BASIC OPERATION AND FEATURES

SX TRANSISTOR CONTROL Page 6

Section 2. FEATURES OF SX FAMILY OF TRANSISTOR

MOTOR CONTROLLERS

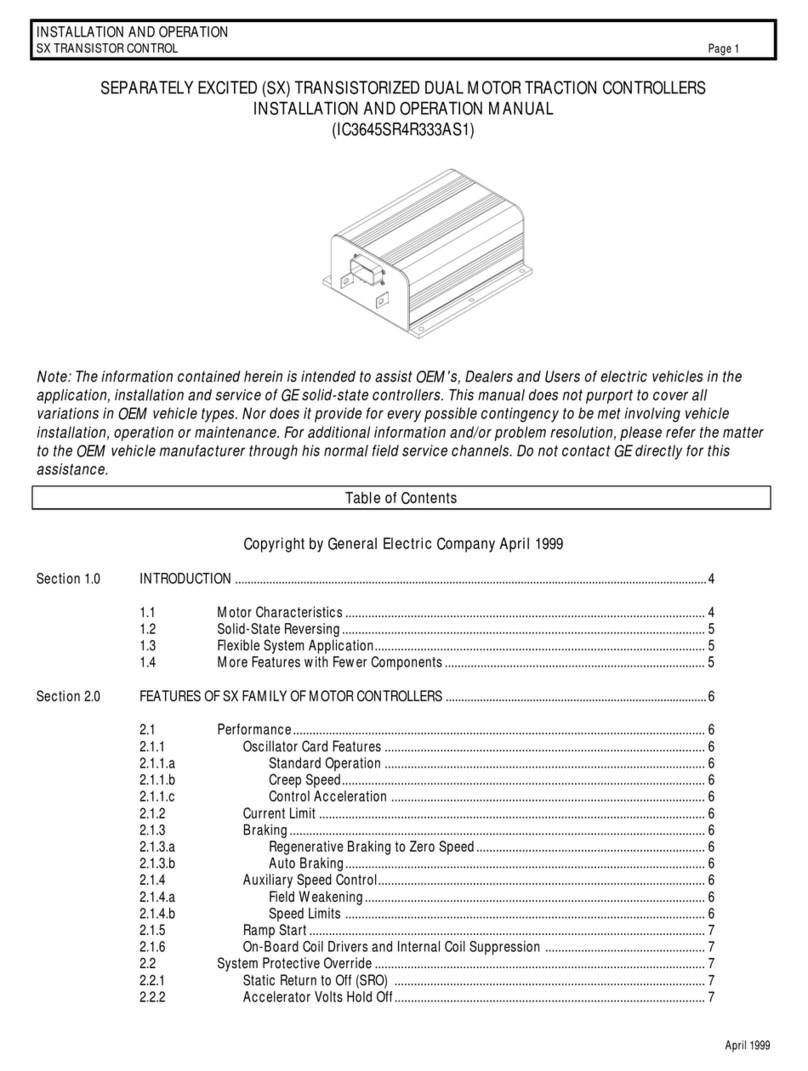

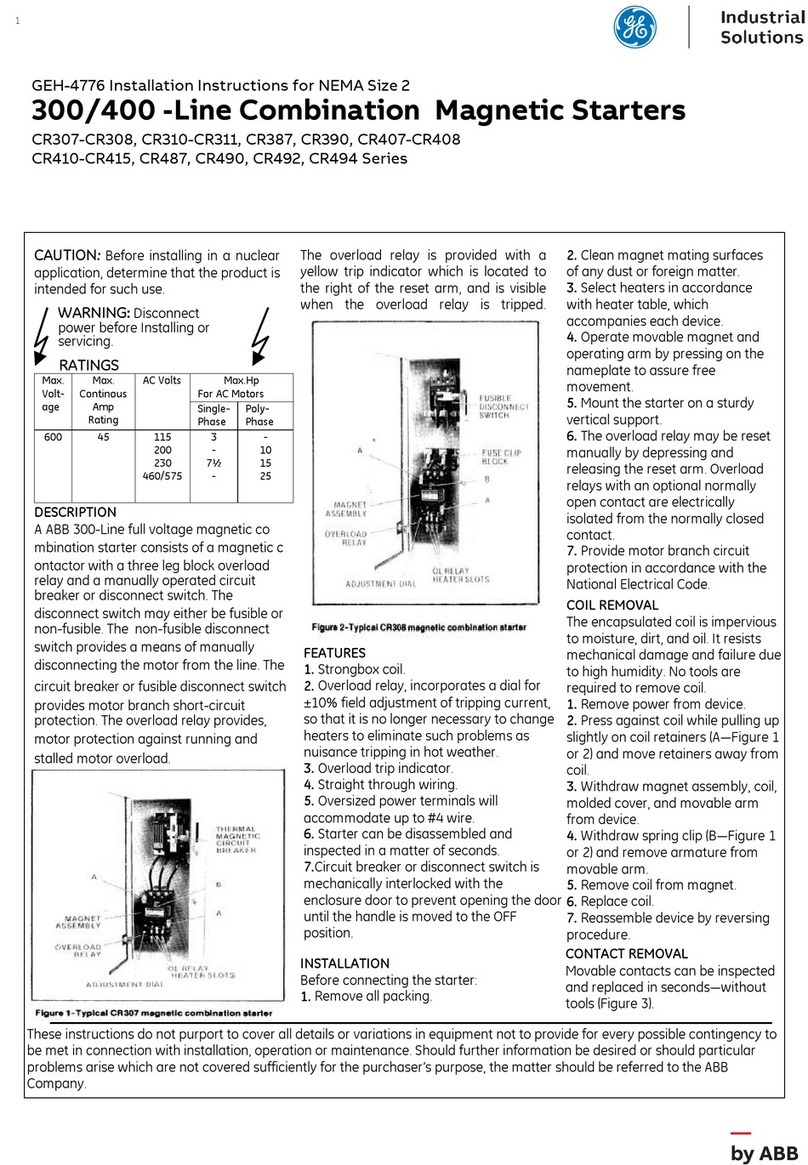

Section 2.1.3.a Regenerative Braking to Zero Speed

Slow down is accomplished when

reversing direction by providing a

small amount of retarding torque for

deceleration. If the vehicle is

moving, and the directional lever is

moved from one direction to the

other, the regen signal is initiated.

Once the regen signal has been

initiated, the field current is

increased (armature circuit shown in

Figure 5). Armature current is

regulated to the regen current limit as set by Function 9. As

the vehicle slows down, the field current continues to

increase, and transistor Q2 begins to chop. The field

current will increase until it reaches a preset value set by

Function 10, and transistor Q2 on-time will increase until it

reaches 100% on-time. Once both of the above conditions

have been met, and regen current limit can no longer be

maintained, the braking function is canceled. The fields

will then reverse, and the control reverts back to motoring.

Section 2.1 Performance

Section 2.1.1 Oscillator Card Features

Section 2.1.1.a Standard Operation

With the accelerator at maximum ohms or volts, the creep

speed can be adjusted by Function 2 of the Handset or a

trimpot. The field control section allows the adjustment of

the field weakening level in order to set the top speed of the

motor. This top speed function (Minimum Field Current) is

enabled when the armature current is less than the value

set by Function 24 and the accelerator pedal is fully

depressed. Top Speed can be adjusted by Function 7 of the

Handset or a trimpot.

The percent on-time has a range of approximately 0 to 100

percent. The SX controllers operate at a constant

frequency and the percent on-time is controlled by the

pulse width of the voltage / current applied to the motor

circuits. Part of the energy produced by the motor during regen is

returned to the battery, and part is dumped in the motor as

heat.

Section 2.1.1.b Creep Speed

Section 2.1.3.b Pedal Position Regenerative Braking

With the accelerator at maximum ohms or volts, the creep

speed can be adjusted by Function 2 of the Handset. At

creep speed, the ON time can decrease to approximately

5%, with the OFF time at approximately 95%. At full

transistor operation, this condition will be reversed (short

OFF time, long ON time). This variation of ON and OFF time

of the oscillator varies the voltage applied to the motor,

thereby varying the speed of the motor for a given load.

This feature allows control of the stopping distance based

on pedal position when there has been a “directional

switch" change. Pedal position will reduce the regenerative

current to the as the accelerator is returned to the creep

speed position. Maximum regenerative current is obtained

with the accelerator in the top speed position.

Section 2.1.3.c Auto Braking

Section 2.1.1.c Control Acceleration

This feature is enabled by initiating a "neutral position"

using either the directional switch or the accelerator

switch. Once activated, Auto Braking operates similar to

Pedal Position Regenerative Braking and is adjusted by

using Function 21 of the Handset.

This feature allows for adjustment of the rate of time it

takes for the control to accelerate to 100% applied battery

voltage to the motor on hard acceleration. Armature C/A is

adjusted by Function 3 from 0.1 to 22 seconds.

Section 2.1.2 Current Limit Section 2.1.4 Auxiliary Speed Control

This circuit monitors motor current by utilizing sensors in

series with the armature and field windings. The

information detected by the sensor is fed back to the card

so that current may be limited to a pre-set value. If heavy

load currents are detected, this circuit overrides the

oscillator and limits the average current to a value set by

Function 4 and Function 8 of the Handset. The C/L setting is

based on the maximum thermal rating of the control.

Because of the flyback current through Q2, the motor

current is usually greater than battery current, except at

100% ON time.

Section 2.1.4.a Field Weakening

This function allows the adjustment of the field weakening

level in order to set the top speed of the motor. The function

is enabled when the armature current is less than the value

set by Function 24 and the accelerator pedal is fully

depressed. It is important to note that this function is used

to optimize motor and control performance, and this setting

will be determined by GE and OEM engineers at the time of

vehicle development. This setting must not be changed by

field personnel, without the permission of the OEM.

ARM

Q1

Q2

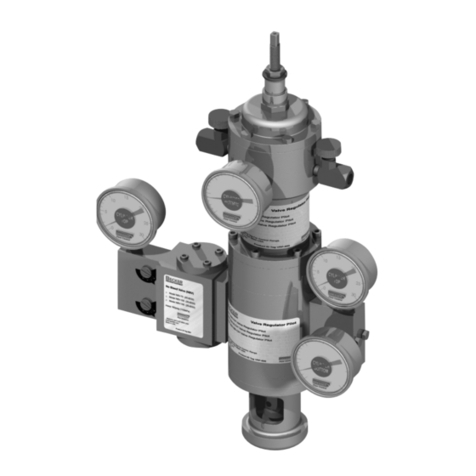

Figure 5

Section 2.1.3 Braking

September 2004