20 21

• Use caution when using the shower - avoid hitting it with other objects.

• Regularly clean the pressure regulator (aerator) with a solution of vinegar (1:3 ratio of 10%

vinegar and water; soak for approx. 2-3 hours); for deposit-resistant rubber elements, rub them

to remove the sediment.

• Regularly (at least once a quarter) clean, rinse and check the system, and if your water type

diers from the standard parameters (such as pressure and hardness), adjust the frequency to

the prevailing conditions , bearing in mind that the use of system under non-standard conditions

decreases its useful life and the lack of maintenance and care drastically reduces it.

• Shower heads (including thermostats) require periodie cleaning and replacement since, as the

basie functional element, they are exposed to increased wear and tear. Cleaning and repla-

cement should be performed by qualied sta - we recommend contacting the service center.

• Function switch (handle) requires maintenance, cleaning and replacement as just like the head,

it is exposed to rapid wear and tear and lime deposits .

• Aerator can be unscrewed and (at least once a quarter) rinsed and soaked for 2-3 hours in an

aqueous solution of vinegar (1:3 ratio of 10% vinegar and water) and then rinsed under running

water.

• For thermostatic heads, test the entire range of temperature once a month as fo ll ows: turn on

the cold water and run for 1-2 minutes and then hot for 1-2 minutes and return to the standard

position of temperature control knob.

• Head and handset rubber components need to be cleaned - hard water causes deposits of

naturaI dirt and sediment, resulting in a weak water stream.

• Please note that when operated as intended and properly maintained, the product is subject to

normaI wear and tear and its parts wear o during the normal cycle of operation - for example,

aerators and lt ers.

Below you can nd information o improper handlinq which is not allowed due to the possibi-

lity of product damaqe and the resultinq rejection of claims.

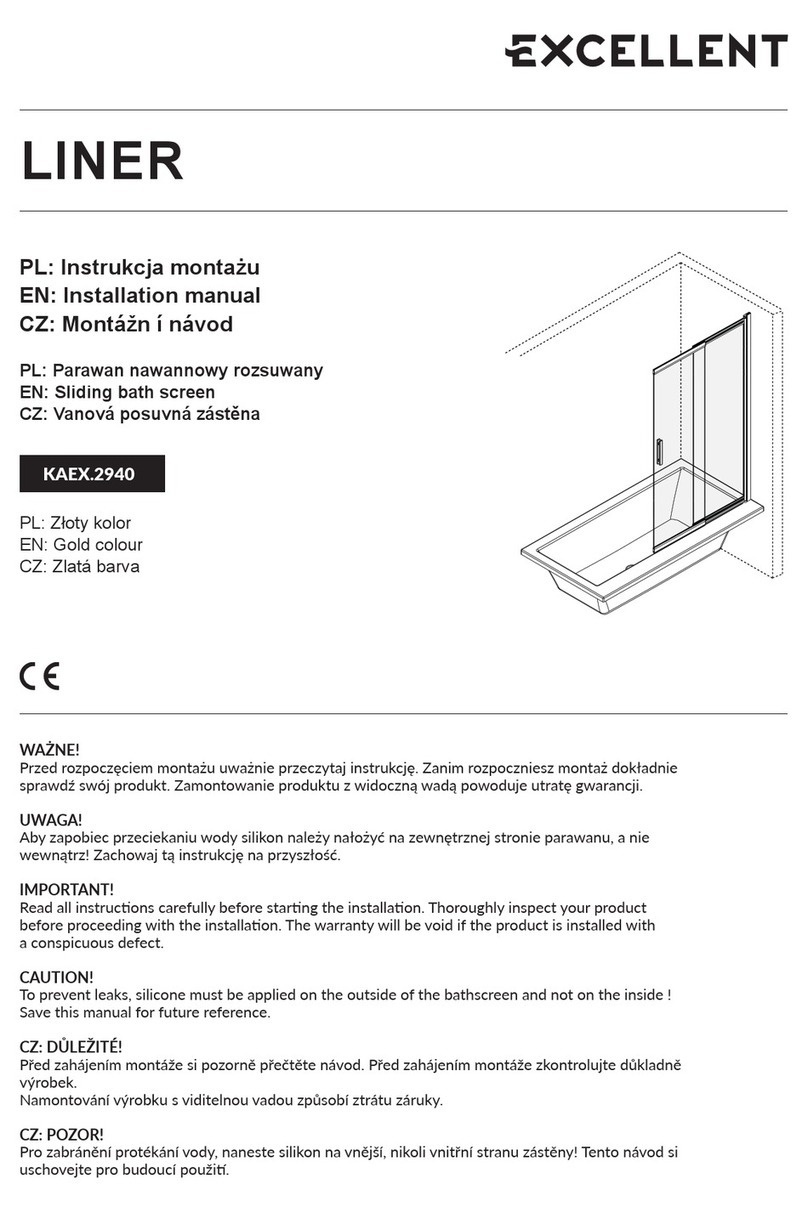

• Activities related to incorrect assembly- installation that does not follow instructions (if detailed

information on this topie is available), fai Iure to fol low locaI country rules and practices viola-

ting the best practices of installation and connect ion.

• lnstallation of the system which has not previously been ushed (run water until it is clean, free

of sediment and pollutants), and following the assembly has not been checked for leaks.

• Connecting the product to the water supply with the pressure that is tao low or tao high (normaI

operating pressure is 3 Bar);

• when there is a dierence in pressure between cold and hot water; connecting the product to

tankless water ow heaters and boilers. Connecting the product to the water system supplying

hard or contaminated water that exceeds national standards in the ar ea; faiIure to use water

lters in the system and water mesh lters when connecting each kit.

• Lack of periodic maintenance, inspection and care of the product and its operation through

proper maintenance.Lack of proper care for the product when it is not used (e.g., leaving water

in the pipes during very low temperatures when the system is not used) or when it is used (e.g.,

connecting the product to the water supply lines where the pressure is not standard or where

water hardness or purity deviates from the standard).

• Cleaning the exterior with abrasive or aggressive cleaning products containing acids, solvents,

chlorine, alcohol, etc.

• Use of the product inconsistent with its purpose and applicable st andards. Repair done by

unauthorised person or using parts of foreign origin.

• Incomplete installation, failing to use the relevant elements (such as gaskets, washers, lters

or other elements that constitute the whole of the system). Skipping additional sealing devices

(e.g.,Teon tape).

• Modifying the structure of the product, dismantling, alterations and improvements interfering

with the product structure by the user or other unauthorised persons.

• Use of inappropriate tools which can damage the product, aect its design or components ,

which because of the damage will be sensitive to the impact of constant high pressure, which

may result in loss of tightness of the components leading to subsequent leakage and ooding.

• FaiIure to gauge the location of the complete kit and its parts and to plan the preparation of

water supply lines. This is particularly important in systems installed ush with the wali, which

require the preparation of respective lines of water beneath the surface of the wali. To gauge

the location, measure the complete syst em, ensuring the mobility function of the system switch

(handle) and measure the depth to which the kit can be installed so that the decorative rosette

mounted on the tiles does not błock the switch. At the same t ime, provide access to parts in the

kit that are subject to wear and tear- the switch (handle) and the head and prevent their ooding

with the sealant that prevents free access to these parts.

• When performing installation and connecting to the water supply, faiIure to provide access to

usable parts that are subject to wear and tear and the connecting hoses. Access to these parts

allows periodie maintenance of the system (leakage) and easy execution of complaint-related

tasks.

• Unstable installation - this is essential for free-standing showers, columns and shower panels.

lnappropriate leveling and mounting result in overuse of connection elements which may start

leaking when exposed to high and persistent pressure.

• FaiIure to carry out emergency repairs which cause progressive destruction of the product.