Gira 2100 Series User manual

Other Gira Controllers manuals

Gira

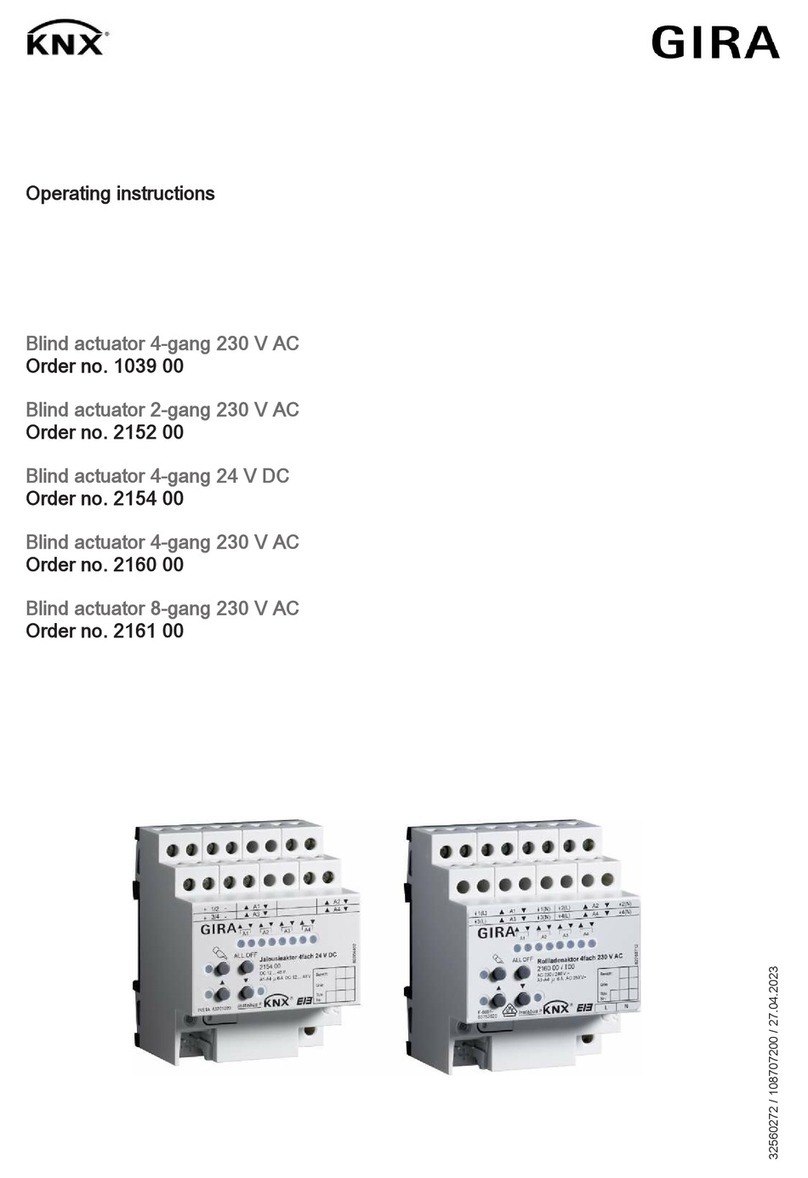

Gira KNX 213900 User manual

Gira

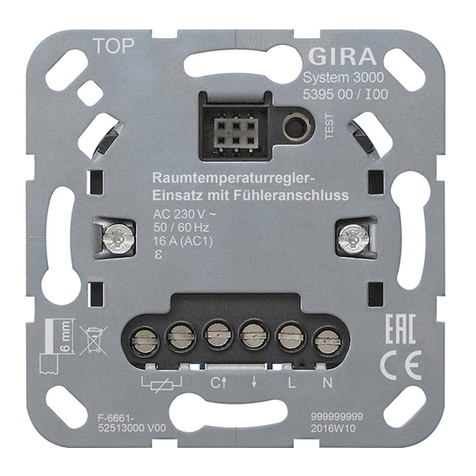

Gira System 3000 User manual

Gira

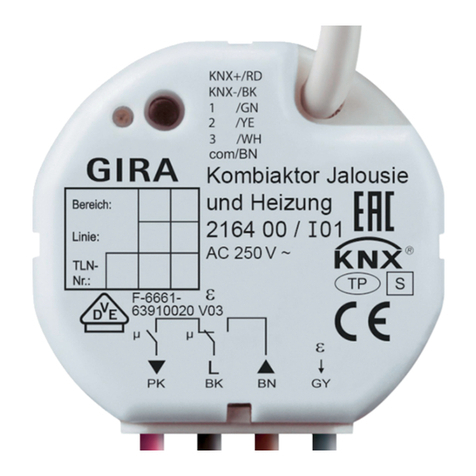

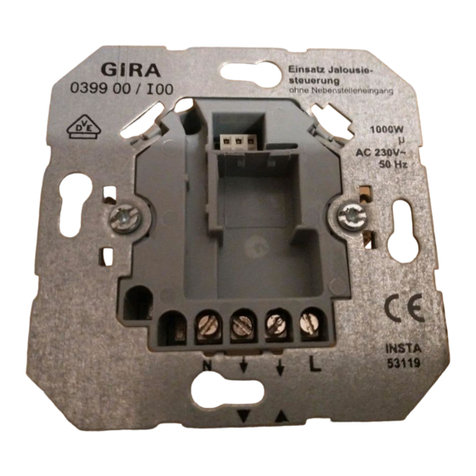

Gira 0399 00 User manual

Gira

Gira 0570 00 User manual

Gira

Gira 1289 00 User manual

Gira

Gira 1288 Series User manual

Gira

Gira KNX 2139 00 Operator's manual

Gira

Gira KNX 5061 00 User manual

Gira

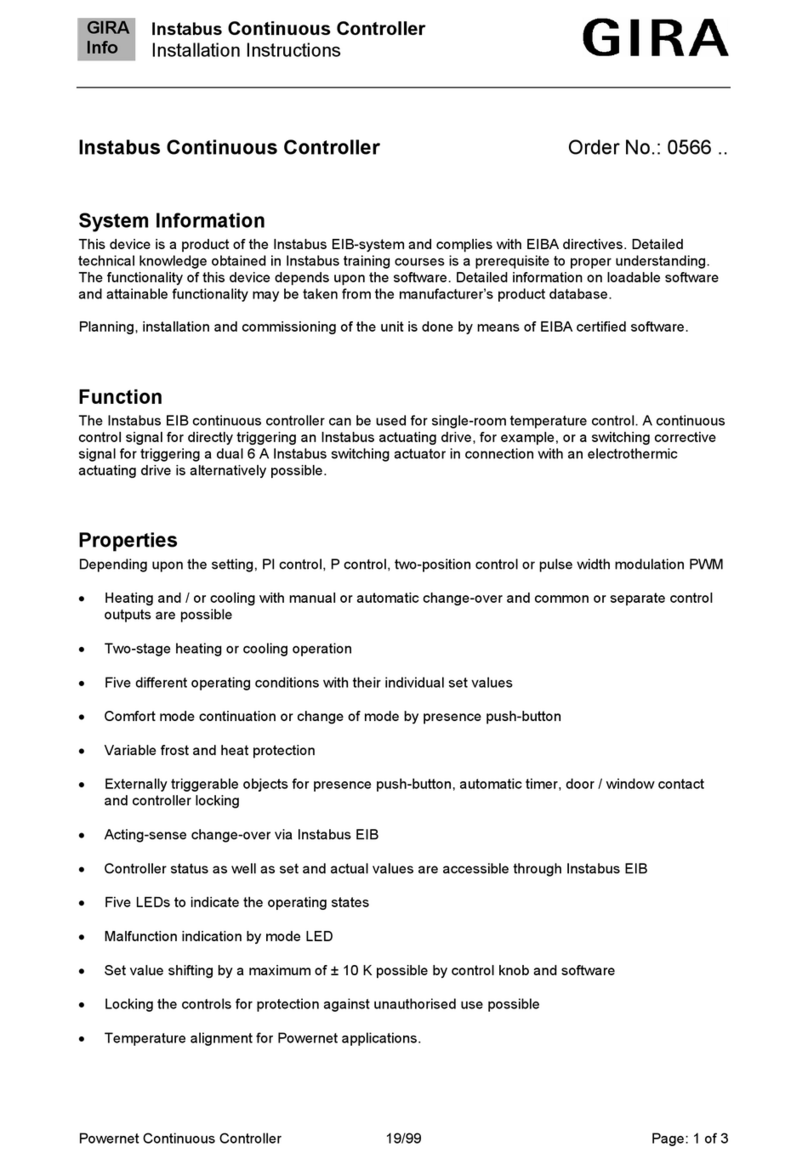

Gira 0566 Series User manual

Gira

Gira 2101 Series User manual

Gira

Gira 0425 00 User manual

Gira

Gira 5023 00 User manual

Gira

Gira One 5023 00 User manual

Gira

Gira KNX 5062 00 User manual

Gira

Gira 5431 00 User manual

Gira

Gira KNX 1039 00 User manual

Gira

Gira System 3000 User manual

Gira

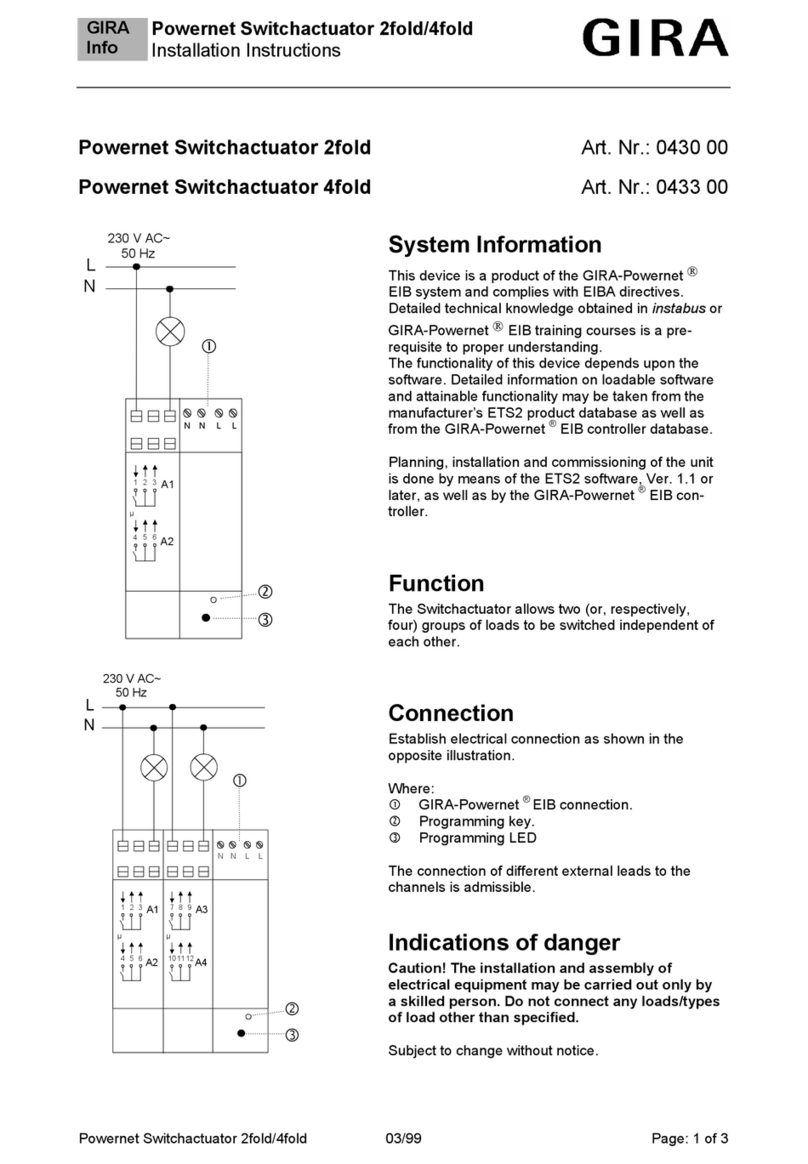

Gira Powernet Switchactuator 2fold User manual

Gira

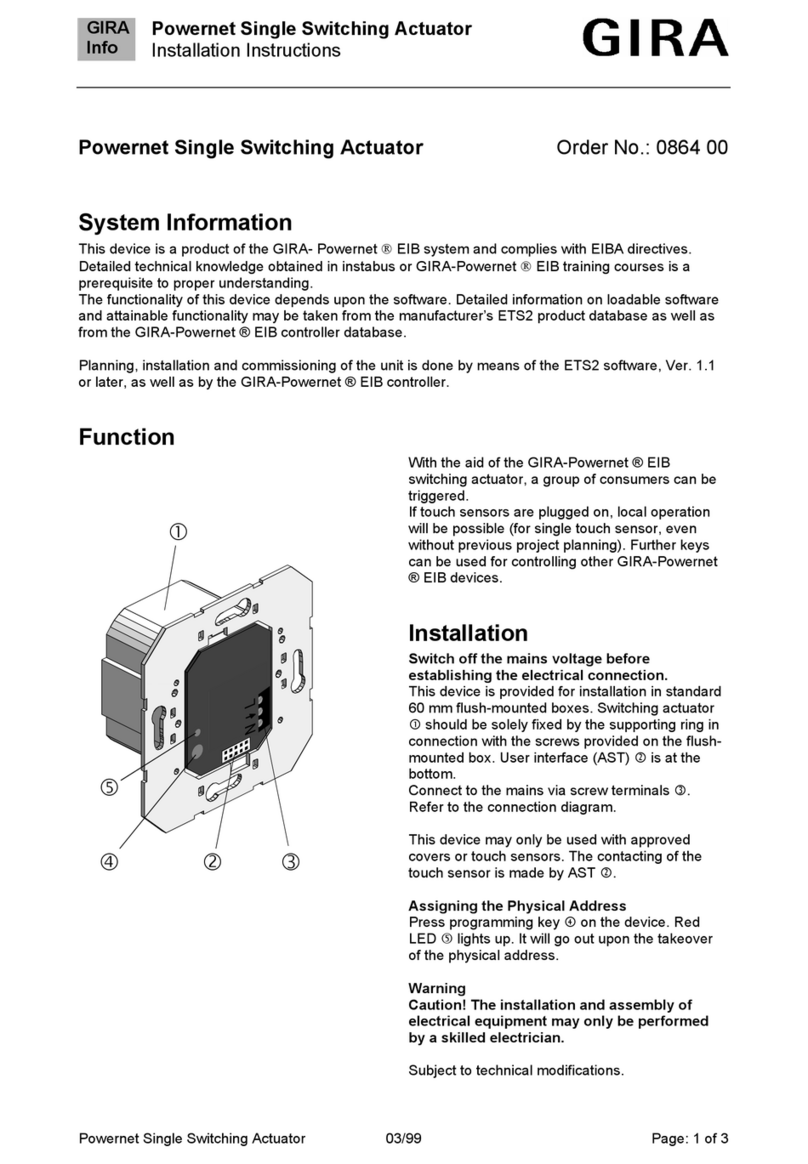

Gira Powernet Single Switching Actuator User manual

Gira

Gira One 5065 00 User manual

Popular Controllers manuals by other brands

Data Video

Data Video RMC-150 instruction manual

System air

System air Topvex VAV installation instructions

AquaMetrix

AquaMetrix Shark user manual

Light Symphony

Light Symphony LS30505SCC instructions

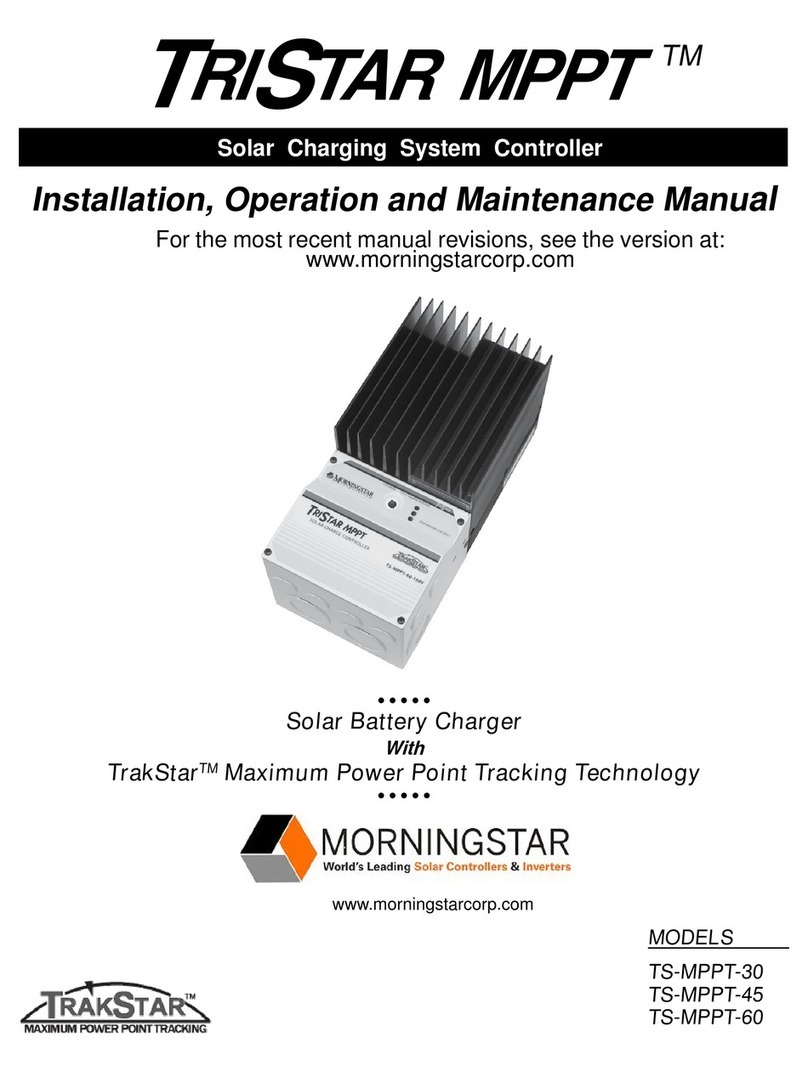

TriStar

TriStar TS-MPPT-30 Installation, operation and maintenance manual

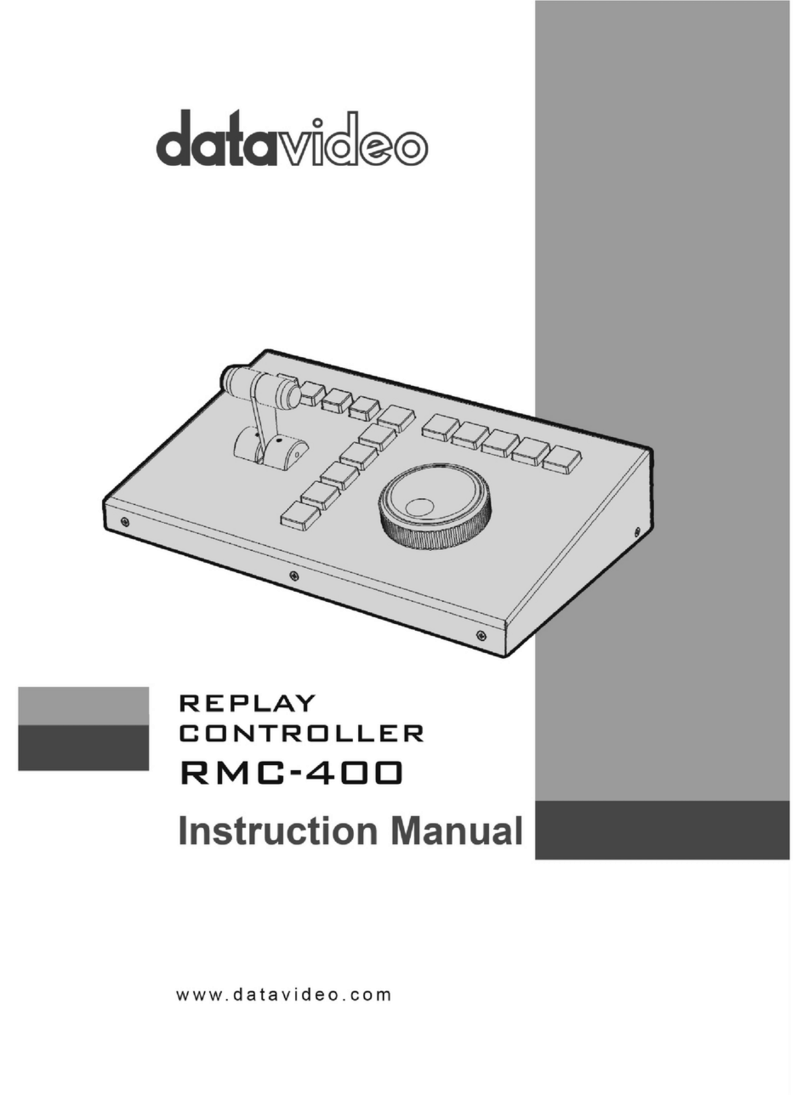

Data Video

Data Video RMC-400 instruction manual

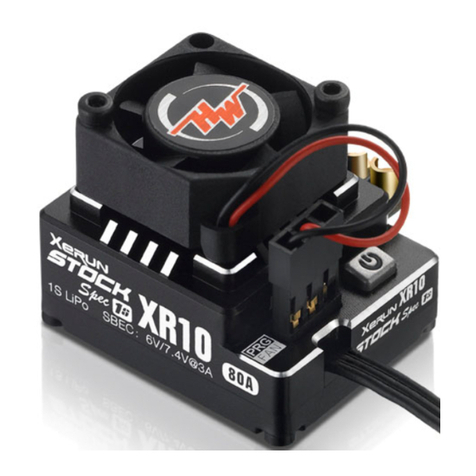

Hobby-Wing

Hobby-Wing XERUN XR10 STOCK SPEC 1S user manual

Data Video

Data Video MCU-100 quick start guide

Promise

Promise FastTrak SX4100 quick start guide

Data Video

Data Video RMC-300C instruction manual

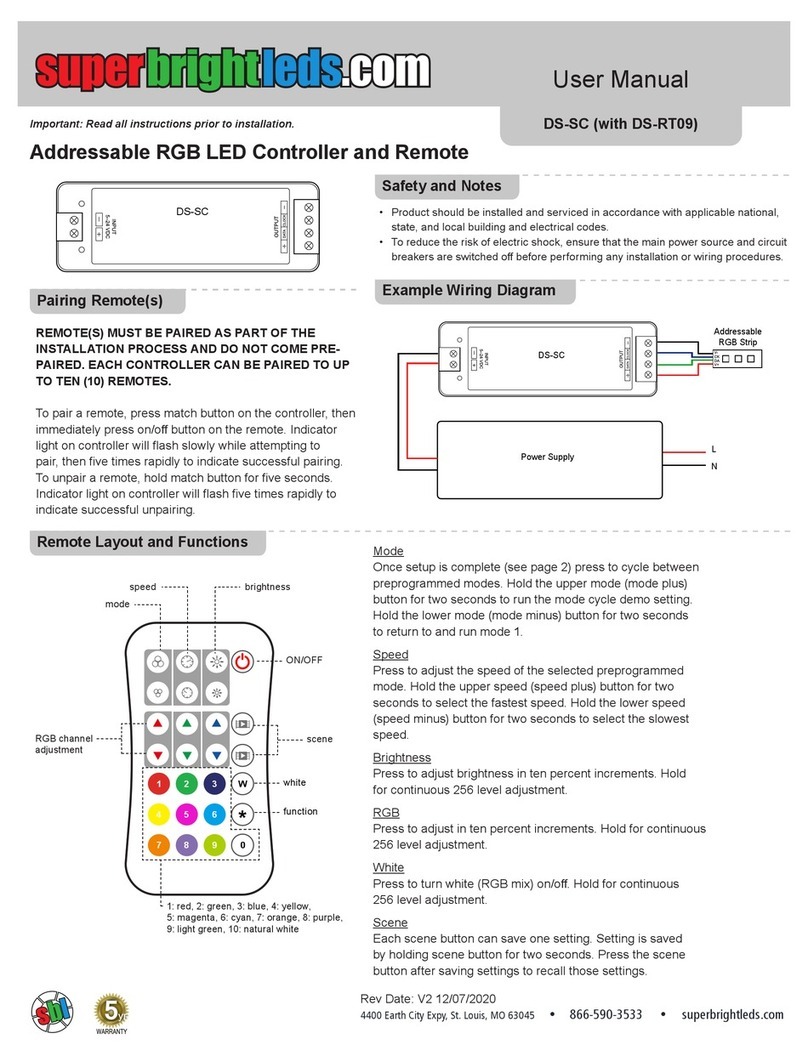

superbrightleds

superbrightleds DS-SC user manual

Shuangri Electron

Shuangri Electron SR288 Operation manual