2

Electrical Power Requirements

VIN = 12 to 24 VDC nominal (11-30 VDC) 21 VDC min. for 24 VDC Sole-

noid, 11 VDC min. for 12 VDC Solenoid 1 to 2 A including DNGP heater

and transmitter heater (3 A fuse line recommended)

Over Current Protection

20 Joule, 2000 A surge and lightning transient protection 3 A fuse for

Logic module 24 VDC power 50/150 mA PTC resettable fuses for posi-

tion input signal and transmitter feedback signal

Position Input Signal (Selectable) Standard 4-20 mA (Split Range: 4 mA min. up to 16 mA max. in 1 mA increments),

minimum 4 mA band

Transmitter Feedback Signal Analog Rotary: External or Internal Digital Linear: Internal only; RTU

Feedback must be dry

Remote Indicator Dual Function Output

Outputs VIN-1.5V @ 20 mA max. (for example if VIN = 24 VDC, this

supplies 22.5 ± 0.5 V)

The remote Indicator function can be selected to function as “Solenoid

Counter” or “In Standby/Manual”. In Counter mode it pulses whenever

either solenoid activates. In Standby/Manual mode, it is active

whenever the DNGP is in Standby or Manual modes.

Valve Position Feedback Module Primary: Linear Digital Transmitter Analog Rotary Types Also Available:

Display

80 (4 x 20) character Vacuum Fluorescent Display for: Command

Signal, Valve Position Feedback, Solenoid Cycle Count (stored in 10 year

non volatile memory), Dead Band value. Incorporates a user

navigational menu system.

Input Mode Selection Manual/Auto/Standby

Electrical Manual Override Manual pushbutton positioning (must engage Manual Mode with Auto/

Manual/Standby Switch)

Communications DNGP Dashboard PC Interface, Modbus™communication protocol

Solenoid Bypass Can be ON or OFF within 1.5% of the end stroke (in full closed and

open position).

Loss of Signal Options (Selectable) Drive to 4 mA position (open or closed valve position) Drive to 20 mA

position (open or closed valve position) Lock in last controlled position

Position Input Signal Impedance 120 to 220 Ω

Transmitter Feedback Input Signal Impedance transmitter) 120 to 220 Ω (additional operating voltage required for

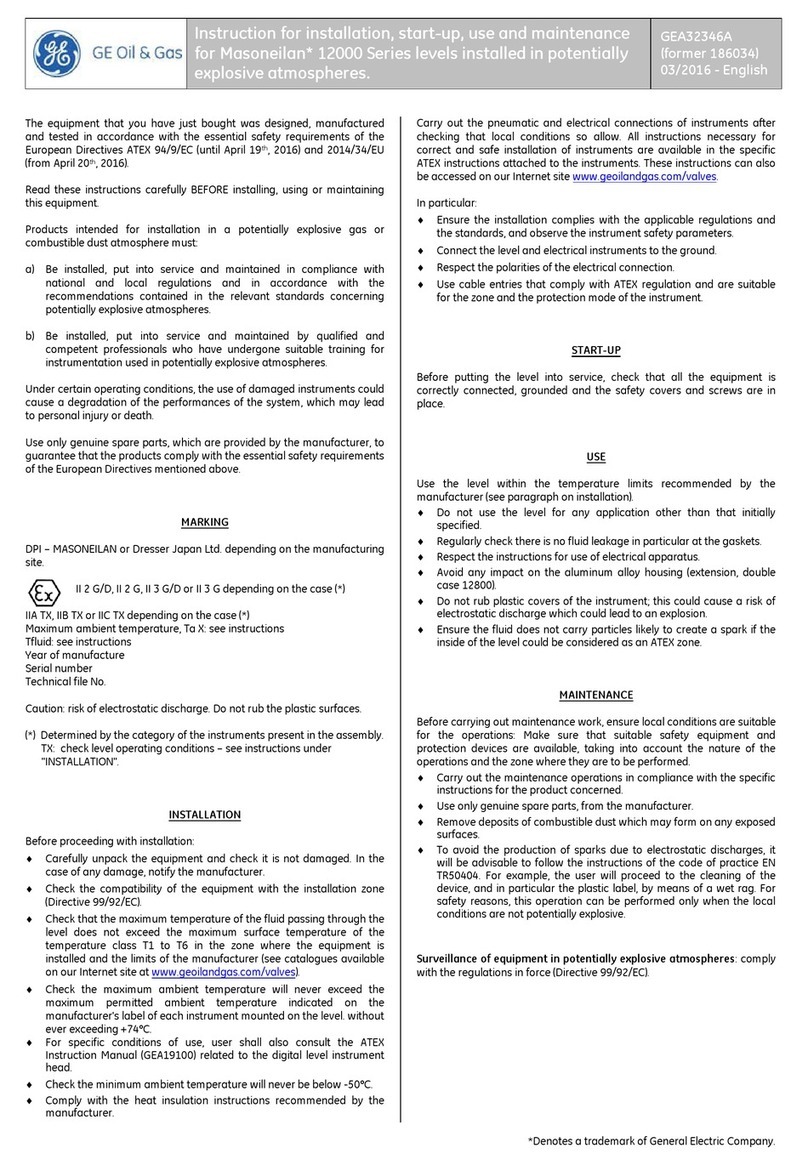

Introduction

The DNGP is designed specifically for the needs of the

Natural Gas industry. By using solenoids to control the

actuator pressures, the DNGP eliminates the continuous

bleed gas produced by I/P transducers and bleeds no

gas until the valve is called upon to move. The DNGP

can even do this while maintaining a pressure difference

across the actuator. Additionally, the discharge can

be directed downstream, and the positioner is capable

of failing in last position on a loss of signal, DC power

or power gas. Reliability and simplicity have been

engineered into the DNGP, while features that make the

positioner versatile, easy to use, and fail safe, have been

retained.

Scope of Manual

This manual provides information on the installation,

adjustment, and maintenance of the DNGP-Digital

Natural Gas Positioner. For information concerning

actuators, valves, and accessories, refer to the

instruction manuals provided with the specific product.

Technical Assistance

Only those qualified through training or experience

should install, operate, or maintain Becker position-

ers. Should you have any questions concerning these

instructions, you may contact your local GE sales

representative, sales office, or manufacturer before

proceeding.

GE Energy

Becker Control Valves

Attn: Technical Assistance

1550 Greenleaf Avenue

Elk Grove Village, IL 60007

Toll Free: +1-800-323-8844

Telephone: +1-847-437-5940

Fax: +1-847-437-2549

web: ge.com/energy

Table 1 - DNGP Technical Specifications