TABLE of CONTENTS

1. INTRODUCTION...................................................................................................................................................1

2. INSTALLATION ....................................................................................................................................................1

2.1 PRELIMINARY TESTS............................................................................................................................................1

2.2 CRACKMETER INSTALLATION..............................................................................................................................2

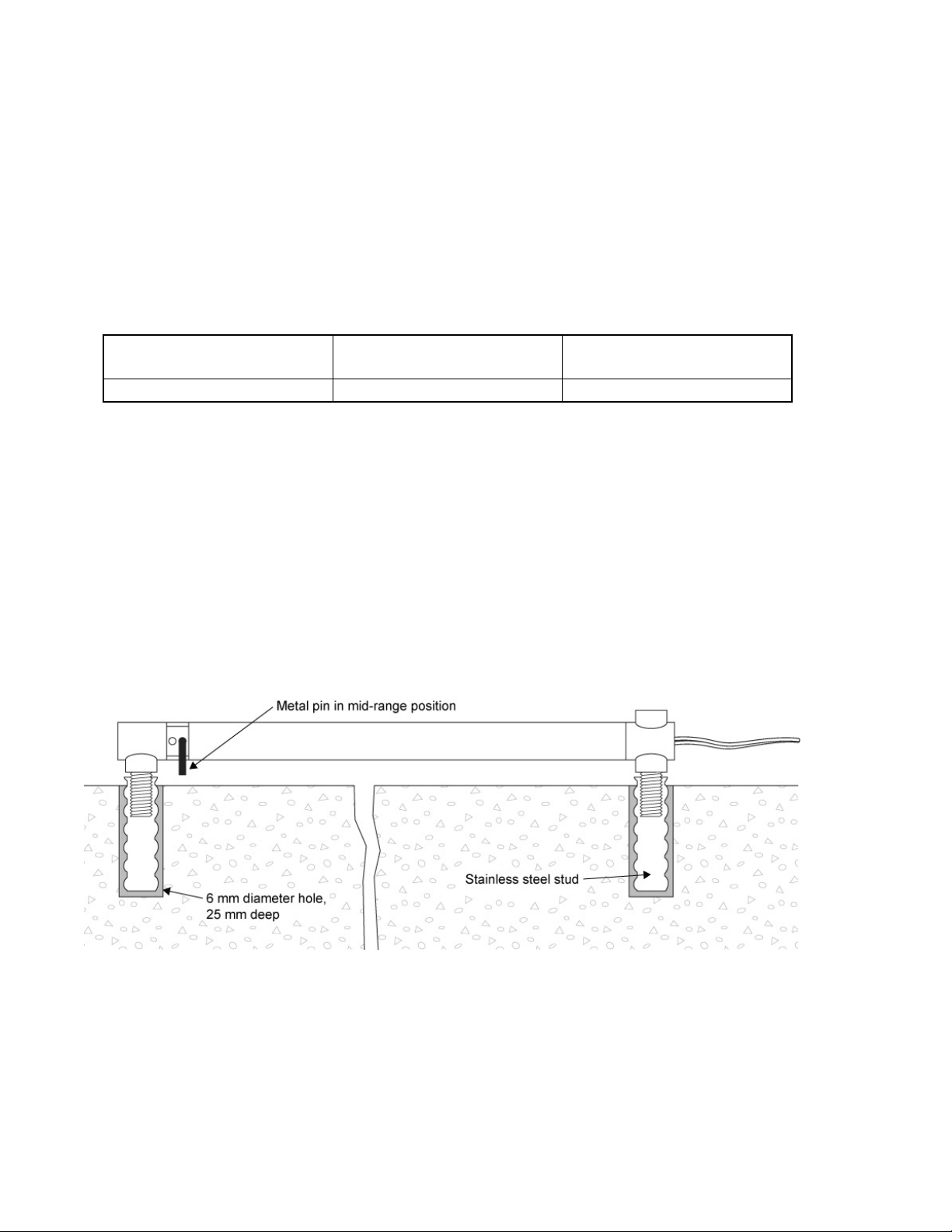

2.2.1 Drill Hole Type...........................................................................................................................................2

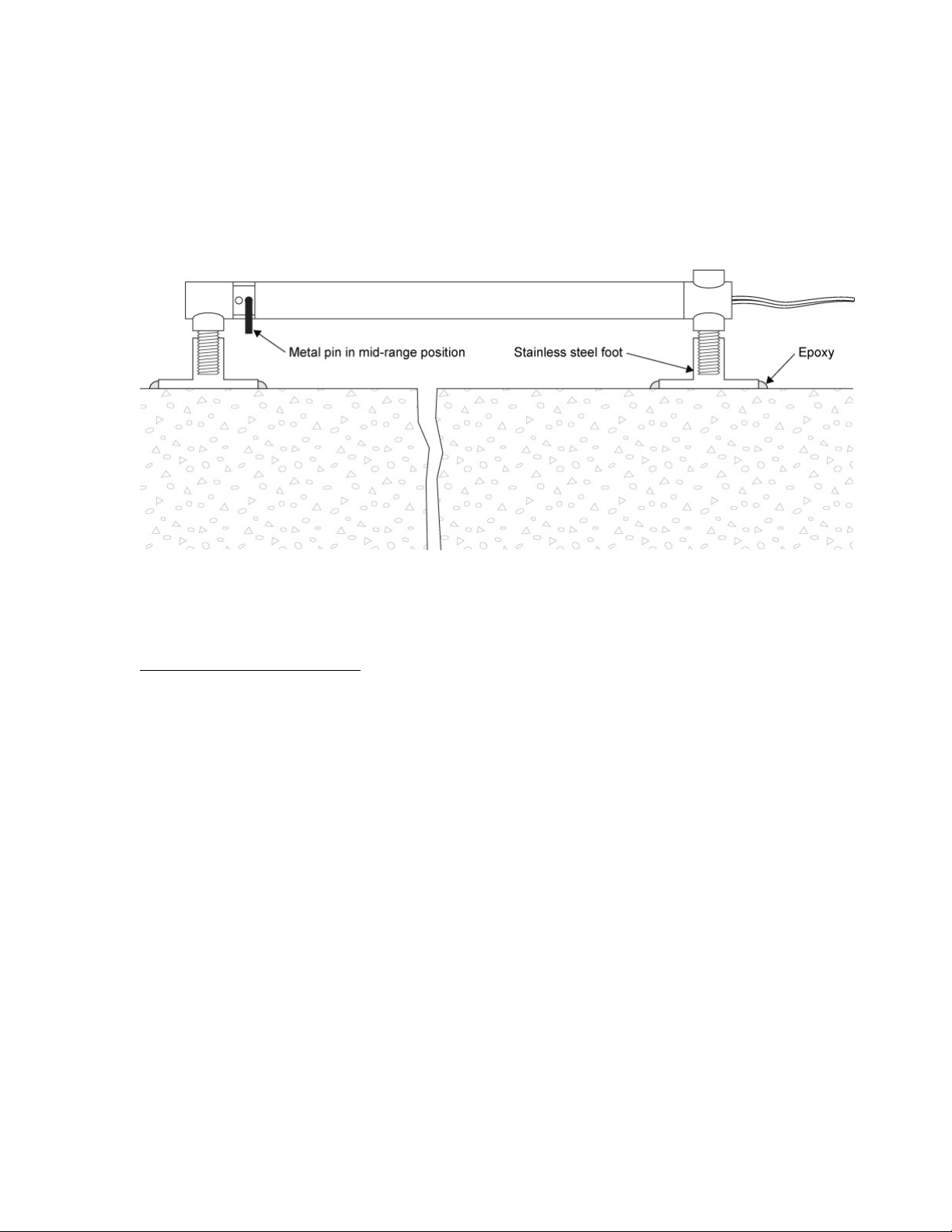

2.2.2 Surface Mounting........................................................................................................................................3

2.3 INITIAL READINGS...............................................................................................................................................3

2.4 CABLE INSTALLATION AND SPLICING ..................................................................................................................3

2.5 LIGHTNING PROTECTION .....................................................................................................................................4

3. TAKING READINGS.............................................................................................................................................5

3.1 GK-404 READOUT BOX.......................................................................................................................................5

3.1.1 Operating the GK-404 ................................................................................................................................5

3.2 GK-405 READOUT BOX.......................................................................................................................................6

3.2.1 Connecting Sensors with 10-pin Bulkhead Connectors Attached...............................................................6

3.2.2 Sensors with Bare Leads.............................................................................................................................6

3.2.3 Operating the GK-405 ................................................................................................................................6

3.3 GK-403 READOUT BOX (OBSOLETE MODEL)......................................................................................................7

3.3.1 Connecting Sensors with 10-pin Bulkhead Connectors Attached...............................................................7

3.3.2 Connecting Sensors with Bare Leads..........................................................................................................7

3.3.3 Operating the GK-403 ................................................................................................................................7

3.4 MEASURING TEMPERATURES...............................................................................................................................7

4. DATA REDUCTION ..............................................................................................................................................8

4.1 DISPLACEMENT CALCULATION............................................................................................................................8

4.2 TEMPERATURE CORRECTION...............................................................................................................................9

4.3 ENVIRONMENTAL FACTORS...............................................................................................................................10

5. TROUBLESHOOTING........................................................................................................................................12

APPENDIX A. SPECIFICATIONS.........................................................................................................................14

A.1 MODEL 4422 CRACKMETER..............................................................................................................................14

A.2 THERMISTOR.....................................................................................................................................................14

APPENDIX B. THERMISTOR TEMPERATURE DERIVATION.....................................................................15