressor

the interruption of the power

supply resets the count

N. PAR. DEF. DEFROST (if r5 = 0) MIN... MAX.

33

d0

8

automatic defrost interval

0... 99 h

0 = only manual

if d8 = 3, maximum interval

34

d2 8.0 threshold for defrost end -99... 99 °C/°F

35

d3

30

defrost duration

0... 99 min

se P4 = 1, maximum duration

36

d4 0 enable defrost at power-on 0 = no 1 = yes

37

d5 0 defrost dealy after power-on 0... 99 min

38

d6

2

value displayed during defrost

0 = cabinet temperature

1 = display locked

2 = dEF label

39

d7 2 dripping time 0... 15 min

40

d8

0

defrost interval counting mode

0 = device on hours

1 = compressor on hours

2 = hours evaporator tem-

perature < d9

3 = adaptive

4 = real time

41

d9

0.0

evaporation threshold for auto-

matic defrost interval counting -99... 99 °C/°F

42

d11 0 enable defrost timeout alarm 0 = no 1 = yes

43

d18

40

adaptive defrost interval

0... 999 min

if compressor on + evapora-

tor temperature < d22

0 = only manual

44

d19

3.0

threshold for adaptive defrost

(relative to optimal evaporation

temperature)

0... 40 °C/°F

optimal evaporation tempera-

ture - d19

45

d20

180

compressor on consecutive time

for defrost 0... 999 min

0 = disabled

46

d21

200

compressor on consecutive time

for defrost after power-on and

overcooling

0... 500 min

if (cabinet temperature - set-

point) > 10°C/20 °F

0 = disabled

47

d22

-2.0

evaporation threshold for adap-

tive defrost interval counting

(relative to optimal evaporation

temperature)

-10... 10 °C/°F

optimal evaporation tempera-

ture + d22

N. PAR. DEF. ALARMS MIN... MAX.

48

AA

0

select value for high/low temper-

ature alarms 0 = cabinet temperature

1 = auxiliary temperature

49

A1

-10.0

threshold for low temperature

alarm -99... 99 °C/°F

50

A2

1

low temperature alarm type

0 = disabled

1 = relative to setpoint

2 = absolute

51

A4

10.0

threshold for high temperature

alarm -99... 99 °C/°F

52

A5

1

high temperature alarm type

0 = disabled

1 = relative to setpoint

2 = absolute

53

A6

12

high temperature alarm delay af-

ter power-on 0... 99 min x 10

54

A7

15

high/low temperature alarms de-

lay 0... 240 min

55

A8

15

high temperature alarm delay af-

ter defrost 0... 240 min

56

A9

15

high temperature alarm delay af-

ter door closing 0... 240 min

57

A10

10

power failure duration for alarm

recording 0... 240 min

58

A11

2.0

high/low temperature alarms re-

set differential 1... 15 °C/°F

59

A13 0 enable alarm buzzer 0 = no 1 = yes

N. PAR. DEF. DIGITAL INPUTS MIN... MAX.

60

i0

5

door switch/multi-purpose input

function

0 = disabled

1 = compressor

2 = reserved

3 = reserved

4 = reserved

5 = reserved

6 = reserved

7 = energy saving

8 = iA alarm

9 = device on/off

10= Cth alarm

11= th alarm

61

i1

0

door switch/multi-purpose input

activation 0 = with contact closed

1 = with contact open

62

i2

30

open door alarm delay

-1... 120 min

-1 = disabled

63

i3

15

regulation inhibition maximum

time with door open -1... 120 min

-1 = until the closing

64

i7

0

multi-purpose input alarm delay

-1... 120 min

-1 = disabled

if i0 = 10 or 11, compressor

on delay after alarm reset

65

i10

0

door closed consecutive time for

energy saving

0... 999 min

after regulation temperature

< SP

0 = disabled

66

i13

180

number of door openings for de-

frost 0... 240

0 = disabled

67

i14

32

door open consecutive time for

defrost 0... 240 min

0 = disabled

N. PAR. DEF. ENERGY SAVING (if r5 = 0) MIN... MAX.

68

HE2 0 energy saving maximum duration

0... 999 min

N.

PAR.

DEF.

REAL TIME ENERGY SAVING (if

r5 = 0) MIN... MAX.

69

H01 0 energy saving time 0... 23 h

70

H02 0 energy saving duration 0... 24 h

71

HEd

7

energy saving day

0 = Monday 1 = Tuesday

2 = Wednesday

3 = Thursday 4 = Friday

5 = Saturday 6 = Sunday

7 = none

N. PAR. DEF. REAL TIME DEFROST (if d8 = 4) MIN... MAX.

72

Hd1 h- 1st daily defrost time h-= disabled

73

Hd2 h- 2nd daily defrost time h- = disabled

74

Hd3 h- 3rd daily defrost time h-= disabled

75

Hd4 h- 4th daily defrost time h-= disabled

76

Hd5 h- 5th daily defrost time h-= disabled

77

Hd6 h- 6th daily defrost time h-= disabled

N. PAR. DEF. SAFETIES MIN... MAX.

78

POF 0 enable ON/STAND-BY key 0 = no 1 = yes

79

PAS -19 password -99... 999

80

PA1 426 level 1 password -99... 999

81

PA2 824 level 2 password -99... 999

N. PAR. DEF. REAL TIME CLOCK MIN... MAX.

82

Hr0 0enable clock 0 = no 1 = yes

N. PAR. DEF. DATA-LOGGING EVLINK MIN... MAX.

83

bLE

1

serial port configuration for con-

nectivity

0 = free

1 = forced for EVconnect or

EPoCA

2-99= EPoCA local network

address

84

rE0 15 data-logger sampling interval 0... 240 min

85

rE1

3

recorded temperature

0 = none 1 = cabinet

2 = auxiliary 3 = all

N. PAR. DEF. MODBUS MIN... MAX.

86

LA 247 MODBUS address 1... 247

87

Lb

2

MODBUS baud rate

0 = 2,400 baud

1 = 4,800 baud

2 = 9,600 baud

3 = 19,200 baud

parity even

8 ALARMS

COD. DESCRIPTION RESET REMEDIES

Pr1 cabinet probe alarm automatic - check P0

Pr2 auxiliary probe alarm automatic - check probe integrity

- check electrical connection

rtc clock alarm manual set date, time and day of the week

COn

forced compressor start

alarm manual

- touch a key

- check C18

LU

compressor alarm not on or

off due to low mains voltage

manual, au-

tomatic after

30 s

- touch a key

- check C14 and C15

HU

compressor alarm not on or

off due to high mains volt-

age

manual, au-

tomatic after

30 s

- touch a key

- check C16

AL low temperature alarm automatic check AA, A1 and A2

AH high temperature alarm automatic check AA, A4 and A5

id open door alarm automatic check i0 e i1

PF

power failure alarm

manual

- touch a key

- check electrical connection

COH high condensation warning automatic check C6

CSd

high condensation alarm

manual

- switch the device off and on

- check C7

iA multi-purpose input alarm automatic check i0 and i1

Cth

compressor thermal switch

alarm automatic

check i0 and i1

th

global thermal switch alarm

manual

- switch the device off and on

- check i0 and i1

dFd

defrost timeout alarm

manual

- touch a key

- check d2, d3 and d11

9 TECHNICAL SPECIFICATIONS

Purpose of the control device

Function controller

Construction of the control device

Built-in electronic device

Container Black, self-extinguishing

Category of heat and fire resistance D

Measurements

75.0 x 33.0 x 59.0 mm (2 15/16 x 1 5/16 x

2 5/16 in) with fixed screw terminal blocks

75.0 x 33.0 x 81.5 mm (2 15/16 x 1 5/16 x

3 3/16 in) with removable screw terminal

blocks

Mounting methods for the control device

To be fitted to a panel, snap-in brackets pro-

vided

Degree of protection provided by the cover-

ing IP65 (front)

Connection method

Fixed screw terminal blocks

for wires up to 2,5 mm²

Removable screw terminal

blocks for wires up to

2,5 mm²; by request

Micro-MaTch connector

Maximum permitted length for connection cables

Power supply: 10 m (32.8 ft) Analogue inputs: 10 m (32.8 ft)

Digital inputs: 10 m (32.8 ft) Digital outputs: 10 m (32.8 ft)

Operating temperature

From 0 to 55 °C (from 32 to 131 °F)

Storage temperature

From -25 to 70 °C (from -13 to 158 °F)

Operating humidity

Relative humidity without condensate from

10 to 90%

Pollution status of the control device 2

Conformity

RoHS 2011/65/CE

WEEE 2012/19/EU

REACH (EC) Regulation

1907/2006

EMC 2014/30/UE LVD 2014/35/UE

Power supply

115... 230 VAC (+10 % -15%), 50/60 Hz

(±3 Hz), max. 4 VA (EV3271) or 4.9 VA

(EV3281) insulated

Earthing methods for the control device None

Rated impulse-withstand voltage

2.5 KV

Over-voltage category

II

Software class and structure

A

Analogue inputs 1 for PTC or NTC probes (cabinet probe)

PTC probes Sensor type

KTY 81-121 (990 @ 25 °C, 77 °F)

Measurement field

From -50 to 150 °C (from -58 to 302 °F)

Resolution

0.1 °C (1 °F)

NTC probes Sensor type

ß3435 (10 K@ 25 °C, 77 °F)

Measurement field

From -40 to 105 °C (from -40 to 221 °F)

Resolution

0.1 °C (1 °F)

Other inputs

Input configurable for analogue input (auxil-

iary probe) or digital input (door

switch/multi-purpose, dry contact)

Dry contact Contact type 5 VDC, 1.5 mA

Power supply None

Protection None

Digital outputs 1 electro-mechanical relay

Compressor relay (K1) SPST, 16 A res. @ 250 VAC (EV3271)

SPST, 30 A res. @ 250 VAC (EV3281)

Type 1 or Type 2 Actions Type 1

Additional features of Type 1 or Type 2 ac-

tions

C

Displays

3 digits custom display, with function icons

Alarm buzzer Incorporated

Communication ports

1 TTL MODBUS slave port for EVconnect app,

EPoCA remote monitoring system or for BMS

N.B.

The device must be disposed of according to local regulations governing the collection

of electrical and electronic waste.

This document and the solutions contained therein are the intellectual property of EVCO and thus pro-

tected by the Italian Intellectual Property Rights Code (CPI). EVCO imposes an absolute ban on the full

or partial reproduction and disclosure of the content other than with the express approval of EVCO. The

customer (manufacturer, installer or end-user) assumes all responsibility for the configuration of the de-

vice. EVCO accepts no liability for any possible errors in this document and reserves the right to make

any changes, at any time without prejudice to the essential functional and safety features of the equip-

ment.

EVCO S.p.A.

Via Feltre 81, 32036 Sedico (BL) ITALY

telefono 0437 8422 | fax 0437 83648