CONTENTS

1

Revision ....................................................................................................................................................5

2

Instructions for safe operation .......................................................................................................... 6

3

Important information ....................................................................................................................... 8

3.1 Intended use....................................................................................................................................8

3.2 Safety precautions ...........................................................................................................................8

3.3 Electronic equipment reception interference...................................................................................8

3.4 Environmental requirements............................................................................................................8

3.5 Glazing materials.............................................................................................................................8

4

Technical specification ...................................................................................................................... 9

5

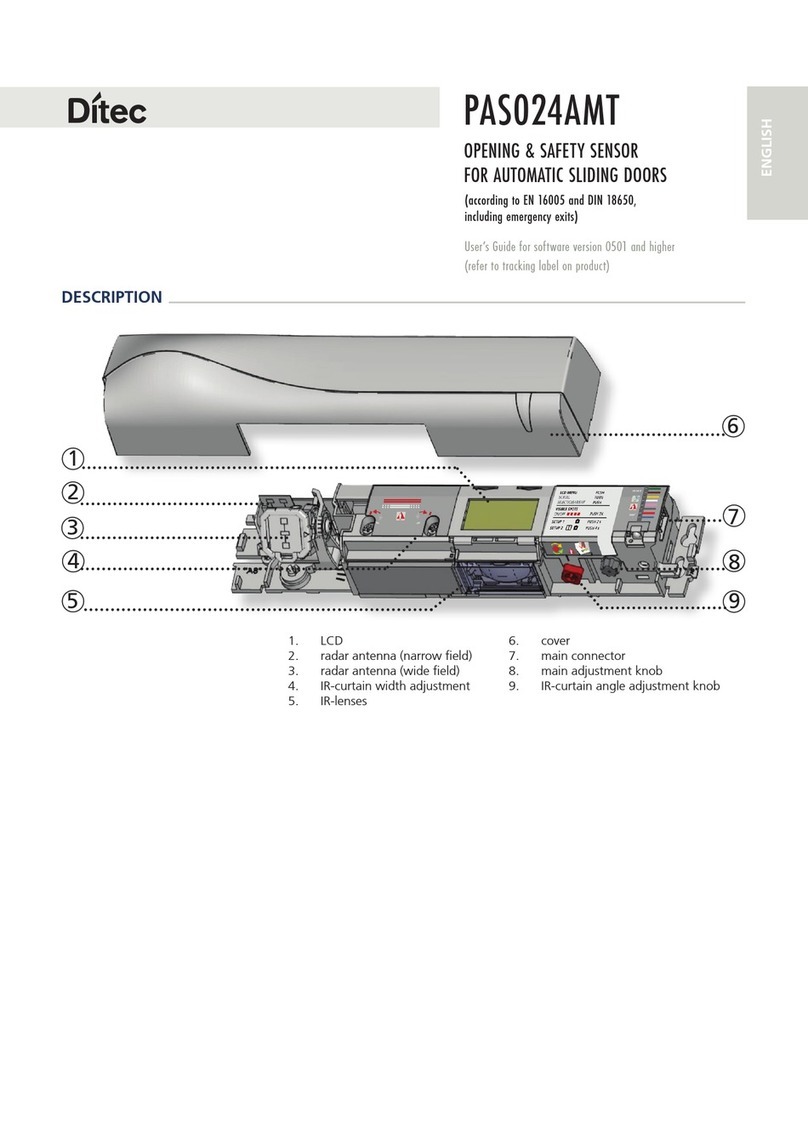

Design and function description ..................................................................................................... 10

5.1 Function.........................................................................................................................................10

5.2 Microprocessor for precise control ................................................................................................10

5.3 Emergency escape........................................................................................................................10

6

Models ....................................................................................................................................................11

7

Identification ...........................................................................................................................................12

7.1

Options ...................................................................................................................................13

8

Space required ............................................................................................................................... 15

9

Pre-Installation........................................................................................................................................16

9.1 General tips/Safety concerns .........................................................................................................16

10

Mechanical Installation ................................................................................................................... 17

10.1

Checking.................................................................................................................................17

10.2 Installation Overview .....................................................................................................................19

10.3 Installation Examples.....................................................................................................................20

10.4 Site Inspection...............................................................................................................................22

10.5 Installation and Adjustment Processes .........................................................................................23

11

Electrical connections .................................................................................................................... 57

11.1 Installation .....................................................................................................................................57

11.2 Mains connection...........................................................................................................................58

11.3 Electrical units ...............................................................................................................................59

12

Break Out/Safety – Hold Beam Connection Diagram .................................................................... 64

13

Start-Up ..................................................................................................................................................65

13.1 Adjustments and selection of special operating functions .............................................................65

13.2 The Learn function can be one of three different types..................................................................67

13.3 Display test and configuring of parameters ...................................................................................68

13.4 Status indication on the display ....................................................................................................69

13.5 Description of parameters .............................................................................................................70

14

Signage ..................................................................................................................................................85

15

Accessories ............................................................................................................................................85

15.1 Interconnection cable....................................................................................................................85

15.2 Program selectors .........................................................................................................................87

15.3 Accessory board............................................................................................................................86

15.4 Program selector options ..............................................................................................................88

15.6

Electrical locks...............................................................................................................................90

15.7

Motion sensors ..............................................................................................................................90

15.8 Night mode .......................................................................................................................90

15.9

Bottom Guide Systems .................................................................................................................91

15.10

Open / Close function ....................................................................................................................91

15.11

Fire alarm connection....................................................................................................................91

15.12

Nurse function ...............................................................................................................................91

15.13

Remote Exit mode.........................................................................................................................91

15.14

Emergency open impulse..............................................................................................................91