Table of Contents

1. Prior to Starting ........................................................................................................................1

1-1. Welcome ...........................................................................................................................1

1-2. About the RS-HD series....................................................................................................1

1-3. About This Manual ............................................................................................................1

2. Panel Descriptions ...................................................................................................................2

2-1. Front Panel........................................................................................................................2

2-2. Rear Panel ........................................................................................................................3

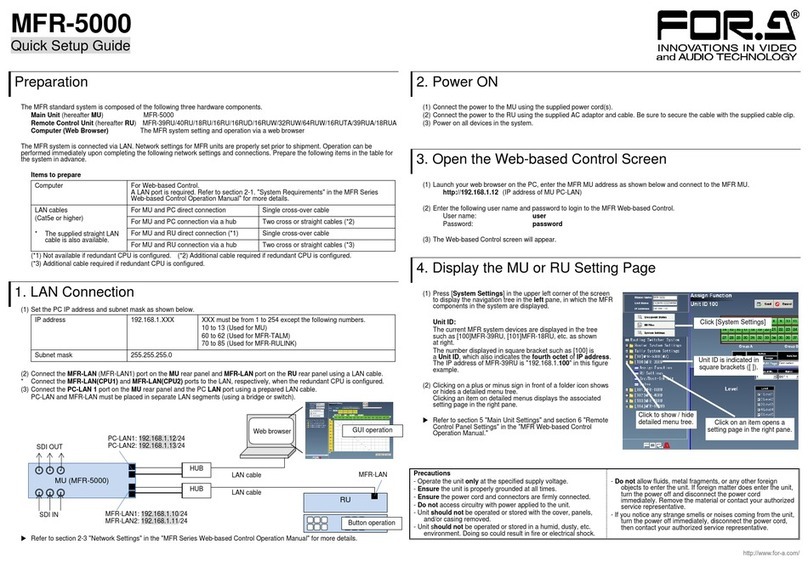

3. Set up.......................................................................................................................................4

3-1. Board Settings...................................................................................................................4

3-1-1. Accessing Internal CPU .............................................................................................4

3-2. Removal and Adjustment of the I/F Card ..........................................................................6

3-3. CPU Settings.....................................................................................................................7

3-4. MTX settings ................................................................................................................... 10

4. Connection.............................................................................................................................11

4-1. Reference Connection..................................................................................................... 11

4-1-1. Reference Switching Point Signals........................................................................... 12

4-2. Connection......................................................................................................................13

4-2-1. AC Power Cord Securing Clip.................................................................................. 13

4-2-2. Basic Connection .....................................................................................................14

4-2-3. Computer Control Connection..................................................................................15

4-2-4. RS-RU Series Remote Control Connection.............................................................. 16

4-3. System Configuration Example.......................................................................................17

4-4. ALARM Connector ..........................................................................................................19

4-5. REMOTE Connector .......................................................................................................21

5. Control Operation...................................................................................................................23

5-1. General ........................................................................................................................... 23

5-2. Communication Parameters............................................................................................ 23

5-3. Protocol Flow...................................................................................................................23

5-4. Operational Flow.............................................................................................................24

5-5. RS-232C Control Commands.......................................................................................... 26

5-5-1. Command Blocks.....................................................................................................26

5-5-2. Output Off.................................................................................................................27

5-5-3. Status Request Commands .....................................................................................28

5-5-4. Response Commands.............................................................................................. 29

5-5-5. Control Commands and ASCII Codes......................................................................30

5-6. RS-232C Control Commands.......................................................................................... 31

5-7. Control Software..............................................................................................................31

6. If Problems Occur...................................................................................................................32

7. Specifications & Dimensions..................................................................................................33

7-1. Unit Specifications...........................................................................................................33

7-2. External Dimensions .......................................................................................................34