15 ENGLISH

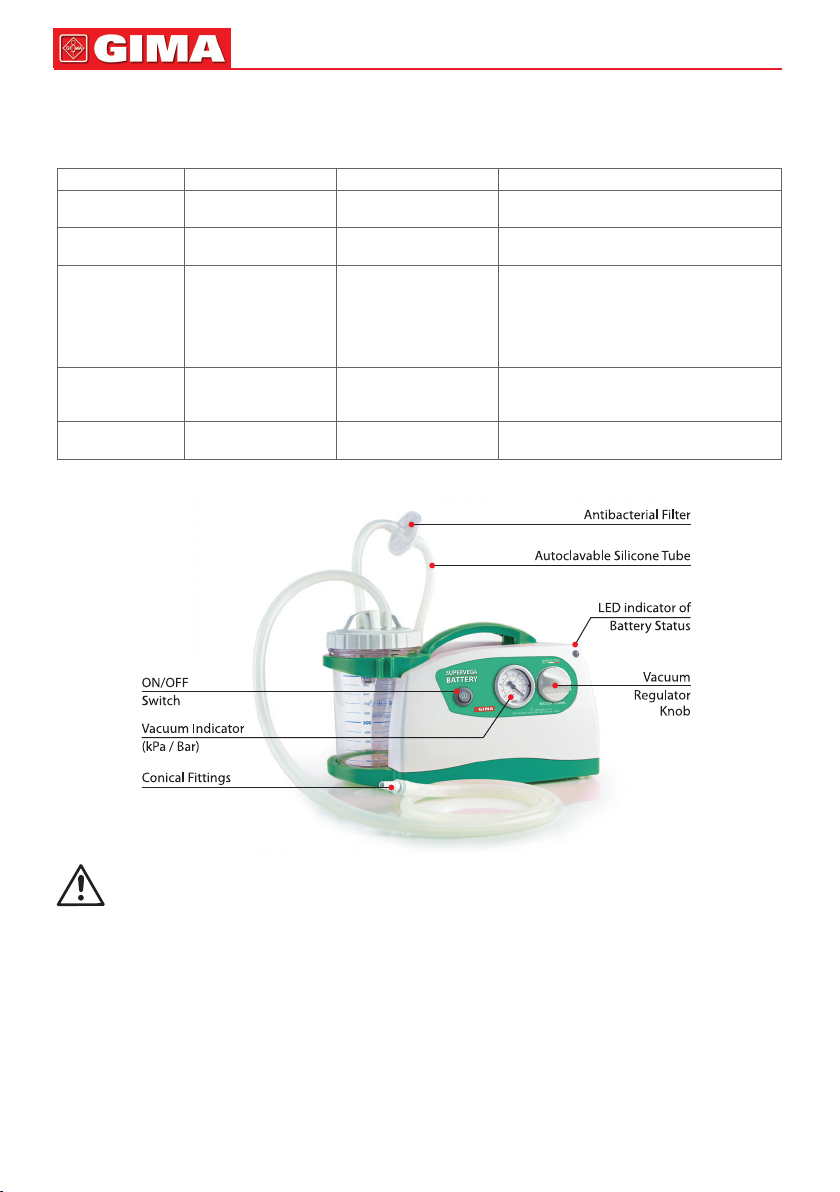

SUPER VEGA BATTERY SUCTION UNIT is a suction pump particularly suited for use in hospital wards,

in patients with tracheotomy, in small surgical applications and post-operative treatments at home. A device

that can be used for nasal, oral and tracheal aspirations in adults or for body liquids in children (for example

mucus, phlegm and blood). A device designed to offer ease-of-transport and almost continuous use thanks

to the adoption of an electronic system to manage the power supply. The luminous LED positioned on the

front panel indicates its activation and the charge status of the device. Its body is made from plastic with high

thermal and electrical insulation in compliance with recently introduced European safety regulations. Sup-

plied with sterilizable polycarbonate jug with overow valve. Features a suction regulator and vacuum gauge

located on the front panel.

GENERAL WARNING

Read instruction manual carefully before use.

The device is for use by qualied personnel (surgeon / professional nurse / assistant)

The use of the device at home is restricted to an adult in full possession of mental faculties and / or home

carers

The instrument must not disassembled. For technical service always contact Gima S.p.A.

IMPORTANT SAFETY RULES

1. Check the condition of the unit before each use. The surface of the unit should carefully inspected for visual

damage.

Check the mains cable and do not connect to power if damage is apparent;

2. Before connecting the appliance always check that the electric data indicated on the data label and the type

of plug used, correspond to those of the mains electricity to witch it’s to be connected;

3. Respect the safety regulations indicated for electrical appliances and particularly:

- Use original components and accessories provided by the manufacturer to guarantee the highest ef-

ciency and safety of the device;

- The device can be used only with the bacteriological lter;

- Never immerge the appliance into water;

- Do not place or store the aspirator in places where it may fall or be pulled into the bathtub or washbasin.

In the event it is accidentally dropped, do not attempt to remove the device from the water whilst the plug

is still connected: disconnect the mains switch, remove the plug from the power supply and contact the

GIMA technical service department. Do not attempt to make the device work before it has been thorough-

ly checked by qualied personnel and/or the GIMA technical service department.

- Position the device on stable and at surfaces in a way that the air inlets on the back aren’t obstructed;

- To avoid incidents, do not place the aspirator on unstable surfaces, which may cause it to accidentally fall

and lead to a malfunction and/or breakage. Should there be signs of damage to the plastic parts, which

may expose inner parts of the energised device, do not connect the plug to the electrical socket. Do not

attempt to make the device work before it has been thoroughly checked by qualied personnel and/or the

GIMA technical service department.

- Don’t use in the presence of inammable substances such as anaesthetic, oxygen or nitrous oxide;

- Don’t touch the device with wet hands and always prevent the appliance coming into contact with liquids;

- Don’t leave the appliance connected to the power supply socket when not in use;

- Don’t pull the power supply cable to disconnect the plug remove the plug from the mains socket correctly;

- Store and use the device in places protected against the weather and far from any sources of heat. After

each use, it is recommended to store the device in its own box away from dust and sunlight.

- In general, it is inadvisable to use single or multiple adapters and/or extensions. Should their use be

necessary, you must use ones that are in compliance with safety regulations, however, taking care not to

exceed the maximum power supply tolerated, which is indicated on the adapters and extensions.

4. For repairs, exclusively contact technical service and request the use of original spare parts.

Failure to comply with the above can jeopardise the safety of the device;

5. Use only for the purpose intended. Don’t use for anything other than the use dened by the manufacturer.

The manufacturer will not be responsible for damage due to improper use or connection to an electrical

system not complying with current regulation.

6. The medical device requires special precautions regarding electromagnetic compatibility and must be in-

stalled and used in accordance with the information provided with the accompanying documents: the SU-