LED MEANING

Compressor LED

if it is lighted, the compressor will be ON

if it flashes, the defrost will be running

• press and or for setting “ -19 “

• press and for 4 s : the instrument

will show

If you have to select a parameter:

• press or

If you have to modify the value of the parameter:

• press and or

If you have to quit the procedure:

• press and for 4 s or do not op-

erate for about 60 s.

5 SIGNALS

5.1 Signals

6 ALARMS

6.1 Alarms

CODE

corrupted

memory

data

cabinet

probe

alarm

REASONS

there is the corruption

of the configuration

data of the memory of

the instrument

• the kind of cabinet

probe you have con-

nected is not right

• the cabinet probe

plays up

• the connection in-

strument-cabinet

probe is wrong

• the cabinet tempera-

ture is outside the

limits allowed by the

working range of

the instrument

REMEDIES

switch off the power

supply of the instru-

ment: unless the alarm

disappears, you will

have to change the in-

strument

• test the integrity of

the probe

• test the instrument-

probe connection

• test the temperature

close to the probe (it

has to be between

the limits allowed by

the working range)

EFFECTS

• you can not gain

access the setting

procedures

• the compressor will

be forced OFF

• the compressor will

be forced OFF

• if the defrost is run-

ning, it will immedi-

ately end

• the defrost will

never be activated

The instrument shows the indications above flashing.

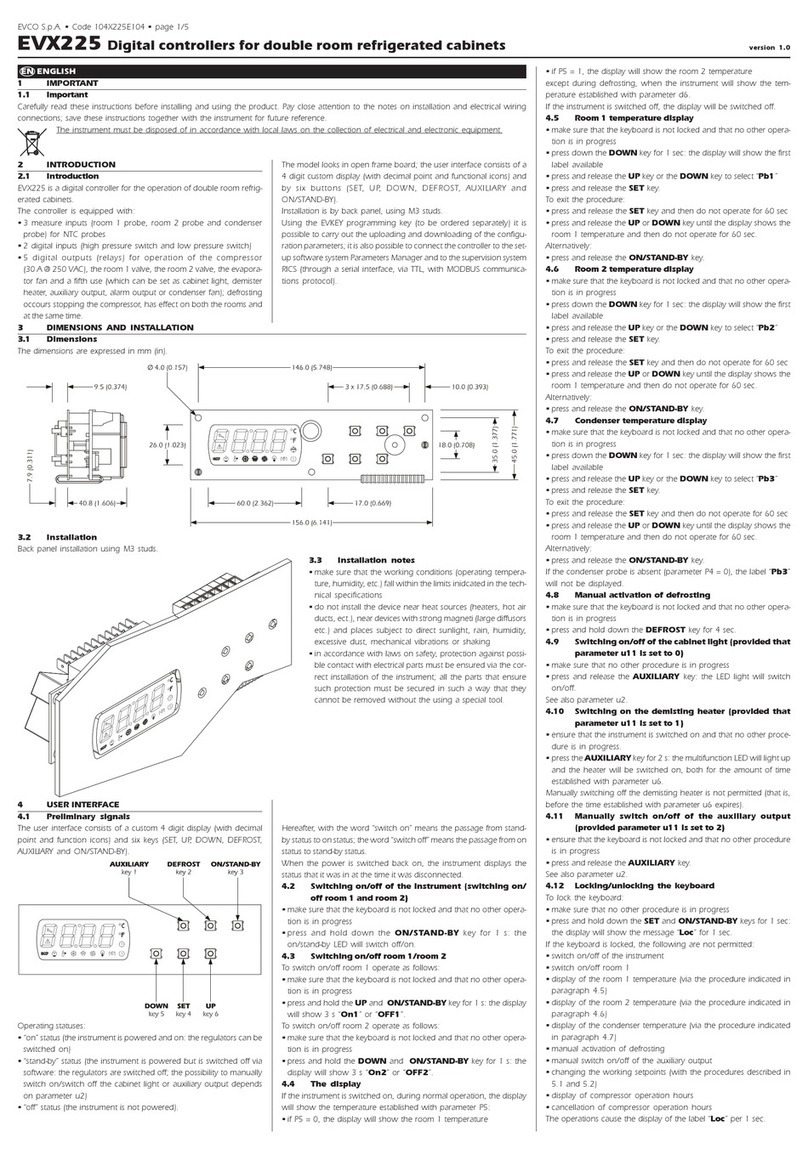

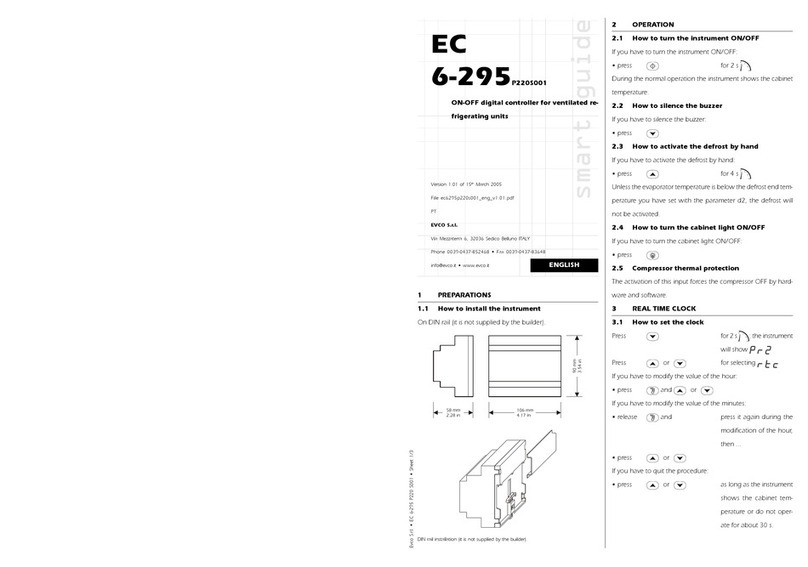

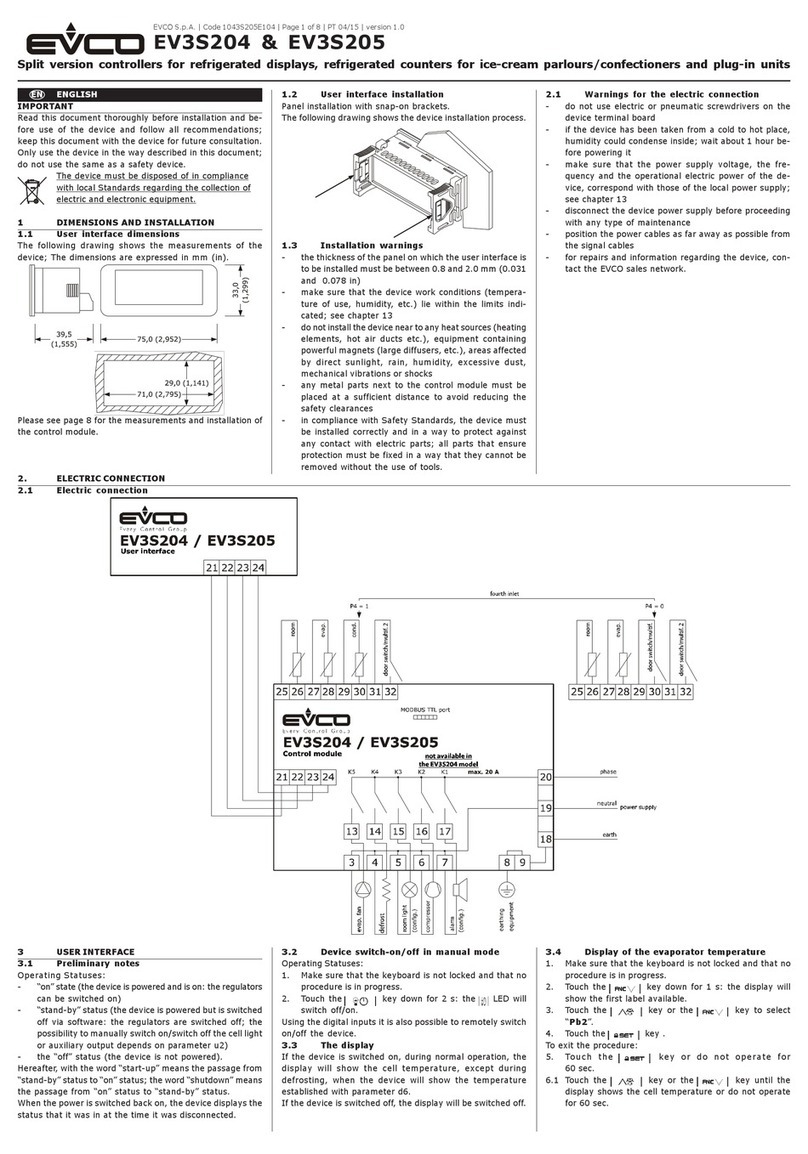

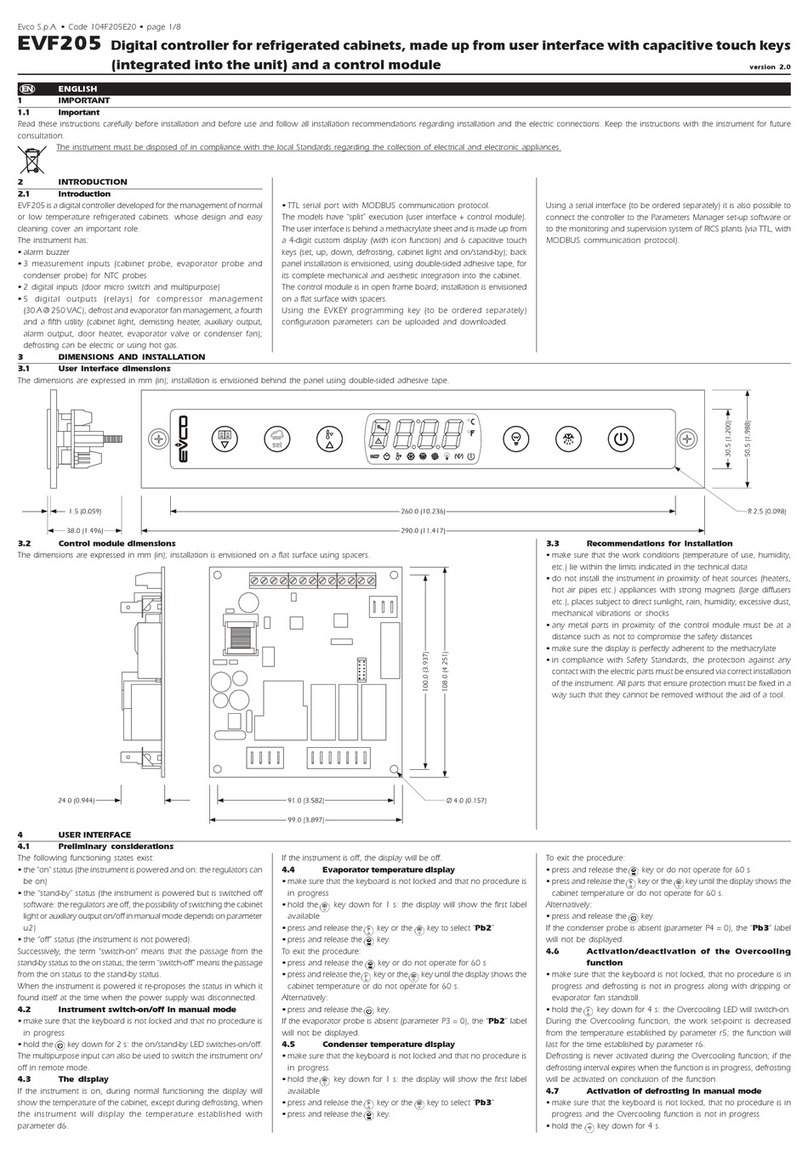

7 TECHNICAL DATA

7.1 Technical data

Box: self-extinguishing grey.

Size: 75 x 33.5 x 62 mm (2.95 x 1.31 x 2.44 in) the model with screw terminal blocks,

75 x 33.5 x 81 mm (2.95 x 1.31 x 3.18 in) the model with extractable terminal blocks.

Installation: panel mounting, panel cut out 71 x 29 mm (2.79 x 1.14 in), with click

brackets (they are supplied by the builder) or screw brackets (by request).

Frontal protection: IP 65.

Connections: screw terminal blocks with pitch 5 mm (0.19 in) for cables up to

2.5 mm² (0.38 sq in, power supply, input and output) or extractable terminal blocks

with pitch 5 mm (0.19 in) for cables up to 2.5 mm² (0.38 sq in, power supply, input and

output).

Ambient temperature: from 0 to 55 °C (32 to 131 °F, 10 ... 90% of relative humidity

without condensate).

Power supply: 230 Vac, 50/60 Hz, 11 VA.

Measure inputs: 1 (cabinet probe) for NTC probes.

Working range: from -40 to 99 °C (-40 to 99 °F).

Setpoint range: from -40 to 99 °C.

Resolution: 1 °C.

Display: one red LED 2-digit display 13.2 mm (0.51 in) high, output status indicator,

defrost status indicator.

Outputs: one 8 A @ 250 Vac relay for one ½ HP @ 230 Vac compressor control

(change-over contact).

Kind of defrost: stopping the compressor.

Defrost control: defrost interval and defrost length (automatic and by hand).

8 WORKING SETPOINT AND CONFIGURATION PARAMETERS

8.1 Working setpoint

LABEL MIN. MAX. U.M. DEF. WORKING SETPOINT

r1 r2 °C 0 working setpoint

8.2 Configuration parameters

LABEL MIN. MAX. U.M. DEF. MEASURE INPUTS

/1 -15 15 °C 0 cabinet probe calibration

LABEL MIN. MAX. U.M. DEF. REGULATOR

r0 1 15 °C 2 hysteresis (differential, it is relative to the working setpoint)

r1 -40 r2 °C -40 minimum value you can assign to the working setpoint

r2 r1 99 °C 99 maximum value you can assign to the working setpoint

LABEL MIN. MAX. U.M. DEF. COMPRESSOR PROTECTION

C0 0 15 min 0 minimum delay between you turn the instrument ON and the first compressor activation

C2 0 15 min 3 minimum delay between the compressor gets OFF and the following activation

LABEL MIN. MAX. U.M. DEF. DEFROST

d0 0 99 h/min (4) 8 defrost interval (0 = the defrost will never automatically be activated)

d3 1 99 min/s (4) 30 defrost length

d4 0 1 --- 0 defrost activation every time you turn the instrument ON (1 = YES)

d5 0 99 min/s (4) 0 delay between you turn the instrument ON and the defrost activation (it is important if

d4 = 1)

d6 0 1 --- 1 freeze of the temperature showed by the instrument during the defrost (1 = YES) (5)

db 0 1 --- 0 unit of measure defrost times (0 = d0 in hours, d3 and d5 in minutes, 1 = d0 in minutes,

d3 and d5 in seconds)

(4) the unit of measure depends on the parameter db

(5) the instrument restores the normal operation once the defrost ends and the cabinet temperature gets the working setpoint.