8

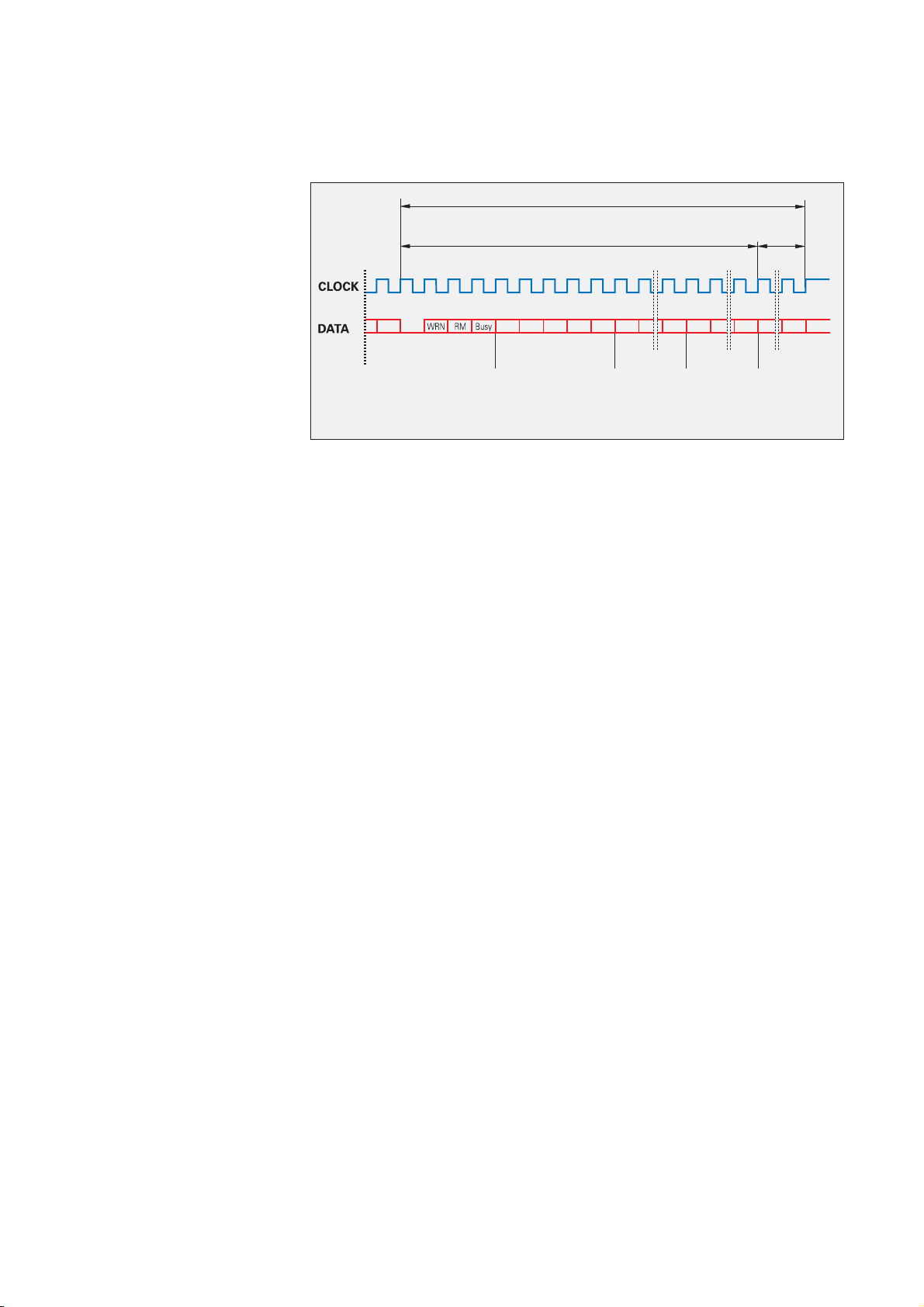

Status data

WRN—warnings

This collective bit indicates whether certain

tolerance limits of the encoder have been

reached or exceeded, for example rotational

speed or light source control reserve,

without necessarily indicating an incorrect

position value.This function makes it

possible to issue preventive warnings in

order to minimize idle time.The cause of

the warning is stored in the encoder

memory. The alarms and warnings

supported by the respective encoder are

saved in the "parameters of the encoder

manufacturer" memory area.

RM—reference marks

The RM bit indicates whether the reference

run has been completed. In incremental

systems, this is required in order to

establish the absolute reference to the

machine reference system.The absolute

position value can then be read from the

additional data 1. On absolute encoders,

the RM bit is always on HIGH.

Busy—parameter request

When LOW, the busy bit indicates that a

parameter request (read/write) is possible.

If a request is being processed (HIGH), the

encoder memory must not be accessed.

Content of the additional data

The content of the additional data is defined

by the mode command for selection of a

memory area.This content, updated with

each clock pulse, is transmitted until there

is a new request. A unique number is

assigned to each additional datum. It is

5 bits in length and is transmitted for

inspection purposes.The following

contents are possible:

Additional datum 1

Diagnostics•

Cyclic information on encoder function

and additional diagnostic values.

Position value 2•

For incremental encoders: Relative

position information (counter starts

from zero at switch-on). The absolute

position value is only available after the

reference marks have been traversed

(RM bit HIGH).

For absolute encoders: Second absolute

position value for safety-related

applications.

Memory parameters•

Parameters saved in the encoder can

also be transmitted along with the

position values.The request is defined

via memory range selection, followed

by output of the parameters with the

associated address.

MRS code—acknowledgment•

Acknowledgment of the requested

memory area selection

Test values•

Test values serve for inspection

purposes, in service diagnostics, for

example.

Temperature•

Transmission of temperature in encoders

with integrated evaluation of

temperature sensors.

Additional sensors•

The EnDat 2.2 protocol enables the

connection of 16 additional sensors (4-bit

address).The sensor values are output in

a rolling request process (x+1); the

assigned sensor can be identified based

on the supplied address.

Additional datum 2

Commutation•

Some incremental encoders provide

“rough” position information for

commutation in electric motors.

Acceleration•

If the encoder has additional sensor

systems for acceleration measurement,

it can transmit the results.

Limit position signals•

Limit position signals and homing

information.

Asynchronous position value•

Position formed by oversampling

between two "regular" requests.

Operating status error sources•

Detailed information about the cause of

the present error message.

Timestamp•

Reserved for touch probes

30 bits

Additional data 5 bits

CIRCLE

Acknowledgment of

additional data 8 bits

address or

data

8 bits data

Additional data

One or two additional data can be appended

to the position value, depending on the

type of transmission (selection via MRS

code).The additional data are each 30 bits

in length, with a LOW level as first bit. Each

additional datum is concluded with a CRC

that is formed from the respective additional

data without the first bit or the CRC.

The additional data supported by the

respective encoder is saved in the encoder

parameters.

The additional data includes status

information, addresses, and data: