Hella PM07 protect Setup guide

Installation instructions and Instructions for use

These instructions must be read

prior to installation

and use!

Concealed awning PM07 protect

Operating guidelines

Installation instructions and Instructions for use

Table of Contents

Preliminary remarks HELLA Concealed awning PM07 protect.............................................3

General notes.......................................................................................................................4

CE marking...........................................................................................................................5

Safety instructions ................................................................................................................6

Designated use ..................................................................................................................12

Interesting facts about awning covers ................................................................................16

Servicing, maintenance and repair ..................................................................................... 18

Operating guidelines...........................................................................................................21

Operating principle Somfy Maestria+ 50 io.........................................................................22

Operating principle of the elero drives................................................................................23

Before installation...............................................................................................................24

Part designation PM07 - box ..............................................................................................31

Part designation PM07 - Plaster base ................................................................................32

Part designation PM07 - Insulation 20/40mm.....................................................................33

Part designation PM07 - standard guide rail 32x55 mm....................................................34

Part designation PM07 - guide rail 32x97/115/130 mm......................................................35

Drive duct ...........................................................................................................................36

Installation options - Guide rail 32x97/115/130 mm............................................................41

Installation options - guide rail 32x97/115/130 incl. adapter profile ....................................44

Direct installation ................................................................................................................47

Adjusting the motor.............................................................................................................53

Activation guidelines for electric drives...............................................................................54

Connection directives for motor drive .................................................................................55

Functional check ................................................................................................................59

Commissioning...................................................................................................................60

Removal roller tube with drive ............................................................................................61

Installation roller tube with drive .........................................................................................66

Removal in general.............................................................................................................73

Handing over report (for the fitter) ......................................................................................74

Handing over report (for the user) ......................................................................................75

Installation instructions and Instructions for use

Subject to technical modifications – Date of Issue

February/2023

3

Preliminary remarks HELLA

Concealed awning PM07 protect

With this HELLA product you have opted for a high-quality product with a most up-to-date

technology that can nevertheless be easily installed and operated. In these instructions we

describe the basic installation, commissioning and use.

For authorized specialist staff

For the consumer (user)

The following symbols will assist you with the installation or use and require a safety-

conscious conduct:

Attention!

This symbol indicates instructions that, if disregarded, can put the user in

danger.

Attention!

This symbol indicates instructions that, if disregarded, can potentially

result in damage to the product.

This symbol indicates instructions for use or helpful information.

This symbol requires you to act.

Attention!

This symbol indicates a risk of injury or danger to life due to an electric

shock.

This symbol indicates parts of the product, for which you will find

important information in these installation instructions.

This symbol indicates the

cleaning of the product.

This symbol indicates the

maintenance and repair of

the product.

Installation instructions and Instructions for use

4

Subject to technical modifications – Date of Issue

February/2023

General notes

Questions

In case of questions concerning the installation or the use of your product, please consult

your authorized specialist shop.

Spare parts/repairs

Spare parts are available at your HELLA specialist shop. Only spare parts that are

approved by HELLA are allowed to be used.

Warranty/guarantee

Precondition for warranty and guarantee is a correct and regular maintenance of the sun

protection device (at least once a year).

Warranty claims are subject to statutory limitation periods. Service parts are excluded

from the warranty; the same applies for changes in color and changes in characteristics

caused by UV radiation.

As the composition or the chemical and physical properties of the plasters used are

beyond our control, the resistance of our systems to corrosion cannot be guaranteed,

Liability

In case of non-observance of the directions and information given in these instructions

and in case of improper operation or unintended use, the manufacturer shall not accept

any warranty claims concerning any damage to the product. In these cases, the liability

for consequential damage to any parts or persons is ruled out as well.

Legal notes

The graphs and texts of these instructions were carefully prepared. We cannot be held

liable for any errors and their potential consequences! Subject to technical modifications

to the product and to these instructions! These instructions include copyrighted

information. All rights reserved! The listed product or brand names are trademarks of the

respective owners.

Installation instructions and Instructions for use

Subject to technical modifications – Date of Issue

February/2023

5

CE marking

The HELLA concealed awning PM07 protect (side seam guided) is in compliance with the

declaration of performance according to the Construction Products Regulation; if the unit is

operated with a motor drive it is additionally in compliance with the Machinery Directive and

the Guideline for Electromagnetic Compatibility; in case of proper use, the awning

corresponds to the basic requirements of the harmonised standard EN 13561. The

respective declarations are deposited with the manufacturers.

*) Wind resistance classes according to product size [m²] - see chapter “Intended use”.

The CE identification applies for the delivery status of the product. The product mounted

meets the requirements of the specified standard only, if

during installation the information and instructions given in these instructions as well

as the information and instructions of the manufacturers of the screws have been

observed,

the product is installed with the recommended type and number of fasteners/screws.

No changes, rebuildings or extensions, with the exception of those described in these

instructions, are allowed with this product. The fixed CE-label expires with any change,

rebuilding or extension.

HELLA Sonnen- und Wetterschutztechnik GmbH

A-9913 Abfaltersbach 125

23

LE-PUMP-01-003

EN 13561:2004+A1:2008

Concealed awning side seam guided

PM07 protect

Exterior textile sun protection

Wind resistance class 3-6* - in connection

with the regulation (EU) 2019/1188

Installation instructions and Instructions for use

6

Subject to technical modifications – Date of Issue

February/2023

Safety instructions

These installation instructions refer to prefabricated elements, that (1) for

100% are made from parts, which are defined by us, and (2) which are

made in manufacturing processes, which are defined by us too; in all other

cases we do not provide any guarantee!

The safety instructions as well as the appropriate instructions must be read

carefully before installation and use. In case of non-observance of the

directions and information given in these instructions and in case of

improper installation and operation or unintended use, the manufacturer

shall not accept any warranty claims concerning any damage to the

product. In these cases, the liability for consequential damage to any parts

or persons is ruled out as well.

- Follow the described installation steps and pay attention to

recommendations and notes.

- Keep these instructions in a safe place.

- All installation and removal works, as well as maintenance and repair

works are only allowed to be carried out by authorised and qualified

specialist staff.

- If switching, automatic or radio control devices are used to operate the

units, the information given in the enclosed instructions of the

manufacturer must be observed.

- During operation do not put your hand into or touch movable parts.

- Ensure that clothing or body parts cannot get caught on the unit.

- Observe the regulations for prevention of accidents of the employer's

liability insurance association!

- Before operation check the unit for visible damage. If the unit is

damaged, it should not be used; please consult authorized specialist

staff immediately.

- Risk of injury and accident due to the weight of the product!

- Take safety measures against the danger of squashing, especially when

operating the unit with automatic devices.

- Place the operating switch within sight of the unit, but not near any of the

moving parts.

- Never let children play with the unit.

A sun protection device with electric drive cannot be retracted without

current. We therefore recommend the use of an emergency power

generating unit or a motor with an emergency crank handle, especially in

regions with frequent power failures.

Danger of suffocation!

Ensure that the foil cannot get into the hands of children. Keep the foil in a

safe place.

Installation instructions and Instructions for use

Subject to technical modifications – Date of Issue

February/2023

7

Safety instructions

ATTENTION!

For children/adults a lowered blind is

no protection against a fall out of the window!

Attention! Risk of injury or danger to life due to an electric shock!

- Set-up, examination, commissioning and error correction of the unit must

only be performed by authorised or trained expert staff (as per VDE

0100).

- Switch off the current to the connecting lines when working at the unit.

There is danger to life! Take safety precautions against unintentional

switching on!

- Check the electrical wires regularly for damage. Do not use the unit if

any damage is found.

- Our electrically driven units are in accordance with the regulations for

power plants acc. to VDE 0100. We cannot guarantee for the operational

reliability of the unit with non-approved modifications.

- White motor cables are not UV-resistant and must therefore be routed in

empty conduits, cable ducts, or similar.

- The enclosed installation instructions of the electrical devices supplied

must be observed.

Units with motor drive:

The drives used are operated with a voltage of AC 230V/50Hz. Please

check the power supply provided by your utility company before connecting.

Any other voltage can destroy the drives.

Installation instructions and Instructions for use

8

Subject to technical modifications – Date of Issue

February/2023

Safety instructions

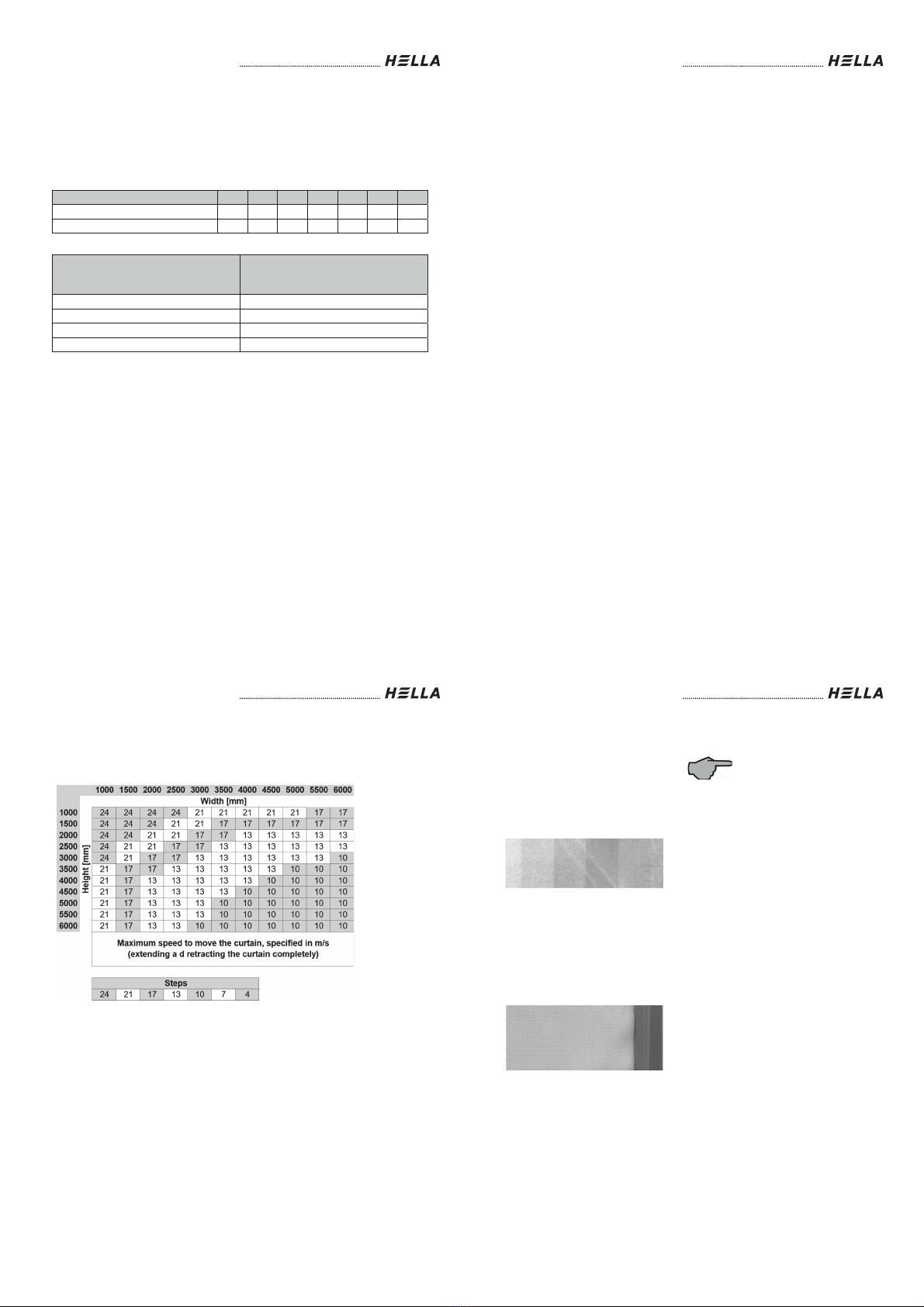

Operation of the sunblind in case of

storm:

If the wind speed exceeds the

tolerable limiting value, close the

windows or raise the sunblind to the

upper end position. Take care, that no

draught can arise, even during your

absence. If the window is open, the

closed sunblinds cannot withstand all

wind loads. The recommended wind

limit values can be ensured only with

a closed window.

Operation of the sunblind in case of

frost or rain:

In case of frost the sunblind can

freeze shut. Avoid using force to

operate the sunblind and do not use it,

if there is snow or ice in the guide

rails. Do not operate the unit if it is

frozen solid. With automatic control

devices it is necessary to switch the

automatic control device off, if there is

danger of freezing.

If the front-mounted blind is raised

whilst wet (e.g. after rain), it must be

lowered again later to dry the cover.

Range of movement of the

sunblind:

Please make sure that no obstacles

block the guide rails of the sunblind.

Installation instructions and Instructions for use

Subject to technical modifications – Date of Issue

February/2023

9

Safety instructions

Danger of squashing:

Do not put your hand between

movable parts when raising or

lowering the sunblind (e.g. front rail).

As long as the sunblind is in motion

persons must be kept away.

Using the product for the wrong

purpose:

Use the sunblinds solely for the given

purpose. Any wrong use can

endanger the user and result in

damage to the product. Do not

overload the sunblind, e.g. with

additional weights. If the product is

used for a different purpose, the right

to claim under guarantee is forfeited.

Behaviour in case of emergency

(e.g. fire, power failure):

Do not lower or raise the blind.

Installation instructions and Instructions for use

10

Subject to technical modifications – Date of Issue

February/2023

Safety instructions

Accessibility of the operating

devices:

Place the operating switch within sight

of the unit, but not near any of the

moving parts. Never let children play

with the operating devices, such as:

hand-held radio transmitter, switches

or automatic devices. There is danger

of squashing, especially when

operating the unit with automatic

devices.

Fix the operating switch at a point

where the disabled also have access.

Automatic sunblinds in front of

balcony or terrace doors:

If a sunblind with motor drive, that is

connected to an automatic device, is

installed in front of the only access to

your balcony or terrace, you can lock

yourself out. Please switch off the

automatic device, if you enter the

balcony or the terrace.

Observe the motor runtime:

The motors used are not suitable for a

non-stop operation. The integrated

thermo protection switches the motor

off after approx. 4 minutes. After

approx. 10 to 15 minutes the product

is ready for use again.

Installation instructions and Instructions for use

Subject to technical modifications – Date of Issue

February/2023

11

Storing

- Keep dry when storing!

- Cover the boxes with materials that are impervious to light.

- Do not use transparent foils, because this can cause the welding of the

EPS due to the possibly occurring lens effect.

Protection of the product during construction phase

During the construction phase, the element to be mounted must be

protected against the weather. Materials made of EPS must be plastered

within three months.

Recommendations:

- Protection of the insulating material by applying a plaster base

- Covering the upper surface (do not use transparent foils!)

Installation instructions and Instructions for use

12

Subject to technical modifications – Date of Issue

February/2023

Designated use

Sun protection

Thermal protection

Sight screen

Anti-glare blind

To avoid damage, do not use the units or retract the covers with strong wind, continuous

rain, snowfall or frost.

If the front-mounted blind is raised whilst wet (e.g. after rain), it must be lowered again later

to dry the cover.

If a wind sensor is used, please observe the building geometry, and set the wind sensor to

the lowest value.

Recommended maximum wind limit values

The HELLA concealed awnings of the type PM07 protect are defined according to CE and

are in accordance with EN 13561.

Wind resistance: Class 3

corresponds to wind force 6 on the Beaufort scale (10.8-13.8

m/s)

Installation instructions and Instructions for use

Subject to technical modifications – Date of Issue

February/2023

13

Designated use

Wind resistance - Specification of wind resistance classes according to EN

13561:2004+A1:2008

in connection with the directive (EU) 2019/1188

(tested according to DIN EN 1932)

Wind resistance class 0 1 2 3 4 5 6

Nominal wind pressure p [N/m²] <40 40 70 110 170 270 400

Safety wind pressure [N/m²] <48 48 84 132 204 324 480

Wind resistance class*

Vertical awnings - side seam guided

VM07 / SM07 / PM07

Product size [m²]

6

5>5-8

4>8-12

3 >12 - 18

* The values correspond to the permissible load with completely extended curtain. The

installation must be made directly on the ground and result in a connection that is closed all

around.

Installation instructions and Instructions for use

14

Subject to technical modifications – Date of Issue

February/2023

Designated use

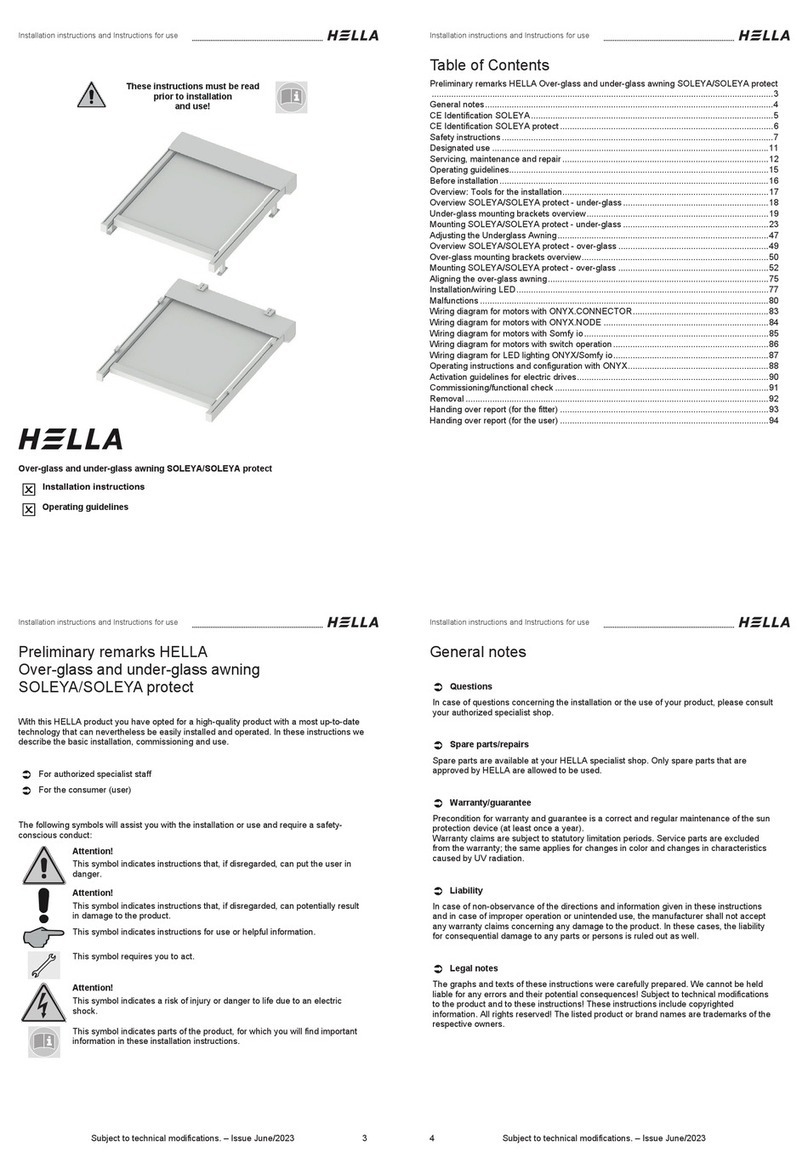

Recommendations of operation for side seam guided HELLA vertical awnings

according to IVRSA

The wind classes according to DIN EN 13561 do not allow to draw conclusions as regards

the usability (extending/retracting/in-between positions) with real wind loads. The

requirements that must be met to fulfil the performance requirements are based on static

loads and do not observe the dynamic effects of recurrent occurring loads (turbulences),

which the cover and the frame are exposed to in the field. Therefore the static pressure

can not be used to specify the fastening of the awnings to the building.

Also the subfloor/the distance to the facade/the height/the corner situation influence the

maximum possible wind speed and are not considered in the standard (DIN EN

1932:2013-09 External blinds and shutters - Resistance to wind loads - Method of testing

and performance criteria) although these influencing factors have a significant influence on

the wind resistance of the product.

In the following application recommendations the wind speeds are specified in m/s.

The wind speeds used in the following table only apply with closed windows and if there is

no corner situation. Also the positioning and the number of wind warning devices used are

decisive for the relevant selection for the wind speed suitable for the object; especially the

building geometry and the building location must be considered.

We recommend the use of wind warning systems in combination with the appropriate

control devices to retract the sun protection devices with predefined wind forces after a set

time delay.

The following table from IVRSA (Industrieverband Technische Textilien – Rollladen –

Sonnenschutz e.V.) shows wind limit values for side seam guided, textile vertical awnings.

The unit should be retracted, when the lower limit value is reached.

Horizontal units, arc-shaped units do not meet the application criteria.

Installation instructions and Instructions for use

Subject to technical modifications – Date of Issue

February/2023

15

Designated use

Recommendations of operation for side seam guided HELLA vertical awnings

according to IVRSA

The table only applies, if the distance from the cover to the glass surface is < 100

mm.

Source: IVRSA (Industrievereinigung Rolladen-Sonnenschutz-Automation e.V.)

In the following case the values given in the table can not be increased:

- With soffit installation the tabular value can be increased to the next higher tabular value

(e.g. from 10 to 13) ( maximum value 24 m/s) up to a maximum width of 3000 mm and a

maximum height of 3000 mm.

In the following cases the values given in the table must be redued:

-,IWKHGLVWDQFHEHWZHHQWKHFRYHUDQGWKHJODVVVXUIDFHLV!PPPPWKH

tabular value must be reduced by 2 levels (e.g. from 24 m/s to 17 m/s)

-,IWKHGLVWDQFHEHWZHHQWKHFRYHUDQGWKHJODVVVXUIDFHLV!PPPPWKH

tabular value must be reduced by 3 levels (e.g. from 24 m/s to 13 m/s)

The table can not be used with larger distances and self-supporting units.

Installation instructions and Instructions for use

16

Subject to technical modifications – Date of Issue

February/2023

Interesting facts about awning covers

Awning covers may show the

below mentioned

characteristics. These do not

affect the proper use or

lifespan of the product.

Kink folds

These stripes may arise due to a kinking of

the cover when cutting, sewing or folding it.

Crayon effect

The impregnating agent used during the

production may cause light stripes in the

cover. Especially with dark-coloured covers

these light stripes

cannot be avoided, despite

correct handling.

Ripples

When rolling-up or unrolling the cover on the

shaft the cover is more tensioned in the area

of the hems, seams and panels than between

the seams. Tensionings of the cover resulting

therefrom may cause ripples (e.g. waffle-

weave pattern or herringbone pattern), which

leave marks in the cover. These ripples are

visible when the unit is extended.

Especially with side seam guided units, these

ripples in the marginal area are a result of the

manufacturing process and cannot be

avoided, because the cover and the zip-

fastener are lying on top of each other and

cover a different distance when the cover is

rolled-up or unrolled.

Installation instructions and Instructions for use

Subject to technical modifications – Date of Issue

February/2023

17

Interesting facts about awning covers

Formation of honeycomb structures

The formation of honeycomb structures is an

effect of the manufacturing process of the

cover and can not be avoided. Rain or

increased air humidity may intensify this

effect. Especially when the cover is retracted

in a wet condition, these honeycomb

structures leave clearly visible marks in the

cover.

Flaws in weaving

During the manufacturing process of the

cover it may happen that the threads tear or

that the thread thickness varies slightly. This

results in light points or knobs in the cover.

Further information can be

found in the documents

"Guidelines for the

assessment of ready-made

awning covers" and

"Guidelines for cleaning and

maintenance of awning

covers" of the Industrial

Association Technical Textiles

– Roller shutter – Sun

Protection in

Mönchengladbach (see

homepage:https://ivrsa.de/tec

hnische_unterlagen).

Installation instructions and Instructions for use

18

Subject to technical modifications – Date of Issue

February/2023

Servicing, maintenance and repair

An unintentional switching on of units with motor drive is possible. Make

sure that the automatic control device is switched off and that the current

supply is interrupted during cleaning or maintenance work.

Cleaning:

As an externally installed sun

protection, your units can get soiled

over time. This will not reduce the

usability of your unit. The powder-

coated parts will remain presentable

for longer, if they are cleaned

regularly with a soft woollen cloth.

Do not use solvents, alcohol (rubbing

alcohol) or scouring cleansing agents!

Use a mild household cleaner and a

soft cloth to wash down fingerprints

and light grease- or oil patches. Rinse

off with clear water and dry with a soft

cloth.

Hard water leaves traces of limescale.

Adding a little bit of vinegar to the

scouring water prevents this effect.

For cleaning of the cover, it is usually

sufficient to occasionally brush it down

using a soft brush or a duster.

Installation instructions and Instructions for use

Subject to technical modifications – Date of Issue

February/2023

19

Servicing, maintenance and repair

Never use a high-pressure cleaner. There is a risk that the surface of the

aluminium parts and the cover are affected by the pressure and the heat.

Maintenance:

All inspection and maintenance works

must be carried out by a specialised

company from HELLA or a HELLA

partner. Regularly check the electrical

wires of motor driven units for

damage. For this purpose it is

necessary to remove the top board

profile. Check the mechanical parts of

your unit for visible damage. After

exceptional events such as storm,

hail, sleet, maloperation or the like,

the unit must be checked for

noticeable damage prior to operating

it. If the unit is damaged, it must not

be used; consult authorized specialist

staff immediately. It is recommended

to have the unit maintained by

specialist staff on an annual basis.

This way wear is detected at an early

stage and damage to the unit is

prevented.

Installation instructions and Instructions for use

20

Subject to technical modifications – Date of Issue

February/2023

Servicing, maintenance and repair

Repair:

Improper repair works may cause both risk of injury to persons or

damage to the units.

Repair works must be carried out by a HELLA specialist company or a

partner company of HELLA.

Only use original spare parts from HELLA.

Table of contents

Other Hella Accessories manuals

Hella

Hella SOLEYA User manual

Hella

Hella C2 Setup guide

Hella

Hella BM03 Setup guide

Hella

Hella VIVA 7040 Setup guide

Hella

Hella CLEO 7030 Setup guide

Hella

Hella CLEO 7040 Setup guide

Hella

Hella SOLANYA Setup guide

Hella

Hella PM03 Setup guide

Hella

Hella ONYX.TAG wind Setup guide

Hella

Hella ONYX.WEATHER User manual