Product Information KCI 1319, KBI 1335 11/2021 Product Information KCI 1319, KBI 1335 11/2021

6 7

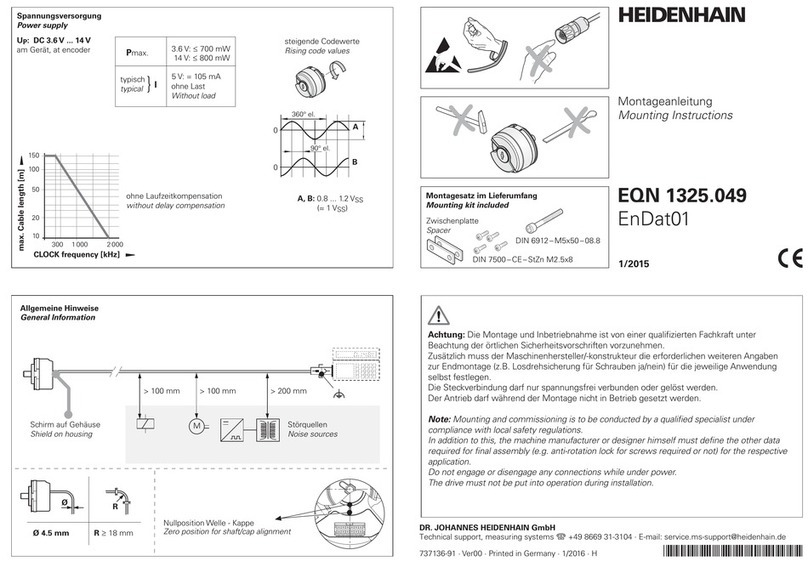

The KCI 1319/KBI 1335 is mounted either

via screw-fastening of the circular scale

or through press-fitting of the disk/hub

assembly and mounting of the scanning

unit. The disk/hub assembly is thereby

either press-fitted onto the shaft, or the

circular scale is screw-fastened to the

given shaft with three screws. The

scanning unit is aligned and mounted via

four holes on the customer’s mounting

surface.

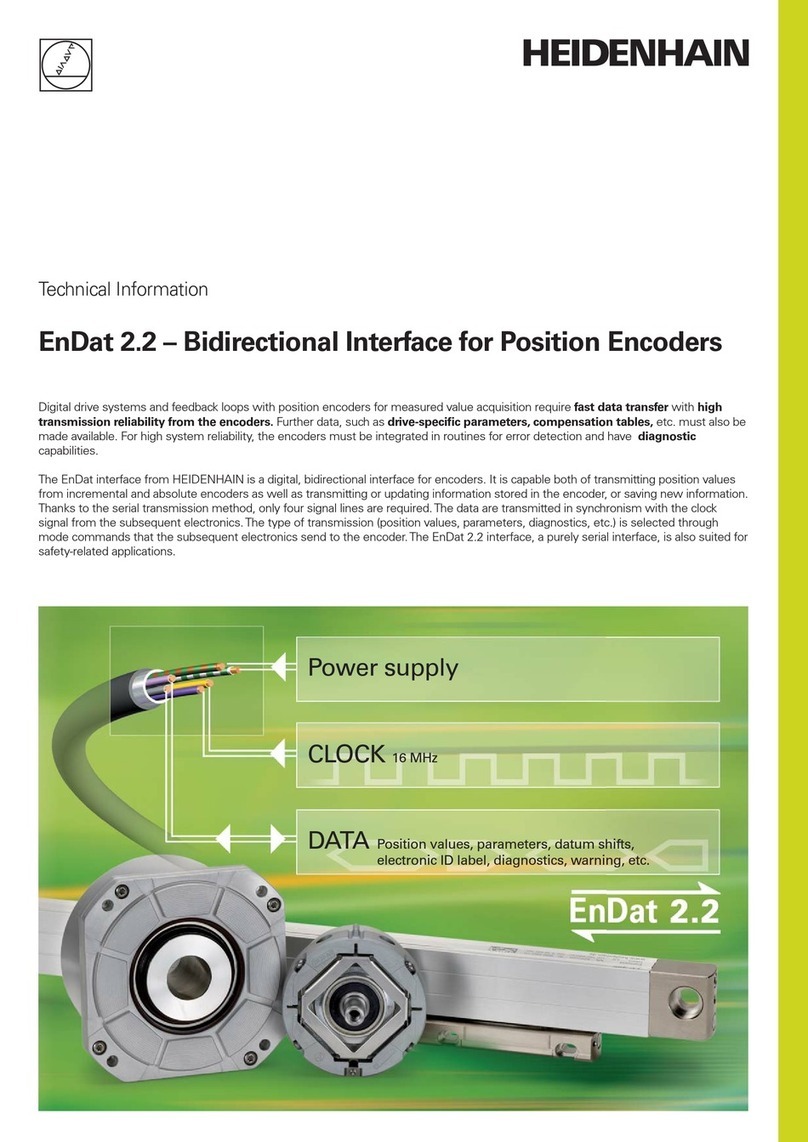

The following material properties and conditions must be complied with for the

customer-side mounting design:

Mating stator Mating shaft

Material Aluminum Steel

Tensile strength Rm≥220 N/mm2≥600 N/mm2

Yield strength Rp0.2 or

yield point Re

–≥400 N/mm2

Shear strength τm130 N/mm2≥390 N/mm2

Interface pressure PG≥250 N/mm2≥660 N/mm2

Modulus of elasticity E

(at 20 °C)

70 kN/mm2to

75 kN/mm2

200 kN/mm2to

215 kN/mm2

Coefficient of thermal expansion therm

(at 20 °C)

≤25 · 10–6 K–1 Screw-fastened

version:

10 · 10–6K–1 to

17 · 10–6K–1

Press-fitted version:

10 · 10–6K–1 to

12 · 10–6K–1

Surface roughness RZ≤16 µm

Friction values Mounting surfaces must be clean and free of

grease. Use screws and washers from

HEIDENHAIN in their condition as delivered.

Tightening procedure Use a signal-emitting torque wrench as per

DIN EN ISO 6789, with an accuracy of ±6 %

Mounting temperature 15 °C to 35 °C

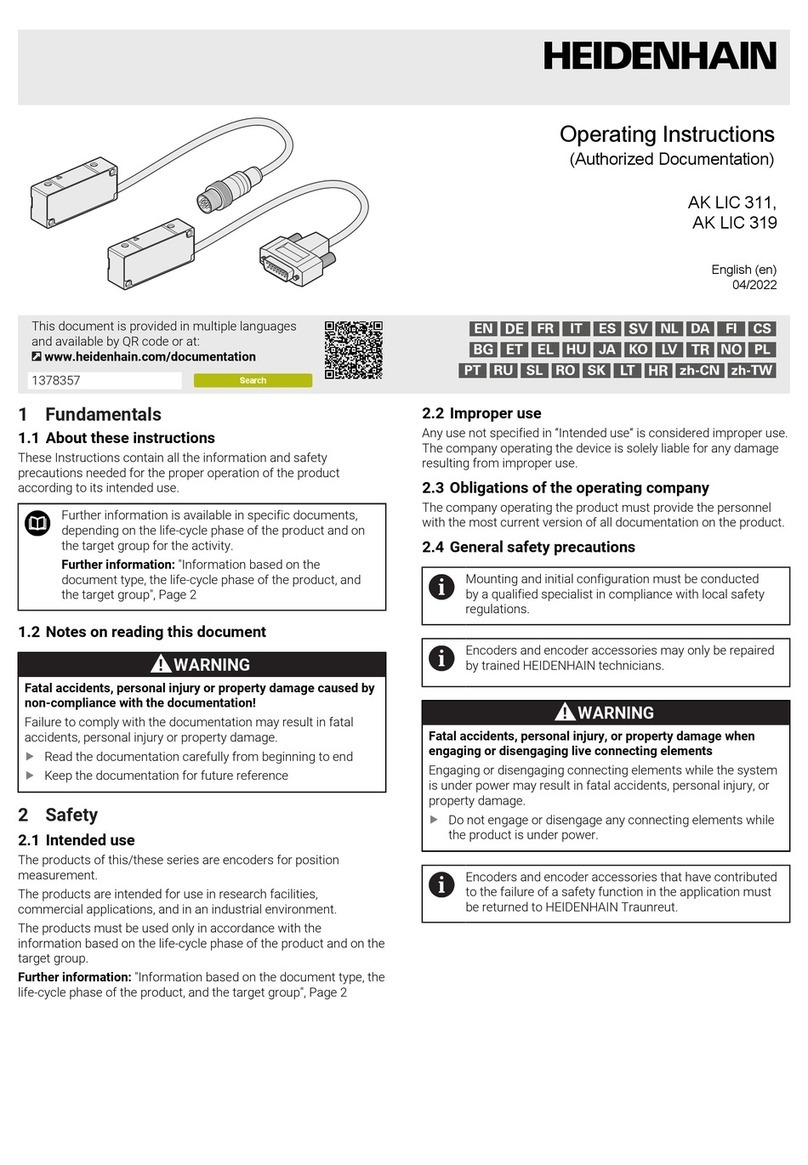

Mounting

KCI 1319

KBI 1335

Screws Quantity

Screw for fastening the

scanning unit

ISO 4762-M3×10-8.8-MKL1) ID 202264-87 10 or 100

Fastening screw for

circular scale

ISO 14581-M2×6-A2-702) – –

1) With coating for material bonding anti-rotation lock (for information on use, see the

Encoders for Servo Drives brochure)

2) Without anti-rotation lock; use at least a medium-strength material bonding anti-rotation

lock

Mounting accessories

Screws

Screws (fastening screws) are not included in delivery; the M3x10 screw with material

bonding anti-rotation lock can be ordered separately.

Mounting aid

To avoid damage to the cable, use the mounting aid to connect and disconnect the cable

assembly. Apply pulling force only to the connector of the cable assembly and not to the

wires.

ID 1075573-01

For more mounting information and mounting aids, see the Mounting Instructions

and the Encoders for Servo Drives brochure.The mounting quality can be inspected

with the PWM 21 and the ATS software (see Document 1082415).

The press-fitting process may be performed

only once for each disk/hub assembly. For

the press-fit, comply with the material

properties and conditions for the mating

surface stated for proper use in the relevant

documents. These requirements must be

followed, even when new disk/hub

assemblies are press-fitted onto customer

shafts that have already been used. Once

the lower limit of the press-fit force has

been exceeded, the press-fit force being

applied must remain within the specified

range for the rest of the procedure until the

end position is reached.