Table of Contents

1 Safety Information .................................................................................................................................................... 6

1.1 Used Safety Symbols..................................................................................................................................... 6

1.2 Radiation Protection Information .............................................................................................................. 8

1.3 Safety notes.................................................................................................................................................. 10

1.4 Danger Posed by this System.................................................................................................................... 10

1.5 Authorised Users ......................................................................................................................................... 10

1.6 Personal Protective Clothing..................................................................................................................... 11

1.7 Safety Measures at the Installation Site ................................................................................................. 11

1.8 Intended Use................................................................................................................................................. 11

2. Operating Manual ................................................................................................................................................... 12

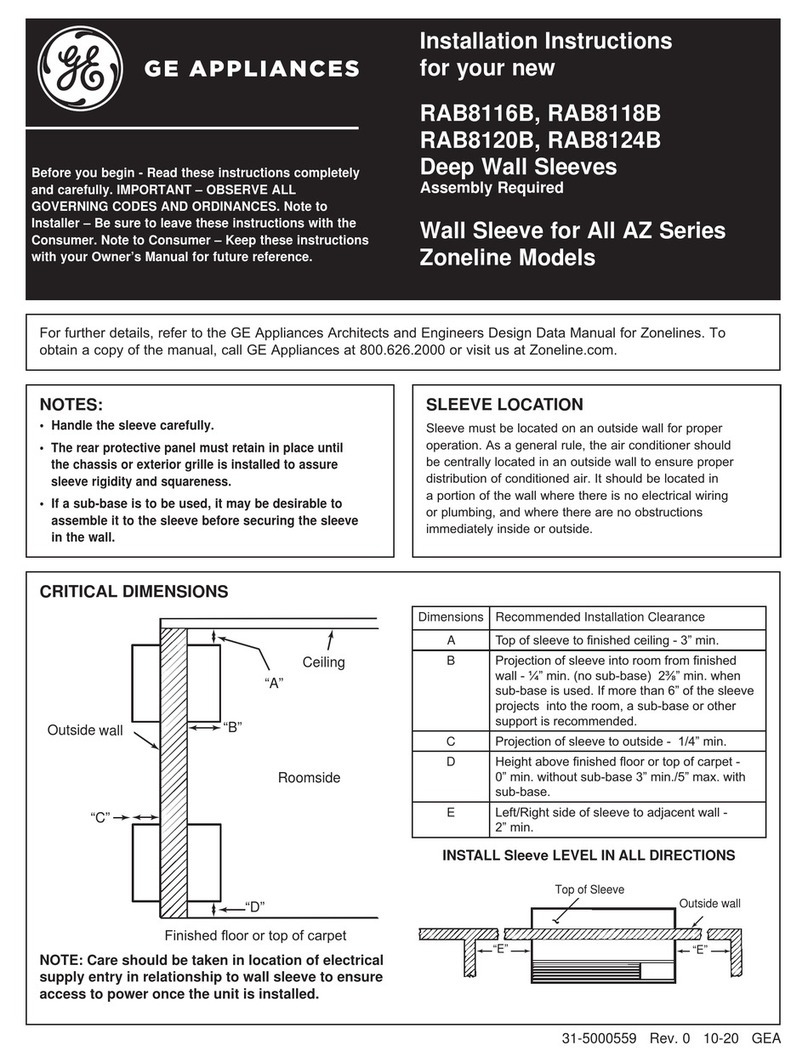

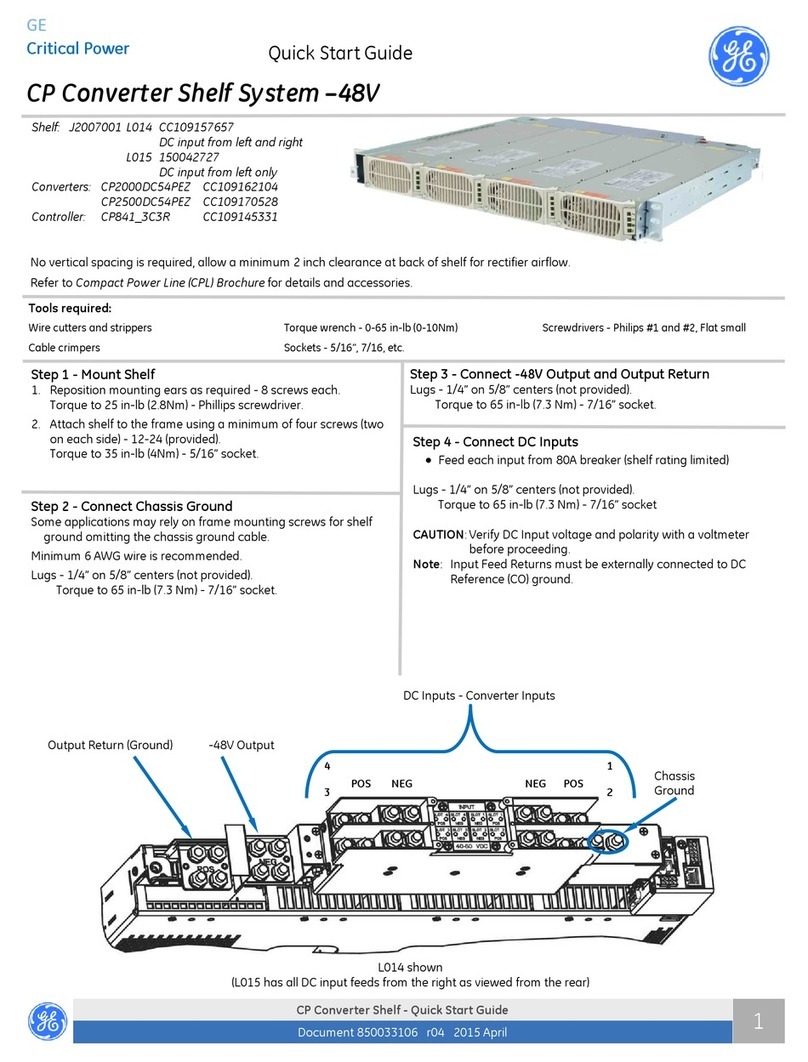

2.1 Installation of the Unit................................................................................................................................ 12

2.1.1 Operation with optional warning ash lamp............................................................................................... 15

2.1.2 Operation with connected door contacts..................................................................................................... 15

2.2 Taking into operation.................................................................................................................................. 16

2.2.1 Mains connection..................................................................................................................................................... 16

2.2.2 Stand-by ....................................................................................................................................................................... 16

2.2.3 Display modes............................................................................................................................................................ 17

2.2.4 Ready for operation and warm-up .................................................................................................................. 19

2.2.5 Extended Warm-up Mode.................................................................................................................................... 23

2.3 Setting the Operating Parameters ........................................................................................................... 25

2.3.1 Exposure time ............................................................................................................................................................ 25

2.3.2 kV setting...................................................................................................................................................................... 26

2.3.3 mA setting.................................................................................................................................................................... 26

2.4 Power mode .................................................................................................................................................. 27

2.5 Exposure calculator..................................................................................................................................... 28

2.6 FFD-Correction............................................................................................................................................. 31

2.7 Starting Exposure ........................................................................................................................................ 33

2.8 Exposure Stop .............................................................................................................................................. 34

2.9 Generating Programs ................................................................................................................................. 35

2.10 Calling and Exiting Programs .................................................................................................................... 39

2.11 Switchingthebacklightonando.......................................................................................................... 40

2.12 Setting the Display Contrast ..................................................................................................................... 40