4 / 92 Festo 7DHTGd_en

Table of Contents

1 Important information 6

1.1 About these repair instructions 6

1.2 Symbols used in these repair instructions 6

1.3 Text designations used in these repair instructions 7

1.4 General safety instructions 7

1.5 Technical requirements 8

1.6 Standards and test values 8

2 General product description 8

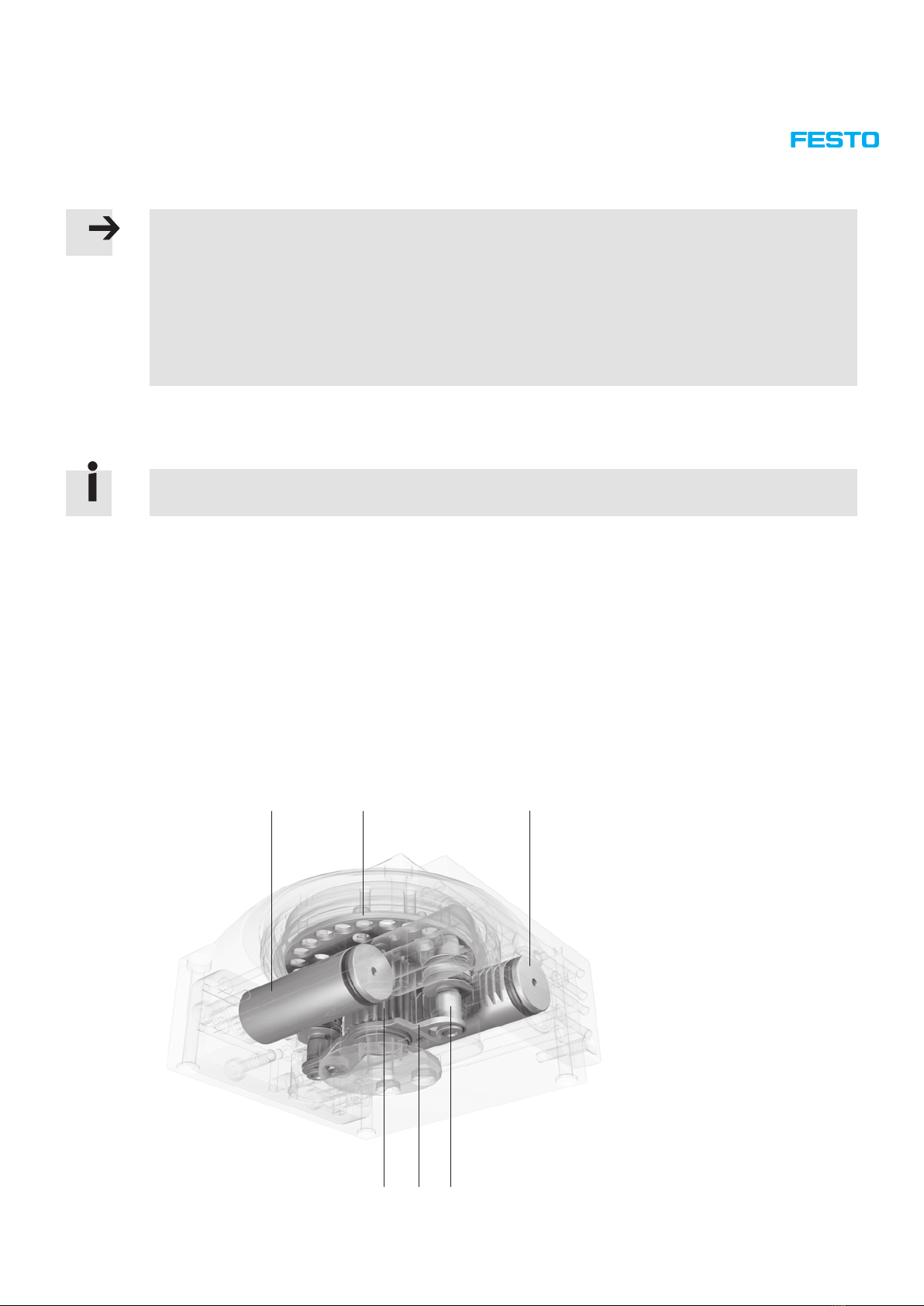

2.1 Functional description 8

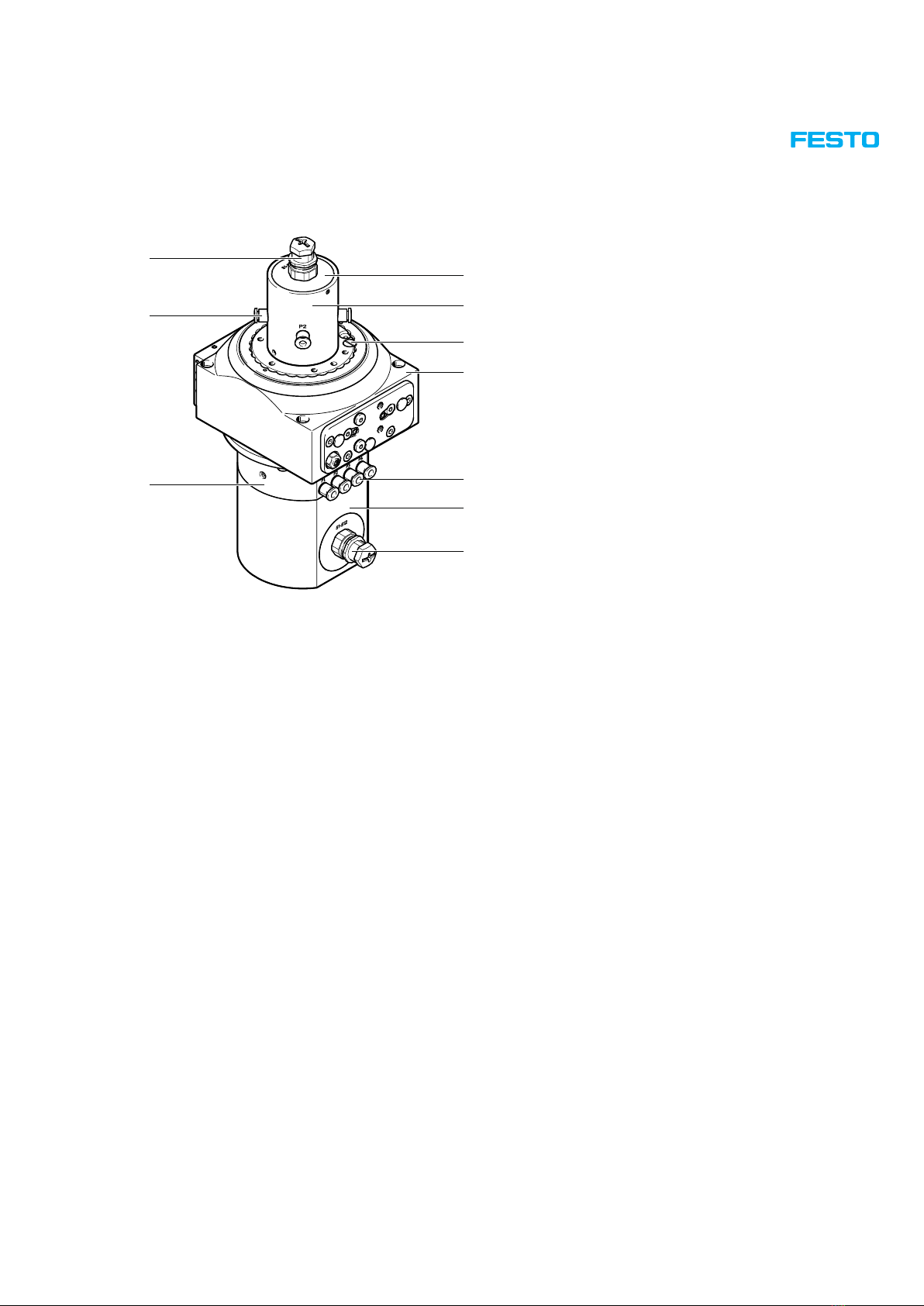

2.2 Energy throughfeed 9

2.2.1 DHTG-…-P4 9

2.2.2 DHTG-…-P4E4 9

2.2.3 DHTG-…-P4L12 10

2.3 Types and part or module numbers 11

2.3.1 Rotary indexing tables without energy throughfeed 11

2.3.2 Rotary index tables with energy throughfeed 11

2.4 Orientation designations 12

2.5 Type code 12

3 Component overviews and bill of materials 13

3.1 Components overview DHTG-65-…-A, series up to F7 (up to July 2015) 14

3.1.1 Bill of materials DHTG-65-…-A, Series up to F7 (up to July 2015) 15

3.2 Components overview DHTG-65-…-A, series from F8 (from August 2015) 16

3.2.1 Bill of materials DHTG-65-…-A, series from F8 (from August 2015) 17

3.3 Components overview DHTG-90-…-A, series up to F7 (up to July 2015) 18

3.3.1 Bill of materials DHTG-90-…-A, Series up to F7 (up to July 2015) 19

3.4 Components overview DHTG-90-…-A, series from F8 (from August 2015) 20

3.4.1 Bill of materials DHTG-90-…-A, series from F8 (from August 2015) 21

3.5 Components overview DHTG-140-…-A, series up to F7 (up to July 2015) 22

3.5.1 Bill of materials DHTG-140-…-A, Series up to F7 (up to July 2015) 23

3.6 Components overview DHTG-140-…-A, series from F8 (from August 2015) 24

3.6.1 Bill of materials DHTG-140-…-A, series from F8 (from August 2015) 25

3.7 Components overview DHTG-220-…-A, series up to F7 (up to July 2015) 26

3.7.1 Bill of materials DHTG-220-…-A, Series up to F7 (up to July 2015) 27

3.8 Components overview DHTG-220-…-A, series from F8 (from August 2015) 28

3.8.1 Bill of materials DHTG-220-…-A, series from F8 (from August 2015) 29

3.9 Components overview DHTG-65-…-A-P4 30

3.9.1 Bill of materials DHTG-65-…-A-P4 31

3.10 Components overview DHTG-65-…-A-P4E4 32

3.10.1 Bill of materials DHTG-65-…-A-P4E4 33

3.11 Components overview DHTG-65-…-A-P4L12 34

3.11.1 Bill of materials DHTG-65-…-A-P4L12 35

3.12 Components overview DHTG-90-…-A-P4 36

3.12.1 Bill of materials DHTG-90-…-A-P4 37

3.13 Components overview DHTG-90-…-A-P4E4 38

3.13.1 Bill of materials DHTG-90-…-A-P4E4 39

3.14 Components overview DHTG-90-…-A-P4L12 40

3.14.1 Bill of materials DHTG-90-…-A-P4L12 41