Ferm 9

BEFORE USING THE

COMBINATION SANDER

The Ferm combination sander can sand flat areas, corners,

round or small parts. Included in the kit is a metal scraper,

which can be used to remove loose paint and glue deposits

from the workpiece.

The sander is designed for sanding wood, removing

rust, sanding metal and polishing only.

This machine is designed to be used hand held - do not fix to a

bench with clamps or vice

Check package contents

Check contents against list in this manual to make sure

each item is present.

Check for damage

Before using this item check each part listed is undamaged.

Save packaging

Save major packaging for return of product for service or

repair.

BEFORE OPERATING

Attach the handle

•The multi-position Handle is attached with the two

thumbscrews provided.

•Fit the handle by pulling apart slightly and putting over

the bosses on either side of the sander.

•Adjust by slackening off the thumbscrews and setting

the handle at the required angle.

•Tighten the thumbscrews securely.

Attach the debris shield

•The shield attaches to the lug on the underside of the

handle.

•Remove the crosshead screw from the shield with a

suitable screwdriver.

•Push the shield over the lug with the curved part facing

forwards.

•Reinstall the crosshead screw and tighten.

CHECK POINTS

•Check the voltage on the sander corresponds with

your power supply voltage and that the plug and lead

are in good condition.

•Check you have the correct type of abrasive for the

job. Depending on the finish required use coarse grade

50 for rough/uneven surfaces and medium grade 80 for

more even surfaces, finally finish with fine grade 120.

•The sander is only for use on dry surfaces – it is not

designed to be used in wet or damp conditions -Do not

use water as a lubricant/cutting medium or wet and dry

abrasive paper

•Useabrasivesheetsdesignedforthesander only – they

are Velcro attached and have dust extraction holes to

remove debris from the surface, so will last longer.

•Ensure you have and wear suitable personal protec-

tion equipment during sanding and cleaning.

•Route the mains lead away from work area.

•Run idle for 30 seconds - if there is any abnormal vibra-

tion or other fault – switch off, inspect and rectify

before continuing

ATTACHING THE ACCESSORIES

Ensure the sander is switched off and the plug is

removed from the mains socket.

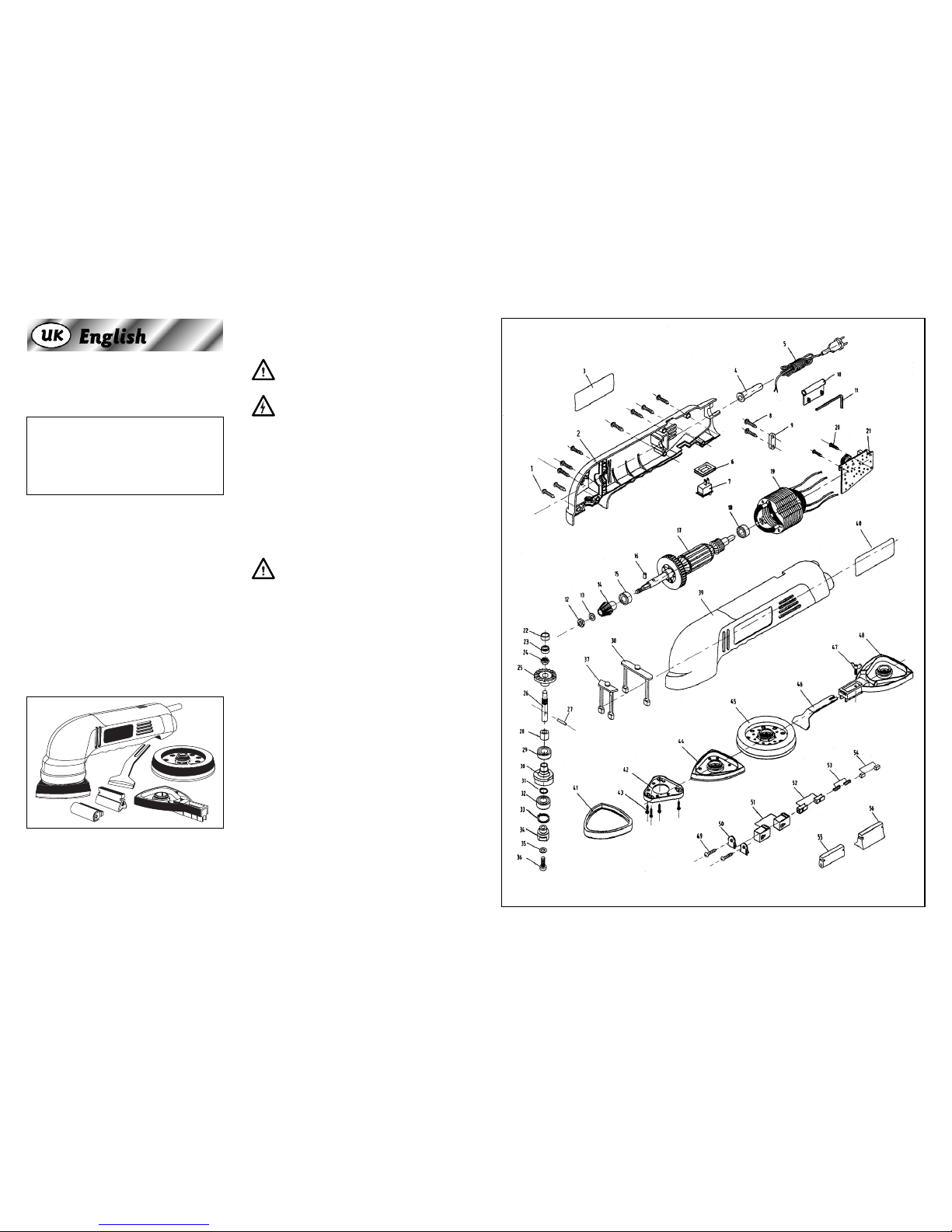

ATTACHING THE TRIANGULAR SANDING

FOOT

Refer to illustration below.

•Remove the Allen bolt and its lock washer from the

sander head.

•Place the foot (Velcro side downwards) on to the

sander drive boss and line up the two lugs in the foot

with the flats on the sander drive boss.

•Ensure the foot is fully home on the boss and reinstall

the Allen bolt with its washer.

•Tighten with the 5mm Allen wrench provided, (its

stored in a rubber holder on the mains lead).

Put the Allen wrench back in its holder after use.

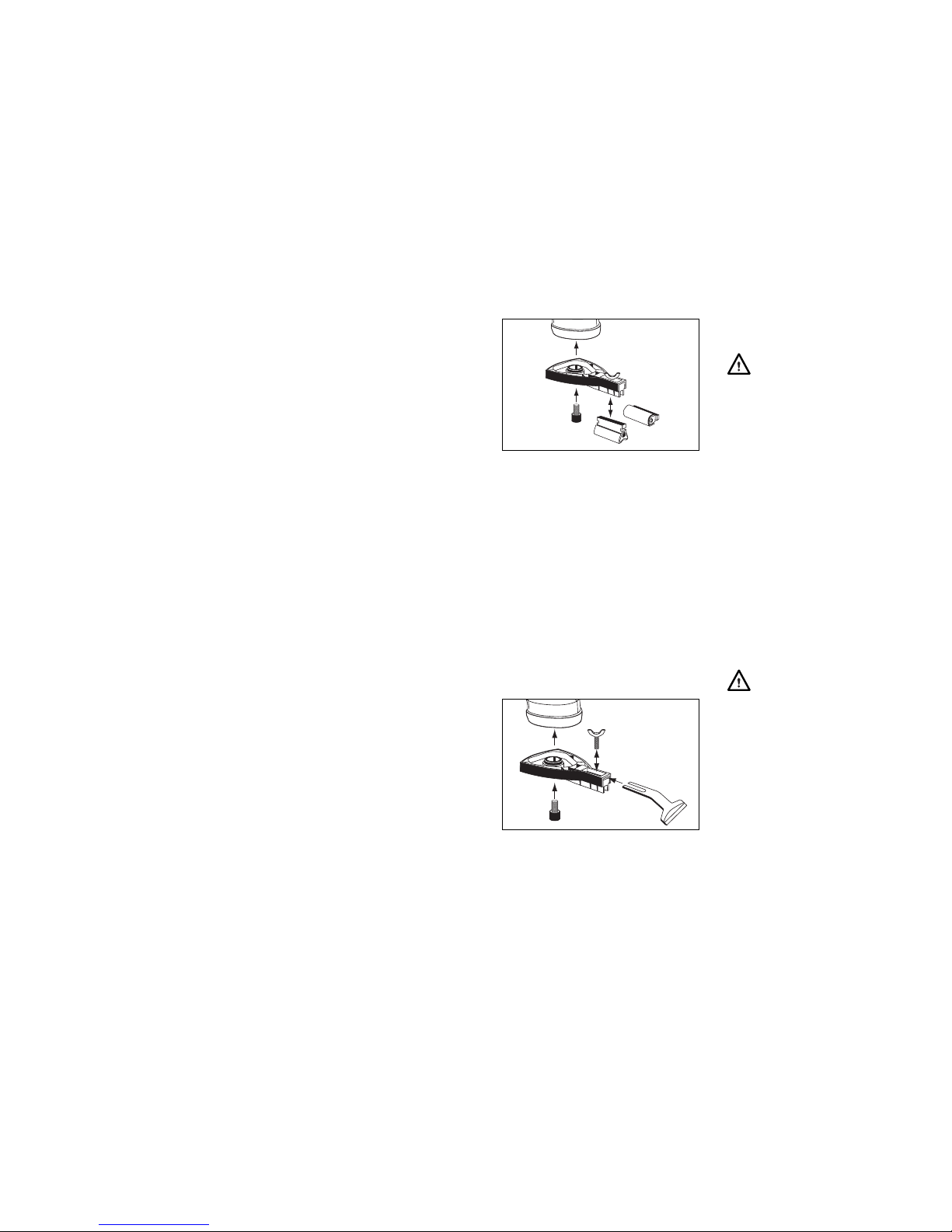

ATTACHING THE ROTATING SANDER

FOOT

Refer to illustration below.

•Remove the Allen bolt and its lock washer from the

sander head.

•Place the foot (Velcro side downwards) on to the

sander drive boss and line up the two lugs in the foot

with the flats on the sander drive boss.

•Ensure the foot is fully home and reinstall the Allen

bolt with its washer.

•Tighten with the 5mm Allen wrench provided, its

stored in a rubber holder on the mains lead.

•Put the Allen wrench back in its holder after use.

ATTACHING THE DETAIL SANDING FOOT

ADAPTOR

Refer to illustration on page 5.

•Remove the wing nut, its lock washer and the clamp

block from the detail sanding foot.

•Attach the foot to the sander as previously described

in attaching the triangular foot.

ATTACHING THE DETAIL SANDING FEET

TO THE ADAPTOR

Push the rubber lug into the adaptor upwards from the

underside as illustrated, it will be quite a tight fit – make

sure the lug in fully in between the rails.

4Ferm