3

measurements, and calibration curves provided herein give sensitivity factors for materials of different moduli. It

should be noted that as the rock modulus changes by a factor of 10, the gage factor changes only by a factor of 2.

The stressmeter is a uniaxial device, and to completely evaluate stress changes in a given plane, three

stressmeters, installed at 0°, 45°, and 90°orientations, are required.

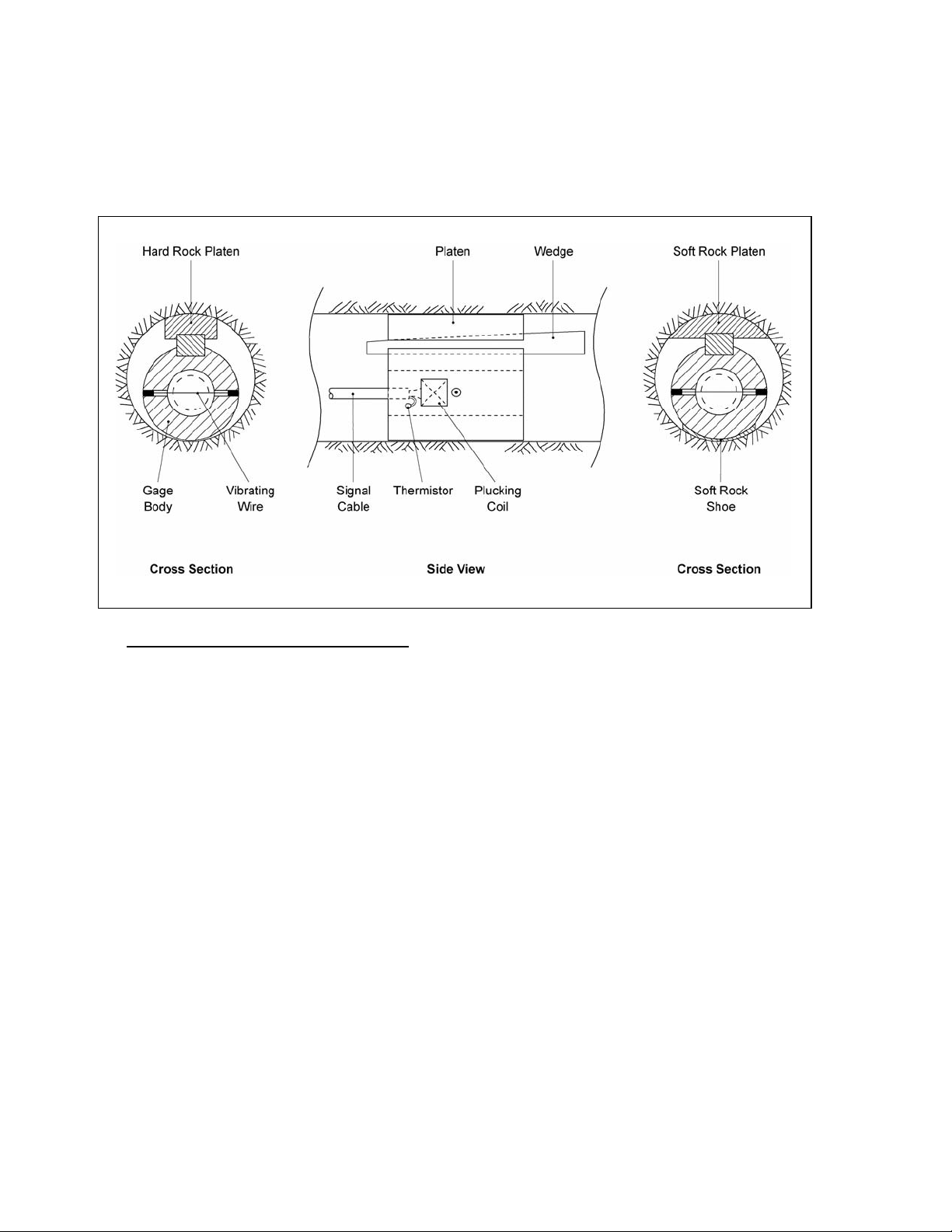

The gage wire in the Model 4300 Series stressmeters runs perpendicular to the direction in which the gage body is

loaded in an effort to minimize the effects of point loading, off center loading, etc. This gives the gage a very high

range and, since as the load increases the wire gets tighter, the wire never goes slack.

Gage installation is accomplished by driving a wedge between the gage body and the platen, which contacts the

borehole walls. Preloading to desired levels is accomplished by further driving of the wedge with the setting tool.

In soft rocks a soft rock platen and soft rock shoe are used to increase the area of contact.

The gage is constructed of corrosion resistant materials and should have an indefinite lifetime under even the

most severe conditions.

3. Installation______________________________________________________

3.1 Borehole Requirements

Stressmeters are designed to be used in smooth-walled diamond drill holes. Stressmeters can be installed in

percussively drilled holes and drag-bit drilled holes, provided that care is taken to get the proper hole diameter with a

smooth wall. If the walls are rough the gage response (calibration) can be radically affected.

The Model 4300EX Stressmeter is designed for use in EX diamond drill holes 38mm (1.5”), and the hole can

range in diameter from 37mm (1.45”) to 39mm (1.55”) when using the standard wedge and platen assembly.

The Model 4300BX Stressmeter is designed for use in BX diamond drill holes 60mm (2.36”), and the hole can

range in diameter from 58.5mm (2.30”) to 62mm (2.44”) when using the standard wedge and platen assembly.

The Model 4300NX Stressmeter is designed for use in NX diamond drill holes 76mm (2.98”), and the hole can

range in diameter from 74mm (2.91”) to 78mm (3.07”) when using the standard wedge and platen assembly.

Oversize platens are available for over-size boreholes (consult factory).

After drilling, the hole should be thoroughly cleaned by washing out with water or blowing out with compressed

air. The borehole diameter should then be checked with the GO-NO-GO gages supplied with the installation tool.

If the borehole checks out the installation can proceed.

3.2 Preliminary Checks

Upon receipt of the stressmeter the zero reading should be checked and noted along with the temperature if a

thermistor is included in the gage. Gage connections are normally red to red and black to black, although with the

GK-401 Readout Box these can be reversed without changing the readings. Zero readings at the site should

coincide with the factory readings within a few digits after corrections for temperature are made.

3.3 Attaching the Wedge/Platen Assembly