Table of contents

01 IM-710429 en-GB i

TTaabbllee ooff ccoonntteennttss

1 Arcam Electron Beam Melting (EBM) .................................................................................................1

2 Revision Notes .................................................................................................................................3

3 Change Log .....................................................................................................................................5

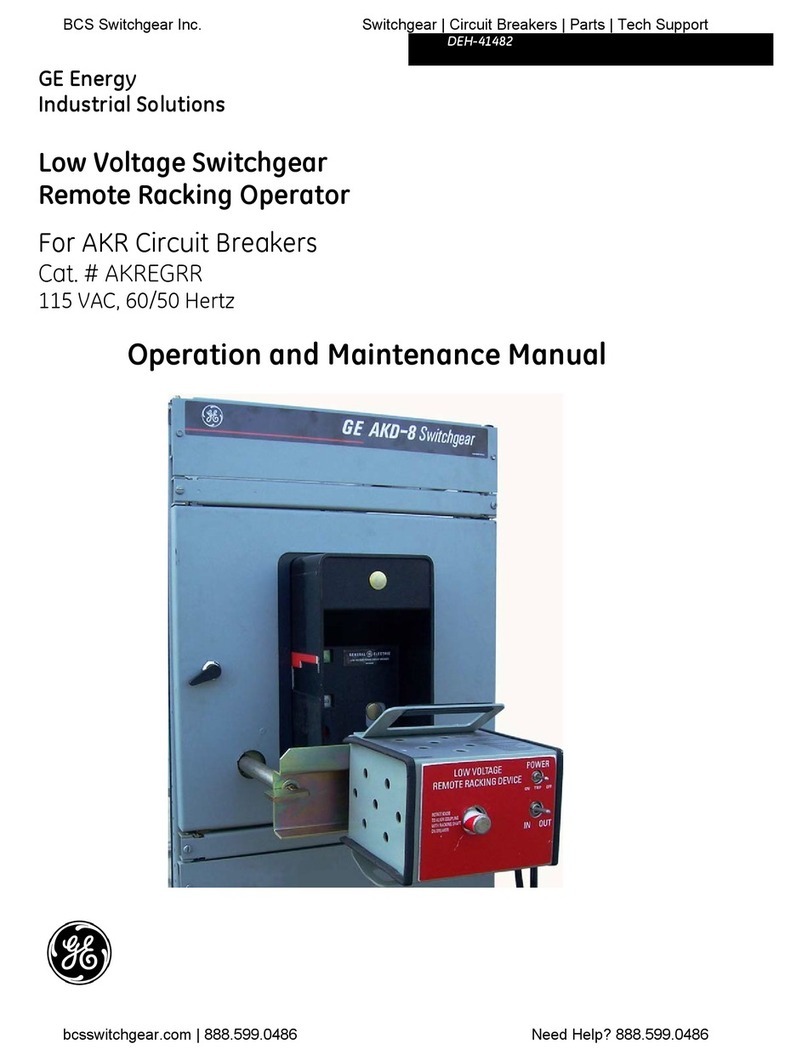

4 About This Manual............................................................................................................................7

5 Safety............................................................................................................................................13

6 Technical Data ...............................................................................................................................33

7 Installation .....................................................................................................................................41

8 Decommissioning .........................................................................................................................145

9 Arcam Transfer ............................................................................................................................157

10 Declaration Of Conformity ...........................................................................................................159