Translation of the original instructions

© 2020 all rights reserved to Festo SE & Co. KG

1 Applicable documents

All available documents for the product èwww.festo.com/sp.

2 Safety

2.1 Safety Instructions

– Do not connect or disconnect plug connector when powered.

– Only mount the product on components that are in a condition to be safely

operated.

– Assembly and installation should only be carried out by qualified personnel.

These personnel have electrical training or a relevant qualification.

2.2 Intended use

Connection of a motor EMMB-AS to a servo drive CMMB-AS or CMMT-AS.

3 Configuration

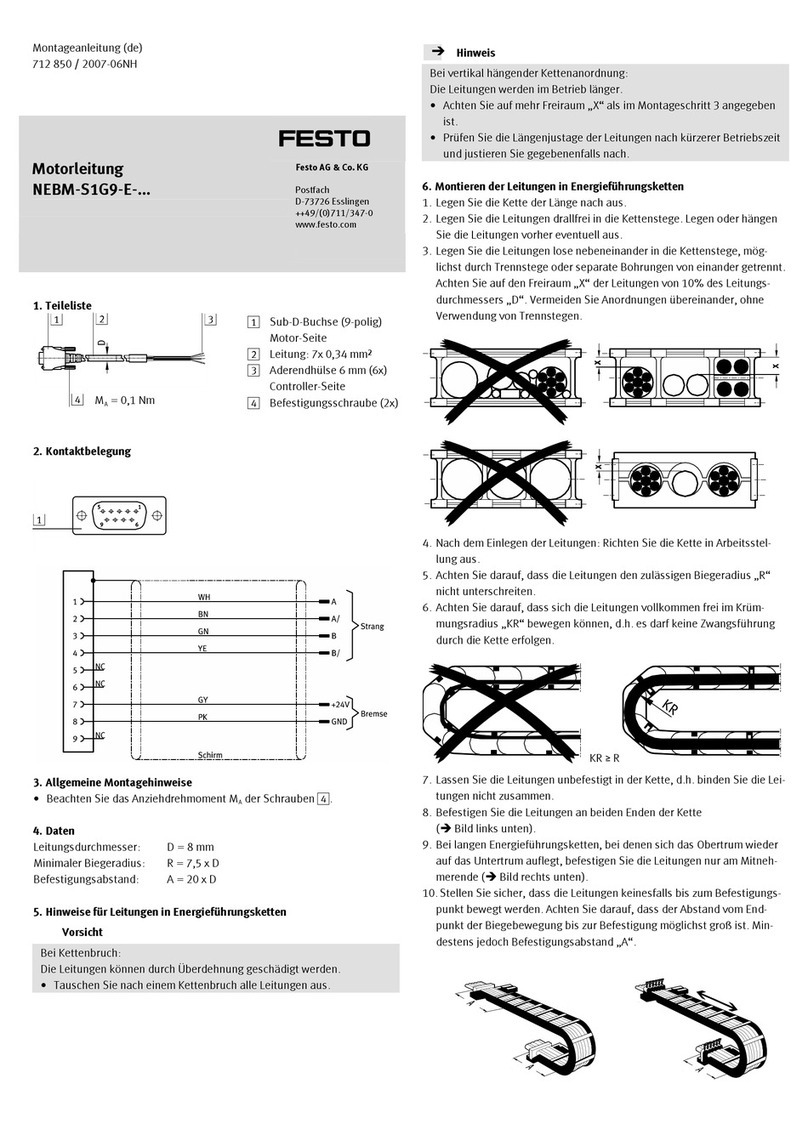

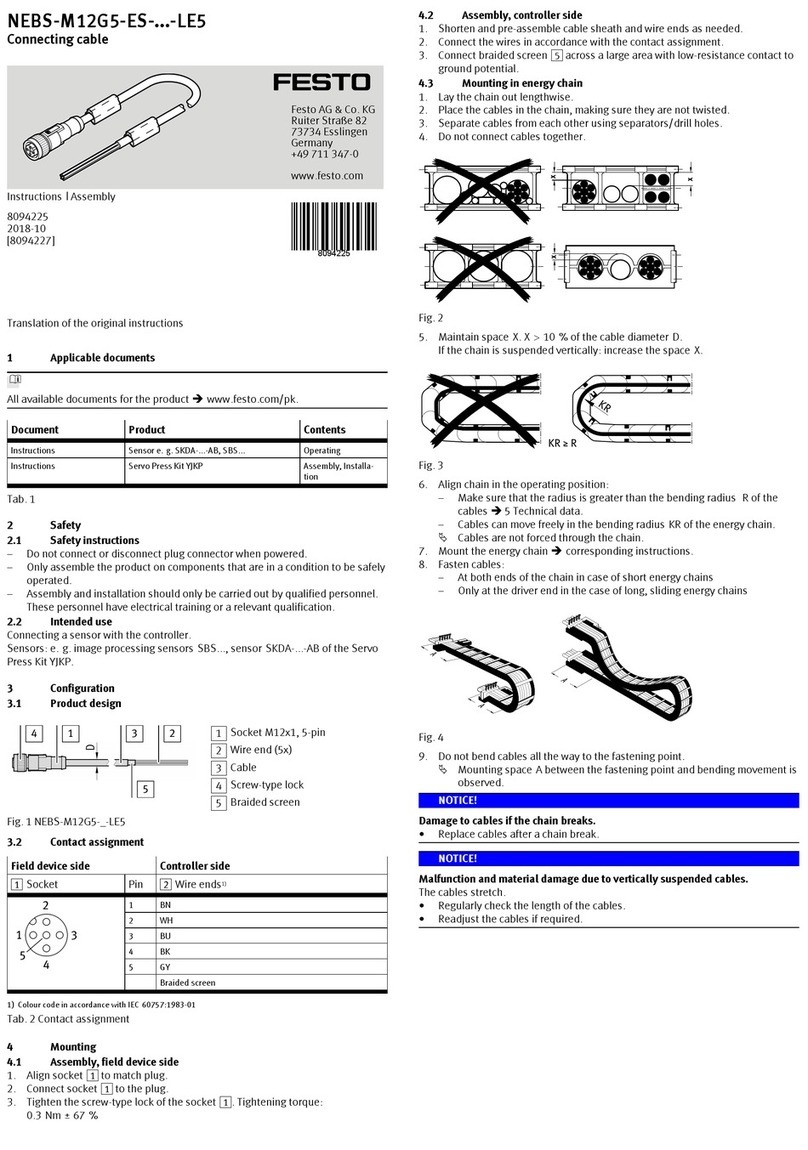

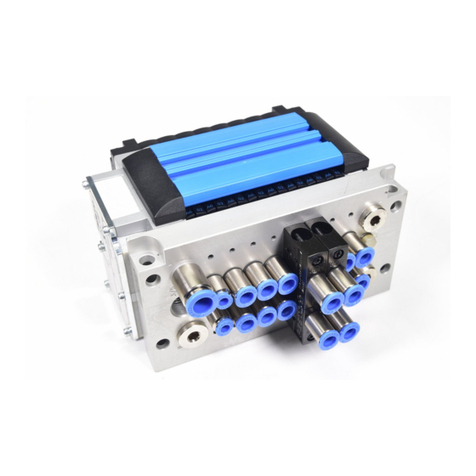

3.1 Product design

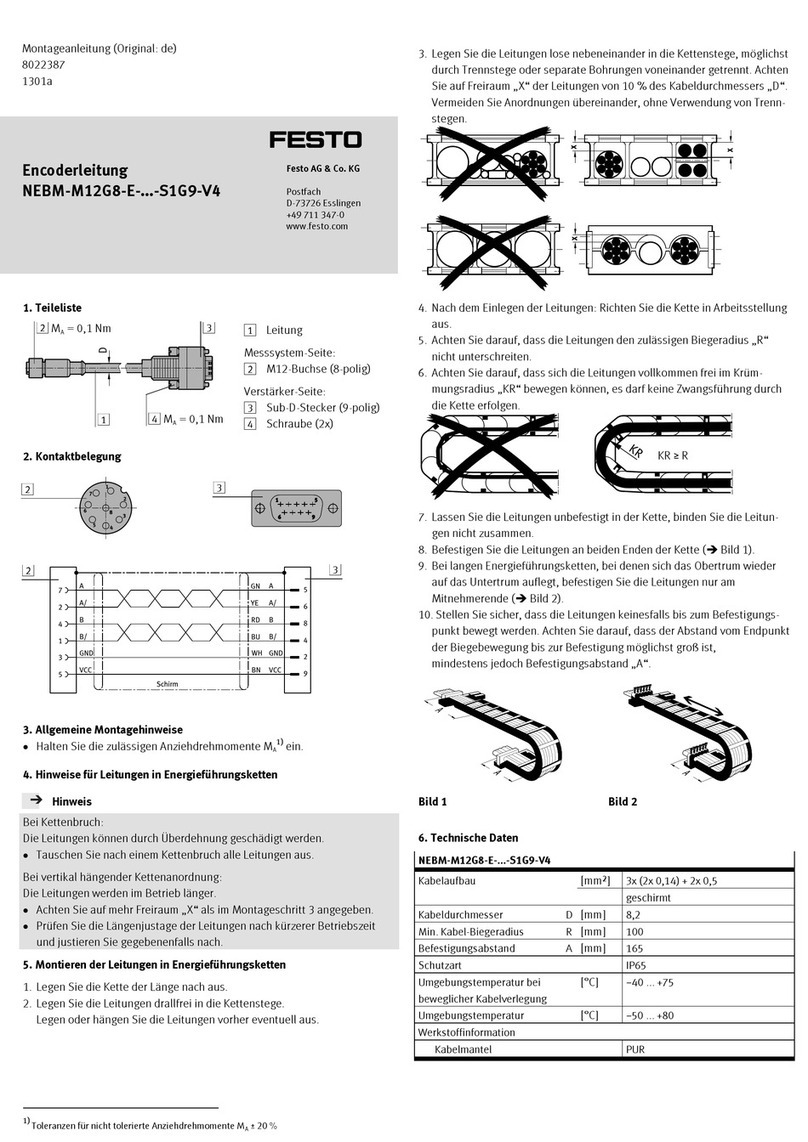

1Socket, plug pattern H6, 4-pin

2Wire end sleeve (3x)

3Cable

4PE insulated wire

5Extension sleeve

Fig. 1

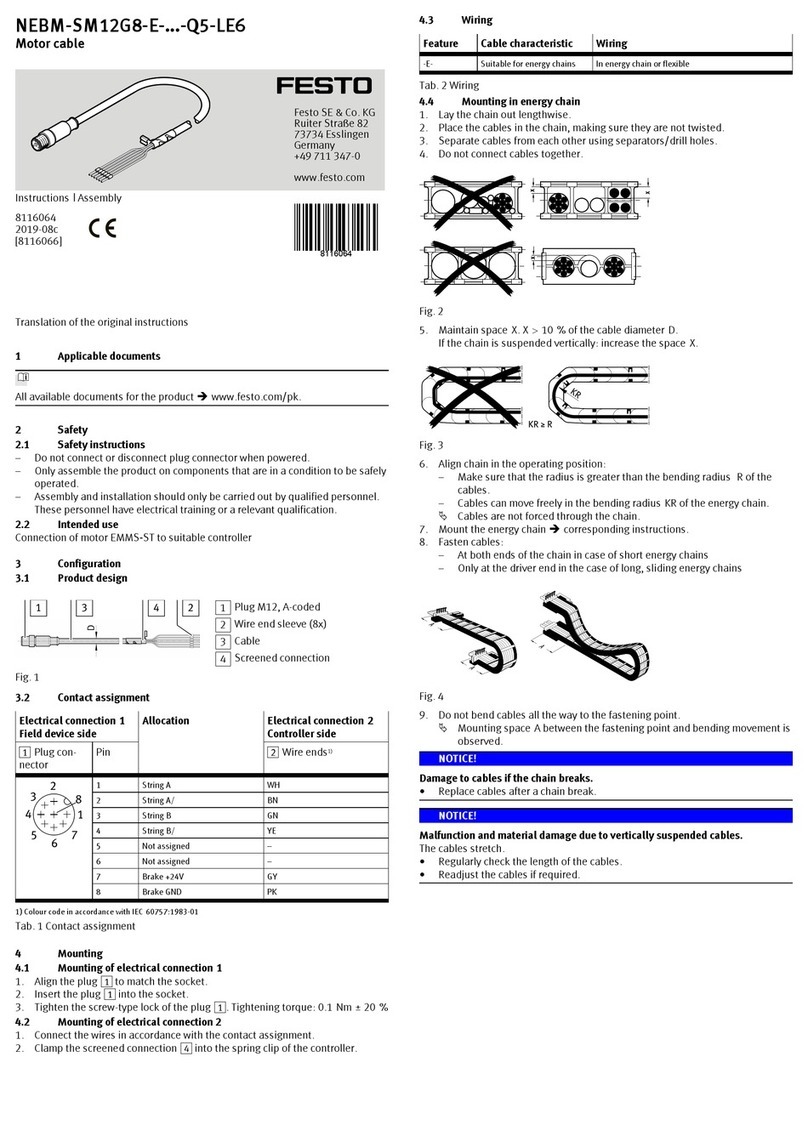

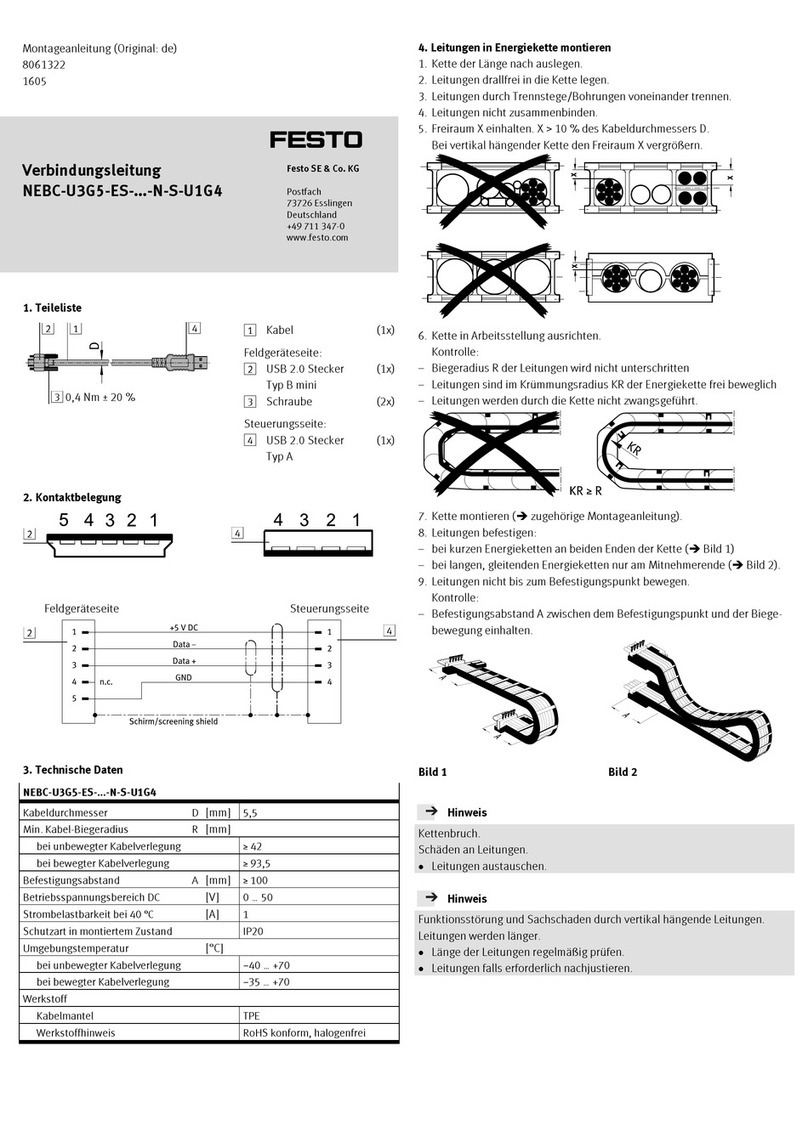

3.2 Contact assignment

Electrical connection1

Field device side

Electrical connection2

Controller side

1Socket Pin

Assignment/signal

2Wire ends1)

1 U YE

2 V RD

3 W BK

4 PE, shielding GNYE

1) Colour code in accordance with IEC 60757:1983-01

Tab. 1 Contact assignment

4 Assembly

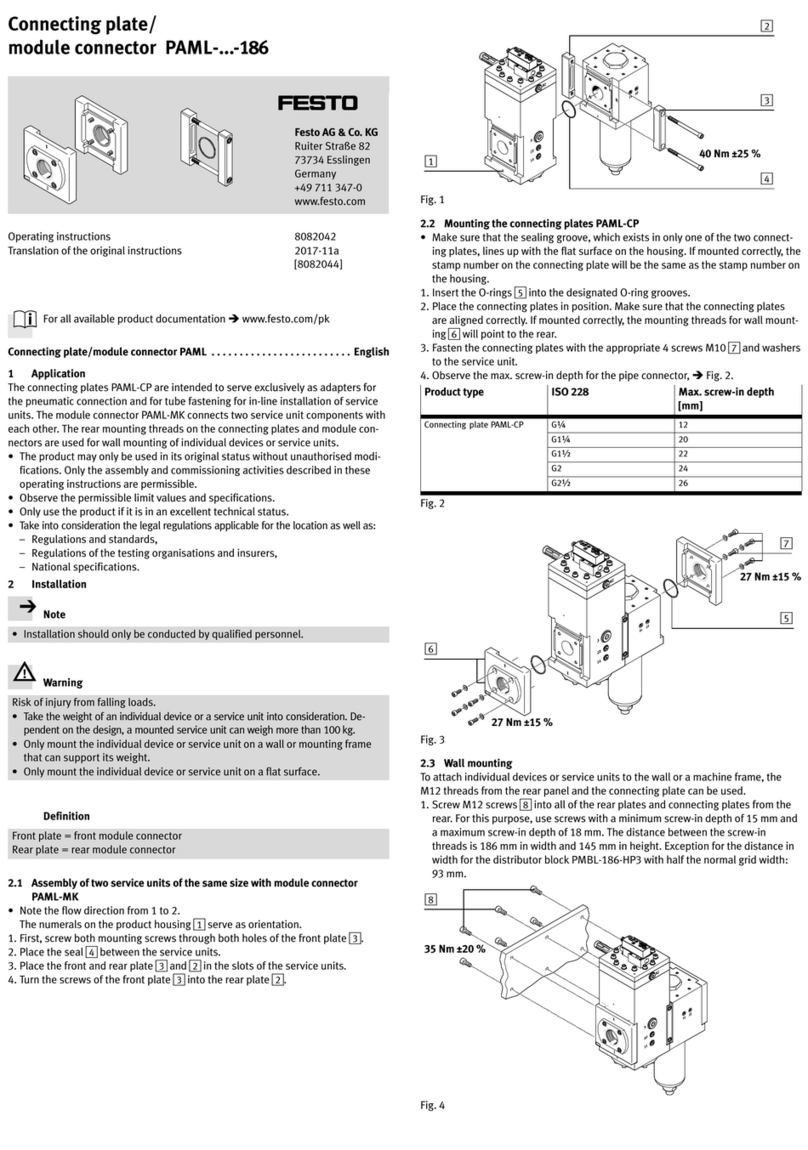

4.1 Mounting of electrical connection1

1. Align socket1 to fit the plug.

2. Connect the socket1 to the plug and click into place.

4.2 Mounting of electrical connection 2

For servo drive CMMB-AS

• Connect the wires in accordance with the contact assignment.

For servo drive CMMT-AS

1. Detach the clevis shoe5.

2. Strip the insulated wire4 and attach a wire end sleeve (1x 0.75mm2x

10mm).

3. Connect the wires in accordance with the contact assignment.

4.3 Wiring

Character-

istic

Cable characteristic Wiring

-K- Standard Flexible (freely movable, unguided wiring)

The line can be dynamically bent, but not for robots

or energy chains.

-E- Suitable for energy chains In energy chain or flexible

Tab. 2 Wiring

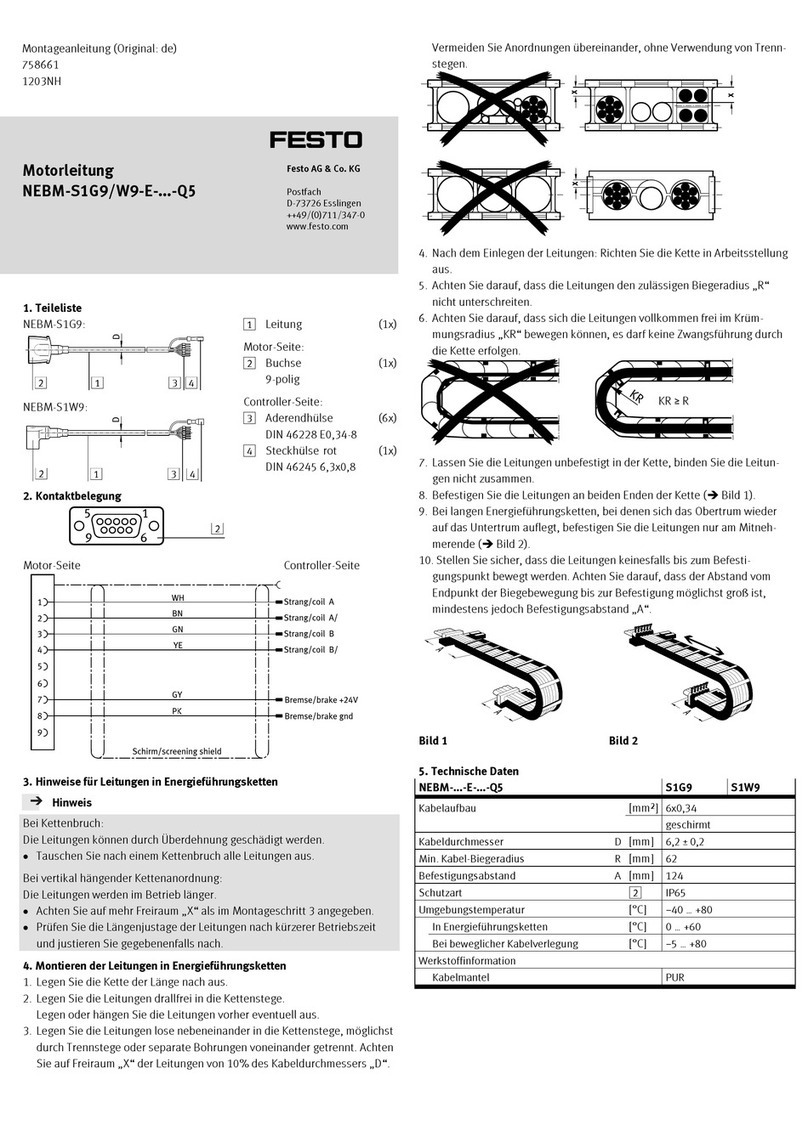

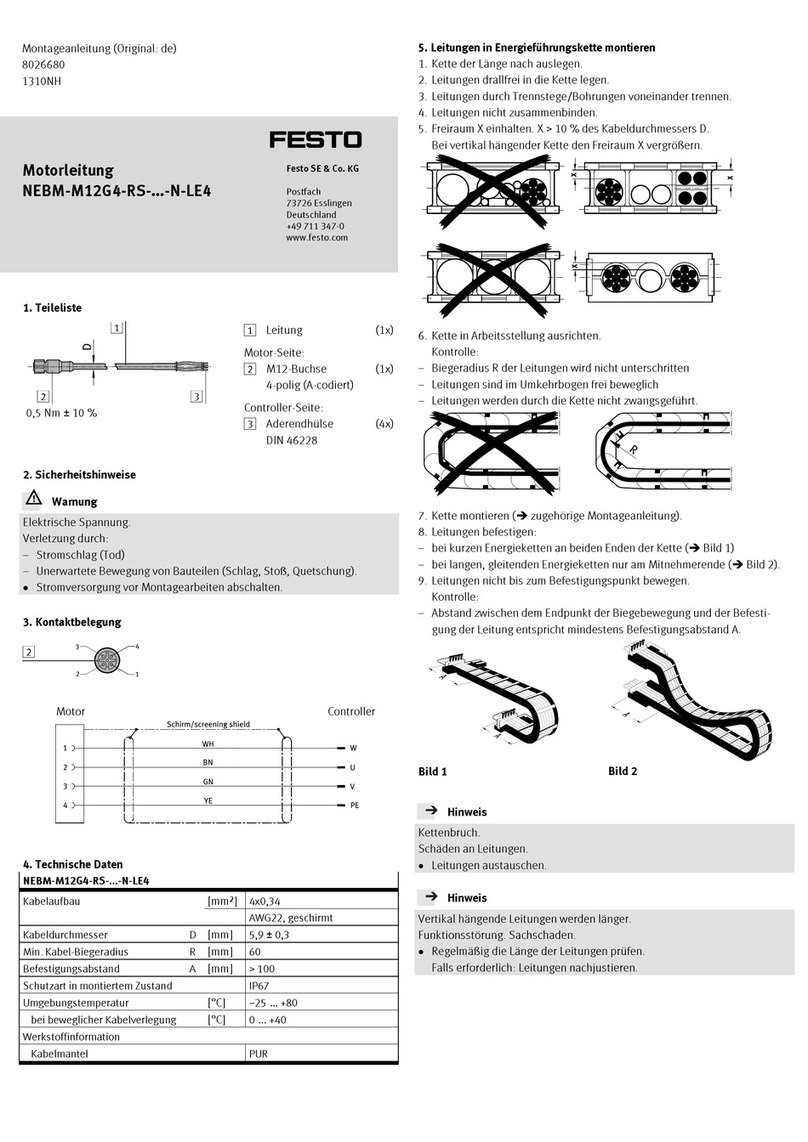

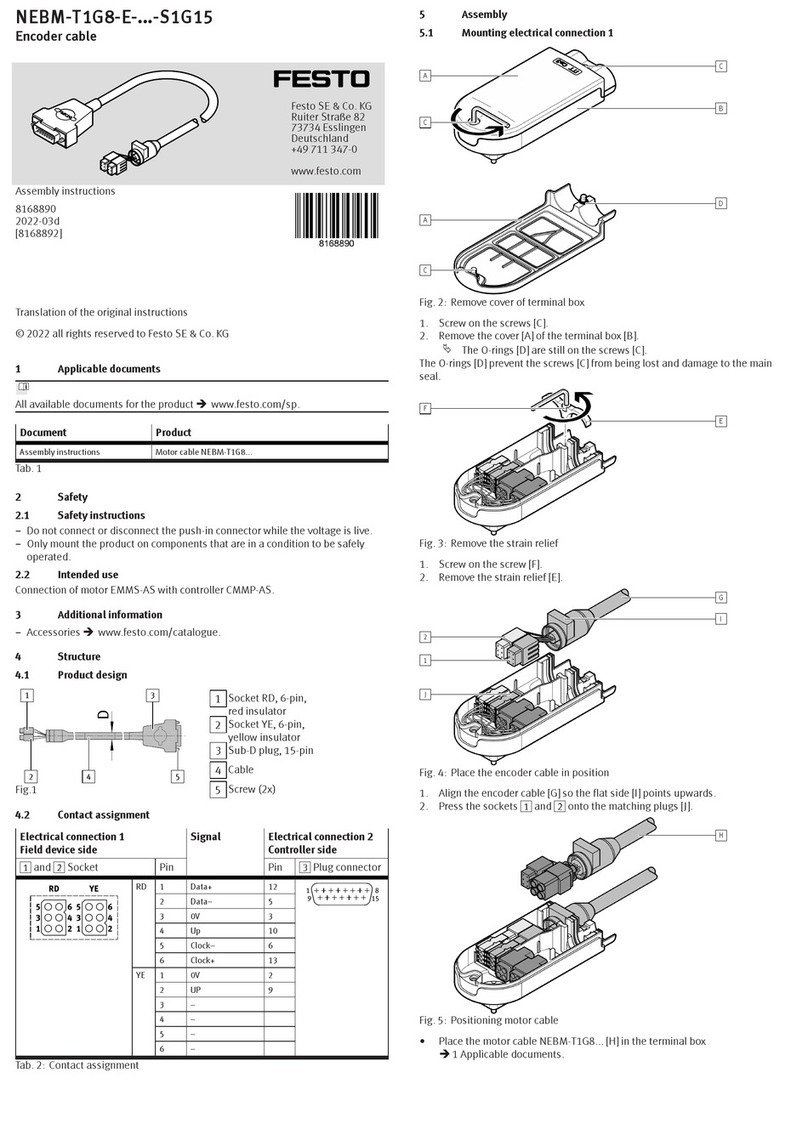

4.4 Mounting in energy chain

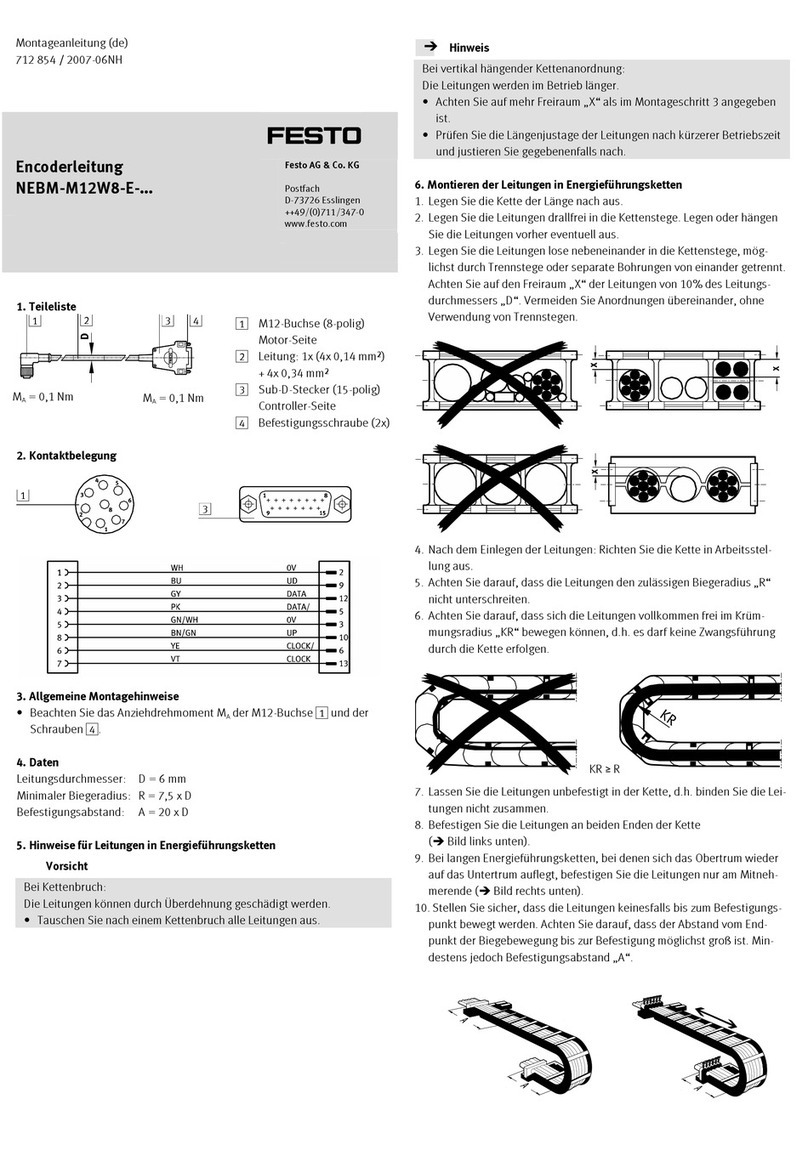

1. Lay the chain out lengthwise.

2. Place the cables on the chain, making sure they are not twisted.

3. Separate cables from each other using separators/drilled holes.

4. Do not connect cables together.

Fig. 2

5. Maintain spaceX. X>10%of the cable diameterD.

If the chain is suspended vertically: increase spaceX.

Fig. 3

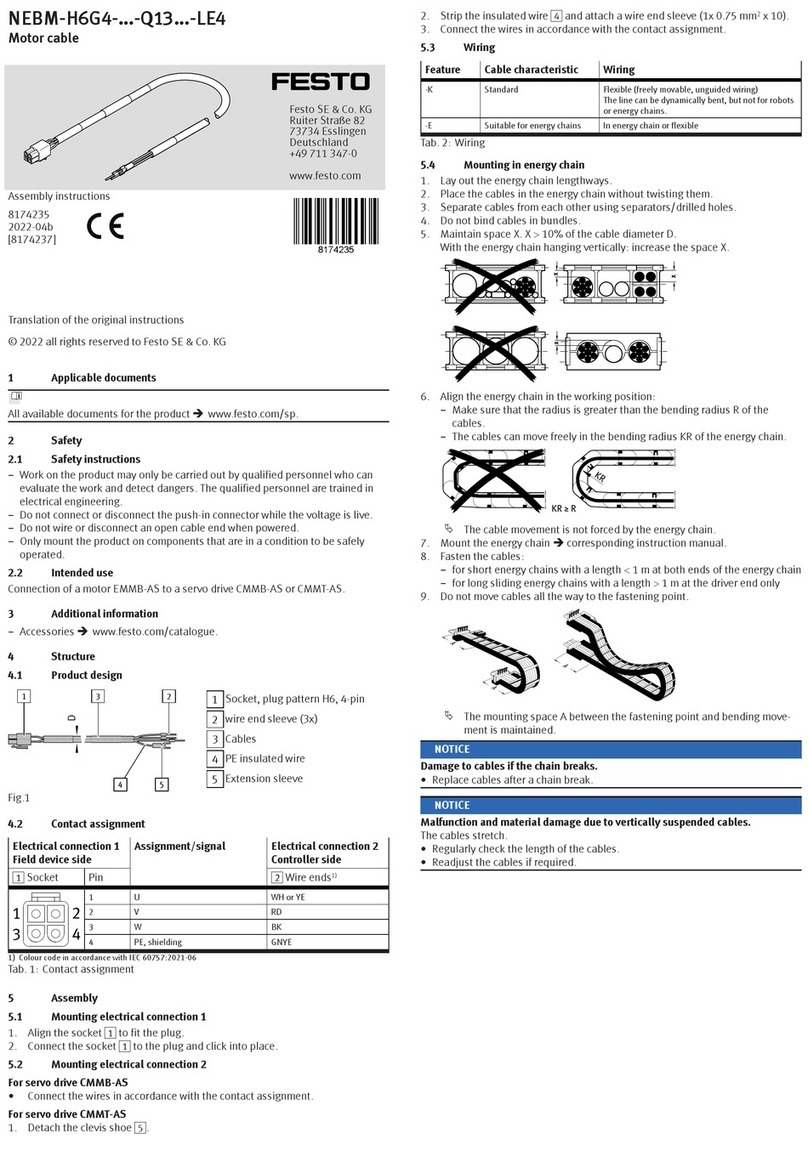

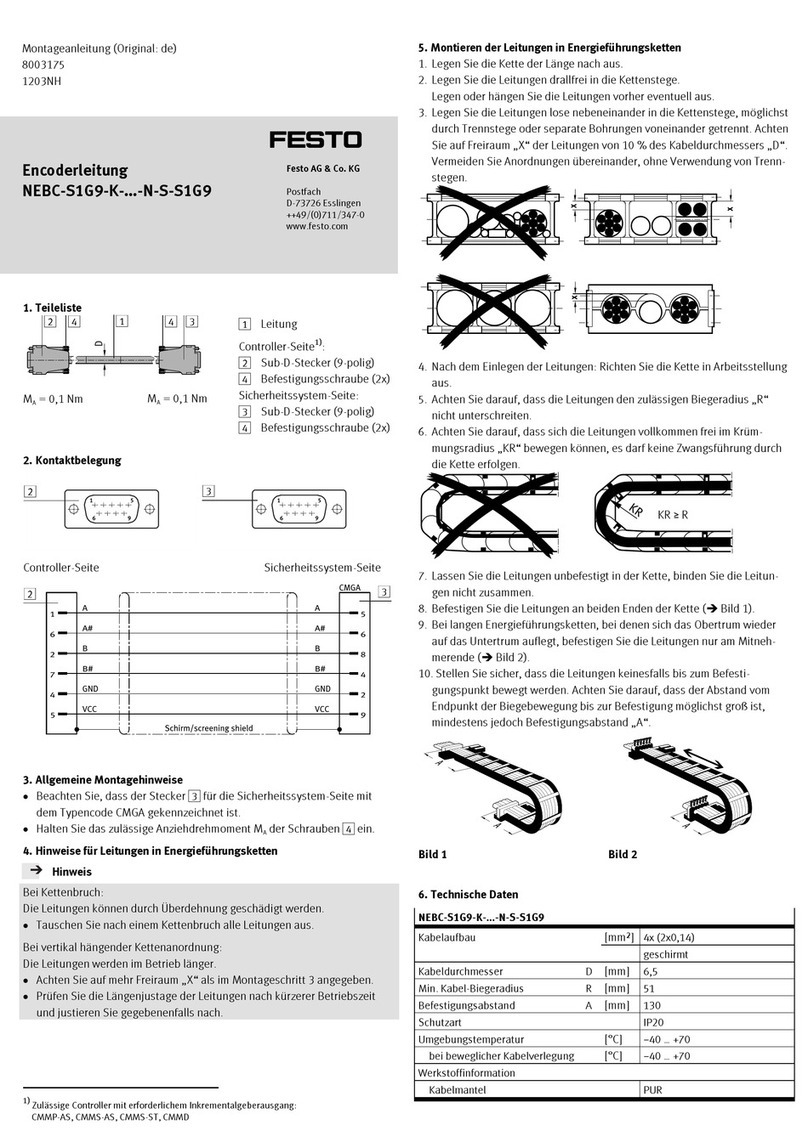

6. Align chain in the operating position:

– Make sure that the radius is greater than the bending radiusR of the

cables.

– Cables can move freely in the bending radius KR of the energy chain.

ÄCables are not forced through the chain.

7. Mount the energy chain ècorresponding instructions.

8. Fasten cables:

–with short energy chains (length <1m) at both ends of the chain

–with long sliding energy chains (length >1m) only at the driver end

Fig. 4

9. Do not move cables all the way to the fastening point.

ÄMounting spaceA between the fastening point and bending movement is

maintained.

NOTICE!

Damage to cables if the chain breaks.

• Replace cables after a chain break.

NOTICE!

Malfunction and material damage due to vertically suspended cables.

The cables stretch.

• Regularly check the length of the cables.

• Readjust the cables if required.

8135533

NEBM-H6G4-...-Q13...-LE4

Motor cable

8135533

2020-05a

[8135535]

Assembly instructions

Festo SE & Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

+49 711 347-0

www.festo.com