FSW63-14 Multilanguage 01/03/2016

27

TECHNICAL MANUAL

INDEX

INDEX .......................................................................................................................................................... 27

DECLARATION OF CONFORMITY ................................................................................................................. 29

Dehumidifiers FSW63 series .................................................................................................................... 29

UTILITY AND CONSERVATION OF THE MANUAL ......................................................................................... 30

NORMS REFERENCES .............................................................................................................................. 30

GENERAL SAFETY NORMS ....................................................................................................................... 31

PERSONAL PROTECTIVE EQUIPMENT ..................................................................................................... 32

UNIT DESCRIPTION...................................................................................................................................... 33

FRAME ..................................................................................................................................................... 33

REFRIGERANT CIRCUIT ............................................................................................................................ 33

CONDENSER AND EVAPORATORS ................................................................................................... 33

FINNED PAC .................................................................................................................................. 33

FINS ................................................................................................................................................. 33

TUBES .............................................................................................................................................. 33

COMPRESSOR ................................................................................................................................. 33

FANS ........................................................................................................................................................ 33

ELECTRIC BOX .......................................................................................................................................... 34

MICROPROCESSORS ................................................................................................................................ 34

Accessories.................................................................................................................................................. 34

Body machine completely in Inox ........................................................................................................... 34

Electric heaters in inox 2,0 W 230/1/50 (E.H): ..................................................................................... 34

Hot water coil (H.W.C) nominal capacity 2,4 W: .................................................................................. 34

3 Way electric valve ON/OFF (E.W): ....................................................................................................... 34

Remote control (humidostat) (On/Off): .................................................................................................. 34

Autorestart (On/Off): .............................................................................................................................. 34

H.D.G. defrost ......................................................................................................................................... 34

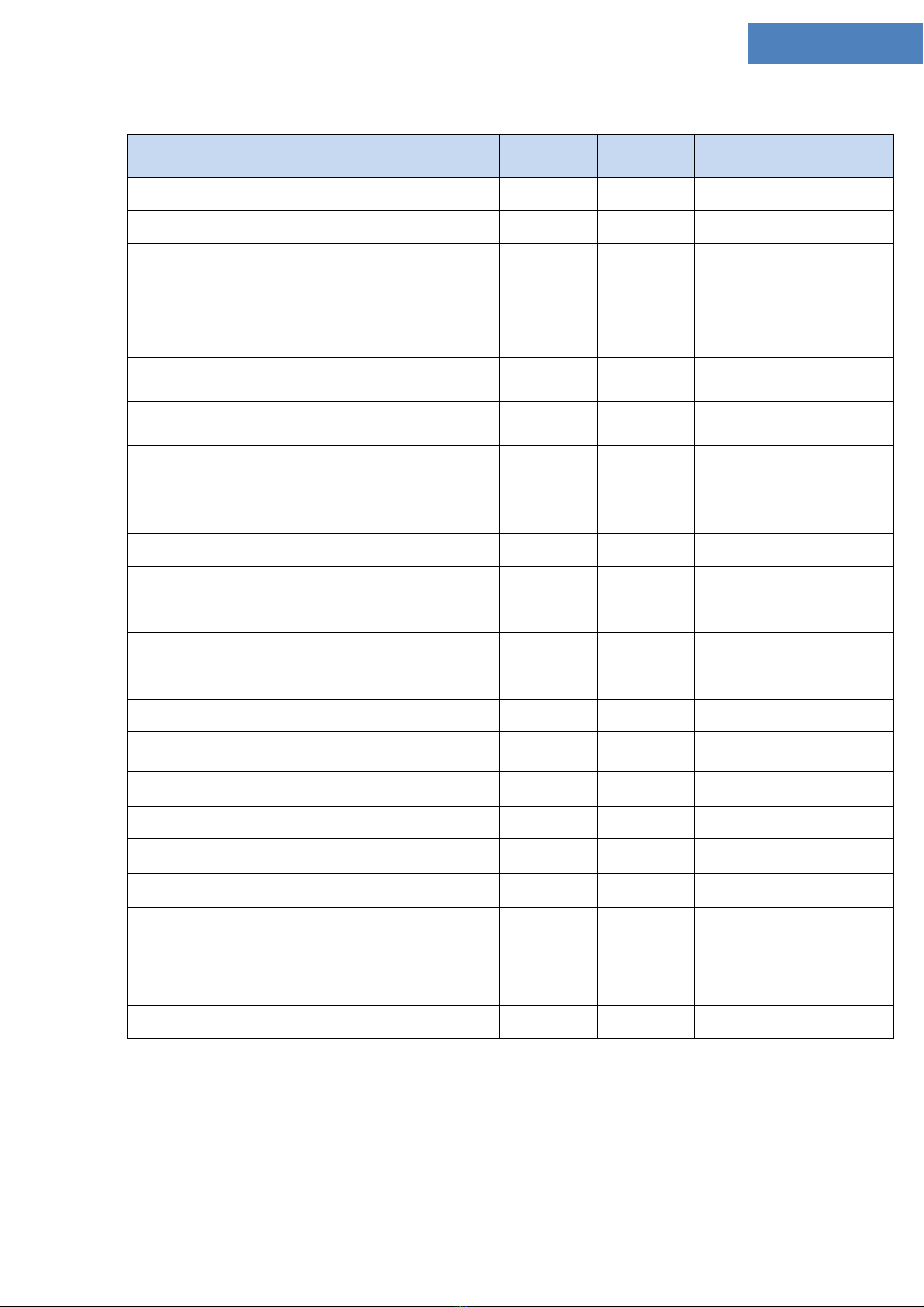

TECHNICAL DATA FSW ................................................................................................................................ 35

DRYING CAPACITY ....................................................................................................................................... 36

PERFORMANCE TABLES FSW63 .................................................................................................................. 36

FUNCTIONING LIMITS ................................................................................................................................. 37

CONTROL AND SAFETY DEVICES ................................................................................................................. 38

CONTROL DEVICES .................................................................................................................................. 38

THERMAL PROTECTION DEVICE (only for machines with electric heaters)............................................ 38