Festo — CAMC-G-S1 — 2022-07d

Table of contents

1 About this document. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Safety and requirements for product use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.1 General safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.2 Intended use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.3 Foreseeable misuse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.4 Achievable safety level, safety function in accordance with EN ISO 13849-1/

EN 61800-5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Requirements for product use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.1 Technical prerequisites. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.2 Qualification of the specialist technicians (requirements for staff). . . . . . . . . . 9

2.2.3 Diagnostic coverage (DC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.4 Range of application and approvals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Product description of safety module CAMC-G-S1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Product overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1.1 Purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1.2 Supported devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

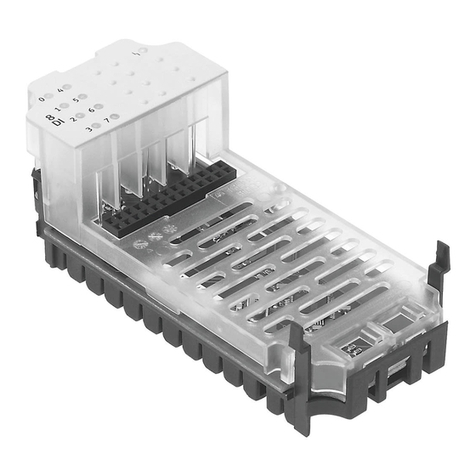

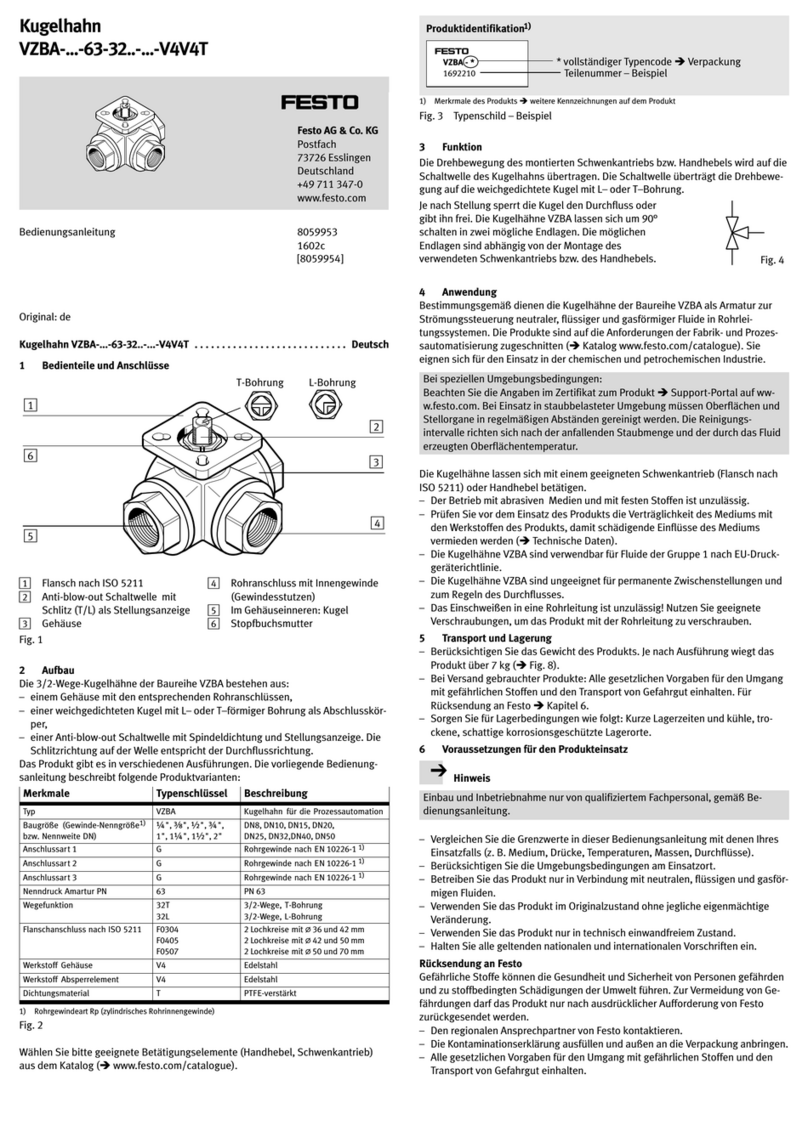

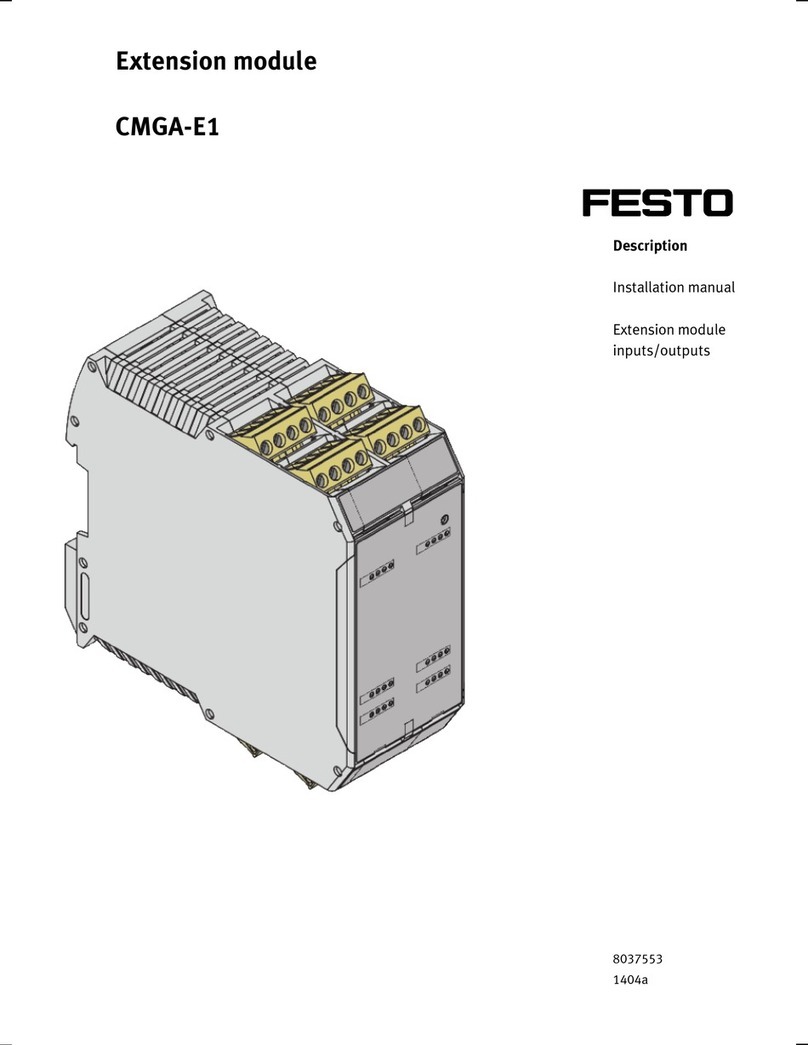

3.1.3 Operating elements and connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1.4 Scope of delivery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 Function and application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2.1 Description of the STO safety function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2.2 Overview of interface [X40]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.3 Control inputs STO-A, 0V-A/STO-B, 0V-B [X40]. . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.4 Feedback contact C1, C2 [X40]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2.5 24 V, 0 V auxiliary power supply [X40]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2.6 Status indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2.7 DIL switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3 Functions in the motor controller CMMP-AS-...-M3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.4 Time response. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4.1 STO basic time response. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4.2 Time response of activation of STO in operation with restart. . . . . . . . . . . . . . 19

3.4.3 Time response of activation of SS1 in operation with restart. . . . . . . . . . . . . . 21

4 Assembly and installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.1 Mounting/removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2 Electrical installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2.1 Safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2.2 Connection [X40]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2.3 Minimum wiring for initial start-up [X40]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.3 Sample circuits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.3.1 Safe Torque Off (STO). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.3.2 Deceleration and Safe Torque Off (SS1, "Safe Stop 1"). . . . . . . . . . . . . . . . . . 27