Contents

i

Table of Contents

Safety and Compliance.................................................................................................v

Chapter 1 Introduction.....................................................................................................1

1.1 Introduction ...........................................................................................................1

1.2 Features................................................................................................................1

1.3 Proper Care...........................................................................................................1

1.4 Assistance.............................................................................................................1

Chapter 2 Installation ......................................................................................................3

2.1 Introduction ...........................................................................................................3

2.2 Unpacking .............................................................................................................3

2.3 Selecting The Fryer Location ..................................................................................4

2.4 Leveling The Fryer .................................................................................................4

2.5 Ventilation Of Fryer ................................................................................................4

2.6 Gas Supply............................................................................................................5

2.7 Gas Leak Test........................................................................................................8

2.8 Gas Pressure Regulator Setting ..............................................................................8

2.9 Electrical Requirements..........................................................................................8

2.10 Motor Bearings ....................................................................................................9

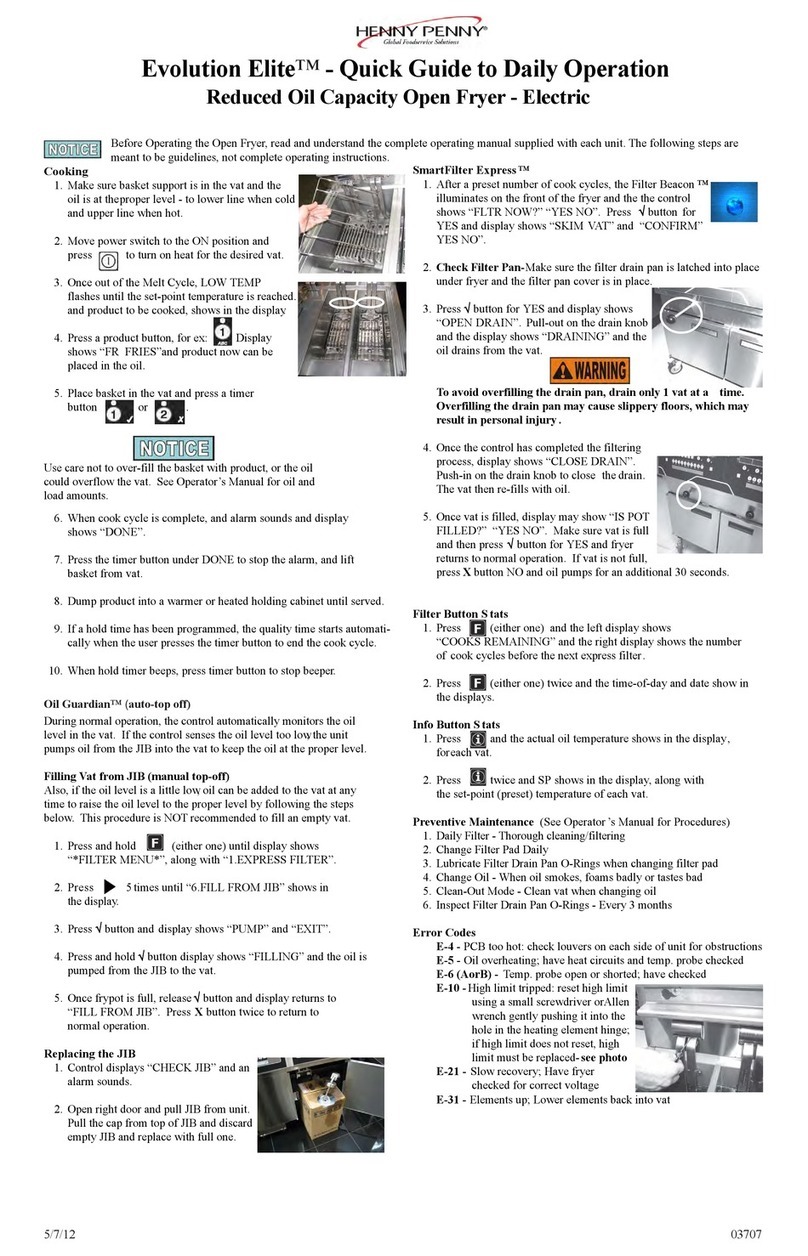

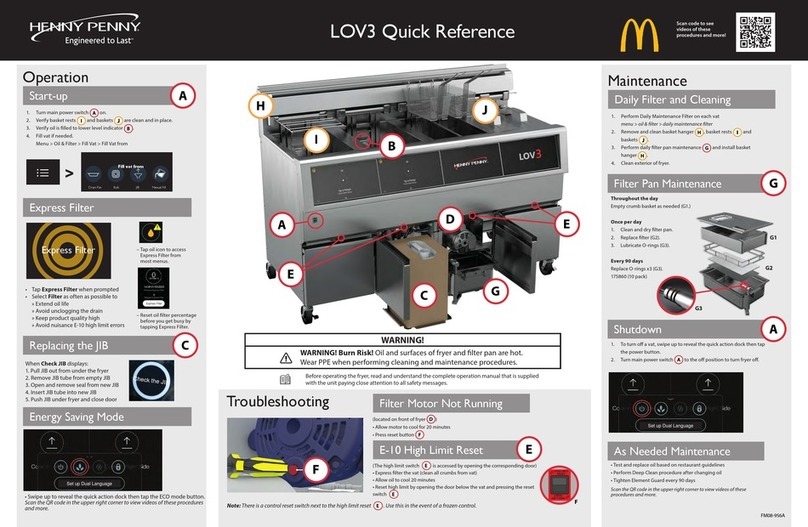

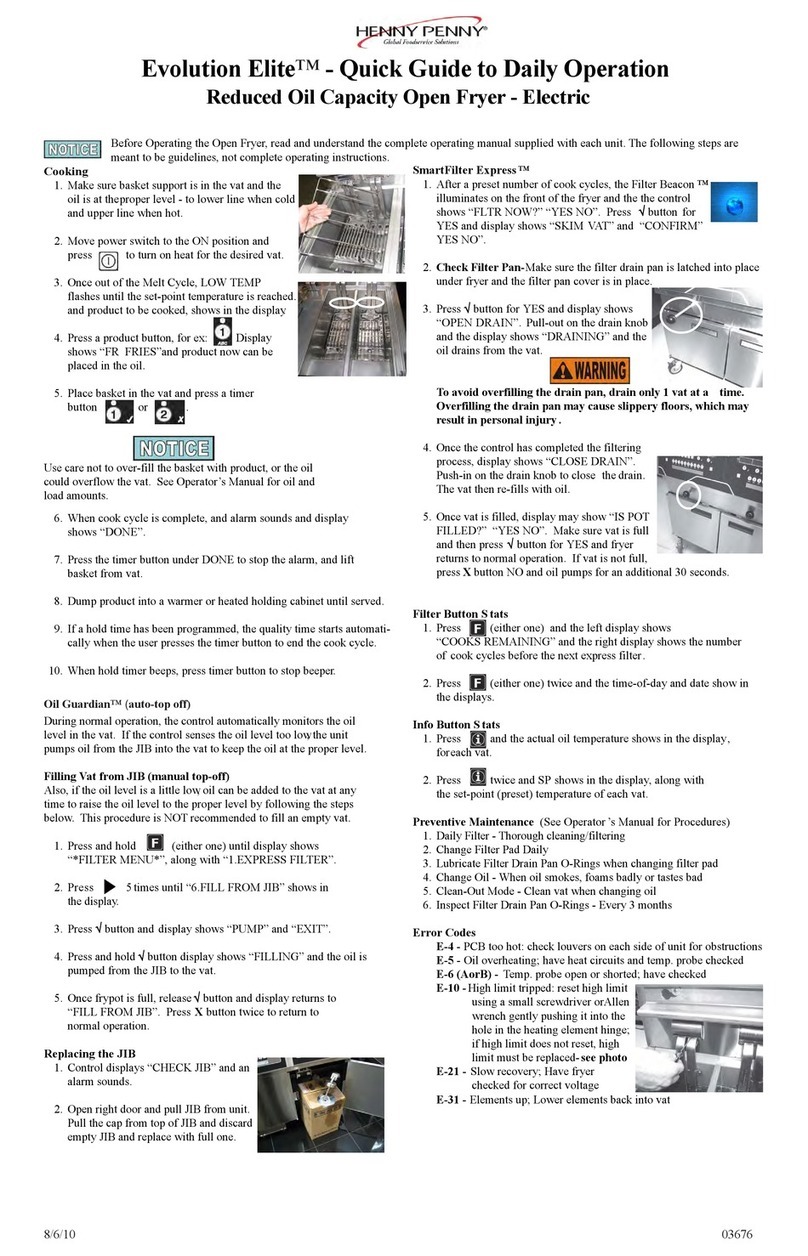

2.11 Lighting & Shutdown Of Burners ............................................................................9

2.11.1 Lighting Burners.............................................................................................9

2.11.2 Shutdown Burners..........................................................................................9

2.12 Testing The Fryer .................................................................................................9

2.13 Dimensions........................................................................................................10

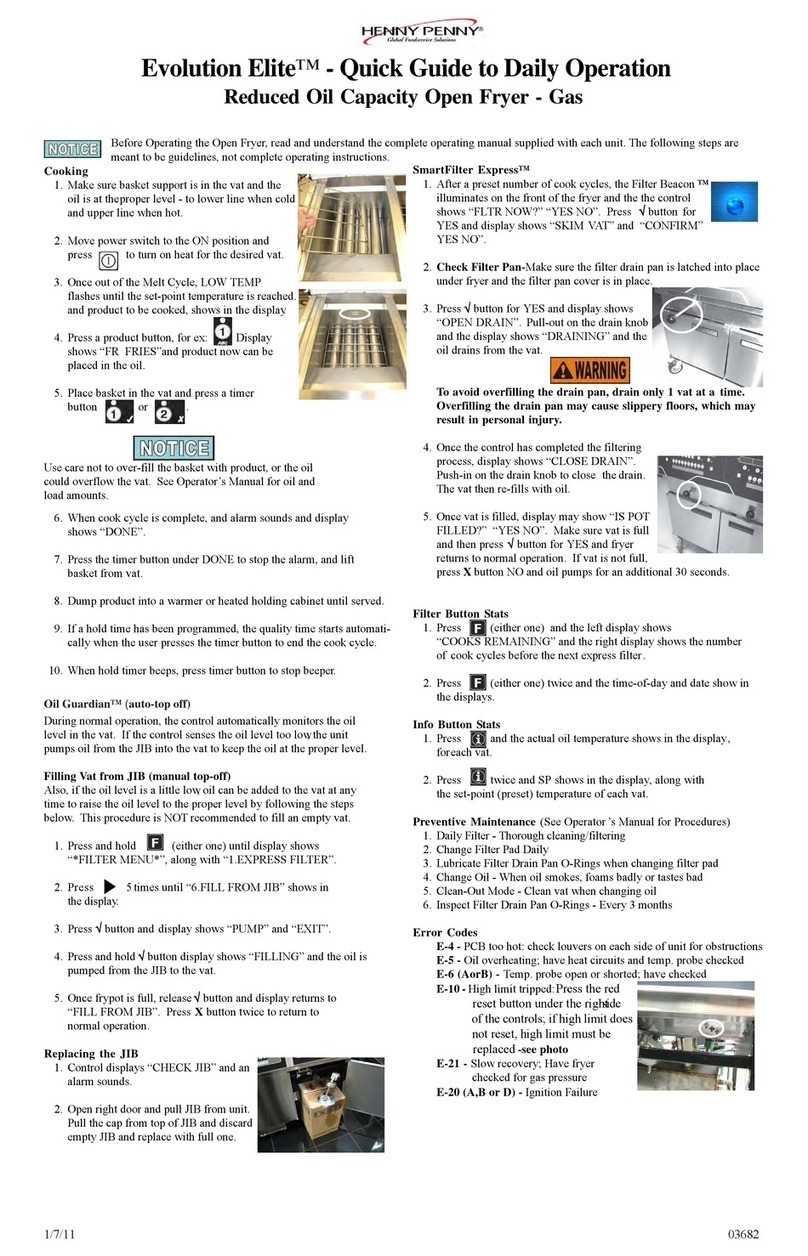

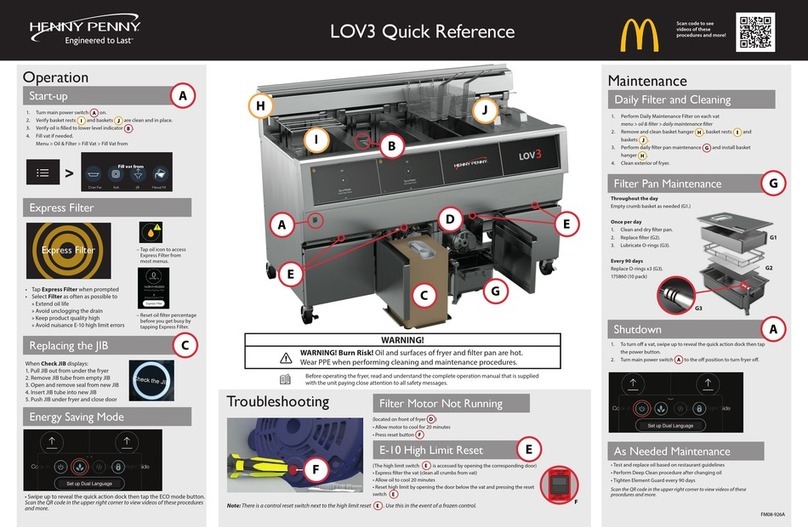

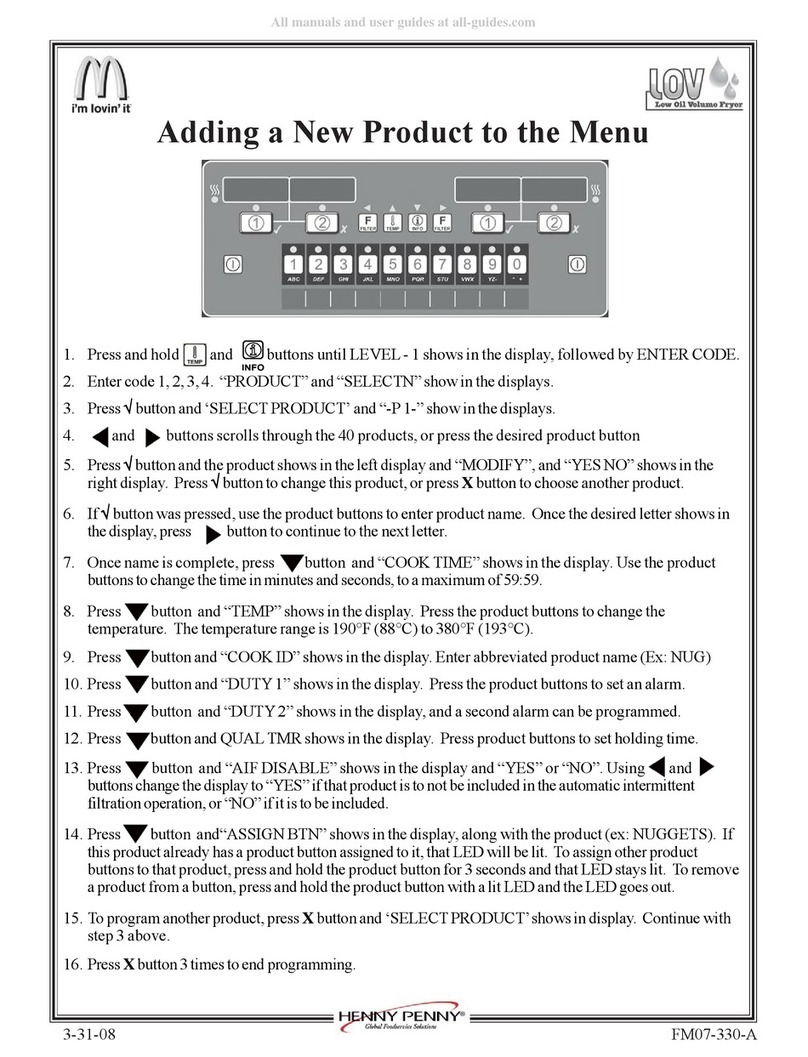

Chapter 3 Operation......................................................................................................13

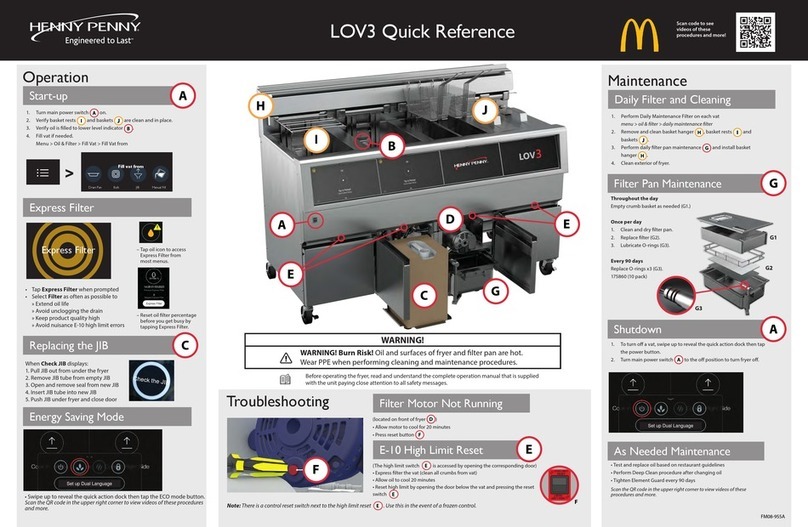

3.1 Operating Components ........................................................................................13

3.2 Set-Up Mode .......................................................................................................16

3.3 Filling Or Adding Oil .............................................................................................18

3.3.1 Filling Vat From Bulk Supply ...........................................................................19

3.4 Morning Start-Up Procedures................................................................................19

3.5 Basic Operation ...................................................................................................20

3.6 Idle Mode ............................................................................................................20

3.7 OIL GUARDIAN™ (Auto Top-Off) ..........................................................................21

3.7.1 Manual Top-Off..............................................................................................21

3.8 Selecting A Product With A Different Set-Point .......................................................21

3.9 Replacing The BIB ...............................................................................................21

3.10 Filtering The Shortening......................................................................................22

3.10.1 Smart Touch with Software Version ...............................................................22

3.10.2 Troubleshooting a Filter Error........................................................................23

3.11 Daily Filtering .....................................................................................................23

3.11.1 Smart Touch Software Version ......................................................................23

3.11.2 Troubleshooting a Daily Filter Error................................................................25

3.12 Discarding Oil From Vat ......................................................................................26

3.12.1 Discarding Oil Using Optional Discard Shuttle ................................................26

3.12.2 Discarding Oil Using Optional Bulk Oil Dispose System...................................27

3.12.3 Discard Oil Using Optional Oil Discard Shuttle ODS-400 .................................28

3.12.4 Discard Oil Using Optional Oil Discard Shuttle ODS-450 .................................31