(

To be handed to the workshop

Operating instructions

for the Sheet Metal Shear QSz 636-1

and

QSz 736-1

(42

Volts)

1.

Technical

Data

Current:

~

(AC

single

phase)

Cutting

Capacity

Radius

of

Type

Ste

el

sheet

up

to

smallest

curve

mm

I in.

mm

I in.

QSz

636-1 3

/64

>fa

1,2

15

QSz

736-1 (42 V)

1)

up

to

28.4

sh.

ton/sq

.

in

.

strength

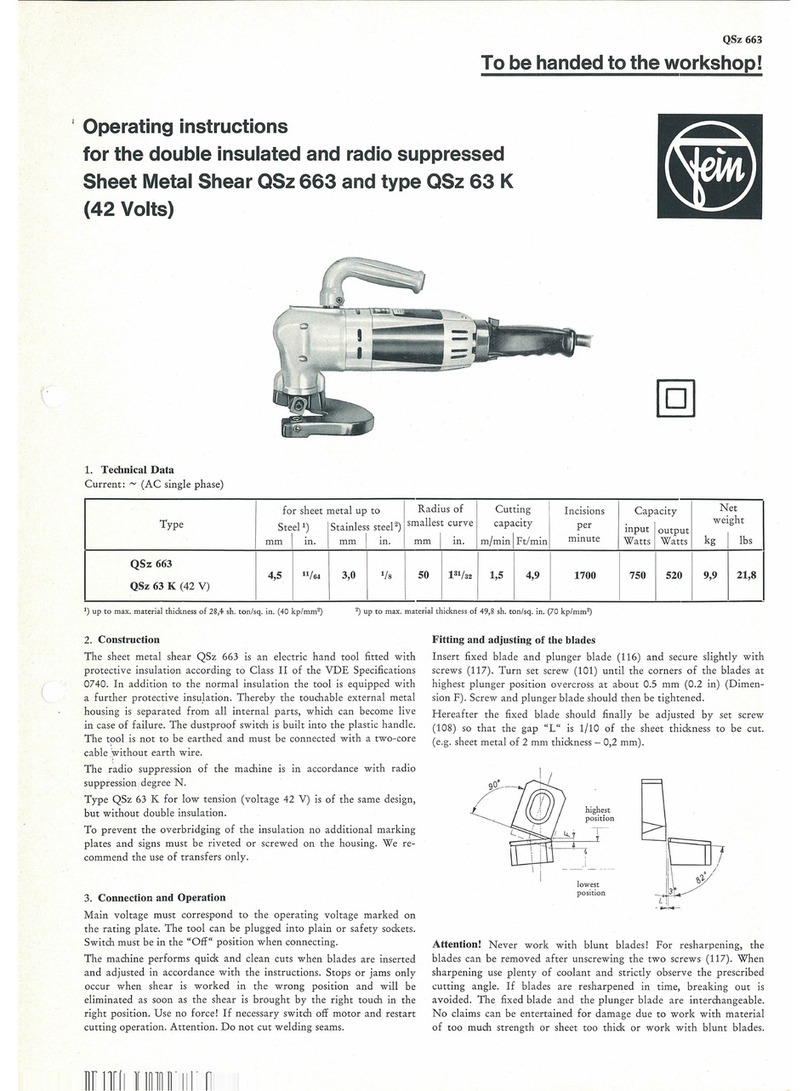

2.

Construction

The

sheet

metal

shear

QSz

636-1

is

an

electric

-

tool

of

Class

II

and

is

in

accordance

with

the

VDE

regulations

0740.

The

protec-

tive

insulation

is

additional

to

the

normal

insulation

and

pro-

tects

the

op

e

rator

against

electric

accidents

which

may

be

caused

by

defects

in

the

normal

insulation.

The

pole

housing

is

insulated

by

the

motor

hou

s

ing

made

of

shockproof

Polyamide

and

the

e

lectric

parts

of

the

armature

are

protected

by

a

sepa-

rating

insulation

against

the

drive

shaft.

The

machine

is

supplied

with

a

two-core

cable

without

earth

wire

and

must

not

be

earthed.

The

high

voltage

test

is

made

with

the

prescrib

ed

test

voltage

of

4000

Volts.

The

machine

is

radio-suppressed

accor-

ding

to

radio

interference

degree

0875.

Type

QSz

736-1 (42 V)

is

of

the

same

design,

but

w

ithout

double

i

nsu

lation.

This

type

must

be

co

nne

cted

with

a

two-core

cable

without

earth

wire.

To

prevent

the

overbridging

of

the

insulation

no

additional

marking

plates

and

signs

must

be

riveted

or

screwed

on

the

housing.

We

recommend

the

use

of

transfers

only.

3.

Connection

and

Operation

Main

voltage

must

correspond

to

the

operating

voltage

marked

on

the

rating

plate.

The

tool

can

be

plugged

into

plain

or

safety

sockets.

Switch

must

be

in

the

"Off"

position

when

connecting.

The

machine

performs

quick

and

clean

cuts

when

blades

are

in-

serted

and

adjusted

in

accordance

with

the

instructions

.

Stops

or

jams

·

only

occur

when

shear

is

worked

in

the

wrong

position

a

nd

will

be

e

liminated

as

soon

as

the

shear

is

brought

by

th

e

right

tou

ch

in

the

right

position.

Do

not

use

force!

If

necessary

switch

off

motor

and

restart

cutting

operation.

BE 409/e X 7.

73

Printed

in

Germany

Cutting

Incisions

per

Capacity

Net

I

capacity

minute

i

nput

I

output

weight

m/min

I

Ft

/

min

Watts

Watts

kg

I

lbs

I

I I

8

26

3500

280

150

1,6

3,52

4.

Fixing

and

adjusting

the

blades

Insert

shoe

blade

(47)

in

t

he

slot

of

the

shoe

(48)

and

secure

slightl

y

with

the

socket

head

cap

screw

(55).

An

eccentric

axle

(43)

is

to

be

seen

at

the

end

side

of

the

housing;

it

should

be

turn

ed

with

a

screwdriver

,

so

that

a

wide

gap

is

reached

between

plunger

and

shoe

. I

ns

ert

the

plunge

r

bla

de

(46)

in

the

gear

cu

tting,

so

that

th

e

corne

rs

of

the

blades

overcross

at

0,1

mm

(0

,004 in.)

to

0,6

mm

(0,02 in.).

A

little

distance

(x)

between

th

e

knife

edg

e

points

up

to

0,3

mm

(0,01

in.

)

raises

the

cut-

ting

capacit

y

on

curves

particu

l

arly

for

the

smaller

radi

us.

Do

not

for

get

disc

(56).

securing

ring

(57).

screw

tightl

y t

he

socket

head

cap

screw

(55).

When

you

turn

the

plunger

blade

from

180°,

the

opposite

cutting

edge

can

be

used

.

The

hori

z

ontal

space

,

that

is

to

say,

the

gap

"L"

between

the

cutting

edges

of

th

e

two

blades

(L,

see

fig

. a)

should

be

proper

placed

.

This

is

very

important

for

a

fa

st

and

continuous

c

uttin

g.

The

thr

ead

ring

(58)

will

be

turned

so

l

ong

that

this

gap

"L"

reac

hes

th

e fo

llo

wing

va

lues

by

sheet

wi

th

strength

40

kp

/

mm

2 (to 28.4

sh.

ton/sq.

in.).

when

cutting

the

maximum

sheet

thickness

(1

,2

mm

; 0,047

in

.)

= 0,24

mm

(0,009

in

.)

when

cutt

ing

the

smallest

sheet:

the

gap

"L" in

mm

= 0,2 x

sheet

t

hickness

(mm),

The

gi

v

en

values

are

indications

for

the

work

of

steel

sheets

of

normal

quality

.

For

the

other

materials

with

ot

her

strengths

and

deformabilities,

the

gap

"L"

should

be

changed:

for

the

soft