GEI-86134, Power Circuit Breokers

ADJUST GAP TO

0.060" t. o.oeo'

WITH BREAKER CLOSED

PIVOT

STUD

STATIONARY

CONTACT

Fig. 7. AKR-30 wipe adjustment - uieoo from

top of breaker

CONTACT ADJUSTMENT Types AKR-SO, sOH

qnd AKRU-SO

Use the follorving procedure toper{orm wipe ad-

justment:

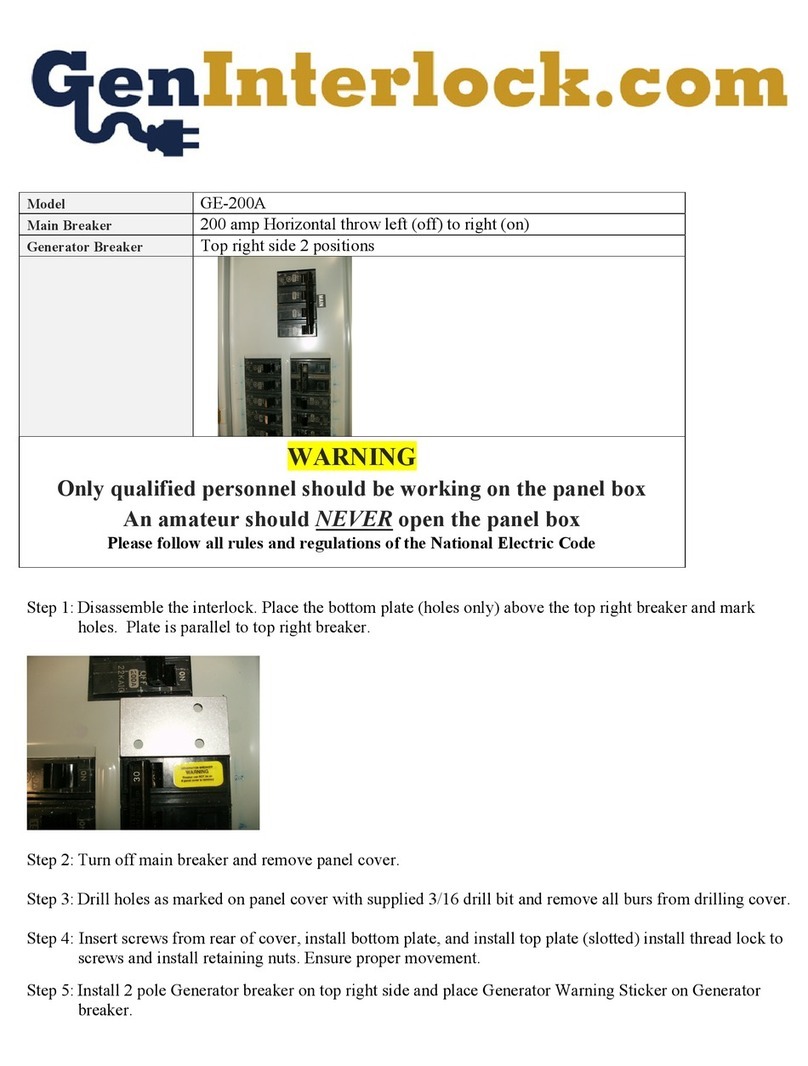

1. Open the breaker, remove arc quenchers.

2. Arrange the breaker forslow-closing, as de-

scribed on page 15 of GEK-7310.

3. Select one pole of the breakerand place a thin

sheet or strip of tough insulating material, such as

myl.ar, over the stationary arcing and intermediate

contacts. This strip should be about two inches

wide and must prevent the arcing and intermediate

contacts from making contact when the breaker is

closed.

4. Using the ratcheting maintenance handle,

slow-close the breaker with the insulation held in

place. Examine the insulation to make sure it

"over-hangs" below the intermediate contacts .

5. Atiach a continuity checker (bell-set or light)

between the upper and lower stud.

6. Facing the breaker, turn the wipe adjustment

stud clockwise until the checker indicates that the

main contacts have parted. An open-end wrench

fits the hex section on the stud.

?. Turn the stud counterclockwiseuntil the main

contacts just touch.

8. From this point, advance the stud counter-

clockwise 270 degrees. This will be 4-1/2 flats.

9. Trip the breaker, remove the insulating strips.

10. Repeatthe above procedure on the other two

poles.

8

CONTACT ADJUST|YIENT lype AKRT-50

The contact structure of this 2000A breaker is

conceptually identical to the 1600A AKR-50 except

that it employs eight stationary main contacts in-

stead of six. Constructionally, however, the upper

stud assembly, movable contact arms and pivot

block are unique to the AKRT-50. See Figs. 8

and 9.

The two movable contact arms are pin-coupled

to a metal driving link whose opposite end is

threaded and screws directly into the insulating

link. This arrangement omits the wrench-operated

wipe adjustment stud provided on the AKR-30 and

-50 frames. Instead, wipe is adjusted by detaching

the driving link from the movable contact arms and

then rotating it with respect to the insulating link.

On the AKRT-50 the proper amount of contact

wipe exists if , on a closed breaker, aII of the sta-

tionary main contacts have moved away from their

stops. This condition can be checked visually by

removing the arc quenchers, closing the breaker

and verifying that all eightstationary main contacts

are "lifted off" their stops. Should wipe adjustment

appear necessary, proceed as follows:

1. Open the breaker.

2. Arrange the breaker for slow-closing as de-

scribed on page 15 of GEK-7310.

3. Selecting one pole, dri-ft out the coupling pin

and detach the drivinE link from the movable con-

tact arms.

4. Screw the driving link completely into the in-

sulating link.

5. Back out the driving tink two and one-half

turns. Exceed this by whatever amount is neces-

sary to properlypositionthe linkwithin the movable

contact arms.

6. Install the coupling pin and retainer rings.

?. Using the maintenance handle, slow-close the

breaker and observe that all eight stationary main

contacts move away from their stops. If this con-

dition is not achieved, open the breaker, againre-

move the coupling pin and back out the driving link

an additional half turn.

8. Reassemble, reclose thebreaker and recheck

wipe.

9. Repeat the above procedure on the other two

poles.