Note

Improper handling can result in malfunctions.

Make sure that the following specifications are always observed.

Compare the limit values contained in these operating instructions with those of

your application (e.g. operating media, pressures, forces, torques,

temperatures, masses, speeds, voltages).

Take the ambient conditions at the location of use into consideration.

Comply with the regulations of the workers’ compensation trade association,

the German Technical Control Board (TÜV), of the VDE or relevant national

regulations.

Remove all transport packing, such as protective wax, foils (polyamide),

caps(polyethylene), cardboard boxes (except for the sealing elements of the

pneumatic connections).

The material used in the packaging has been specifically chosen for its

recyclability (exception: oiled paper = residual waste).

Use the product in its original status. Unauthorised modification is not

permitted.

The device is intended for use in an industrial environment. Measures may need

to be implemented in residential areas for interference suppression.

Range of applications and certifications

The information in this section, in combination with the UL marking on the product,

must be observed in order for there to be compliance with the certification

conditions of Underwriters Laboratories Inc. (UL) for USA and Canada. Observe the

following English-language remarks from UL:

This device is intended to be used with a Class 2 power source or Class 2

transformer in accordance with UL1310 or UL1585.

As an alternative a LV/C (Limited Voltage/Current) power source with one of the

following properties can be used:

– This device shall be used with a suitable isolating source such that the

maximum open circuit voltage potential available to the product is not more

than 30 V DC and the current is limited to a value not exceeding 8 amperes

measured after 1 minute of operation.

– This device shall be used with a suitable isolating source in conjunction with

afuse in accordance with UL248. The fuse shall be rated max. 3.3 A and be

installed in the 30 V DC power supply to the device in order to limit the available

current.

Note that, when more than one power supply or isolating device is used,

connection in parallel is not permitted.

In determining the acceptability of the combination, the following details are to be

examined:

– The suitability of the final mounting is to be determined.

– The devices are to be mounted in an enclosure with adequate strength and

thickness.

– The devices have not been investigated for field wiring. The suitability of the

final application is to be determined.

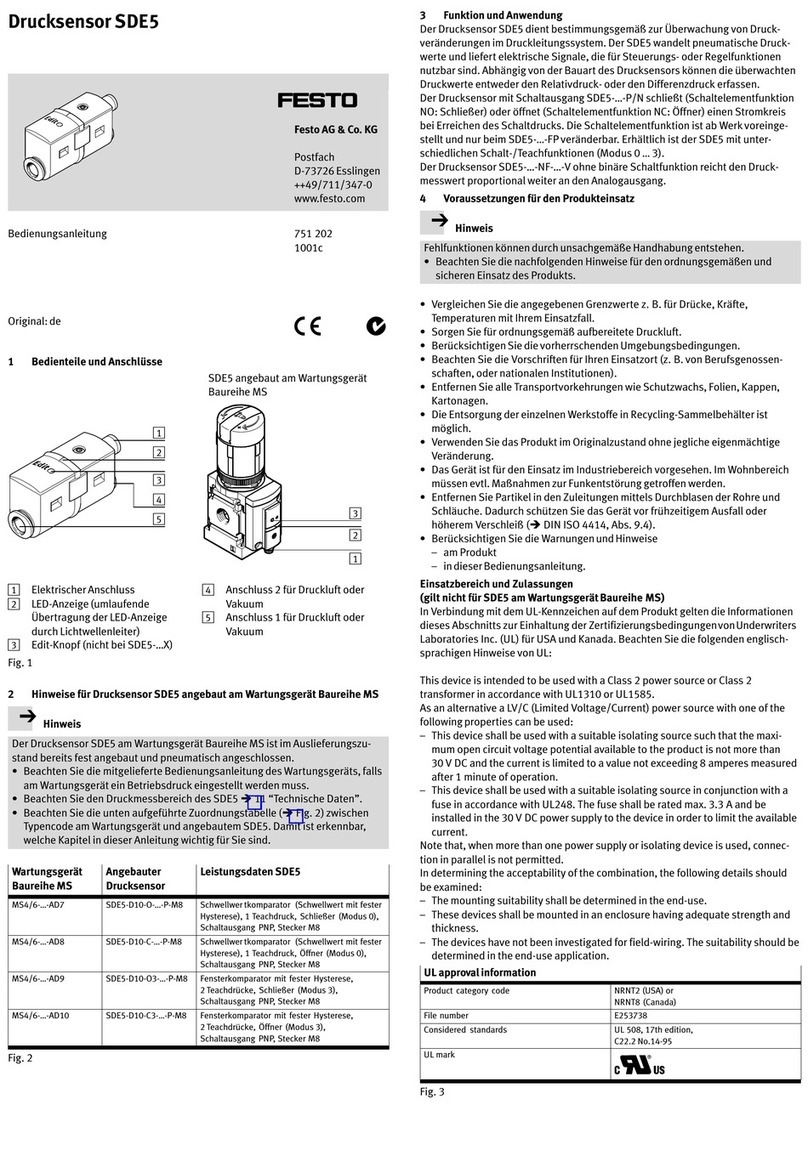

UL approval information

Product category code NRNT2 (USA) or

NRNT8 (Canada)

File number E253738

Considered standards UL 508, 17th edition,

C22.2 No. 14-95

UL mark

Fig. 4

4 Installation

4.1 Mechanical system

Note

Mount the SDE3 and connect the tubing so that no condensation from the

compressed air lines can gather in the device.

It can be mounted in any position. Mount the SDE3 as follows:

H-rail (manifold assembly)

1. Hang the SDE3 into the H-rail.

2. Press the SDE3 in the direction of the

arrow until the mounting slide catches

èFig. 5.

Fig. 5

Wall mounting

Observe the hole pattern (èFig. 24)

1. Attach the adapter plate, for example,

with two screws M3.

2. Hang the SDE3 into the adapter plate.

3. Press the SDE3 in the direction of the

arrow until the mounting slide catches

èFig. 6. Fig. 6

Plate mounting (threaded mounting)

Observe the hole pattern (èFig. 24)

Mount the SDE3 with washers and

screws M3 (èFig. 7).

Max. tightening torque 0.5 Nm

Fig. 7

Front panel mounting

1. Push the SDE3 into the recess

(70x22 mm) in the front panel.

2. Hang the clamping plate and press it

until the mounting slide locks into place.

3. Screw in the screws M3 with washers

(èFig. 8).

Max. tightening torque 0.3 Nm

In case of thin front panels (s < 2 mm),

washers might not be necessary.

Fig. 8

4.2 Pneumatic system

Connect the tubing of SDE3 as follows:

Insert the tube into the push-in fittings. Make sure the system is connected

correctly (èFig. 3).

4.3 Electrical system

Warning

Use only power sources which guarantee reliable electrical isolation of

theoperating voltage as per IEC/EN 60204-1. Observe also the general

requirements for PELV power circuits as per IEC/EN 60204-1.

Note

Long signal lines pick up more interference.

Make sure that the signal lines are always shorter than 30 m.

Wire the SDE3 as follows:

Pin Allocation Core colours1) Plug connectors2)

1Supply voltage

+24 V DC

Brown (BN) 4-pin M8 5-pin M12x1

5

2

3

4

1

2Switching output B

(Out B)

White (WH)

30 V Blue (BU)

4Switching output A

(Out A)

Black (BK)

5 n.c. –

1) In case of SDE3-…-K and/or the usage of the plug socket with the cable (èwww.festo.com/catalogue)

2) Tightening torque for the union nut on plug connector M8: max. 0.3 Nm; on plug connector M12:

max. 0.5 Nm.

Fig. 9