9 Fault clearance

Malfunction Possible cause Remedy

No display No operating voltage or

impermissible operating voltage

Apply permissible operating

voltage

Electrical connections swapped Connect the device in accordance

with the circuit diagram

Device defective Replace device

Display or

switching output

does not react in

accordance with

the settings

Short circuit or overload at the

output

Eliminate short circuit or overload

Incorrect switching point taught

(e.g. at 0 bar)

Repeat teaching procedure

Device defective Replace device

Parameter incorrect Reset to factory settings

[Er_1] / [FAIL] 1) Device defective Replace device

[Er_2] / [ASIC] 1) Device defective Replace device

[Er10] / [OVER] Measuring range exceeded Comply with the measuring range

[Er20] / [tEMP] 2) Temperature error Check operating conditions

Replace device

[Er21] / [SHRt] 2) Short circuit at OutA Eliminate short circuit

[Er22] / [SHRt] 2) Short circuit at OutB Eliminate short circuit

[Err] / [BUSY] OutA is switched active Check device settings

[Err] / [ID] Device ID error,

replication function failed

When replicating, use sensors with

the same type (same device ID)

[Err] / [COMM] IO-Link communication error Check the C/Q line

Check settings of the device sensor

1) Display flashes red

2) Display illuminated red

Fig. 21

10 Accessories

Accessories: èwww.festo.com/catalogue

11 Technical data

SPAN-

General

Approval certificate RCM

CE marking (èdeclaration of conformity) In accordance with EU EMC directive

Note on materials RoHS compliant

Input signal / measuring element

Operating medium Compressed air in accordance with

ISO 8573-1:2010 [7:4:4]; inert gases, operation

with lubricated medium possible

Temperature of medium [°C] 0 … +50

Ambient temperature [°C] 0 … +50

Output, general

Accuracy

– P16 [% FS] ±2 at room temperature

– B2, B11, V1, P1, P2, P6, P10,

P025, P05, V025, V05, P12

[% FS] ±1.5 at room temperature

– B2, B11, V1, P1, P2, P6, P10 [% FS] ±3 in the entire temperature range

– P025, P05, V025, V05, P12,

P16

[% FS] ±4 in the entire temperature range

Repeat accuracy [% FS] ±0.3 with Filt = OFF

Temperature coefficient [% FS/K] Typically 0.05

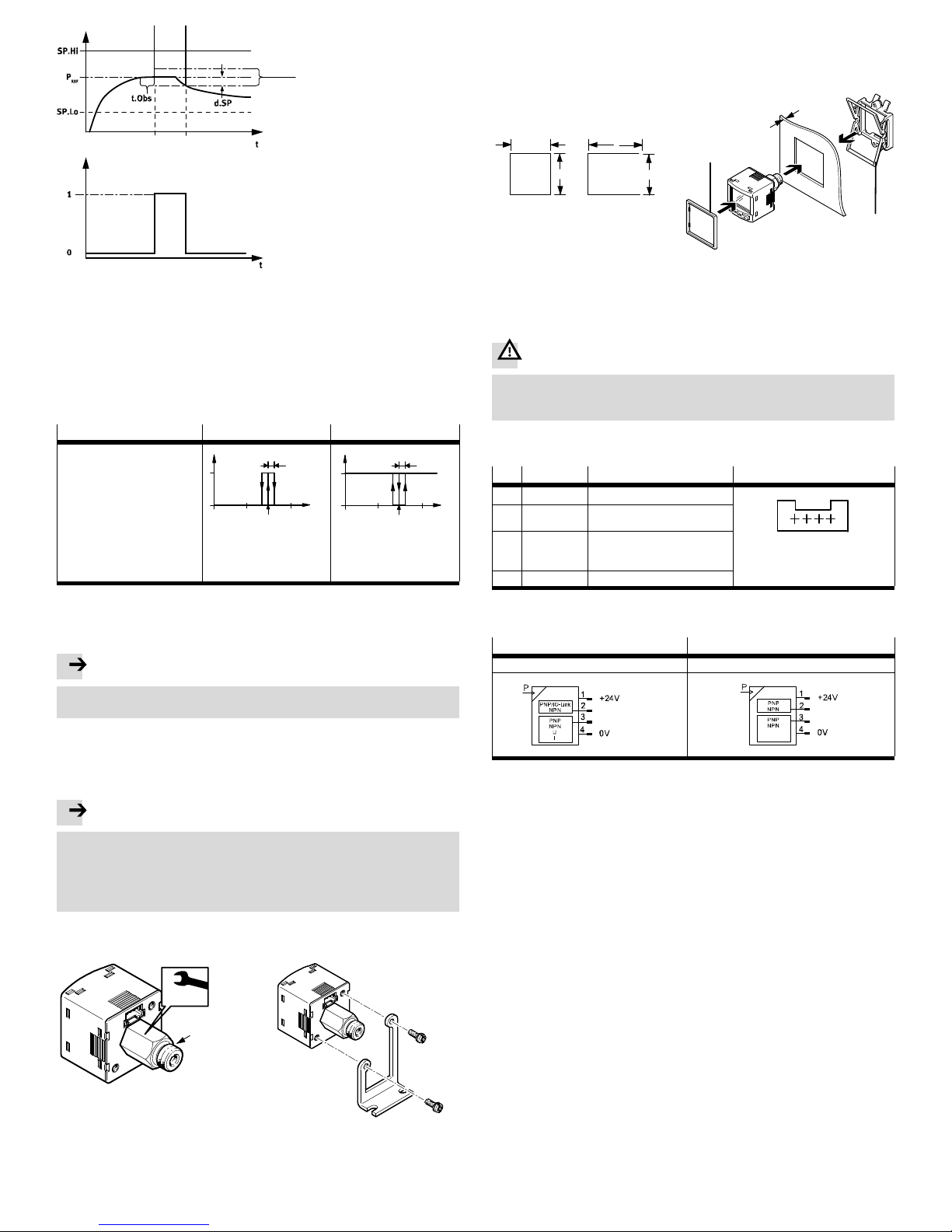

Switching output

Switching output 2x PNP or 2x NPN switchable

Switching function Threshold value comparator

Window comparator

Auto difference monitoring

Switch-on/switch-off time [ms] typ.: 2, max.: 4 with FILT = OFF

Max. output current [mA] 100

Capacitive load maximum DC [nF] 100

Voltage drop [V] Max. 2

Pull-down / pull-up resistor PNP: integrated; NPN: not integrated

Inductive protective circuit Present

Analogue output

Output characteristic curve

initial value … end value

[V]

[V]

0 … 10

1 … 5

[mA] 4 … 20

Max. load resistance of current

output

[Ω] 500

Min. load resistance of voltage

output

[kΩ] 20

Output, additional data

Short circuit protection Yes

Overload protection Present

Electronics

Max. current consumption [mA] 230

Nominal operating voltage DC [V] 24

Operating voltage range DC [V] 15 … 30

No-load supply current [mA] Max. 30

Ready-state delay [ms] typ. 801)

Protection against polarity reversal All connections against each other

Mechanical system

Mounting position Any, avoid condensation gathering in the sensor

Housing material PA reinforced

Keyboard material TPE-O

Threaded connections material Brass (nickel-plated)

Display

Displayable units bar, kPa, MPa, psi, mmHg, inchHg, inchH2O,

kgf/cm2

Immissions / emissions

Storage temperature [°C] –20 … +80

Max. permissible relative air

humidity

[%RH] 85

Degree of protection (in

accordance with EN 60529)

IP40

Protection class (in accordance with DIN

VDE 0106-1)

III

Resistance to shocks (in accordance with

EN 60068-2)

30 g acceleration with 11 ms duration

(half-sine)

Vibration resistance (in accordance with

EN 60068-2)

10 … 60 Hz: 0.35 mm / 60 … 150 HZ: 5 g

1) After this time, the electrical outputs take a defined, stable condition

Fig. 22

SPAN- -B2 -B11 -V025 -V05 -V1 -P025 -P05

Pressure measuring

range

Start value

[bar]

[MPa]

-1

-0.1

0

0

Pressure measuring

range

End value

[bar]

[MPa]

1

0.1

10

1

-0.25

-0.025

-0.5

-0.05

-1

-0.1

0.25

0.025

0.5

0.05

Overload range

Start value

[bar]

[MPa]

-1

-0.1

Overload range

End value

[bar]

[MPa]

5

0.5

15

1.5

1

0.1

2

0.2

5

0.5

1

0.1

2

0.2

Fig. 23

SPAN- -P1 -P2 -P6 -P10 -P12 -P16

Pressure measuring

range

Start value

[bar]

[MPa]

0

0

Pressure measuring

range

End value

[bar]

[MPa]

1

0.1

2

0.2

6

0.6

10

1

12

1.2

16

1.6

Overload range

Start value

[bar]

[MPa]

-1

-0.1

Overload range

End value

[bar]

[MPa]

5

0.5

6

0.6

15

1.5

20

2.0

Fig. 24

IO-Link1)

Protocol version Device V1.1

Profiles Smart sensor profile

Function classes Binary data channel (BDC)

Process data variable (PDV)

Identification

Diagnostics

Teach channel

Communication mode COM2 (38.4 kBaud)

Port class A

Process data width IN 2 byte

Process data content IN 2 bit BDC (pressure monitoring)

14 bit PDV (pressure reading)

IODD, IO-Link device description èwww.festo.com/sp

1) Only SPAN-...-PNLK-PNVBA

Fig. 25