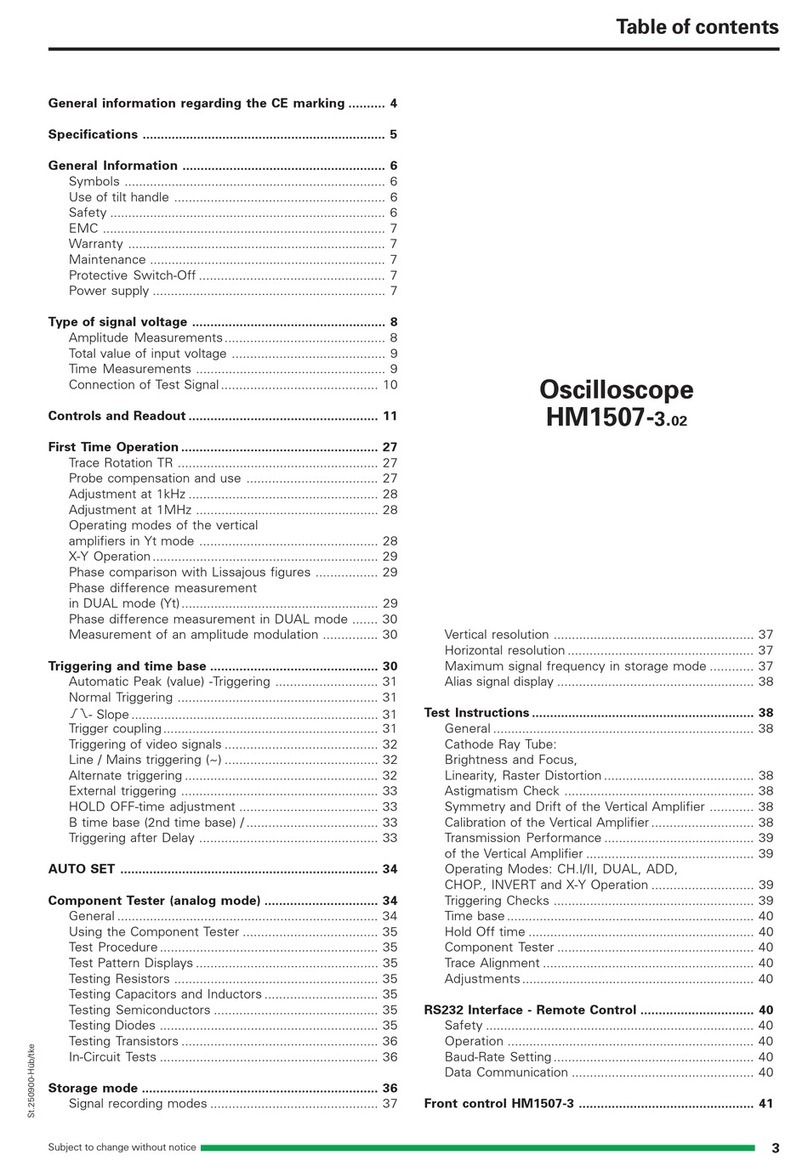

Table

of

contents

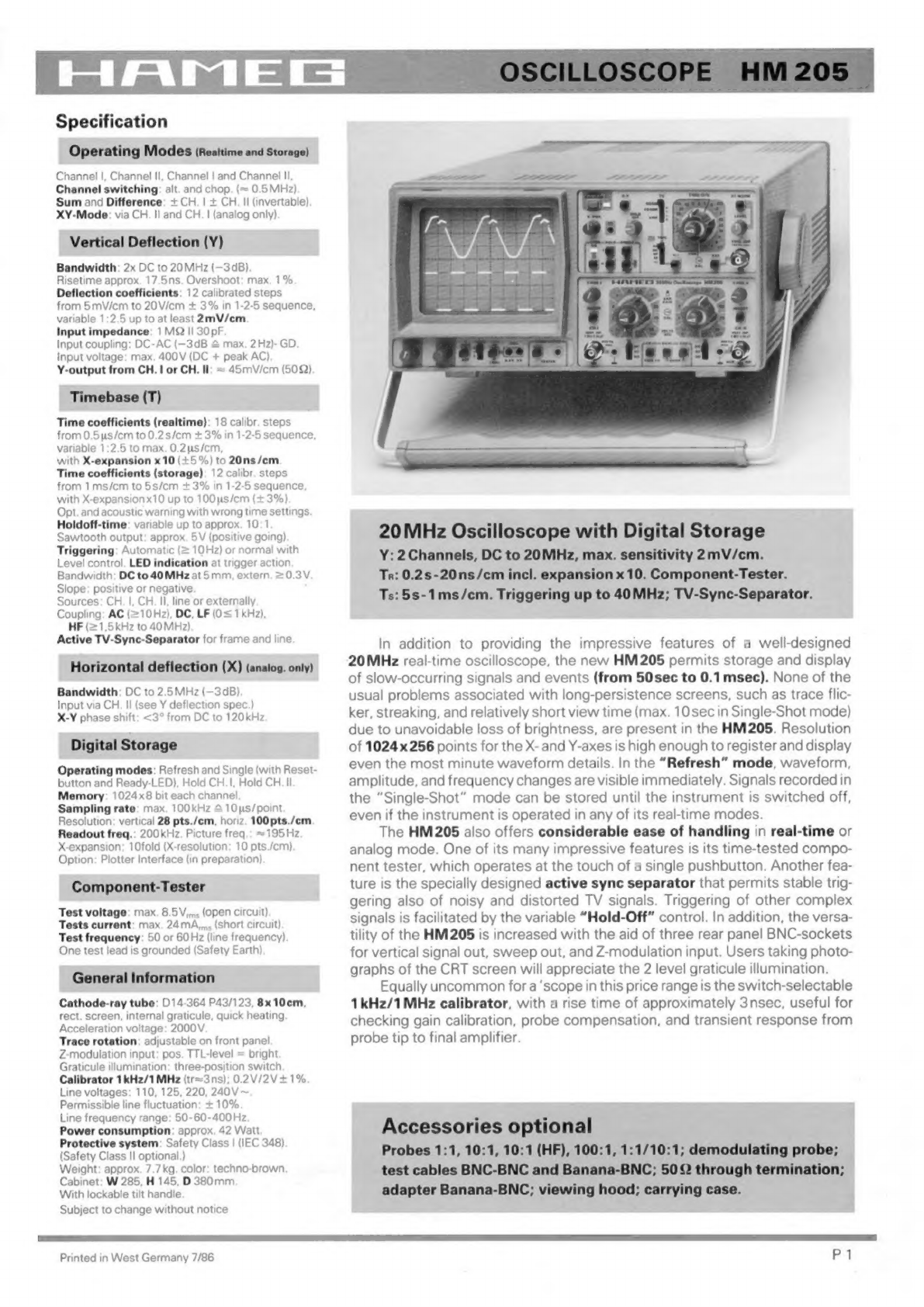

Oscilloscope

datasheet

with

technical

details

.......-.~.2.~.2...

P

1

Accessories

..................-..

Z

1

Operating

Instructions

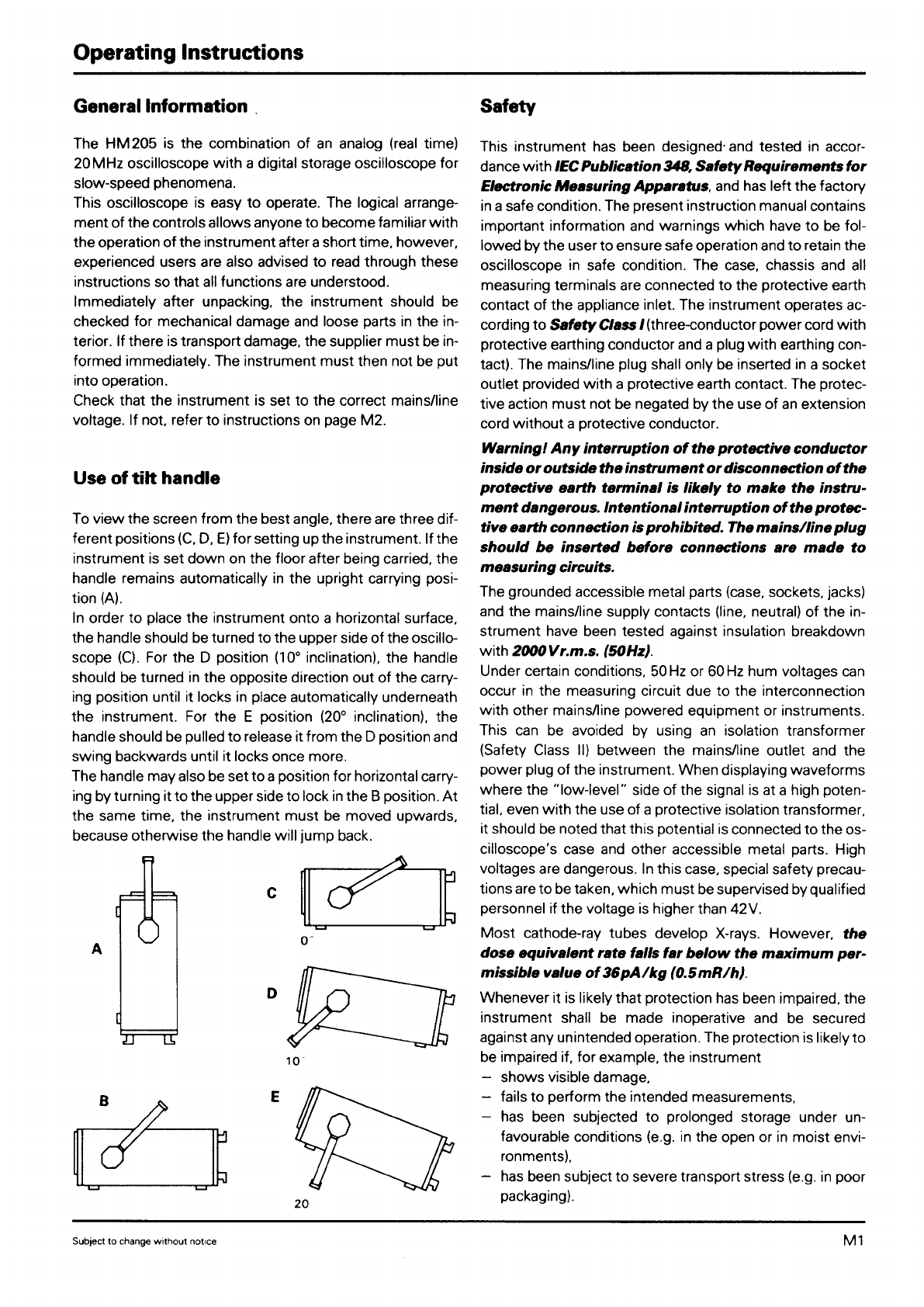

General

Information

..........0.....

M

1

Use

oftilthande

.............0.2...

M1

Safety...

0...

ee

ee

M

1

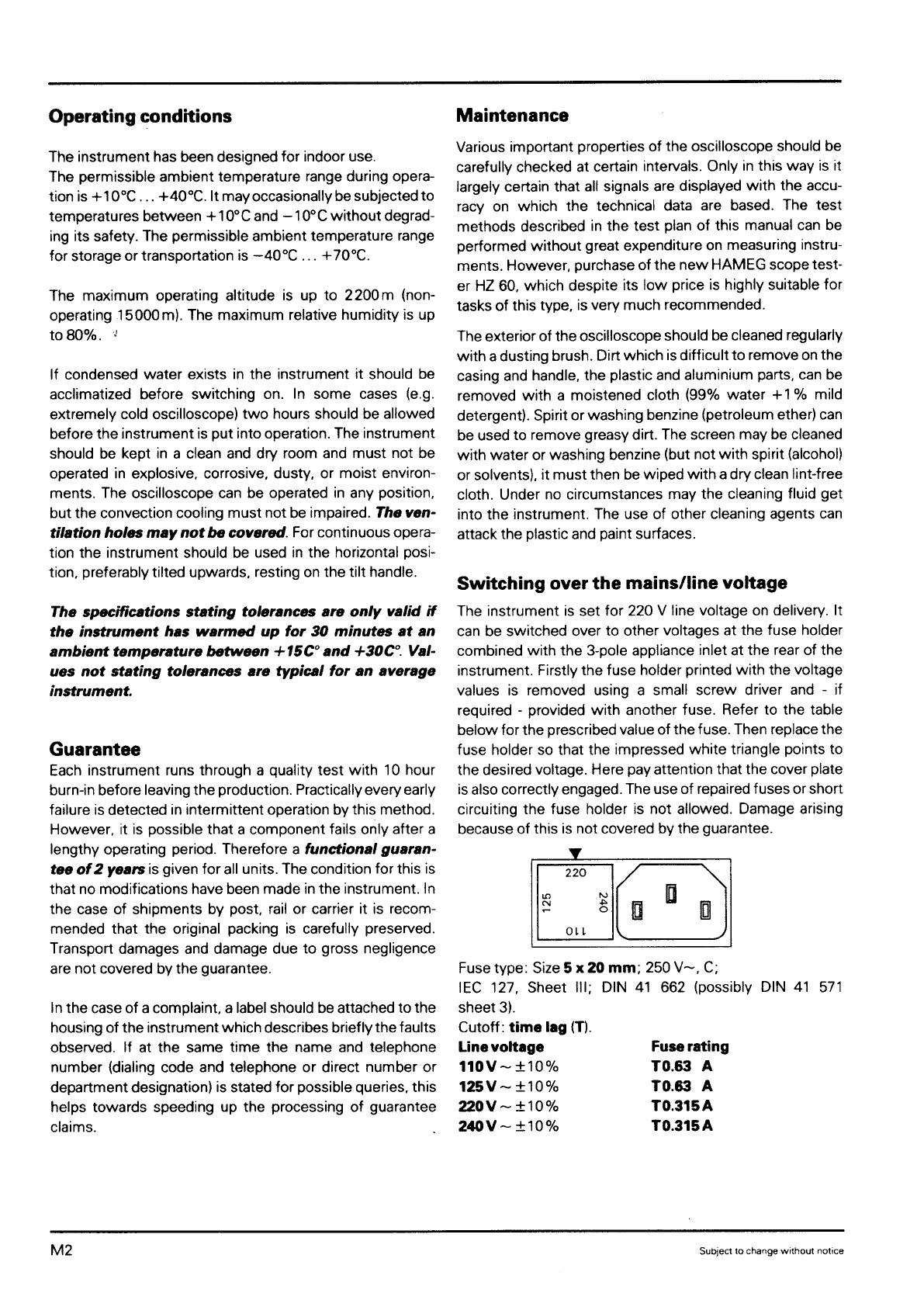

Operating

conditions

............2.2..

M

2

Guarantee

..............0..--4.

M

2

Maintenance

............-.....-..

M

2

Switching

over

the

mains/line

voltage

......

M

2

.

Type

of

the

signal

voltage

..........2..

M

3

Osci

I

loscope

Amplitude

Measurement.............

M

3

HM

205

Reference

Line.

................-.

M

4

Time

Measurements

...............

M

4

Connection

of

Test

Signal

.........~.~..

M

6

First

Time

Operation

...............

M

7

Trace

Rotation

.............-.-4.

M8

Short

instruction

K

1,

DC

Balance

Adjustment

.............

M8

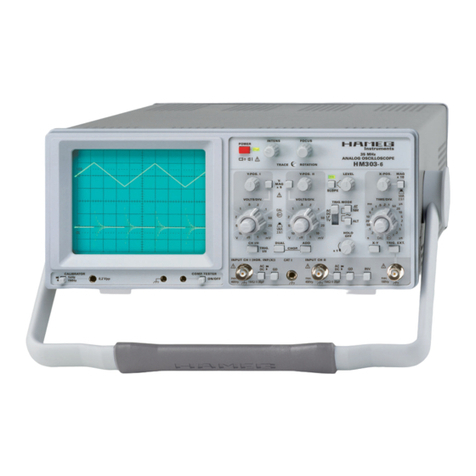

Front

panel

elements

Probe

compensation

anduse...........

M8

Folder

with

front

view

...............

K

2

ikHzcompensation

..............

M

8

1MHzcompensation..............

M9

Test

Instructions

Operating

modes

of

the

vertical

amplifiers...

.

M10

General...

2...

2

ee

T

1

X-Y

Operation...

2...

.0..0202.2..2.-.-..

M10

Cathode-Ray

Tube:

Brightness

and

Focus,

Phase

difference

measurement

in

DUAL

mode

M11

Linearity,

Raster

Distortions

.....

T1

Measurement

of

an

amplitude

modulation...

.

M12

Astigmatism

Check.

.............-..

T

1

Triggering

andtime

base

.............

M12

Symmetry

and

Drift

of

the

Vertical

Amplifier...

.

T

1

Automatic

Triggering.

.............

M12

Calibration

of

the

Vertical

Amplifier...

2... 2...

T

1

Normal

Triggering,

Slope...

.........

M13

Transmission

Performance

(Vertical

Amplifier)

.

.

.

T

2

Triggercoupling

.............-0.4

M13

Operating

Modes:

CHI/Il,

DUAL,

ADD,

CHOP.,

Line

Triggering

............-.....

M14

INVERT

and

X-Y

Operation...

.

.

T

2

Triggering

of

video

signals,

External

Triggering.

M14

Triggering

Checks

.................

T3

Trigger

indicator

............00.0.,

M15

Timebase...

2...

0-20.00.

-2.

002000.

T

3

Holdoff-time

adjustment...

......2.2..

M15

Holdofftime

.............2..2

000.4

T

4

ComponentTester................

M15

Component

Tester

.............-..0.0.

T

4

Testpatterns

..............0..0..

M18

Trace

Alignment

..................

T4

Mains/Line

Voltage

Checks.

.........2...

T4

Storage

Operation

Front-panelcontrols

...............

M19

Service

Instructions

Storage

resolution

and

operating

modes

....

.

M19

General...

2...

.....2.2.2...2...2.-.

S$

1

Singiechanneldisplay

..............

M20

Instrument

Case

Removal

..........2...

$1

Dualdisplay............-..-2005

M21

Operating

Voltages

..........-.2..2...

$1

Sum

and

difference

display.

...........

M21

Maximum

and

Minimum

Brightness

........

$1

Reference

linedisplay

..............

M21

Astigmatism

control

..

2...

.....02.2.0-.

S$

2

Timebase

of

low

frequency

signals.

.......

M21

Trigger

Threshold...

2...

...2.0-.-22,4

$2

Trouble-Shooting

the

Instrument...

.......

S

2

Miscellaneous

Replacement

of

Components

and

Parts

......

$3

Sawtooth

output,

Z-modulation

input...

...

.

M23

Replacement

of

the

Power

Transformer

......

S$

3

Vertical

output

(Y),

Graticule

illumination...

.

.

M23

Adjustments

.........0.....-.2004

S$

3

Subject

to

change

without

notice

7.86

-

205